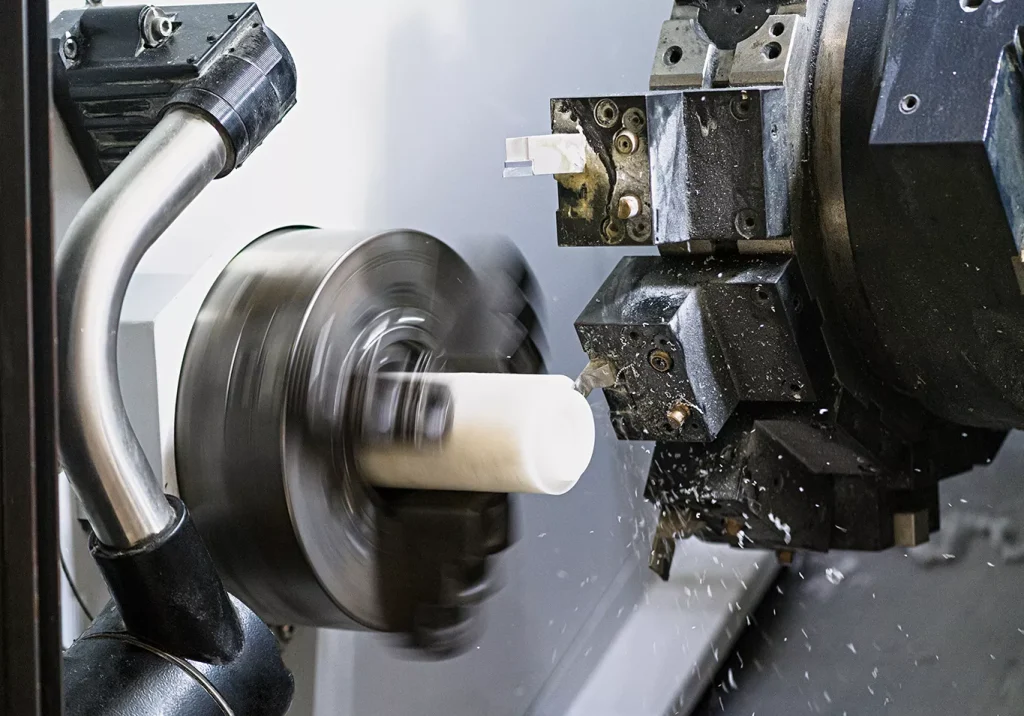

Plastic CNC Machining Services

Does your project require plastic CNC machining services? Our experienced team of professionals can provide you with the highest quality plastic parts. We maintain high standards and ensure that you are satisfied with the results of our work. Whether you need a custom plastic prototype or an end-use production part, Elimold can manufacture high-quality machined plastic parts for customers around the world at a very competitive price.

Fast Plastic CNC Machining Service Provider

Do you need to quickly produce a plastic CNC part or a custom prototype part for display models, design verification, or functional testing? Elimold’s rapid CNC plastic machining services can help. We can provide you with a confirmed quote in as little as 2-4 hours and provide finished parts in as fast as 1 days.

We know that most factories engaged in plastic CNC machining have limited capacity and long lead times. In fact, lead times can be as long as months, but you can’t wait that long. If you need to bring a new product to market quickly, Elimold’s plastic machining services are exactly what you need.

Professional Plastic CNC Parts Manufacturing Company

Elimold is a premier plastics manufacturing company that places a premium on quality, expertise, and dedication at every stage of the machining process. Our facility features state-of-the-art CNC plastic machining technology and is renowned for exceptional quality inspections. Our meticulous workmanship ensures efficient, fast machining and highly competitive pricing, ensuring your precision parts are delivered on time. Our facility specializes in high-performance and custom plastic machining, utilizing state-of-the-art equipment and methods to accelerate production. We utilize advanced computer software to perform comprehensive inspections, provide detailed reports, and ensure full traceability of all materials.

Furthermore, Elimold has a first-class, dedicated plastics machining shop equipped with a variety of advanced machinery and equipment capable of producing a wide range of plastic machined parts. Our team of industry experts provides plastics manufacturing services, including design and engineering assistance, to help customers streamline their development process and reduce costs.

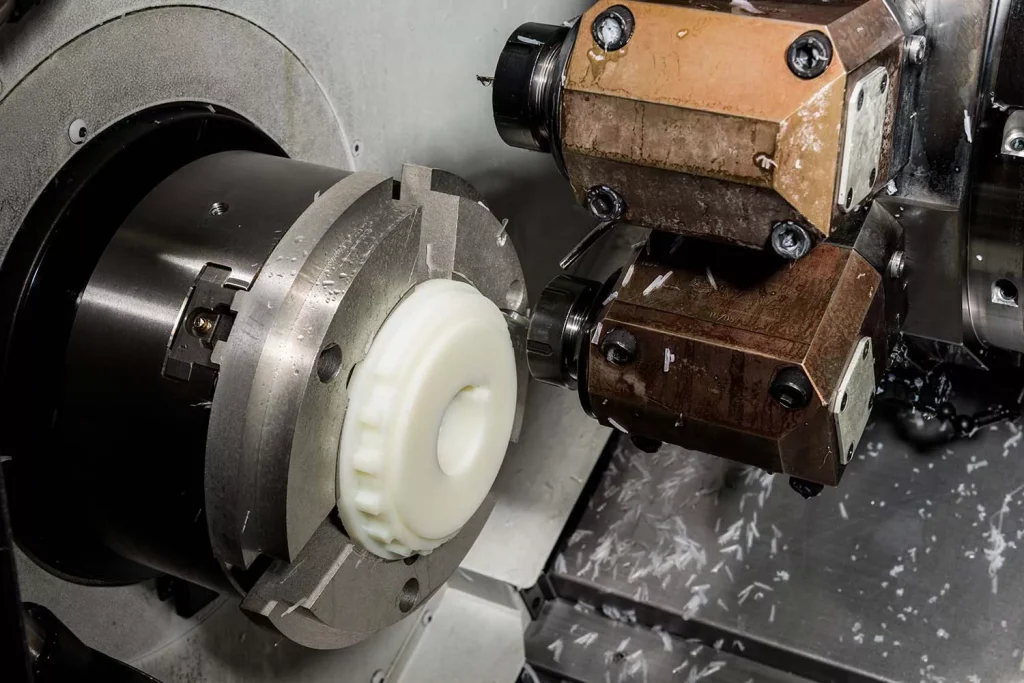

In-house Plastic CNC machining Shop

We are a full-service plastic machining shop capable of producing parts with complex geometries and tight tolerances. We are able to achieve high precision and quality without the high costs and red tape of large machining service providers, so we can complete orders faster and at a lower cost. We are happy to pass these advantages on to our customers.Our 30,000 square foot facility is equipped with more than 200 advanced CNC centers. Our advanced equipment allows us to run at higher speeds and complete large-volume orders without sacrificing product quality. In addition, after evaluating the material, geometry and production volume of each project, our experienced team of engineers will determine the manufacturing method that is best suited for the project. In this way, we ensure that our customers always receive the highest quality parts at the best price.

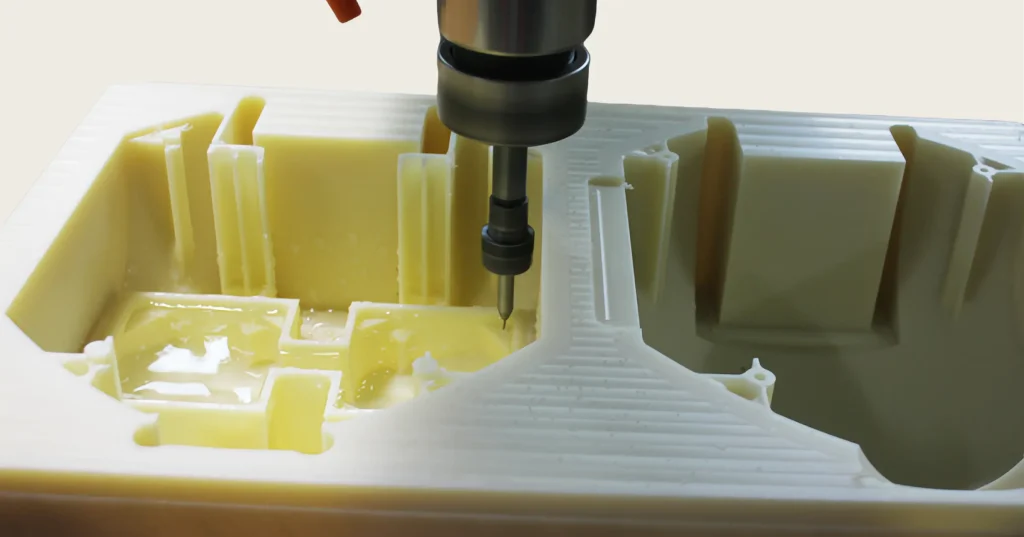

Plastic CNC Part Rapid Prototyping Services

Elimold produces custom plastic parts for routine or special projects to your exact specifications. From the early stages of design through production, we are committed to providing the highest quality machined plastic parts, whether it is a single prototype or an urgent short-run production run.

And our strong CAD modeling capabilities, combined with our engineering expertise, allow us to develop prototypes for products in a variety of materials, including plastics. Our team works closely with you to continuously refine and optimize your design, ensuring that your prototype meets and exceeds the expected specifications. With a focus on precision and innovation, Elimold is your trusted partner for fast and reliable prototyping solutions, no matter the size of your project.

Turnkey Plastic CNC Parts Manufacturing Services

We specialize in machining plastic parts to your drawings, specifications, or purchase order requirements. We also welcome applications for unique, yet unvetted, designs. As a one-stop shop, Elimold is happy to work with you to ideate and prototype. Once the design is approved, production can begin. Our CNC plastic machining capabilities support a wide range of applications and are designed to meet the specific needs of each project. Each process is carefully configured for precise, repeatable results, allowing us to accurately handle the most complex designs. With the added benefit of CAD design services, we simplify the transition from concept to completion. In addition to machining, we also provide ancillary services such as chemical bonding, flame polishing, welding, and precision cutting. These services ensure that each part meets the required appearance and functional standards for your application.

Start Your Project With A Free Quote

At Elimold, we pride ourselves on being able to meet a wide range of plastics processing needs. If you have any questions, please contact us to learn how we can help you turn your creative vision into reality and meet your plastics processing needs.

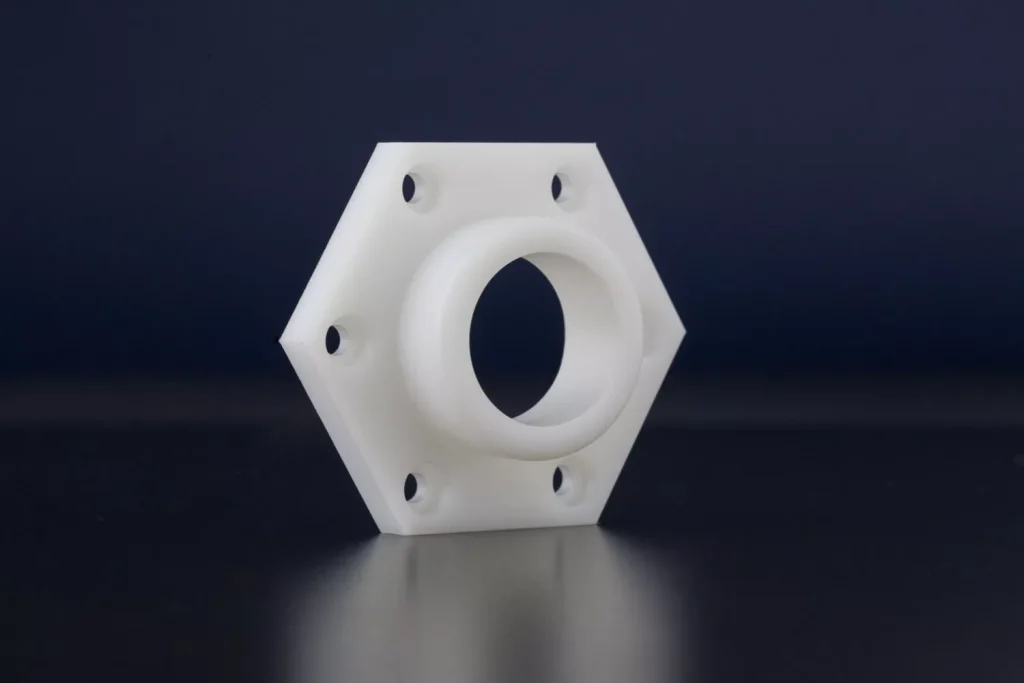

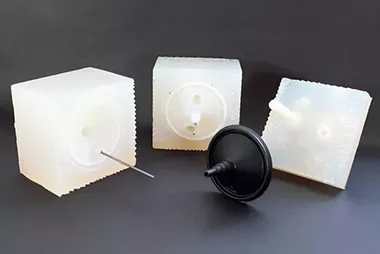

Custom Plastic CNC Machined Parts for Your Project

Our in-house CNC plastic machining capabilities allow us to handle orders of any size and guarantee that you will be satisfied with your product. We also provide assistance with rapid prototyping and R&D, as well as the development of new product designs. Our goal is to deliver your product as quickly and economically as possible. This means that we use the most efficient methods at every step of the machining process. From product design to manufacturing and delivery, you can rely on us to complete it on time and at a reasonable price. We welcome complex projects. To ensure precision, we have a workshop equipped with advanced machines, in most cases with robot loading and/or bar feeders. At Elimold, we use the latest plastic processing technology to produce around the clock, flexibly respond to demand peaks, and manufacture the most precise parts.

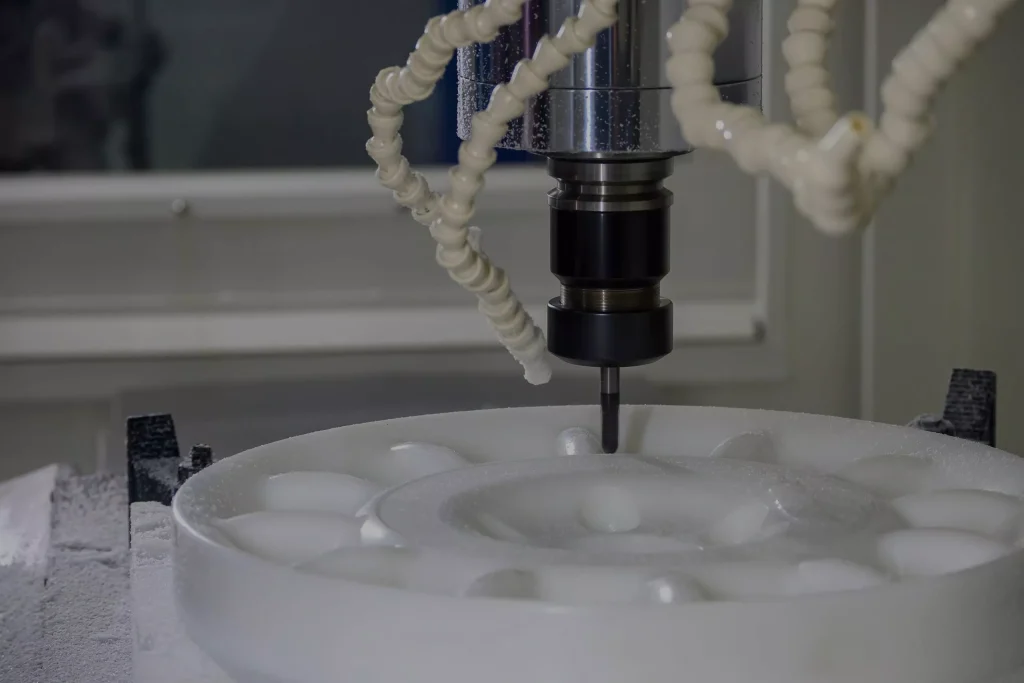

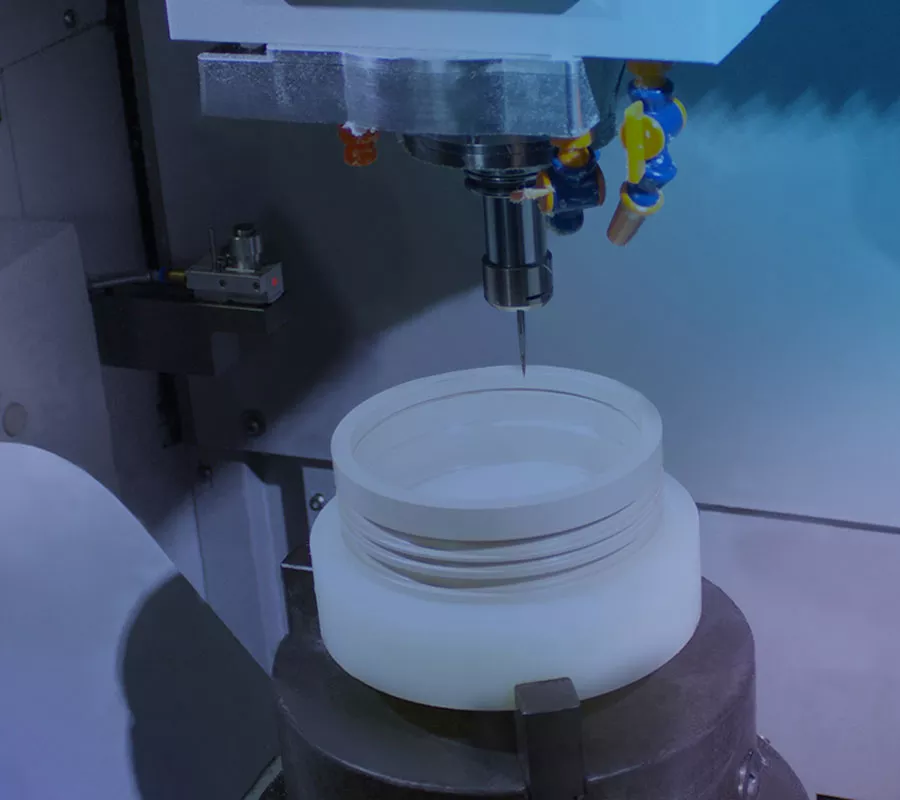

Types of our CNC plastic machining services

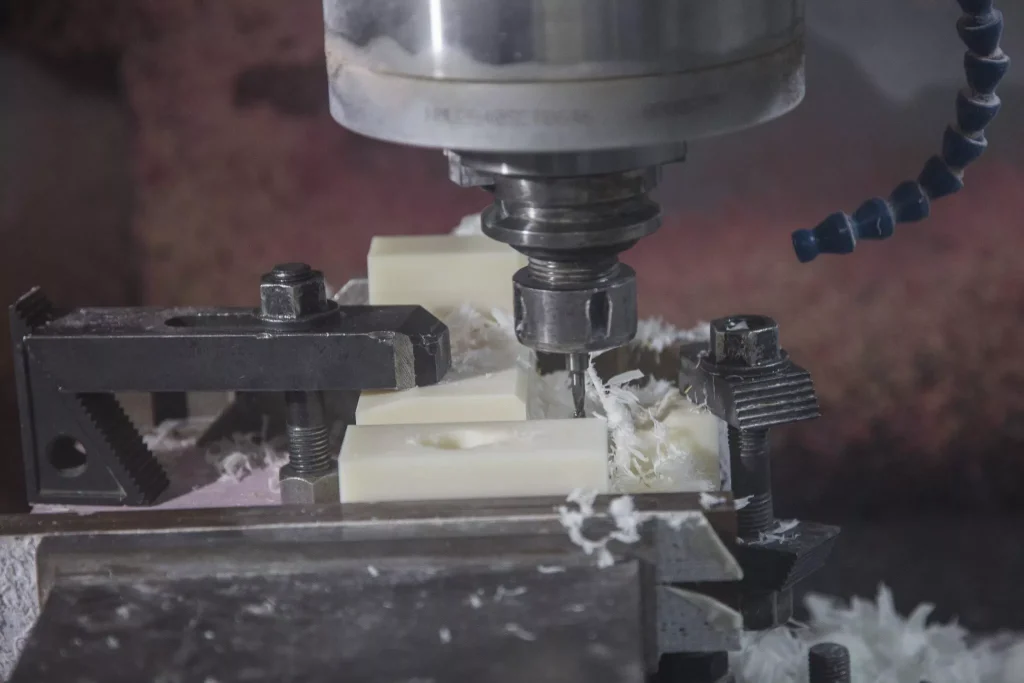

We have extensive experience in CNC machining a wide range of engineering plastics, and we have advanced CNC equipment that allows us to provide high-end solutions for a wide range of projects. Many customers consider us their preferred CNC machining partner and trusted provider of quality plastic CNC parts manufacturing services. We are happy to provide the following plastic machining services:

CNC Milling

CNC Turning

3 Axis CNC Machining

4 Axis CNC Machining

5 Axis CNC Machining

CNC Prototypes

Wire EDM Machining

CNC Threading and Tapping

CNC High-Speed Drilling

Swiss Machining Service

CNC Routing Service

CNC Grinding Service

Materials We Machine

There are hundreds of different plastics on the market today. At Elimold, we have experience machining many plastics, from high-temperature to high-resistance materials. Below is a preview of some of the most popular plasticswe machine:

- ABS (Acrylonitrile Butadiene Styrene)

- POM (Polyoxymethylene / Acetal / Delrin)

- Nylon (PA)

- Polycarbonate (PC)

- Polyethylene (PE)

- Polypropylene (PP)

- PVC (Polyvinyl Chloride)

- PTFE (Polytetrafluoroethylene / Teflon)

- PEEK (Polyether Ether Ketone)

- UHMW (Ultra High Molecular Weight Polyethylene)

- Acrylic (PMMA)

- PPS (Polyphenylene Sulfide)

- PVDF (Polyvinylidene Fluoride)

- HDPE (High-Density Polyethylene)

- LDPE (Low-Density Polyethylene)

- HIPS (High Impact Polystyrene)

- PC/ABS (Polycarbonate/Acrylonitrile Butadiene Styrene blend)

- PEI (Polyetherimide / Ultem)

- PPSU (Polyphenylsulfone)

- PS (Polystyrene)

- PET (Polyethylene Terephthalate)

- PETG (Polyethylene Terephthalate Glycol)

- CPVC (Chlorinated Polyvinyl Chloride)

- SAN (Styrene Acrylonitrile)

- TPU (Thermoplastic Polyurethane)

- TPO (Thermoplastic Olefin)

- LCP (Liquid Crystal Polymer)

- ETFE (Ethylene Tetrafluoroethylene)

- ECTFE (Ethylene Chlorotrifluoroethylene)

- FEP (Fluorinated Ethylene Propylene)

Plastic Part Manufacturing Capabilities

Our CNC machining capabilities complement advanced molding techniques to ensure your custom plastic parts meet their specified size, shape and configuration. CNC plastic machining provides high-precision, fast processing results. Dimensions and performance are maintained within tight tolerances to perfectly meet your needs. Elimold custom parts can be up to 12 feet (about 3.6 meters) in maximum width or length, and 0.5 inches (about 1.2 cm) in minimum length and width. Our dedicated production shop provides a full range of prototyping services, with minimum production quantities of 1 piece and high-volume production capabilities up to 50,000 pieces. Typical turnaround time for custom machined products is 2 days to 1 week, and functional prototypes require 3 to 4 days. Specific delivery time will be quoted based on the specific job. In addition, our Swiss-type CNC lathes are ideal for high-volume production of small cylindrical parts, accommodating more than 50,000 parts up to 32 mm (1.25 inches) in diameter.

Tolerances

Tolerances on custom plastic parts are critical. Tight tolerances can add cost and complexity to the machining process, so it is important to strike a balance between precision and practicality. All of our CNC machined plastic parts are manufactured to ISO 2768 by default. Geometric tolerances can be as low as +/- 0.002 inches, but must be clearly marked on the technical drawing and communicated to us prior to production. If you have questions about tighter tolerances, please feel free to ask.

Tight Tolerances

| Dimension | Tolerances |

|---|---|

| 0.5 – 6.00 mm | ± 0.10 mm |

| 6.00 – 30.00 mm | ± 0.20 mm |

| 30.00 – 120.00 mm | ± 0.30 mm |

| 120.00 – 400.00 mm | ± 0.50 mm |

| 400.00 – 1000.00 mm | ± 0.80 mm |

| Angular: ±0.5° | |

| Surface Roughness 3.2μm Ra | |

We are ready to help you with your next plastic CNC machining project

Our experienced team of manufacturing experts, machinists and engineers deliver high-quality CNC plastic parts on time. Whether you need a one-off prototype or low-volume production, we can work with you to turn your design into reality.

DFM and Engineering Services

Elimold’s CNC plastic machining services begin with an initial DFM design by our team of engineers, who will identify any non-machinable areas in your part drawings. They will recommend engineering changes or other methods to meet your requirements. If you decide to place an order with us, they will perform a deeper DFM analysis to identify design optimization and cost reduction opportunities for CNC machined plastics. Parts will be machined to your specifications.

In addition to DFM design and reverse engineering, we also provide emergency manufacturing and delivery, engineering design, and value-added manufacturing solutions. Elimold’s team assists customers throughout the life cycle of the project, including customer input and design, prototyping, tooling/mold production, and high-volume production. We also recommend custom plastic part modifications to simplify assembly design for easier installation, cleaning, and repair. In addition, our production facility can also provide a variety of surface treatment options, including painting, screen printing, and inserts. We also provide custom processes. And even in emergency situations, we can manufacture, source, package, and ship parts on time.

Engineering Support and Inventory Management Services

Your long-term success is our priority. Our services support your production and business from start to finish with our strong engineering support capabilities. Whether you need design assistance in the initial stages of your CNC plastic machining process or want to establish ongoing, scheduled deliveries, Elimold can help. Our digital product definition services ensure the accuracy of plastic parts and maintain the integrity of CAD drawings, while our inventory management solutions ensure that you get the parts you need delivered on time and to order.

Plastic part design services to meet your needs

Elimold specializes in practical plastic part design. We focus on precision, functionality and efficiency. Whether you need a single prototype or a short production run, we are committed to providing high-quality machined plastic parts. Our services cover initial design, material selection and design optimization. With our expertise in CNC machining (including micro-machining), we are able to customize plastic parts to your specific needs. And we focus on precision and quality to turn design ideas into reality. Our advanced equipment and experienced team ensure efficient production of plastic parts. Elimold is your trusted partner, and we can provide you with innovative custom plastic parts that meet your specific needs.

Machining Certification

We are proud to hold ISO 9001:2015 certification and comply with the latest international quality management system ISO 13485 standard, allowing us to fully control materials and processes for our customers. All our machined parts are accompanied by complete quality control documentation, listing and recording all features and tolerances. Parts are tested at a minimum of 2% frequency, or even higher (depending on customer requirements), by external laboratories using meters and instruments certified to NIST standards. This ensures that you receive accurate and reliable parts with every order. Our quality policy allows for any additional quality control checks required by the customer, including raw material laboratory testing, batch tracking and part serialization.

Quality Management & Inspection

After parts are manufactured, we thoroughly inspect each component to ensure that every customer requirement is exceeded. We use an in-depth range of product verification methods and equipment, such as DCC Zeiss coordinate measuring machines, ROI vision systems, optical comparators, microscopes and manual contact gauges to check specifications from basic linear tolerances to complex geometric dimensioning and tolerance (GD&T) geometries. And at Elimold, all of our machining processes are optimized to implement Six Sigma practices and achieve lights-out and lean manufacturing.

Testing Equipment

After manufacturing, machined plastic components should be inspected to ensure they are qualified and precise. Precision parts, which frequently have complex structures and unique shapes, must be measured in multiple steps.

- Full 3D CMM (Coordinate Measuring Machine)

- Ability to Scan and Completely Reverse-Engineer Even Your Most Complex Parts

- Complete Digitizing Capability With Laser-Scanner

- CMM Can Completely Scan a Part or Gear and Produce a Useful Model

- Ability to Scan and Completely Compare Your Parts to CAD Model

Surface Treatment Options

All machinable plastics can be treated with a variety of surface treatments, such as basic smoothing or sandblasting, while some plastics can be high-gloss polished, brushed, painted, chrome-plated or metallized, providing a variety of surface treatments for different plastic machined parts. If you are unsure, Elimold can guide you in choosing the right surface treatment.

- Vapor polishing

- Flame polishing

- Bead blasting

- Sanding

- Buffing

- Painting

- Silk screening

- Pad printing

- Electroplating (for specific plastics)

- Anodizing-like coatings (for certain plastics with conductive coatings)

- Coating with UV-resistant layers

- Powder coating (rare, with special plastics)

- Laser etching

- Chemical polishing

Custom Packaging Service

At Elimold, customer satisfaction is of utmost importance. Each part is inspected by precision testing equipment and all orders are reviewed for accuracy before shipment. We also offer a variety of shipping options to ensure your order arrives intact. We ship large orders in custom packaging on pallets to minimize the possibility of damage to the goods. The goods are affixed with corner guards on all four sides, wrapped in cardboard, and tied with strapping. Each pallet contains a protective plastic film and a protective film underneath to prevent nail punctures. For small land shipments, Elimold determines the appropriate packaging method based on the size of the goods. We use the smallest possible carton. If required, special packaging can be provided to meet your needs. You can also set up your own shipping plan, and a handling fee will be added to the order to cover the packaging costs.

Why work with Elimold?

We are defined by precision. We work with extraordinary care from the moment you first call us to final delivery anywhere in the world. Whether you give us a well-crafted final drawing or an undeveloped concept, Elimold treats every project with the mission-critical care our clients demand.

Production-Quality Prototypes Done Right

When the success of a design depends on the accuracy of the prototype, a “close” part isn’t close enough. At Elimold, we ensure design fidelity through rigorous quality review. Through workmanship quality checks and FaroArm technology, we deliver prototypes that match your design intent. You can test your designs with confidence, knowing your parts are as true to the real world as they are.

Expert Approach to Part Optimization

Your design is brilliant. The prototype looks good. But will it be mass produced? With Elimold, there will be no surprises when it comes to production. We combine extensive advanced subtractive manufacturing expertise with proven design-to-manufacturing processes to ensure your prototype can be manufactured in the most cost-effective way possible. If there is a way to reduce costs, improve quality, or enhance transition to production, we will find it.

Industries Served

Elimold serves a wide range of industries around the world, providing them with plastic CNC machining solutions that meet various project needs. Our precision, flexibility and commitment to quality have benefited a wide range of industries.

- Medical

- Optics

- Robotics

- Measurement equipment

- Military and defense

- HPLC

- Semiconductors

- Chemicals

- Water and waste treatment

- Electronics

- Food processing

- Oil and gas

- Aerospace

Components & applications

Plastic CNC machining is used in a wide range of industries and the range of applications is endless. Elimold has an experienced team and has completed more than 1000 plastic projects covering a wide range of sizes, materials and surface treatments. We are constantly developing unique products for our customers to meet the needs of each customer.

- Tooling

- Enclosures

- Brackets

- Base plates

- Manifolds

- Housings

- Heatsinks

- Handles

- Scraper blades

- Blocks

- Surgical instruments

- Medical implants

- Bearings

- Bushings

- Valves

- Washers

- Insulation

- Casings

- Connectors

- Boxes

- Furniture components

- Covers

- Structural components

- Guards

- Collars

- Pivots

- Handles

- Seals

Machining vs. 3D Printing

When it comes to metalworking, machining is almost always preferred over printing metal. Machining allows for a wider range of materials, finer finishes, and is typically less than a quarter the price of printing metal. Machining is also a great solution for complex tools like injection molds. Plastics are a little more complicated. Machining plastics is generally more expensive than 3D printing, requires longer lead times, and has more design restrictions. However, machining is available for a wider variety of plastics than 3D printing. Machining is a good option if the material you need can’t be printed.

Why Choose CNC Plastic Over 3D Printing

- When designing parts using plastic materials such as PVC, POM, PEI, or PEEK, they can’t be printed using 3D processes. There are no reliable and affordable printing formulations of these plastics. But with plastic machining, you can design any type of plastic with ease according to the customer specifications.

- 3D printed specialty materials are typically more expensive and manufacturing costs are priced based on the amount of material used, which means larger parts or larger quantities of parts cost more, while CNC plastic is a more convenient and cost effective process.

- 3D printing processes leave a layer of marks on the plastic parts that can be difficult to remove. This is not suitable when creating concept models or functional prototypes that need a high-quality surface finish. We use milling processes to ensure that the part has a quality finish and is ready for use.

- Plastic CNC machining offers greater dimensional accuracy, and 5-axis CNC milling machines can help you tackle the most difficult manufacturing challenges by providing high precision machining of more complex parts.

Alternatives to Plastic CNC Machining

For some plastic parts, plastic CNC machining may not be an ideal option. Elimold offers several alternatives for custom plastic parts. These options are listed and described below:

3D Printing

Injection Molding

Vacuum Casting

Request Your Free Plastic CNC Machining Quote Today

After receiving your drawings, our engineers will analyze your custom Plastic CNC machining parts right away. We actively work with you to clarify all details before providing a quote that is both economical and accurate.