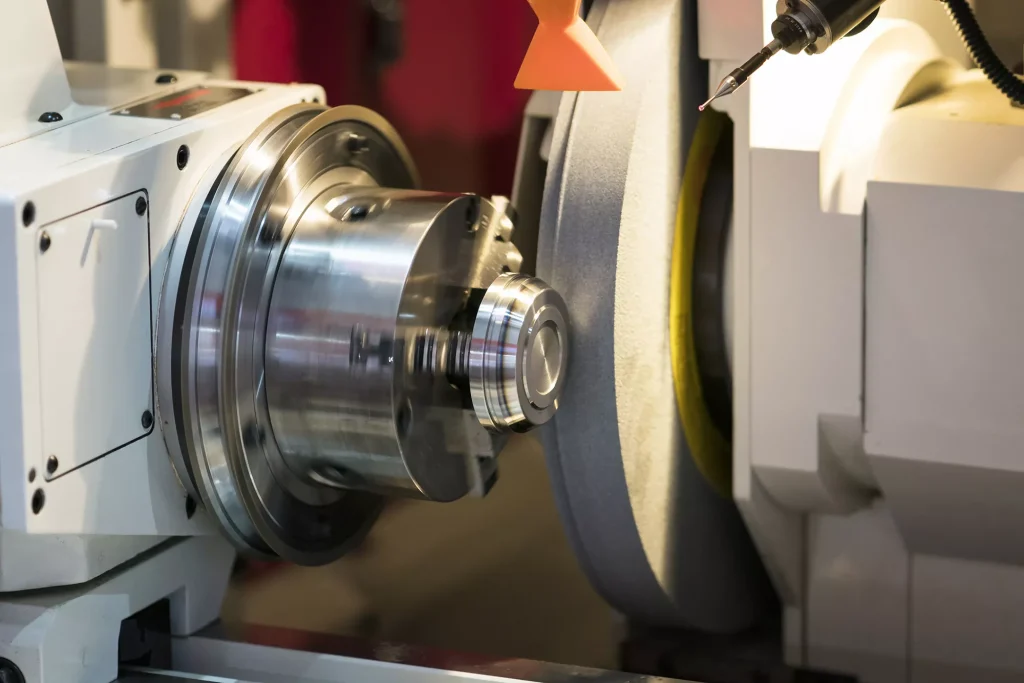

Precision Grinding Services

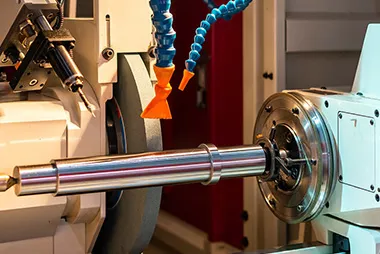

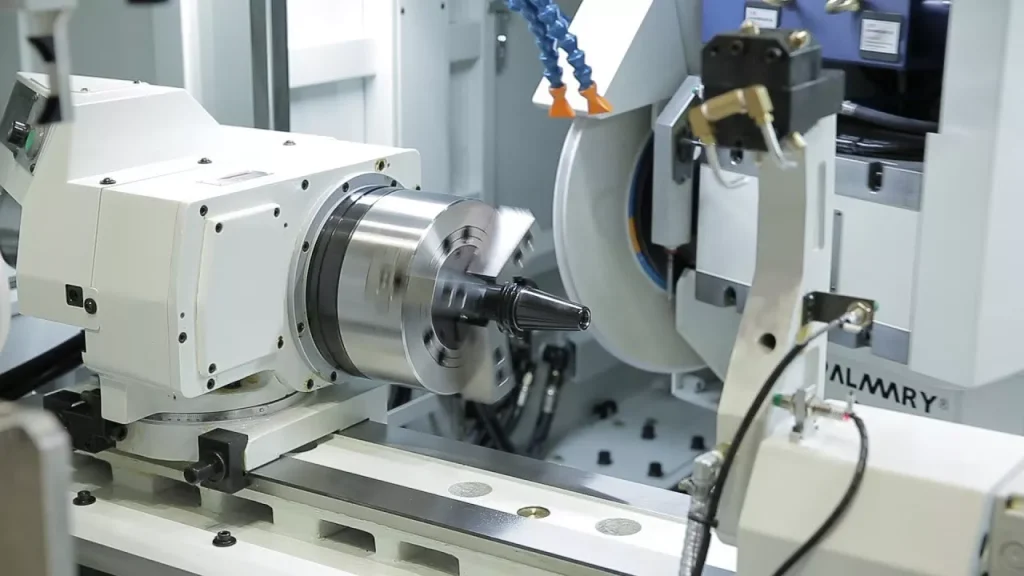

At Elimold, we are experts in a variety of precision grinding processes. We have specialized equipment and skilled machinists that enable us to provide close tolerance surface grinding for all materials. Whether your project requires multi-axis geometry on complex metals or a unique surface finish, we can provide precision grinding services for complex contours, shapes, multiple tapers, narrow grooves, angles and pointed metal parts. Contact us now for a free instant quote.

In-House Precision Grinding Shop

Elimold offers simple, convenient, and high-quality precision grinding services. We are well-known for our exceptional service and flexibility as we continue to expand our service offerings to meet a wide range of engineering and precision manufacturing needs. At Elimold, our in-house, 15,000 square foot ISO-compliant facility is able to meet the demanding needs of all our customers. Our surface grinding services are suitable for small to large batch precision grinding orders; average lead time is 1 to 2 weeks and can be expedited for urgent situations. Other services include FEA, tolerance and hardness verification, quality assurance, design, engineering, warehousing, and logistics.

Our team of precision grinding experts provide flawless grinding services with years of experience in the field of surface grinding. Our team has the experience and knowledge to evaluate the ideal surface grinding operation method and customize each process to the specific needs of each part.

One-stop precision grinding solutions

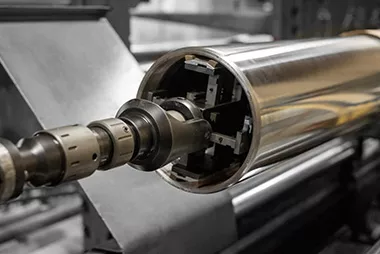

Elimold has a precision grinding department that provides one-stop manufacturing and grinding services. With many years of experience in precision grinding manufacturing, we not only have dozens of centerless grinders, cylindrical grinders, surface grinders, but also have skilled workers to ensure that our machine shop can support CNC turning, CNC milling, precision grinding, and comply with your specifications to produce high-quality parts in a short time. If you choose Elimold to undertake regular metal parts orders, we will provide you with fast delivery and product development, because our technology is all developed by Elimold itself.

Professional Precision Grinding Service Provider

Elimold understands that every project has its own unique challenges and opportunities. Therefore, we provide personalized solutions to meet the specific needs of your project. Whether you are developing a prototype for a breakthrough innovation or sourcing precision components for basic functions, our collaborative team will work closely with you to grasp your goals and provide customized solutions that exceed expectations.

Choosing Elimold’s precision grinding services can significantly save costs and increase productivity. With cutting-edge processing technology and expertise, we manufacture high-quality components with extreme tolerances, reduce the need for secondary operations, and minimize material waste. Whether you need rapid prototyping, on-demand manufacturing, just-in-time production, or any other service, we can meet your needs quickly and efficiently, ensuring fast delivery, reducing production costs, and maximizing return on investment.

Types of Precision Grinding Services

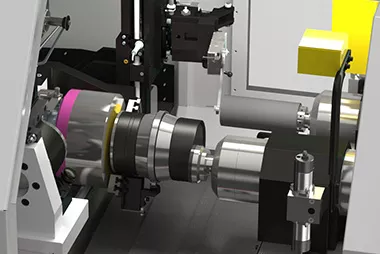

Our precision grinding capabilities meet the needs of a wide range of projects across a wide range of industries. We offer advanced technologies such as centerless grinding, surface grinding, cylindrical grinding, and honing to achieve superior precision and efficiency. Our skilled machinists, advanced equipment, and commitment to quality ensure consistent results for your unique specifications. Whether you need a prototype, small batch production, or large-scale production, Elimold can provide top-quality precision grinding solutions tailored to your needs.

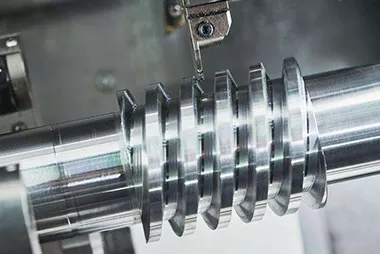

OD Grinding

ID Grinding

Vertical Grinding

Rotary Grinding

Centerless Grinding

ID Honing

Flat Lapping

Superfinishing

Jig Grinding

Tolerance capability

If your part requires a very flat surface, precision grinding is the first option to consider. Special grinding wheels are passed over the workpiece surface under computer control to provide the final surface evenness.

- External diameter tolerances as tight as +/- 0.00005″ (±0.001mm)

- Internal diameter tolerances as tight as +/- 0.00005″ (±0.001mm)

- Roundness to +/- 0.00005″ (±0.001mm)

- Cylindricity to +/- 0.00005″ (±0.001mm)

- Grinding surface finishes 0.6Ra~0.8Ra

- Diameter from 0.1mm to 300mm

Ready to use Elimold's precision grinding service?

Precision grinding produces parts and products that meet exact design specifications and tight tolerances. Elimold offers a wide range of industrial precision grinding services to ensure your company’s products are designed to fit perfectly. Our expert grinders and technicians deliver high-quality ground parts that meet or exceed your standards on time and at competitive prices. For help with your next custom grinding project, request a quote today.

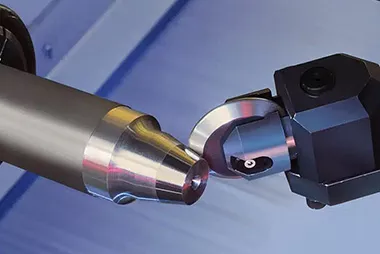

20°C Dust-Free Grinding Shop

All precision grinding services are performed in our climate-controlled facility, which is maintained at 68°F (approximately 19°C) year-round, ensuring the highest standards of accuracy and uniform processing results for large or small batches. When parts are ground to tolerances as high as ±0.001mm (+/-0.00005 inches), even slight changes in the environment can affect the grinding process. To ensure consistency and precise measurement of all ground parts, the shop temperature must be maintained at 20 degrees Celsius, with constant humidity and temperature. Elimold’s precision grinding services are performed in clean rooms equipped with temperature-controlled facilities. After grinding, our machinists will measure and inspect the parts using advanced coordinate measuring machines (CMM) to ensure that the parts meet your precise specifications. Our advanced quality assurance procedures are strictly enforced on all jobs, ensuring that our precision grinding services can provide reliable, repeatable results that always meet customer specifications.

24/7 Operation

Our precision grinding shop can operate 24 hours a day, 365 days a year, requiring only scheduled maintenance. One employee can monitor multiple machines simultaneously, reducing labor costs and increasing production efficiency. We pass this efficiency on to our customers at an affordable cost and fast turnaround time. Because our CNC grinders operate continuously and automatically, they can achieve high efficiency and high output to meet any production volume needs.

Material Options

At Elimold, our experts can evaluate your needs and provide custom precision parts, from prototypes to small batches to large-volume production. We can process a wide variety of metals, composites, and specialty materials. Here is a list of materials used in our precision cylindrical grinding services:

- Aluminum

- Brass

- Beryllium

- Bronze

- Carbide

- Cast Iron

- Cobalt

- Copper

- Gold

- Incomel

- Lead

- Magnesium

- Molybdenum

- Nickel

- Platinum

- Silver

- Steel

- Stainless Steel

- Tin

- Tantalum

- Titanium

- Tungsten

- Zinc

- Zirconium

- Ceramics

- Plastics

- Rubber

- Composites

Quality Management and Certification Standards

With decades of experience and ISO certification, Elimold is uniquely positioned to deliver high-quality parts to your operation. Our precision grinding process begins with a meticulous setup, ensuring each workpiece is accurately centered and ready for machining. Throughout the grinding process, we take meticulous measurements to ensure all specifications are met. Once grinding is complete, we perform a comprehensive final inspection, including a detailed report of surface finish, total cut, and other critical measurements. Our skilled staff is dedicated to meeting demanding specifications and maintaining your high standards. We can meet military specifications, medical and automotive standards upon request. Leverage our extensive manufacturing capabilities to reduce lead times for highly complex, high-specification custom precision parts.

Testing Equipment

- Optical Profilometer

- Standard Metrology Instruments

- Micrometers

- Slide Calipers

- Height Gages

- Depth Gages Indicators

- Bore Gages

- Squares / Angles

- Gage Blocks

- Granite Surface Plates

- Rotary Tables

Alternatives to Precision Grinding

For some parts, precision grinding may not be the ideal choice. Elimold offers several alternatives to precision grinding. These are listed and described below:

Reaming

Grooving

Burnishing / Polising

Journal/Infeed Grinding

Through-feed/Bar Grinding

Lapping

Value-Added Services

Elimold has in-house capability to provide additional services to OEM that require specialized treatments and coatings for their components. Additionally, Elimold has partnered with industry-leading companies to provide further value to manufacture the wide array of products.

- Laser Marking

- Laser or Plasma Welding

- Cleanroom Assembly

- Ink Pad Printing

- Passivation

- Electropolish

- PTFE Coating

- Wire EDM Cutting

Industries we serve

Elimold uses specialized surface grinding equipment to create two-dimensional and three-dimensional metal parts for the world’s most demanding industries. Our precision grinding capabilities serve the following industries:

- Aerospace

- Automotive

- Defence

- Hydraulic

- Machine Tool

- Medical

- Motor Sport

- Wind Turbines

- Hydropower

- Marine

- Food Processing

- Heavy Industries

- Nuclear

- Optics

- Petrochemical

- Power Generation

- Plastic Moulding

- Telecommunication

- Motorbikes

- Pulp & Paper

- Packaging

- Non-woven

- Wood Products

- Rock Crushing

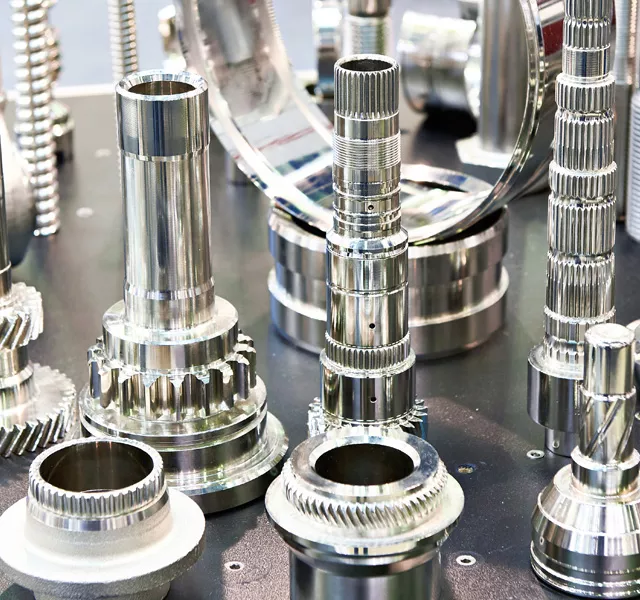

Quality products for a wide range of industries

Elimold has decades of experience, a state-of-the-art manufacturing environment, advanced job tracking and integrated quality assurance, all of which ensure your parts are built to the drawing and delivered on time every time, providing top quality products for critical applications around the world.

- Turbine blades

- Landing gear components

- Jet engine shafts

- Actuator components

- Camshafts

- Crankshafts

- Transmission gears

- Valve seats

- Surgical instruments

- Orthopedic implants

- Dental tools

- Bone screws

- Cutting tools

- Injection molds

- Punches and dies

- Precision jigs and fixtures

- Silicon wafers

- Photomask components

- Microelectronic substrates

- Gun barrels

- Missile components

- Optical mounts

- Armor components

- Drill bits

- Valve components

- Sealing surfaces

- Pump shafts

- Wind turbine shafts

- Gearbox components

- Solar wafer substrates

Our Other Manufacturing Capabilities

We also offer other machining services, and if you have multiple projects, we can provide you with a solution to meet all your needs.

CNC Machining Services

Laser Cutting Services

Precision Wire EDM

Request Your Free Precision Grinding Quote Today

After receiving your drawings, our engineers will analyze your custom Precision Grinding parts right away. We actively work with you to clarify all details before providing a quote that is both economical and accurate.