Prototyping

Elimold’s Prototyping Services,Our experts can help you optimize your part designs for production.Prototypes as Fast as One Day,Get high-quality prototype parts at unprecedented speeds with Elimold.Request your instant quote today!

One Stop for All Your Prototyping Needs

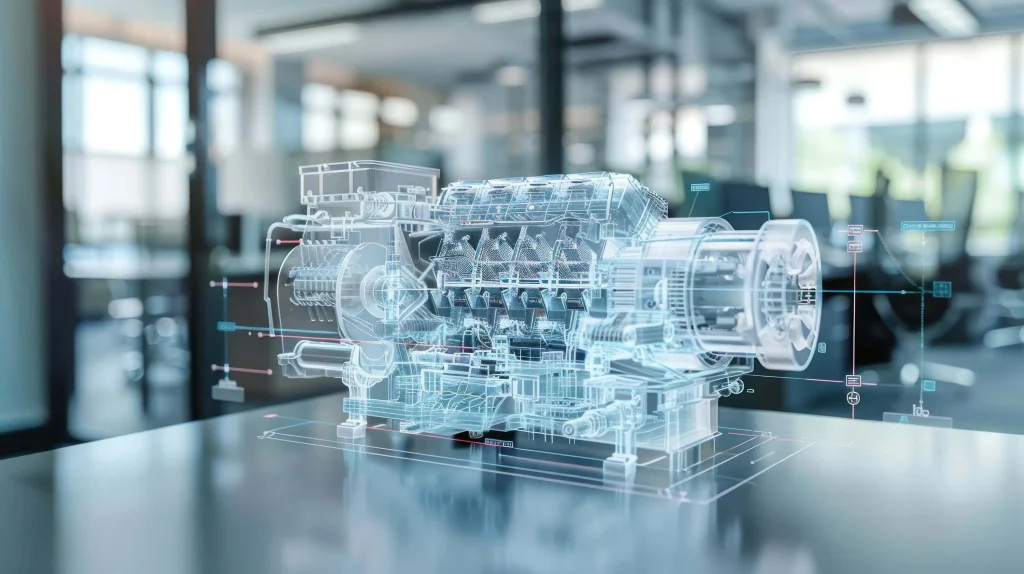

Do you need prototype parts to accelerate new product development? Our experts can help you select the right manufacturing technology, refine and validate your part design, and prepare it for production. Elimold is your one-stop shop for all your prototyping needs. We offer a full suite of custom manufacturing services built on a convenient manufacturing platform, saving you time and accelerating your progress.

Validate Your Design

Most companies are under pressure to accelerate their new product development programs. Prototypes are a critical part of the process. They not only provide product development, marketing and sales teams with a 3D model to validate their design concepts. Prototypes also help them verify fit, finish and performance before moving finalized part designs into production.

CNC as quickly as 1 day

3D Printing as fast as 24 hours

Urethane Casting as fast as 10 days

Injection Molding T1 samples as fast as 10 days

Prototyping Capabilities

Elimold offers a variety of prototyping options to refine and validate your designs.

Polyurethane Casting Prototypes

STEP Technology

Metal Prototyping

Injection Molding Prototypes

Fiberglass Layup Prototyping

High-Quality Parts at Unprecedented Speeds

When you’re on a tight deadline, you can’t afford long lead times or delays caused by quality issues. Elimold provides instant quotes & DFM feedback, rapid lead times, and robust quality management systems to ensure you stay on track.

Built To Spec

- 2D drawings and intricate geometries

- Tight tolerances

- Full range of capabilities and materials

Speed

- Parts as fast as 1 day

- Domestic options

- Instant quote, DFM feedback

- Expedited Shipping Options

Quality

- ISO 9001:2015 QMS

- Visual inspections

- Parts photos at every stage

How it Works

Upload your Designs

Determine your manufacturing requirements

Get Instant Pricing & DFM

Checkout

Start Production

Ready to Start?

Why Use a Prototyping Tool?

Design Feedback

- Receive interactive design for manufacturability feedback with every quote to make early adjustments before prototyping begins.

- Talk with applications engineers to discuss any design challenges and manufacturing questions that arise.

Iterative Development

- Have physical prototypes in hand within days to quickly modify designs during early product development.

- Produce multiple prototypes at the same time to compare and iterate designs simultaneously.

- Reduce overall time to market with an iterative product development cycle.

Design Validation

- Test the form and fit of components with small quantities of molded parts.

- Perform functional test with prototypes manufactured in production-grade materials.

- Full library of online design resources including guidelines, tips, white papers, and videos.

Market Testing

- Produce a pilot run injection-molded parts to validate market interest before launch.

- Reduce financial risk at market launch by implementing affordable aluminum tooling before full-scale production begins.

Need It Faster Than Fast? Try Our Rapid Prototyping Service

Rapid prototyping technology enables engineers to quickly transform their ideas into printed parts with physical and mechanical properties similar to the finished product. Using automated production technologies like 3D printing and CNC machining, these parts can be produced in hours.

This allows them to use these parts to validate designs and test their fit, appearance, and functionality. Furthermore, because prototype parts can be produced so quickly, engineers can test multiple designs simultaneously or quickly iterate to a final version.

From Prototyping to Production

Work with us at every stage of your project, seamlessly navigating the entire process from prototyping to mass production from a single source. Our collaborative approach helps you accelerate time to market, improve cost efficiencies, and achieve the quality and certification levels your project requires.

Rapid Prototypes

Design & Engineering Validation

Commercial Production

Why choose Elimold for your prototyping needs?

Elimold has extensive expertise and technology to help you meet your needs faster. Your partnership with Elimold begins with personalized, one-on-one guidance from an engineer who will work closely with you to understand your needs. Our comprehensive Design, Function, and Function (DFM) process helps you identify and resolve potential design issues early in product development and recommends improvements to enhance part manufacturability.

Our team of engineers will also help you optimize material selection and production processes to achieve the best results at the best price. Our experienced engineers will help you efficiently advance your project from prototyping to mass production. Our focus on prototyping and low- to medium-volume, highly customized parts makes us the perfect choice for any company seeking to accelerate new product development.

Let's Build Something Great, Together

Elimold makes it easy to go from research and development all the way to commercial production. With a wide range of quantity, pricing, geographic, and quality options, Elimold can be your single custom manufacturing partner from start to finish.