Plasma Cutting Services

Custom plasma cutting for prototyping and production part manufacturing. Free quote and DFM review within 1 day. Fastest delivery time 3-5 days.

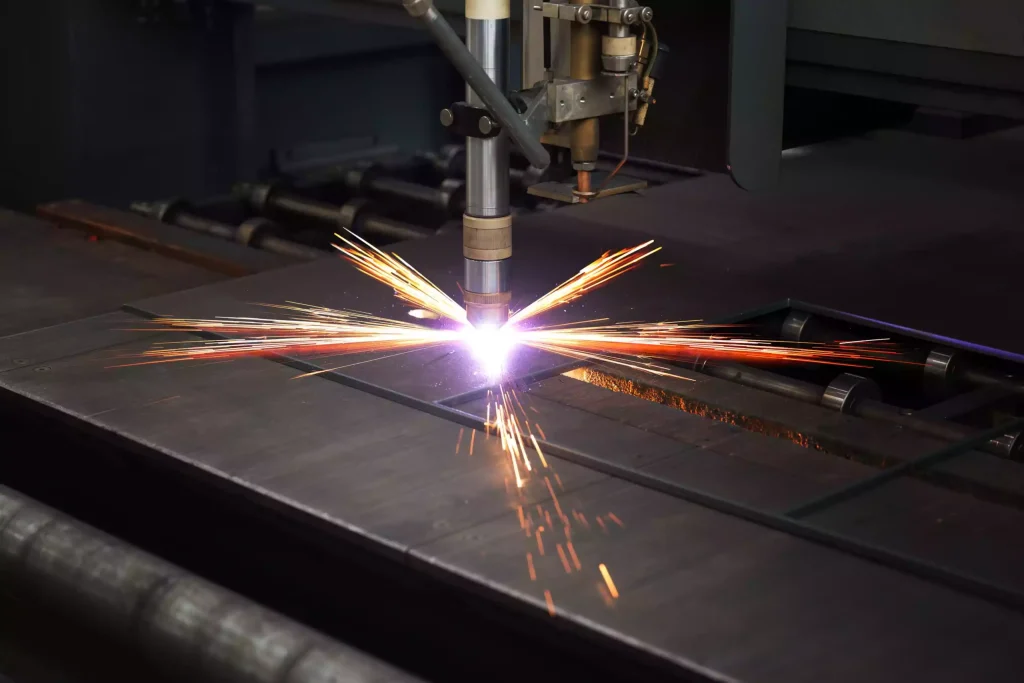

Professional Plasma Cutting Manufacturer

Are you looking for a cost-effective solution for thick metal cutting? Do you need to accurately cut complete patterns into metal? Then you have come to the right place. Elimold offers CNC plasma cutting services designed to help you complete your project successfully the first time. Our team of skilled technicians will provide you with a custom plasma cutting solution to meet your exact specifications, helping you improve performance and profitability. Whether you are doing small prototypes or large-scale production, we have the expertise and equipment to provide you with excellent results. In addition, our online platform simplifies the ordering process and provides instant quotes based on your specific design files. This streamlined process ensures fast delivery, making it an affordable choice for all your plasma cutting needs, from prototyping to mass production.

In-House Plasma Cutting Fabrication Facility

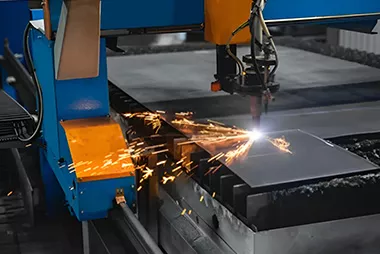

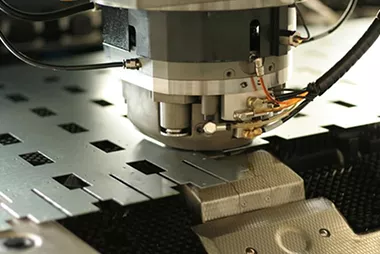

With an in-house, ISO-certified fabrication facility, Elimold’s experienced team and state-of-the-art equipment provide exceptional plasma cutting services to a wide range of industries. Elimold is committed to providing our customers with a complete “metal fabrication experience”. Rather than moving your project from one facility to another until completion, we manage the entire project design, construction, and assembly process in-house. This provides greater convenience and consistent pricing for customers interested in metal fabrication services such as plasma cutting. In addition, in-house, just-in-time inventory management ensures that all fabrication components are operating efficiently. We always prioritize delivery deadlines, so we are always ready to handle your urgent tasks. Elimold custom plasma cutting services are suitable for small custom projects as well as large-scale production. We use advanced CNC plasma cutting machines to ensure that each project is completed with precision and quality.

Available Types Of Plasma Cutters

2 Axis Plasma Cutting

3 Axis Plasma Cutting

Excellent plasma cutting capabilities

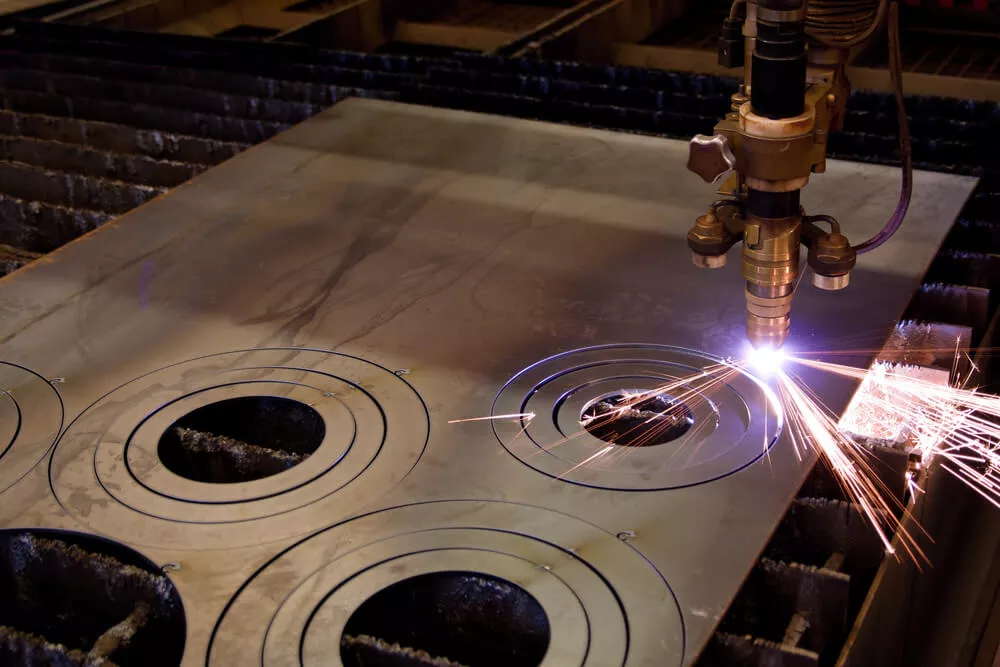

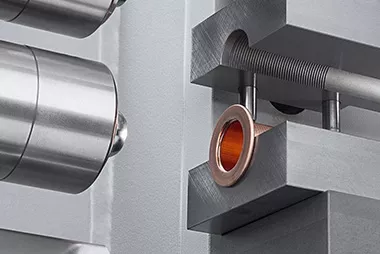

Our 5-axis bevel head plasma cutters feature a high definition cutting head capable of making intricate cuts with precise results. The heavy duty cutting table can handle plate and sheet sizes up to 120″ wide x 240″ long and 3″ thick, with a maximum cutting depth of 3″ for steel and 2″ for aluminum, a kerf width of 0.15″ and a dimensional tolerance of plus or minus 0.02. Additionally, our CNC plasma cutters allow for custom modifications including angles and more. Additional services include drawing CAD files for production, true hole capabilities, and welding services for plasma cut products. These precision machines eliminate the need for custom stamping tooling and are a cost-effective way to

Types of Plasma Cutting Techniques We Provide

CNC Plasma Cutting

Conventional Plasma Cutting

High-definition plasma cutting

Dual-Gas Plasma Cutting

Water Table Plasma Cutting

Tell us about your custom requirements

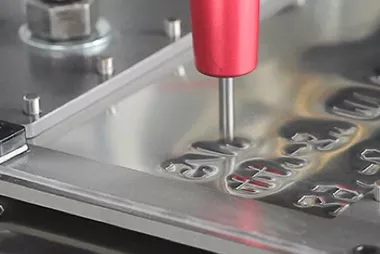

Perhaps you need a “outside the box” metal product to solve your company’s unique manufacturing challenges. Or perhaps you have your own design and need our help to bring it to life. Our in-house design services range from designing to customer concepts, providing your product design drawings, to embedding the design into sheet metal using our high-definition CNC plasma cutting machines. The efficiency and tight tolerances of our equipment ensure the most cost-effective design and production process. The products we offer are renowned for their high quality. All our production, testing, and inspection procedures are in compliance with our ISO 9001:2015 certified quality management system.

A Trustworthy Team

We have an engineer with 26 years of experience on our team and he is one of Elimold’s most respected senior team members. Elimold believes in service excellence and is committed to providing it. The best part of our job is the satisfaction of processing customer orders on time and without errors. Our experienced team has played a vital role in tens of thousands of orders over the years. The most commendable one: Elimold’s team completed a project for one customer involving 42,000 parts. Handling a project with so many parts is no easy task, but Elimold’s team stepped up to meet the customer’s needs. We are committed to providing fast, accurate and reliable service, so when you need help, we will provide you with the best service.

Fastest Lead Time

Orders follow an efficient and logical path through our system, providing customers with convenient ordering and simple interactions. Elimold responds quickly; you don’t have to wait days for a quote, it only takes a few hours. Our orders are typically shipped within one to two weeks of receiving the purchase order (unless expedited), or even faster. Shortening lead times is a big focus for Elimold. In addition, our project quotes are calculated on a per-item basis based on complexity and quantity, and expedited services are available. We accept orders of any size and complexity. We can handle expedited work, and as a full-service metal fabrication company, we also provide many other additional services.

Our Commitment to Quality

Elimold offers a vertically integrated, turnkey manufacturing process, including full in-house machining capabilities. Our fully automated cutting and assembly equipment represents state-of-the-art technology. Each facility is ISO 9001:2015 certified, with strong capacity and manufacturing redundancy. We collaborate on new and existing products using a Value Analysis/Value Engineering (VA/VE) process. This allows us to validate the manufacturing process prior to production, saving development time, reducing costs, and consistently delivering on time. Quality is at the heart of everything we do. Our plasma cutting services are designed to provide the best results for every project. We follow a rigorous quality control process to ensure that every product we produce meets or exceeds your expectations. From the initial consultation to the final cut, we are committed to providing precision, consistency, and excellence.

Engineering Design Capabilities

We are committed to being an extension of your team to ensure that your metal fabrication and metal cutting project needs are met. Elimold’s team of engineers can provide you with engineering design capabilities with expertise in metal cutting and steel plate cutting. From design to installation, our experienced team is committed to providing you with high-quality, durable and efficient solutions. In addition, if there are special needs or challenges, our team in the office and workshop is proactive in identifying potential problems and developing solutions. And during the quotation stage, our team will check the design for manufacturability (DFM). We want to ensure that the parts shipped from our factory meet the customer’s application requirements. Please contact us today to discuss your design needs.

Looking For Experienced Metal Fabricators?

Our team is here to help. Material supply, welding gases, custom design, fabrication or repair for nearly all of your metal project needs. Contact us today for a free quote.

Plasma Cut Parts Supplier

Our plasma cutting department offers fast delivery to our customers, and no matter the size or complexity of your project, our plasma cutting experts are capable of handling it. Our CNC plasma cutting shop and manufacturing team can provide customers with the best quality and most affordable service. And our CNC plasma cutting focuses on excellent precision and detail, ensuring that your end product is of the highest quality. Gas and electric current melt and cut the metal, leaving the plasma cut edge slightly rough, with beveled and rounded top edges. Compared to laser cutting and water jet cutting, plasma cutting can cut thicker materials. Therefore, CNC plasma cutting metal is more economical than laser or water jet cutting metal.

Full Range Of Plasma Cutting Services

Our experienced technicians are proficient in every aspect of CNC plasma cutting and welding, from design programming to final production and finishing. We use only the highest quality materials and take great care to ensure that every detail of our work is accurate. In addition, we specialize in providing complete kits of parts and use professional packaging to ensure that the parts are protected during shipping and storage. As part of our comprehensive machine shop capabilities, we also provide services such as beveling, drilling and part stamping, as well as etching. If you are looking for a trusted partner to meet your CNC plasma cutting and welding metal processing needs, our metal processing services are your best choice. Contact us today to learn more about our services and schedule a consultation.

What is Plasma Cutting?

Plasma cutting is a process used to quickly and accurately cut steel and other metals of varying thicknesses. Plasma cutting is commonly used in metalworking and fabrication because of its speed, accuracy, and ability to process complex shapes. Plasma cutting uses an inert gas blown in at high speeds at temperatures above 20,000°C (36,032°F). An electric arc is then created in and around the gas, forming a plasma. The plasma is hot enough to cut through metal and leave a smooth edge. Plasma gases are typically argon, argon/hydrogen, or nitrogen. These inert gases can be replaced with air, but this requires special hafnium or zirconium electrodes. The choice of gas depends on the material being cut and the desired surface finish.

Material Options

We offer a wide variety of sheet metal materials for you to choose from, each selected for its unique properties so that we can recommend the most appropriate material for your project’s specific needs and application.

- Stainless steel

- Black iron

- Galvanized metals

- Copper

- Aluminum

- Brass

- Titanium

- Diamond plate

Surface Treatment Options

Choose Elimold’s full-service approach for all your project needs, from prototyping to full assembly. Therefore, we offer a variety of surface treatment options to meet your specific needs.

- As Machined

- Anodizing

- Polishing

- Sand Blasting

- Tumbling

- Electropolish

- Alodine

- Heat Treatment

- Brushed Finish

- Powder Coating

- Electroplating

- Black Oxidize

Plasma Cutting Considerations

Depending on your application you will need to consider the following factors in choosing plasma cutting. Parts that require extreme precision will benefit from laser cutting for stringent tolerances.

- An oxide layer will be present on the cut surface.

- For all metals, but particularly aluminum, the cut edge will be rough.

- Cut edges may experience some pitting. Pitting can be as large as the thickness of the material.

- Edge angles are not exactly 90%, many times the deviation can be as much as 10 – 20%

- Intricate parts might experience some warping, in these cases your welding pro will find a better solution.

Advantages of Plasma Cutting

- Lower cost: One of the big benefits is the lower cost of a plasma cutting service compared to other cutting methods. The lower price for the service derives from different aspects – operational costs and speed.

- High speed: Plasma cutting service’s one of the main benefits is its quickness. This is especially evident with metal plates, while laser cutting is competitive when it comes to sheet cutting. The increased speed enables to produce larger quantities in a given time-frame, lessening the cost per part.

- Low operational requirements: Another important factor to keep service prices down. Plasma cutters use compressed air and electricity to operate. This means that there is no expensive equipment needed to accompany a plasma cutter.

- Low heat input: Plasma cutters focus the outgoing plasma jet using a nozzle. This concentrates the energy into a small dot, meaning that the energy requirements are not that great to perform a cut.

- Small heat-affected zone: The material properties and microstructure change in the HAZ. It can also cause material warping. Therefore, keeping the zone small is one of plasma cutting’s advantages.

- Good quality: Plasma cutting provides good clean cuts, especially with small to medium size thicknesses (up to 30 mm), although its cutting kerf is larger compared to other methods.

- Short preparation time: The prep time is kept to a minimum because there is no need for preheating the metal before cutting.

- Versatility: This cutting method lets you cut through a stack of material or use it for bevelling, shape cutting, gouging and piercing. All these possibilities make it possible to fulfil many different needs with one operation.

Industries We Serve

Typically, CNC plasma cutting applications are used in the following industries:

- Aerospace

- Agricultural

- Architectural

- Auto

- Chemical

- Construction

- Food

- Heavy Industry

- Machine Tool

- Marine

- Military

- Mining

- Oil Field

- Steel Mill

- Packaging

- Power Generation

Plasma Cutting Applications

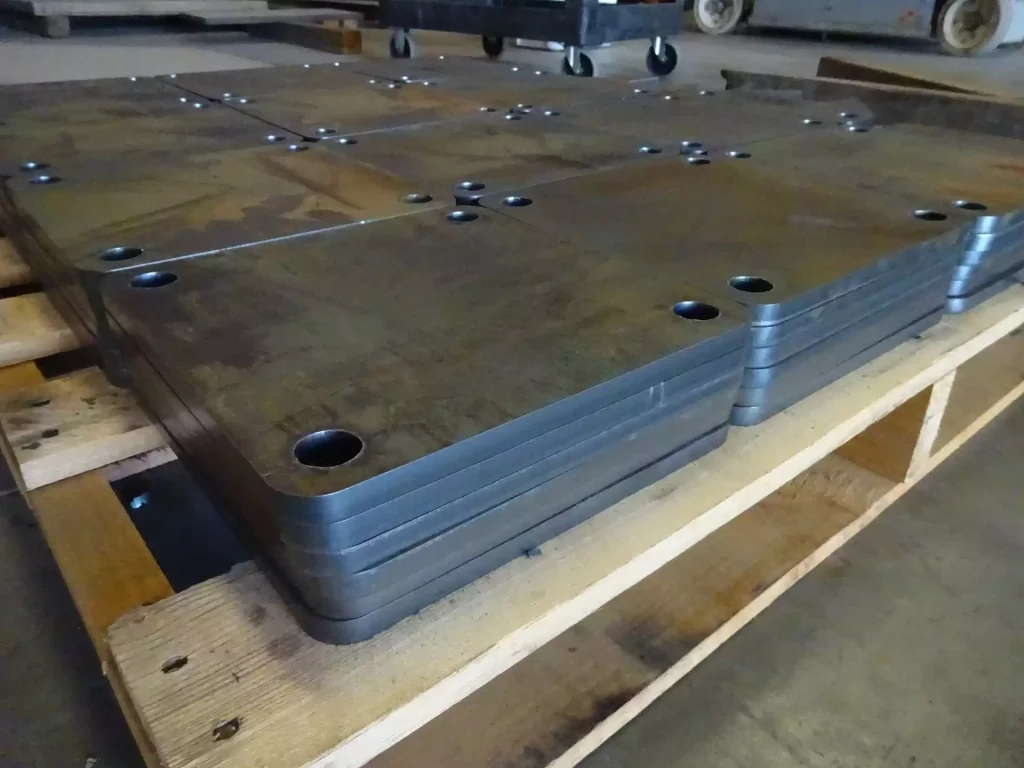

Plasma cutting is a flexible and precise technology that can be used to manufacture a wide range of parts types. Here are some examples of how plasma cutting can be used to produce specific types of parts:

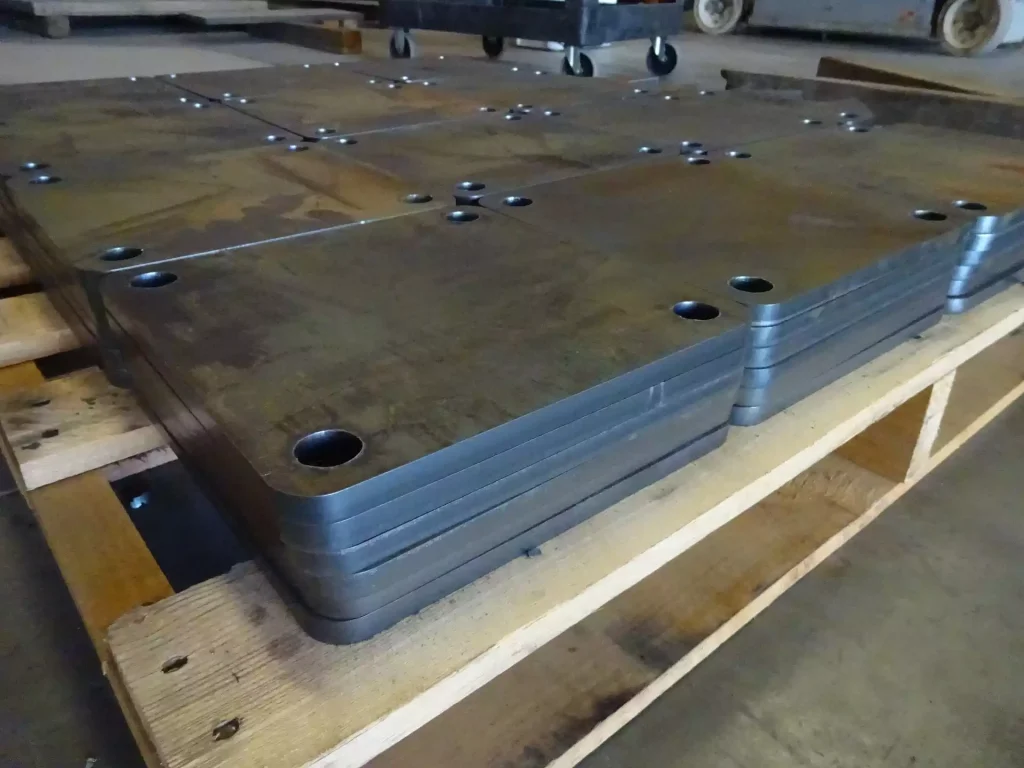

- Anchor plates

- Mounting plates

- Engine skid bases

- Tool racks

- Frame reinforcements

- Valve covers

- Loader arms

- Excavator attachments

- Braking system plates

- Sprocket guards

- Manhole covers

- Transmission covers

- Gearbox housings

- Winch mounts

- Plow blades

- Baler shields

- Seeder brackets

- Mixer paddles

- Dump truck liners

- Suspension plates

- Counterweights

- Pump mounting brackets

- Industrial ladders

- Catwalk components

- Furnace enclosures

- Press machine parts

- Dock levelers

- Wind turbine frames

- Solar panel mounts

- Elevator support beams

- Bridge truss components

- Skid steer attachments

- Clamping fixtures

- Oil tank covers

- Road grader blades

- Concrete mold plates

- Bunker doors

- Flame-cut logos

- Warehouse racks

- Truck chassis braces

Other Sheet Metal Fabrication Services

Elimold offers the widest range of services required in the metal industry, and can provide both standard services and custom services to meet our customers’ specific needs. Below are the other sheet metal fabrication services we offer.

Laser Cutting

Punching

Stamping

Die Cutting

Bending

Welding

Extrusion

Embossing

Forming

Riveting

Waterjet Cutting

Request Your Free Plasma Cutting Quote Today

After receiving your drawings, our engineers will analyze your custom Plasma Cutting parts right away. We actively work with you to clarify all details before providing a quote that is both economical and accurate.