PPSU CNC Machining Services

Elimold offers precision CNC machining services for PPSU. Whether you need rapid prototyping or small-batch production of PPSU parts, we can meet your specific requirements. Contact us now for a quote.

Looking for Professional PPSU CNC Machining Services?

Does your project require components that can withstand extreme temperatures, heavy impacts, or rigorous sterilization cycles? PPSU material easily meets these challenges. This high-performance plastic is one of the most durable and versatile materials available. Elimold manufactures PPSU plastics using precise and reliable CNC machining processes, providing reliable components for aerospace, medical, energy, automation, and industrial applications for companies worldwide. When you contact us, our experienced team will process your PPSU machining order quickly and economically, while ensuring quality.

What is Polyphenylsulfone (PPSU)?

Polyphenylsulfone (PPSU) is a high-performance thermoplastic that combines high temperature resistance, high mechanical strength, hydrolysis resistance, and chemical inertness. PPSU was first introduced in 1976 under the trademark Radel® by Union Carbide. The backbone of this polymer consists of aromatic rings linked by sulfone groups (-SO₂-). This structure gives PPSU excellent thermal and chemical stability.

PPSU exhibits superior hydrolysis resistance and durability compared to many other commercially available high-temperature design materials. It has a high flexural temperature and excellent resistance to environmental stress cracking. This polymer is inherently flame-retardant and possesses excellent thermal stability and good electrical properties. Furthermore, its heat distortion temperature reaches up to 196°C, and its transparent amber color makes it easy to color, enhancing design flexibility. The amorphous nature and lack of a melting point of PPSU make it suitable for a variety of manufacturing processes. It can withstand rigorous sterilization and can endure over 1000 steam cycles at 134°C.

Custom CNC Machining Services for PPSU Parts

Our precision CNC machining services offer a comprehensive solution for manufacturing custom PPSU parts. We focus on precision, versatility, and efficient manufacturing to ensure your PPSU components meet the highest quality and functional standards. No matter how complex the design of your project, our expertise and advanced technology guarantee a reliable and tailored solution to meet your unique needs. We produce over 500 different products monthly for orders from global companies, meaning our technology and quality control systems are highly mature, our production capacity is almost always sufficient, and our prices remain competitive.

PPSU CNC Machining Value-Added Solutions

With over 10 years of engineering experience, we are committed to providing the highest quality PPSU machined products and other related services. We can provide machining design or reverse engineering services for your custom PPSU parts. Our superior service and efficient production ensure timely delivery and excellent service. In addition to custom reverse engineering services, we also offer value-added manufacturing solutions such as emergency manufacturing and delivery, engineering, rapid prototyping, and high-volume manufacturing.

Comprehensive Production Support Team

We have a team of experienced manufacturing experts working behind the scenes to fulfill your production orders. We manage the entire process and keep you updated on the latest progress.

Account Manager

Application Engineers

Logistics

Quality Control

PPSU CNC Machining Cost-Effectiveness Strategy

We employ lean manufacturing principles to reduce the overall cost of PPSU CNC machining. Lean manufacturing is ideal for achieving cost-effective plastic CNC machining solutions. It includes optimizing the machining process to improve efficiency, reducing waste, and adopting just-in-time and continuous production processes. Therefore, it significantly improves cost-effectiveness. Furthermore, Elimold’s online platform greatly enhances the accessibility and efficiency of services in the PPSU CNC machining field. Customers can now obtain PPSU CNC machining service quotes online, simplifying the project initiation process.

One-Stop PPSU CNC Machining Solution Provider

When designing custom PPSU machined parts, Elimold’s staff assists customers throughout the entire lifecycle, from customer requirements and design, prototyping, fixture manufacturing to final production. We also offer suggestions for seal design improvements to facilitate installation. Furthermore, even in emergency situations, we can produce, procure, package, and ship parts on time, making Elimold your one-stop PPSU CNC machining solution provider.

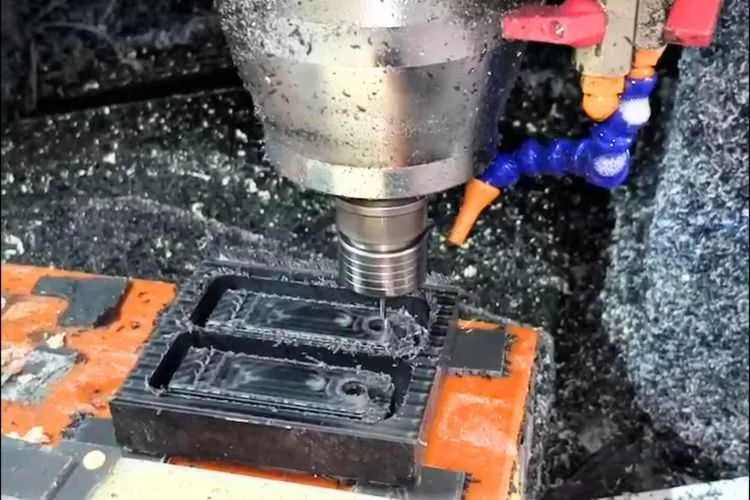

PPSU CNC Machining Workshop

Our 136,000-square-foot in-house CNC workshop in Shenzhen, China, boasts over 100 CNC machine tools, capable of producing PPSU parts ranging from micro to large and from simple to complex geometries. We utilize a wide variety of advanced equipment and processes, including: 5-axis CNC routers, 3-axis, 4-axis, and 5-axis CNC milling machines, CNC lathes, CNC mill-turning machines, CNC Swiss-type lathes, waterjet cutting, state-of-the-art metrology and CAD/CAM software.

From Prototyping to Mass Production and Technical Support

In the early stages of PPSU product development, we work closely with our clients to assist with prototyping, including material selection and design, to maximize the manufacturability and performance of machined parts. Furthermore, we can support production of machined parts from small batches to large batches. When the number of parts reaches a certain scale and a transition from machined to injection molding is necessary, we also have injection molding capabilities.

PPSU CNC Prototyping and Validation

CNC machining of PPSU plastic is both complex and expensive. Therefore, we typically create prototypes by machining semi-finished parts or using alternative materials with similar properties. This approach allows us to quickly validate the feasibility of designs in practical applications. For larger-scale testing, we provide zero-lot samples of 30 to 50 pieces, such as for trade show demonstrations or testing environments. This method saves costs, mitigates risks, and ensures that the PPSU material performs as expected during mass production.

Quality Assurance and On-Time Delivery

Ensuring the highest quality and on-time delivery is at the heart of our PPSU CNC machining services. We follow rigorous processes and meticulously monitor the entire production process. Each part we produce is inspected for dimensions, surface finish, and geometry using a coordinate measuring machine and other calibrated instruments to ensure precise specifications. Furthermore, all batches are traceable, processes are documented, and strict adherence to ISO standards ensures consistent product quality from prototype to production. Additionally, we provide photos and videos of the PPSU parts for customer confirmation before shipment, ensuring complete customer confidence in the final product.

Customer Inventory Planning and Just-In-Time (JIT) Supply

We provide inventory management solutions for customers adopting a Just-In-Time (JIT) supply model, thereby reducing the costs associated with managing and maintaining large inventories of parts. Leveraging our machining and forming capabilities, we can also help customers consolidate supply sources, further reducing costs.

FAQ

We have very strict tolerance control for PPSU components (±0.05 mm or better, depending on the geometry). Please contact us to confirm your specific requirements.

PPSU plastic is more impact-resistant, heat-resistant, and steam-resistant than PSU and PES. Polyphenylsulfone (PPSU) is often used in applications where durability and ease of cleaning are more important than transparency or cost.

We can provide deburring, polishing, threading, assembly, and custom packaging to deliver finished PPSU components for your production line.

PPSU has higher impact strength and better chemical resistance than PSU, making it the preferred material for critical components in harsh environments.

Get An Accurate Quote For Your Next Projects

No matter your project is complicated or simple, no matter is metal or plastic, you will get an accurate quotation within 4 hours.