POM (Polyoxymethylene) Injection Molding Service

We offer professional POM (Polyoxymethylene) and Delrin injection molding services, including custom POM prototypes and parts production, with delivery within 5 days. Get durable products, expert support, and cost-effective solutions for your projects.

Professional POM Injection Molding Manufacturer

Looking for a reputable supplier of injection-molded POM plastic parts? Look no further! Elimold is an expert in producing high-quality POM plastic parts using the latest injection molding technology. Our professional team has years of experience and can manufacture all types of Delrin parts. Whether it’s large, complex components or small, precision parts, we can handle any scale of task.

We understand that every client seeking injection molding services is unique, with their own distinct needs and goals. Therefore, we are happy to provide customized parts and molds. Because we are not just an injection molding company, we are problem-solving experts. From concept to finished product, we are with you every step of the way.

Complete Production Support Team

We have a dedicated manufacturing team working behind the scenes to meet your production order needs. We manage the entire process and keep you updated on the latest progress.

Engineering & DFM

Mold Making

Injection Molding

Surface Treatments

Quality and Compliance

Assembly and Shipping

POM Injection Molding Industry Experts

Elimold’s understanding of POM plastics far surpasses that of its competitors. We excel at processing various modified Delrin materials, including but not limited to POM variants with enhanced toughness, abrasion resistance, and UV protection. With sophisticated processes and extensive experience, our engineering team precisely considers mold design factors such as shrinkage and flow ratio, effectively preventing various injection molding defects. In large-scale POM parts production projects, we are confident in controlling defect rates below 1%. Our meticulous processes and advanced technology keep us at the forefront of the industry, ensuring superior quality and precision in POM injection molding projects. Choose Elimold; excellence is not only our pursuit but also our guarantee of quality.

What is Polyoxymethylene (POM)?

Polyoxymethylene (POM), also known as acetal, polyoxymethylene, or polyoxymethylene resin, is a natural white, semi-crystalline engineering thermoplastic. It is a high-strength, flexible material with excellent creep resistance, outstanding dimensional stability, and impressive impact strength, maintaining good performance even at extremely low temperatures. POM can be divided into copolymers and homopolymers. Homopolymers generally have higher ultimate tensile strength, fatigue resistance, and ideal hardness, but poorer processability. In contrast, copolymers are superior in terms of thermal stability, chemical resistance, and processability. They all share the characteristics of crystallinity and low hygroscopicity. Various grades of POM materials are available on the market and can be customized for different applications.

Types and Differences of POM Injection Molding Materials

POM materials used for injection molding can be classified into two types based on differences in their molecular chain chemical structure: homopolymer formaldehyde and copolymer formaldehyde.

POM-H (Homopolymer)

Homopolymers are produced by anionic catalytic polymerization of anhydrous formaldehyde monomer in an organic liquid reaction medium, and further stabilized by reaction with acetic anhydride. POM-H has higher crystallinity. Known under the brand name Delrin® and manufactured by Delrin USA LLC, POM-H has slightly higher density, hardness, and strength than copolymers. Homopolymers have higher density, crystallinity, and melting point, but poorer thermal stability, a narrower processing temperature range (approximately 10°C), and slightly lower acid and alkali stability.

POM-C (Copolymer)

Copolymers require the initial conversion of formaldehyde to trioxymethylene using acid catalysis and cationic polymerization. Subsequently, trioxymethylene is purified by distillation or extraction to remove water and other hydrogen-containing reactive impurities. Copolymer formaldehyde has lower density, crystallinity, melting point, and strength, but better thermal stability, is less prone to decomposition, has a wider processing temperature range (approximately 50°C), and better acid and alkali stability.

Properties of Polyoxymethylene (POM) at Room Temperature

- Tensile Strength: 60–70 MPa

- Flexural Strength: 90–110 MPa

- Impact Strength (Notched/Unnotched): 40–60 J/m

- Elastic Modulus: 2.8–3.0 GPa

- Heat Deflection Temperature: 110–120°C

- Density: 1.41 g/cm³

- Chemical Resistance: Excellent; resistant to most solvents, fuels, and weak acids/bases

- Water Absorption: 0.2–0.5%

- Shrinkage: 1.0–2.0%

- Flammability: UL94 HB

Acetal Material Grades for Injection Molding

We work with various Acetal grades optimized for injection molding:

Delrin® (General Purpose POM)

Delrin® is a versatile general purpose polyoxymethylene (POM) known for its high stiffness, excellent dimensional stability, and ease of processing. It has a density of 1.42 g/cm³, a tensile strength up to 85 MPa, and a flexural modulus of 3.2 GPa.

Delrin® AF (Filled POM and PTFE)

Delrin® AF combines POM with PTFE to create a low-friction material with excellent abrasion resistance and a coefficient of friction as low as 0.12. It has a density of 1.47 g/cm³, a tensile strength up to 78 MPa, and a flexural modulus of 3.1 GPa.

Delrin® 570 (FDA Compliant)

Delrin® 570 is an FDA-compliant polyoxymethylene (POM) with a density of 1.41 g/cm³. Its tensile strength reaches up to 75 MPa, and its flexural modulus is 2.8 GPa.

Hostaform® (Engineering Grade POM)

Hostaform® is an engineering grade polyoxymethylene (POM) that maintains extremely high strength even at high temperatures. It has a density of 1.42 g/cm³, a tensile strength up to 75 MPa, and a flexural modulus of 3.2 GPa.

Celcon® (Low-Friction POM)

Celcon® is a low-friction polyoxymethylene (POM) designed for applications requiring minimal wear and low friction. It has a density of 1.42 g/cm³, a tensile strength up to 77 MPa, and a flexural modulus of 3.2 GPa. Celcon® combines low friction, high abrasion resistance, and dimensional stability.

Impact-Modified POM

This type of POM has impact modifiers added to improve its toughness and impact resistance. Impact-modified POM is commonly used in applications requiring extremely high impact or vibration resistance.

UV-Stabilized POM

Designed for outdoor or UV-exposed environments, UV-stabilized acetal resists degradation and discoloration caused by sunlight or UV radiation, ensuring a longer service life.

Reinforced POM

By adding glass fiber or other fillers, this type of polyoxymethylene (POM) exhibits higher stiffness, strength, and dimensional stability. Reinforced POM is commonly used in structural components and demanding industrial applications.

Conductive POM

Conductive fillers are added to achieve conductivity, making it suitable for electronic and antistatic applications.

The POM Material Brands We Offer

Brand names are essentially the trade names of the products developed by the company. The following are the POM brand names we can offer:

- Delrin® is a polyoxymethylene homopolymer plastic manufactured by DuPont.

- Celcon® is a POM copolymer plastic manufactured by Ticona.

- Duracon® is a POM copolymer plastic manufactured by Polyplastics.

- Kepital®-POM is a POM copolymer plastic manufactured by KEP.

- Hostaform® is a POM copolymer plastic manufactured by Celanese.

- Tecaform® is a POM copolymer plastic manufactured by Ensinger.

- Ultraform® is a POM copolymer plastic manufactured by BASF.

POM Material Selection and Procurement Services

Elimold prides itself on its expertise. Whether you need mold design, mass production of parts, or assistance in selecting the right POM material, our team is dedicated to providing you with the necessary guidance and support. Don’t let the complexities of material selection hinder your project. Contact our professional team, and we will help you determine the precise engineering resin required for your application. If you have already identified your desired resin, you can directly request a personalized quote, saving you time. We have extensive experience in processing these POM materials to produce a variety of high-quality products.

Are You Ready to Work with Elimold?

Get an estimated quote for your custom project within 4 hours.

Custom Acetal Injection Molding Solution

If we find that a customer’s product concept is too expensive to manufacture, we will assist them in designing parts that are not only manufacturable but also cost-effective from prototyping to mass production. With our extensive experience, we are confident in providing solutions for your next injection molding application. Contact us today to collaborate with our experts in planning, manufacturing, and ultimately implementing your next project. Our staff’s years of professional experience and continuous training ensure you always receive the best solutions for your POM projects.

Comprehensive POM Injection Molding Services

Elimold’s team treats each product as an independent project and assigns a dedicated project manager. The project manager organizes project members to develop a complete and reasonable project plan, directly oversees the entire project process (product design improvement, mold development, production process, quality control, assembly and testing), and implements comprehensive management (cycle, schedule, and cost). This ensures efficient planning, full control over all activities, and guarantees high-quality products and services for our customers.

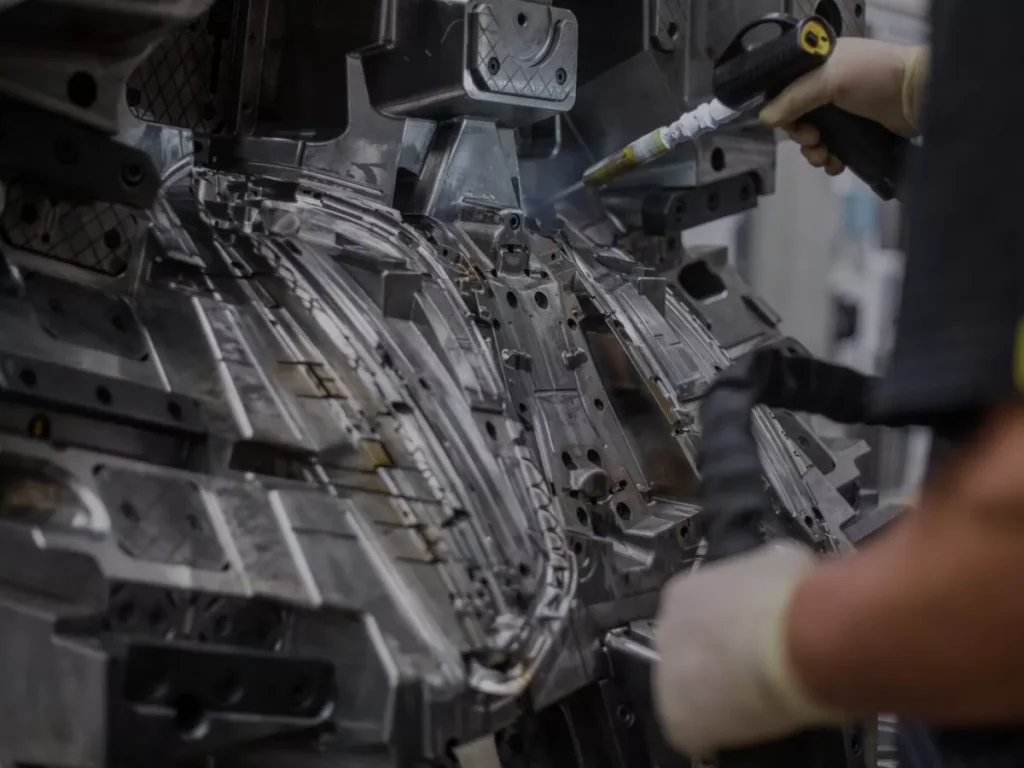

POM Injection Mold Manufacturing Workshop and Molding Plant

Elimold’s in-house factory in Shenzhen, China, covering over 10,000 square meters, features an in-house mold workshop offering cost-effective and rapid mold manufacturing services. Our injection molding workshop boasts over 120 injection molding machines ranging from 70 to 2200 tons, and most post-processing steps can be completed within our factory. Currently, our engineering team has developed specialized technologies and processes for manufacturing POM plastic prototype parts and small-scale production.

Precision Engineering, Extremely Fine Tolerances

Our POM injection molding capabilities produce parts with dimensional accuracy down to ±0.05mm, meeting the most stringent industry requirements. The low moisture absorption (<0.2%) of our POM injection molded components ensures stable performance across a temperature range of -40°C to 120°C. Utilizing advanced mold flow analysis technology, we meticulously complete every POM injection molding project, achieving consistently superior performance even for parts with complex geometries.

Custom POM (Polyoxymethylene) Injection Molding Prototyping

If you are developing a new product, you understand the importance of testing your designs in a real-world environment. Custom injection molding prototyping allows you to create fully functional, high-quality parts without investing in the molds required for mass production. At this stage, you can take full advantage of the wide variety of POM material types, helping your product achieve the performance and appearance you envision within a similar timeframe to standard prototyping.

Our Inspection Standards

We have a rigorously audited ISO 9001 certified quality management system to ensure that your parts production consistently meets industry-specific certification standards. Elimold’s quality inspection team selects appropriate measuring instruments, compares the dimensions against valid drawing versions, and records the specified dimensional data. For other dimensions (used only for conformity verification), only non-conforming data is recorded. If critical dimensions are not specified, the dimension with a decimal point is used as the critical dimension.

Our appearance inspection standards for prototypes and mass-production parts include color, screen printing, surface treatment, appearance, inserts, packaging, etc., all of which must conform to the drawing requirements. Defects are generally determined by the drawings. If not explicitly specified in the drawings, the following requirements apply.

Why Choose Elimold as Your Partner?

Are you looking for precision specialty parts made of polyoxymethylene (POM)? Our services will convince you! We understand our clients’ needs and provide reliable supply chains, advanced expertise, and cost-effective production solutions. Our experienced team maintains control over the entire production process, enabling us to offer personalized guidance at any time. We work closely with our clients to develop products and frequently make improvements on key details. From design analysis and material selection to final part production, we manage every step of the injection molding process for you with our extensive expertise. Contact us today to discuss your project and learn how our injection molding services can turn your ideas into reality.

FAQ

Elimold's engineering team uses advanced technologies, such as mold flow analysis, CNC machining, and rigorous quality control processes, to ensure the precision and performance of each part.

POM is the general name for polyoxymethylene, while Delrin is the trade name for DuPont's homopolymer POM. Delrin injection molding offers slightly higher strength and toughness, while copolymer POM provides better chemical resistance and thermal stability.

Yes, POM can be modified by adding additives such as glass fiber or lubricants to enhance its strength, heat resistance, and abrasion resistance.

Yes, POM is commonly used in medical devices due to its high strength, durability, and biocompatibility, suitable for surgical instruments, connectors, and housings.

Yes, POM's naturally low coefficient of friction makes it suitable for dry-running applications.

POM (polyoxymethylene) has a naturally low coefficient of friction (approximately 0.2), allowing parts to slide smoothly without lubrication. Combined with its high wear resistance and dimensional stability, it is an ideal material for precision gears, bearings, and sliding mechanisms.

Yes, POM has extremely low water absorption (below 0.2% after 24 hours), meaning it is not prone to swelling or deformation. Therefore, it is ideal for water treatment components such as faucets, water pumps, and dishwasher assemblies.

Due to the low surface energy of polyoxymethylene (POM), it is difficult to bond with adhesives. When joining, techniques such as ultrasonic welding or mechanical fastening are typically used.

Ready to Transform Your Manufacturing?

Get a free quote for your custom Acetal injection molding project. Our team of experts is ready to help you achieve high-quality parts with fast turnaround and superior performance.