Precision Machining Services

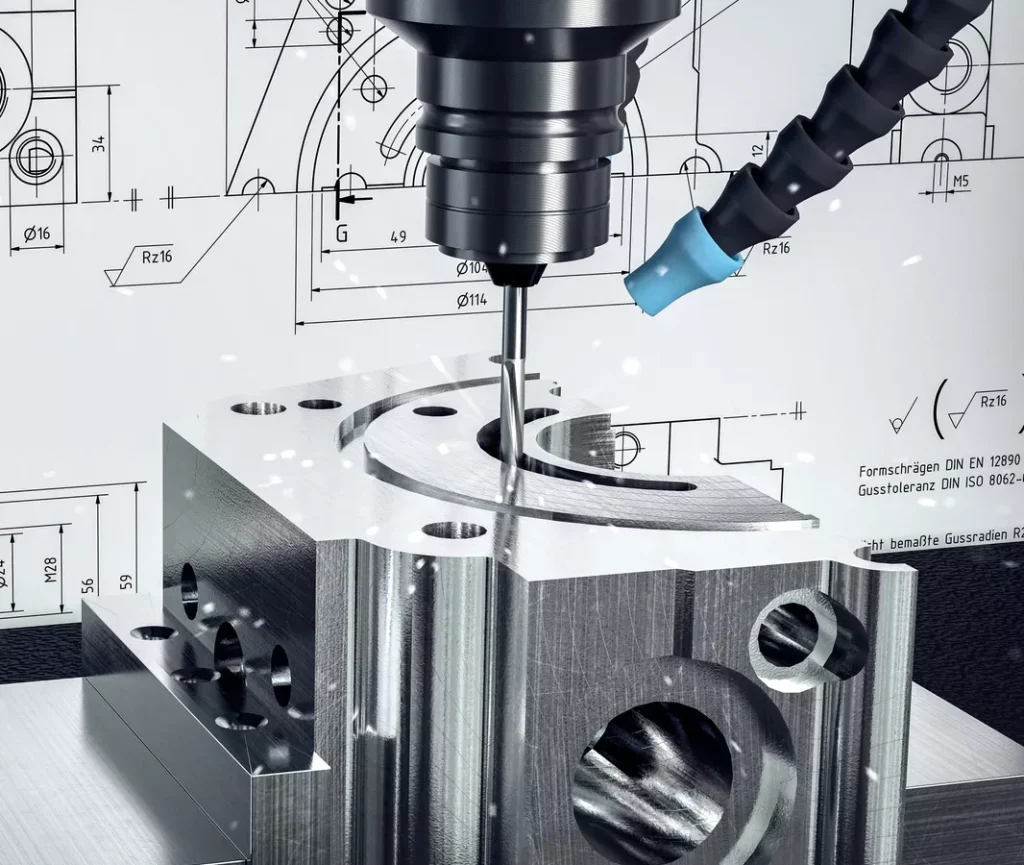

Elimold is a trusted precision machining manufacturer that specializes in ultra-precision custom parts machining and manufacturing with tolerances up to ±0.001 mm to meet the most demanding application requirements. With years of manufacturing experience and an integrated production system, we can provide non-standard custom precision machined parts according to your specific needs. Contact us now for a free instant quote.

Precision Machining Service Provider

Elimold is one of the leading precision machining service providers in the world. We always strive for excellence when it comes to precision machining services. We use the most advanced technology and equipment, and are staffed with well-trained professional technicians to ensure that we consistently provide customers with quality products. Over the years, we have worked with many customers to meet their precision machining needs. And we understand the importance of providing high-quality services and take our commitment to excellence seriously.

Elimold is AS9001AD and ISO 9001:2015 certified. In addition, our streamlined and self-sufficient process is able to execute projects from concept to final production. In addition, we pay great attention to details, which helps us maintain a competitive advantage in the market. We always maintain high standards of quality control. Our skilled and dedicated technical team ensures strict adherence to quality procedures. In addition, our excellent administrative management capabilities ensure that key quality control processes are effectively implemented within the factory.

Professional Precision Machining Manufacturer

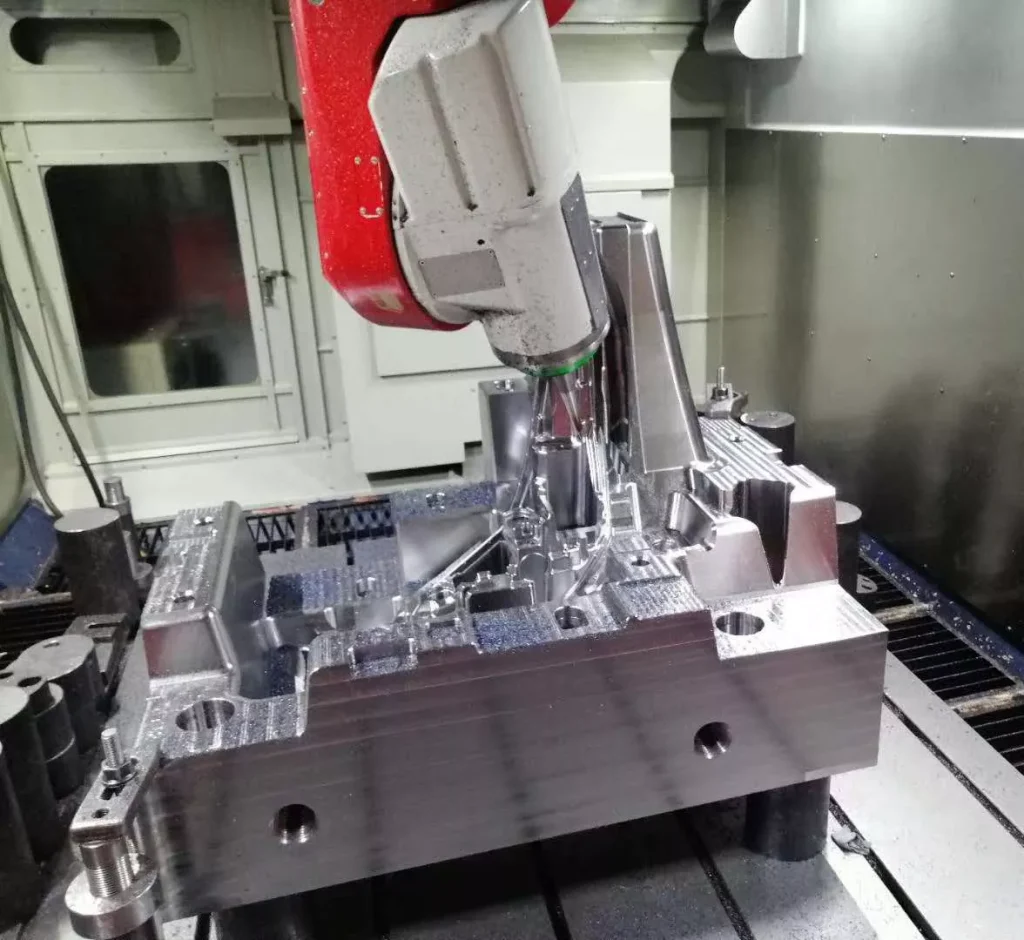

We have been committed to providing precision machining and assembly services for medium and large parts in a wide range of industries, and employ the best and brightest talents in the industry. The Elimold technical team consists of market-leading machinists and technicians, a comprehensive engineering team, and responsive manufacturing consultants, committed to helping you achieve business success. We enhance core competencies through material procurement and inventory programs to provide turnkey solutions. We have a large facility of more than 200,000 square feet to provide top-level precision machining processes. Moreover, Elimold’s in-house factory has a wide variety of machining equipment designed to achieve high speed and high precision. With strong processes, we are able to provide production orders, short-lead parts and prototypes in the same environment. With more than 150 different machining centers, we are able to provide support throughout the life cycle. Whether it is prototyping, new product introduction (NPI), spot procurement, contract agreements or traditional services.

In-House Precision Machining Facility Capabilities

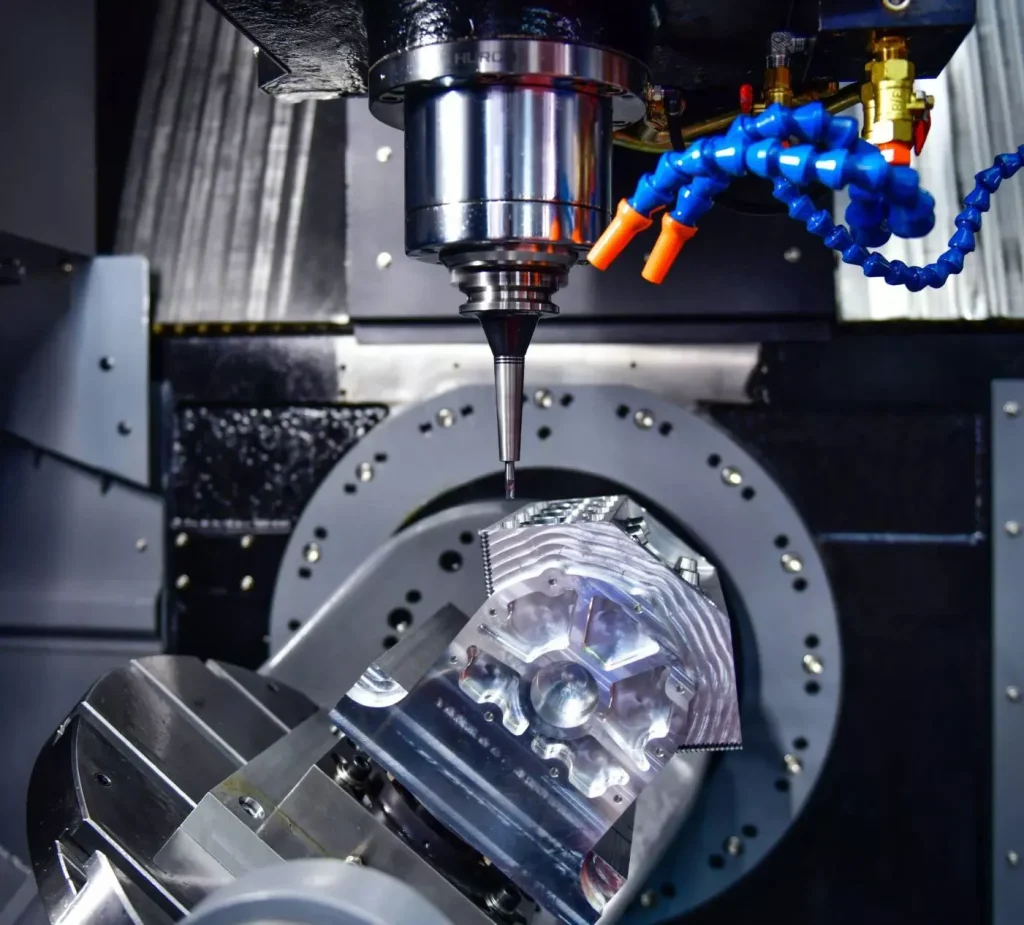

Elimold offers precision machining services with a world-class machine shop and experienced operations team to ensure the production of finished parts with superior quality and precision. Our in-house facilities are capable of handling all precision machining services. If you are looking to outsource projects to increase your production capacity, Elimold is the ideal choice. With 37 state-of-the-art CNC machining centers dedicated to large part machining, over 200,000 pounds of machining capacity, and a team of over 155 employees ready to serve you, there is nothing we can’t do. In recent years, we have continued to expand our shop and invest in the latest equipment to not only ensure that our customers receive the highest quality precision machined products, but also enhance our ability to meet customer needs, shorten lead times, increase project control, and reduce associated logistics challenges.

Ready to start your next precision machining project?

Are you ready to achieve unparalleled precision in your manufacturing projects? Contact Elimold today to learn more about our precision machining services and how we can help you achieve your goals.

Ultra-Precision Machining Tolerance Capabilities

Elimold ultra-precision machining services achieve extremely tight tolerances, often down to the sub-micron or nanometer range. The tolerances that can be achieved depend on factors such as machining technology, materials, part complexity, and equipment. Typically, ultra-precision machining achieves tolerances ranging from a few microns (μm) to sub-micron (0.001 mm). Achieving such high precision requires attention to detail, specialized equipment, skilled operators, and process control.

The capabilities of Elimold’s in-house facility provide the best performance and security for custom parts that require tight tolerances. Therefore, you can work with Elimold’s experienced team of professionals to determine the appropriate tolerances and feasibility. You can also work with our team of machinists, engineers, and designers to evaluate requirements and recommend appropriate techniques and equipment. Elimold’s ultra-precision machining services provide unparalleled accuracy to meet the most demanding specifications for your project’s critical applications.

Our Precision Machining Services

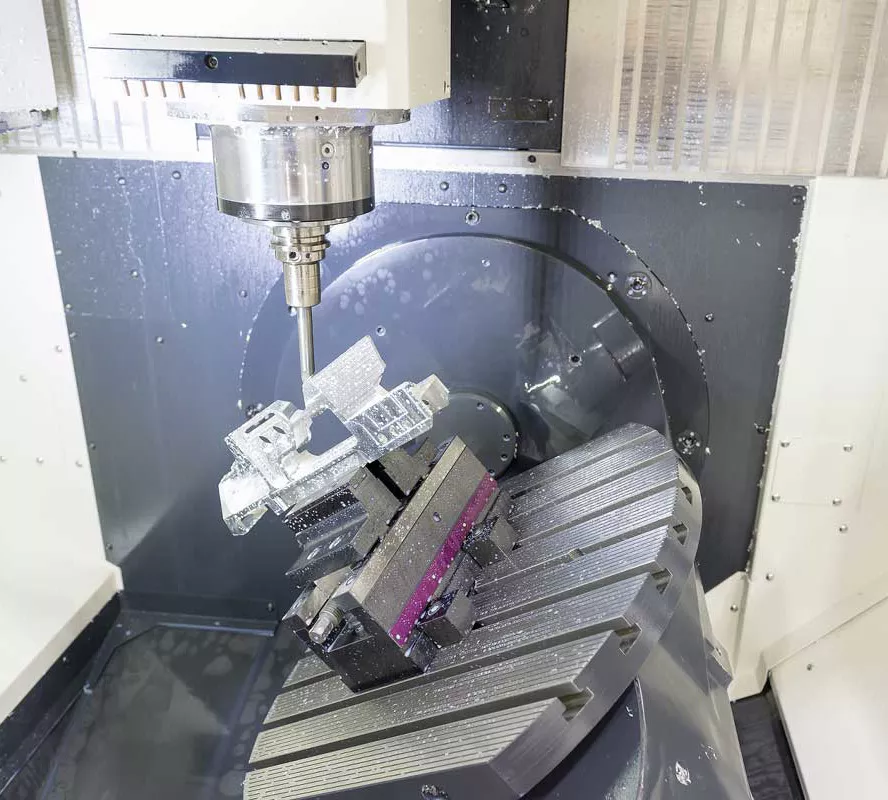

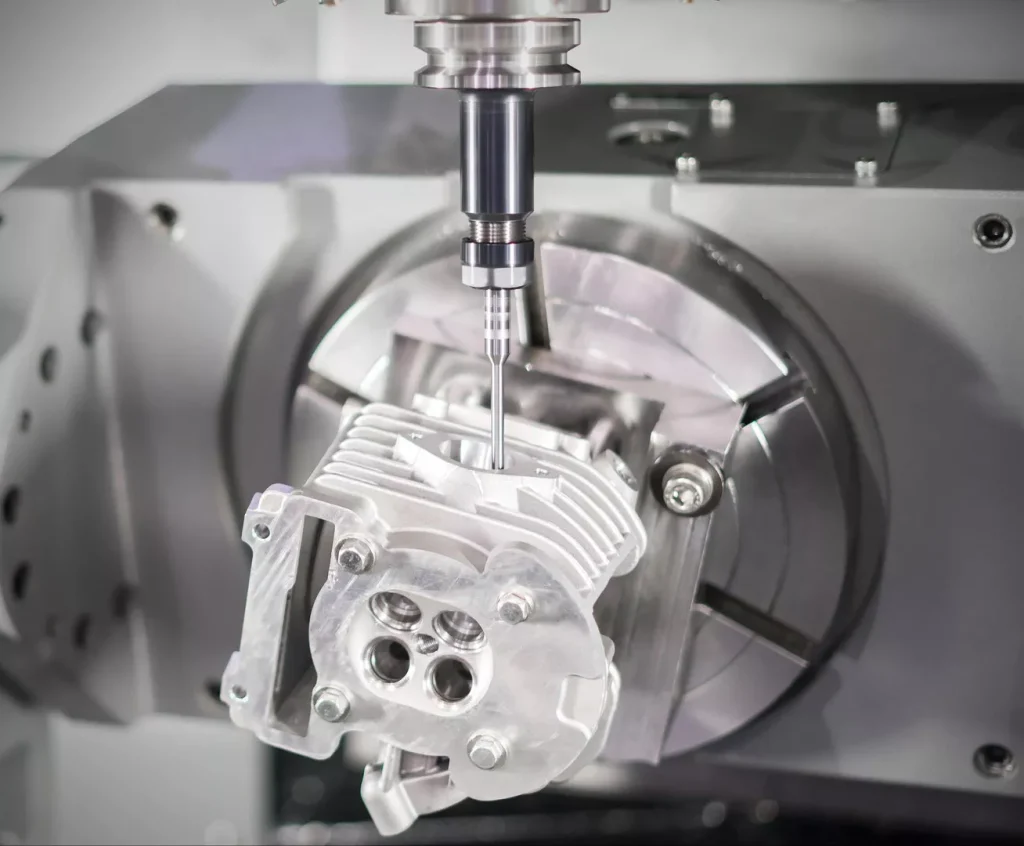

Elimold has state-of-the-art equipment and a wide range of CNC machining services to provide fast and precise machining from prototype to final product. Our equipment and machinists can produce custom parts to your specifications. Our services cover a wide range of industries. Learn more about our machining capabilities below.

CNC Milling

CNC Turning

3 Axis CNC Machining

4 Axis CNC Machining

5 Axis CNC Machining

CNC Prototypes

Wire EDM Machining

CNC Threading and Tapping

CNC High-Speed Drilling

Swiss Machining Service

CNC Routing Service

CNC Grinding Service

24/7 Machining Services

We are your first choice for 24/7 precision machining services! We understand the importance of being available to our customers at all times, so we are proud to provide 24/7 support to meet your machining needs. We offer a comprehensive range of services, all delivered with the highest precision and efficiency. Our cutting-edge technology and highly skilled professionals enable us to handle even the most challenging projects with ease.

There are several key advantages to our precision machining services that set us apart. We are committed to providing high-quality components that meet your exact needs, ensuring tight tolerances and excellent surface finishes. With advanced CNC technology, we are able to efficiently handle complex designs, ensuring a smooth and precise process. In addition, our experienced team will work closely with you to provide tailor-made solutions to ensure your satisfaction every step of the way. Trust us to deliver excellent results and help you succeed.

Engineering, Design & Analysis Services

Our team of manufacturing experts will evaluate your design and work closely with you to determine the best tooling and materials to meet your requirements. Our engineers use a CAD platform that supports solid modeling to advance projects from concept to completion and develop solutions to meet your design needs. We can also perform 3D scanning, reverse engineering and prototyping, feasibility studies for conceptual designs, and structural analysis.

- Research and Development

- Material and Metallurgy Consultation

- Feasibility Analysis

- Engineering Consultation

- Prototyping

- Application Consultation

From Prototype to Production

At Elimold, we work with you from the beginning, from prototyping to mass production, to ensure you get the parts you need. Our team of experienced programmers and machinists will assist you with everything you need and provide you with the best possible service. Elimold excels at turning prototypes into high-quality, mass-produced components and assemblies, optimizing efficiency and precision at every stage.

With rapid prototyping services, our engineers are able to iterate multiple times between digital design and physical prototypes in a fast and cost-effective workflow, resulting in a better end product. Plus, our prototype processing cell is unique, offering world-class processes and industry-leading turnaround times. We can provide production orders, short-lead parts, and prototyping in the same environment.

Through communication and teamwork, we are an extension of your engineering team, with a deep understanding of product lifecycle needs and customer requirements. Our engineers and technicians proactively address challenges and find solutions to tough problems to ensure you deliver the results you need on time.

A one-stop precision machining and manufacturing service provider for all your needs.

Elimold can help you design, source and manufacture high-precision parts to your specifications for your manufacturing needs. Elimold is committed to machining high-quality products, and our quality control guarantee is your guarantee. To learn about the tolerances, raw materials and precision machining processes that best suit your needs, contact one of our machining experts today.

Quality Management and Inspection Processes

Our precision machining services are complemented by a quality control system that ensures that no product leaves our factory without meeting customer expectations. Our quality and engineering teams follow an ISO-compliant quality system when inspecting parts after finishing or assembly. We offer climate-controlled Swiss coordinate measuring machine (CMM) inspections as well as optical measurement capabilities utilizing Smart Scope technology. Our measurement equipment is traceable to NIST. In addition, we use Gagetrack software to track and maintain regular calibration of our inspection equipment. We pride ourselves on consistency and accuracy. We develop and deploy inspection plans for all our production processes. Together, these quality processes ensure that all of our machined parts meet our world-class standards. Rest assured that we can produce your products with precision. At Elimold, we are happy to provide machining services that exceed our customers’ expectations.

Testing & Inspection Equipment

Our 1,000 square foot, temperature-controlled laboratory is fully equipped to handle all of your inspection needs.

- Air Gaging

- Carbide Ring Gages

- CMM Equipment

- Deltronic Pins

- Digital Height Gages

- Digital MicroscopeDigital Micrometers & Calipers

- Hardness Testers

- Master Gauge Blocks

- Optical Comparators

- Virtek (Laser Scanner)

Material Options

Elimold uses a wide variety of raw materials to meet standard machining tolerances and quality control specifications across a variety of industries. Using high-quality materials is critical in precision manufacturing. Our premium materials, along with advanced manufacturing processes, work together to ensure durability and reliability of the final part or product.

Metals

- Aluminum (e.g., 6061, 7075)

- Brass

- Copper

- Stainless Steel (e.g., 303, 304, 316)

- Carbon Steel

- Tool Steel (e.g., A2, D2, O1)

- Titanium (e.g., Grade 2, Grade 5)

Plastics

- ABS

- Nylon (PA)

- Delrin (POM)

- PTFE (Teflon)

- Polycarbonate (PC)

- PEEK

- PVC

- UHMW

- Acrylic (PMMA)

- Polypropylene (PP)

Special Alloys

- Inconel (e.g., 625, 718)

- Hastelloy

- Monel

- Waspaloy

- Kovar

- Nitronic

- Alloy 20

Other Materials

- Ceramics

- Graphite

- Fiberglass

- G10/FR4

- Carbon Fiber Composites

- Foam (e.g., Urethane foam)

- Bakelite

- Mica

Surface Treatment Options

We offer a wide range of finishing capabilities and secondary operations to transform custom machined components and sub-assemblies to the desired finished state upon request.

- As-Machined Finish

- Sandblasting

- Anodizing (Type II & III)

- Powder Coating

- Electroplating

- Polishing

- Brushing

- Passivation

- Black Oxide

- Tumbling / Vibratory Finishing

- Laser Engraving

- Painting

- Electropolishing

- Roller Burnishing

- Superfinishing

- Pickling

- Burnishing

- Shot Peening

- Thread Rolling

- Chromate Conversion Coating

Value-added Services

Elimold also offers a wide variety of support services, both in house and through our trusted suppliers that have been vetted through years of service.

- Assembly

- Painting

- Precision Plating

- Soldering

- Tumbling

- Deburring

- Media Blasting

- Hardness Testing

- NDT

- Heat Treating

Industries We Serve

Modern manufacturing relies heavily on the wide range of applications and accuracy of precision machining. Elimold is proud to offer a range of custom precision machining services to a wide range of industries. Our extensive experience enables us to undertake projects that require the highest levels of accuracy and quality. The following industries can benefit from our services:

- Aerospace

- Automotive

- Computers

- Construction

- Defense

- Electronics

- Energy

- Entertainment

- Environmental

- Furniture

- Hospitality

- Jewelry

- Lighting

- Marine

- Medical

- Military

- Mining

- Retail

- Security

- Telecommunications

- Textile

- Transportation

Products and Applications

We use precision machining to create a variety of parts for your products so that they can be produced and assembled to your exact specifications. Elimold’s range of advanced manufacturing technologies can produce components and complete machines with extremely high precision and complexity. Whether you need 10 or 1,000 parts, we can meet any scale of production needs. Below are some of the precision parts we have customized for customers in various industries.

- Spacers

- Enclosures

- Adapters

- Heat sinks

- Seals

- Casings

- Fasteners

- Actuators

- Implants

- Surgical tools

- Shafts

- Housings

- Brackets

- Bushings

- Valves

- Couplings

- Gears

- Pistons

- Sensor mounts

- Drive components

- Manifolds

- Fittings

- Flanges

- Mounts

- Sleeves

- Pins

- Connectors

- Nozzles

- Turbine blades

- Chassis components

Why choose Elimold for precision machining services?

Elimold is committed to building partnerships with our customers to increase productivity and reduce total costs. Our team of professionals provides precision machining services at highly competitive prices to enhance customer profits. Other advantages of working with us include but are not limited to:

- Innovative and cost-effective solutions designed to increase productivity and save time and money.

The best engineers and machinists in the industry.

Streamlined processes designed to provide expertise and reduce lead times.

Full range of machining/milling services provided in-house.

Safe and green business practices designed to support workplace and environmental safety.

Comprehensive Precision Machining Services

Elimold provides precision machining services to customers around the world. We can perform single-piece prototypes or mass production runs of millions of pieces. We build a trusted partnership with you based on superior quality. Our quality programs are customized to your needs and exacting specifications, and inspection documentation including first article inspection reports is provided as required. We have sufficient capacity to meet prototype, small batch or long-term production needs and deliver the highest quality parts to your exacting specifications. We have an in-house team of experts who can manage your project from initial concept ideation, prototyping to final manufacturing.

Most customers who meet our core manufacturing strengths have established long-term relationships with Elimold. We prefer to focus our efforts on those customers who seek precision machining services from a reliable and trustworthy supplier. This allows us to build long-term relationships with our customers, which is beneficial to all parties involved.

Request Your Free Precision Machining Quote Today

After receiving your drawings, our engineers will analyze your custom Precision Machining parts right away. We actively work with you to clarify all details before providing a quote that is both economical and accurate.