PP (Polypropylene) Plastic Injection Molding Service

Elimold offers high-quality polypropylene (PP) injection molding services. With our expert engineering, advanced manufacturing capabilities, and unwavering commitment to quality, we ensure your polypropylene parts perform as expected, while optimizing costs and increasing production efficiency. If polypropylene is the right material for your application, simply send us your drawings or samples to receive a quote.

Looking for a Trusted PP Custom Molding Partner?

Elimold offers tailored solutions for your PP plastic parts projects, meeting your design, functionality, and budget requirements. With over a decade of experience in PP plastic molding, we help you fully leverage the advantages of PP material, making us ideal for complex geometries, thin-walled parts, and high-volume custom parts production. Our in-house facility boasts a full suite of capabilities, from mold design and material selection to final part inspection, ensuring smooth production processes and reliable results.

To date, Elimold has served over 300 clients worldwide, delivering over 10,000 batches of PP injection molded parts. Based on experience accumulated across numerous projects, we have developed best practices for PP parts manufacturing, encompassing materials science, process optimization, and precision injection molding technology.

What is Polypropylene (PP)?

Polypropylene (PP) has the chemical formula (C3H6)n and is a thermoplastic resin polymerized from propylene. It is a white, waxy substance, transparent and lightweight, with a density of 0.89~0.91 g/cm³. It is flammable, with a melting point of 189℃, a softening temperature of 155℃, and a service temperature range of -30~140℃. It can withstand corrosion from acids, alkalis, salt solutions, and many organic solvents below 80℃, but it will decompose under high temperatures and oxidizing conditions. In addition, polypropylene (PP) has advantages such as chemical resistance, heat resistance, electrical insulation, high strength, high abrasion resistance, and good processing performance. PP is often modified by adding glass fibers, mineral fillers, or thermoplastic rubber.

Advantages of PP Injection Molding

Compared to ABS and PA materials, PP offers a unique combination of performance and cost, making it particularly suitable for parts requiring repeated bending, exposure to chemical media, or strict cost control.

Low Cost

Raw material costs are only one-third that of engineering plastics. A density of 0.9 g/cm³ reduces the weight cost of parts.

Efficient Production

Low material costs and fast production cycles reduce overall production costs.

Design Flexibility

Excellent flow properties enable complex geometries and thin-walled designs.

Chemical Resistance

Resistant to a variety of acids, alkalis, and solvents.

Lightweight

Low density (0.895-0.92 g/cm³) results in lightweight yet durable parts.

Recyclable

100% recyclable material supports sustainable production.

Active Hinge Capability

Unique ability to manufacture one-piece hinges capable of millions of bends.

Moisture Resistance

24-hour water absorption <0.01%. Dimensional stability in humid environments far surpasses that of nylon.

High electrical insulation

Volume resistivity >10¹⁶ Ω·cm. Dielectric strength 50kV/mm.

Low friction

Its coefficient of friction is 0.1-0.3, which reduces demolding resistance and wear.

Complete Production Support Team

We have a dedicated manufacturing team working behind the scenes to meet your production order needs. We manage the entire process and keep you updated on the latest progress.

Engineering & DFM

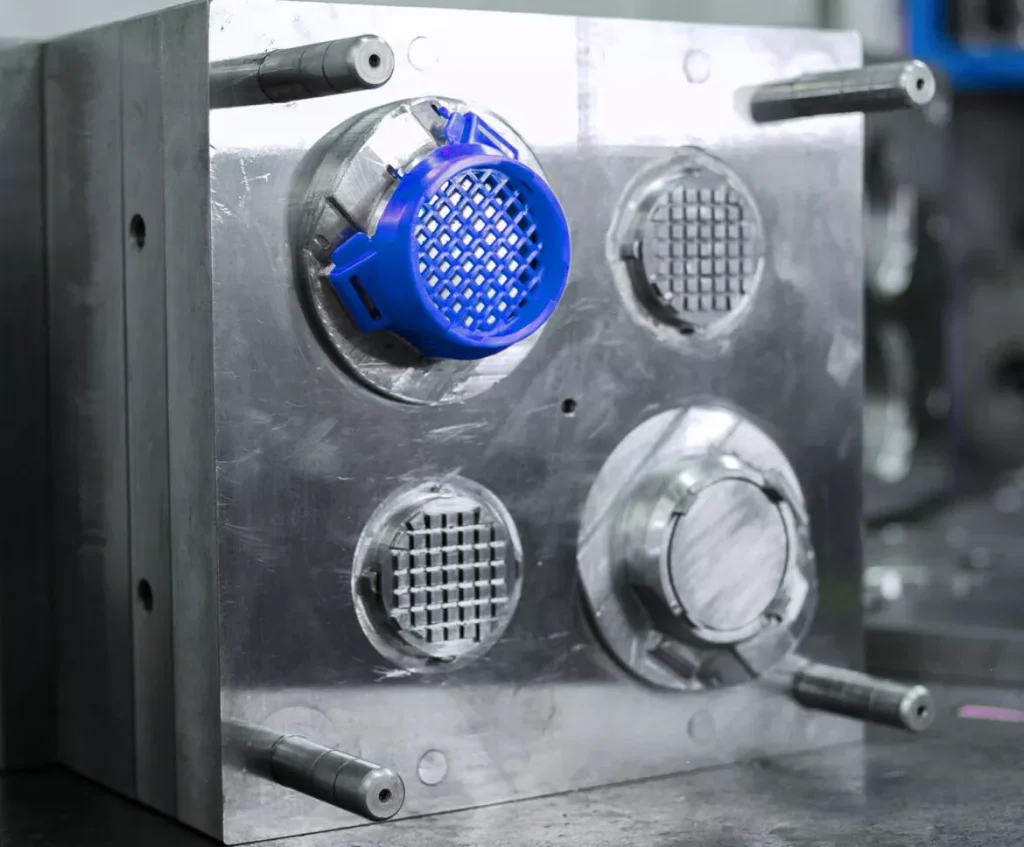

Mold Making

Injection Molding

Surface Treatments

Quality and Compliance

Assembly and Shipping

We Can Provide PP Material Grades and Types

PP Homopolymer (General Purpose PP)

PP homopolymer is a versatile and affordable thermoplastic. Its basic properties include a density of 0.91 g/cm³, tensile strength of 35 MPa, and heat deflection temperature of 100°C. It exhibits good chemical resistance and relatively high rigidity.

PP Copolymer (Impact-Modified PP)

PP copolymers are known for their impact resistance and versatility. They possess flexibility and durability, with a density of 0.91 g/cm³ and a tensile strength of 35 MPa. PP copolymers have the ability to maintain their shape while withstanding mechanical stress.

PP Random Copolymer (Transparent PP)

PP random copolymers are favored for their transparency and versatility. They typically have a density of 0.91 g/cm³, a tensile strength of 40 MPa, and a heat deflection temperature of 100°C. Their unique properties, including transparency and good impact resistance, make them ideal for applications requiring transparent materials.

Glass Fiber Reinforced Polypropylene (High-Strength Polypropylene)

Glass fiber reinforced polypropylene (PP) is reinforced with glass fibers to improve its strength and stiffness. It has a high density, ranging from 1.02 to 1.35 g/cm³, and a tensile strength of 100 MPa or higher. This material grade performs excellently in applications requiring high mechanical properties, offering good dimensional stability and abrasion resistance, making it suitable for parts subjected to high stress and high load requirements.

PP Homopolymer with UV Stabilizer (Outdoor PP)

This polypropylene homopolymer with added UV stabilizer is specifically designed for outdoor environments. It has similar properties to general-purpose polypropylene, such as a density of 0.91 g/cm³ and a tensile strength of 35 MPa, but the addition of a UV stabilizer resists UV degradation. It can withstand prolonged exposure to sunlight and environmental factors, ensuring long-lasting durability in outdoor environments.

Start your PP injection molding project with Elimold

The Elimold team provides expertise and advanced technology to help you streamline your production process and ensure the highest quality injection molded parts. Elimold is your platform for sourcing industrial components, offering in-house manufacturing capabilities, a complete supply chain, and comprehensive manufacturing technology.

Furthermore, with our in-house AI-powered quoting tools, order management, and delivery services, we can help you through every step from initial prototyping to mass production. Get a quote now and experience the benefits of advanced on-demand manufacturing for your injection molding project.

Customized Polypropylene Molding Solutions

Are you looking for opportunities to improve existing products or develop new ones? We offer a variety of services to help you achieve your goals. Elimold has its own in-house injection molding testing center, allowing us to delve into the processes that influence and control the quality of plastic products. This has given Elimold a wealth of expertise. With years of experience and advanced injection molding equipment, we are able to precisely produce your PP (Polypropylene) injection molded products. This enables us to manage the entire injection molding process for you.

Custom PP (Polypropylene) Plastic Molding Services

Elimold offers a full range of PP (Polypropylene) injection molding services designed to exceed and meet your specific project needs.

Professional PP Plastic Molding Companies and Factories

Our in-house facility in Shenzhen, China, houses over 150 different injection molding machines, ranging from 45-ton computer-controlled injection molding machines to 2,200-ton electric injection molding machines with closed-loop systems. We can produce almost any custom plastic part you can think of.

In addition, we also have a clean room injection molding workshop and a clean inspection room, which are fully equipped to conduct various inspections during the production process and final inspection of the products. Inspection equipment includes optical comparators, electronic altimeters, digital scales and pin gauges, all operated by professional quality assurance personnel.

Reverse Engineering and Mold Manufacturing Services

Elimold knows its way around plastics. We have been producing the highest quality injection molded OEM Polypropylene plastic parts for years, and our plastics experts know the machines inside and out and are happy to work on any machine to ensure your OEM parts meet your specifications exactly.

So whether it’s custom PP mold design or reverse engineering, our excellent service and efficient production ensure timely delivery and quality service. When designing custom PP (Polypropylene) molds, Elimold’s employees will assist customers through the entire life cycle from customer requirements and design, prototyping, mold manufacturing to final production. We also make recommendations on improved designs for OEM parts to facilitate installation. No PP parts samples? no problem! Our team can reverse engineer large PP parts and provide you with suitable alternative designs.

Why Choose Elimold for Your PP (Polypropylene) Injection Molding Project?

Custom polypropylene injection molding is one of our proudest professional services. Elimold can customize polypropylene parts to your unique specifications. Unlike standard off-the-shelf parts, custom polypropylene injection molded assemblies are designed to perfectly fit specific applications. We work closely with you from the initial concept stage, carefully listening to your needs and understanding the function of the part. Whether it’s a unique shape, specific dimensions, or special performance characteristics, our team has the expertise to translate these requirements into feasible injection molding solutions. We use advanced design software to create 3D models of custom parts, allowing clients to preview the final product before production begins. This collaborative approach to custom polypropylene injection molding ensures that the final result fully meets the client’s expectations.

FAQ

Yes, we offer color matching services to meet your branding or aesthetic needs. Custom colors can be incorporated directly into the PP resin during the molding process.

Yes, we offer PP overmolding services, a technology that can combine different materials together, or add multiple layers of materials for enhanced functionality. This technique is often used to add soft-touch grips or other assistive features.

certainly. Using aluminum molds and a quick-change system, we can produce molds for small batches of PP plastic parts starting at 50 pieces at a low price (depending on complexity, as low as $1.20 per piece), which is 40% cheaper than SLS 3D printing.

We usually use HALS stabilizer in PP injection molding materials, keep the mold temperature ≤60°C, and apply anti-UV coating, which has been tested to withstand 2,000+ QUV hours.

Preheat the insert to 110±5°C, maintain PP thickness ≥1.5×insert diameter, and apply 120% of standard packaging pressure.

PP materials will undergo 0.3% post-shrinkage. We compensate for this shrinkage by annealing at 80°C/2 hours and allowing for 0.2% shrinkage in the design.

Typically we dry the resin to 80°C (although PP is not hygroscopic), use melt decompression and increase the mold temperature to 70-80°C to slow the cooling rate.

PP is more resistant to chemical corrosion and fatigue than ABS, but is less rigid. Compared with PE, PP has higher rigidity and heat resistance, but less flexibility.

Polypropylene has a melting point between 220-280°C, making it suitable for moderate temperature applications. Standard polypropylene typically withstands continuous service temperatures up to 100°C. For higher temperature requirements, we offer special polypropylene formulations with added heat stabilizers that extend their applicable temperature range. For extreme high temperature applications we may recommend alternative materials such as nylon or polycarbonate.

Polypropylene injection molded parts are available in a variety of surface finishes, from high-gloss to matte textures. Note that the semi-crystalline nature of PP can sometimes make it difficult to achieve a completely consistent, high-gloss surface compared to amorphous plastics such as ABS or PC. Common options include:

- High gloss finish for aesthetic purposes

- Surface texture design for enhanced grip and scratch resistance

- Matte finish reduces glare

- Customize textures to match existing products

Ready to Discuss Your PP Injection Molding Project?

Contact our team today for expert guidance, design support, and competitive pricing on your next polypropylene project.