PS (Polystyrene) Injection Molding Service

Partnering with Elimold on PS (Polystyrene) injection molding projects allows you to receive custom plastic part prototypes and production parts in as little as five business days. We offer professional engineering support and a special discount for your first mold. A variety of PS materials and surface finishes are available.

Looking for the Ideal PS (Polystyrene) Injection Molding Manufacturing Partner?

Elimold boasts over 10 years of advanced experience in injection molding. We work closely with you at every stage of the product lifecycle, assisting with initial part discussions and production launch. Our early engineering involvement allows us to effectively reduce product design issues and costs during New Product Introduction (NPI), while shortening time to market. With a team of over 20 experienced engineers and over 60 seasoned manufacturing professionals, Elimold can handle complex product designs, specialty materials, and precision mold making, making us the ideal PS (Polystyrene) injection molding manufacturing partner for your next project.

Complete Production Support Team

We have a dedicated manufacturing team working behind the scenes to meet your production order needs. We manage the entire process and keep you updated on the latest progress.

Engineering & DFM

Mold Making

Injection Molding

Surface Treatments

Quality and Compliance

Assembly and Shipping

What is Polystyrene (PS)?

Polystyrene (PS) is a general-purpose thermoplastic with an amorphous structure. It has excellent gamma-ray resistance, making it suitable for radiation sterilization. Transparent polystyrene has a light transmittance exceeding 90%. This material is easily colored and possesses good electrical insulation, processing fluidity, rigidity, chemical resistance, and non-biodegradability. However, unmodified polystyrene is transparent, hard, brittle, and has moderate strength. As a thermoplastic, its melting point is 410-480 degrees Fahrenheit (approximately 210-240 degrees Celsius). After melting, polystyrene can solidify upon cooling and then be reheated without degradation. The disadvantages of ordinary polystyrene include brittleness, low impact strength, susceptibility to stress cracking, poor heat resistance, and inability to withstand boiling water. Its ability to melt rather than burn makes it an ideal material for injection molding. Furthermore, polystyrene is inexpensive and suitable for injection molding.

Polystyrene Plastic Properties

Polystyrene (PS) possesses excellent mechanical, thermal, electrical, and optical properties, making it suitable for a variety of dynamic applications. The mechanical properties of PS are significantly affected by various processing conditions. Standard PS has high hardness, rigidity, and dimensional stability, but relatively poor ductility, exhibiting high tensile strength and low elongation at break. When polystyrene parts or components are used within the glass transition temperature range of 80 to 120°C, their strength and hardness decrease sharply. PS performs best in the temperature range of 70 to -70°C. Polystyrene has good electrical resistance, which is almost unaffected by moisture content. PS has a visible light transmittance of approximately 90%, high ultraviolet light absorption, and a refractive index of 1.59.

Injection Molding Polystyrene Specifications

- Melting Point: 410-480◦F

- Tensile Strength: ~7700 psi

- Injection Molding Temperature: 100-150◦F

- Impact Strength ~0.8 ft-lb/in notched Izod

- Hardness Level: R75

- Flexural Strength: ~12000 psi

- Shrink Rate: 0.3-0.7%

Most Commonly Used PS Injection Molding Material Types

Polystyrene (PS) is a versatile synthetic polymer available in various forms, which can be customized for specific applications. These types differ in properties, processing methods, and uses. Below are some of the PS materials used by Elimold in its injection molding projects.

General Purpose Polystyrene (GPPS)

GPPS is a transparent, hard, brittle, and lightweight material with high transparency, good electrical insulation, and a glossy surface. It is commonly used in food containers, disposable tableware, CD/DVD cases, and transparent electronic product housings.

High Impact Polystyrene (HIPS)

High impact polystyrene (HIPS) is modified with rubbery polybutadiene, reducing its brittleness, enhancing its impact resistance, and providing an opaque appearance and good processability. It is an ideal material for applications requiring high durability, such as refrigerator liners, toys, medical trays, and electronic product housings.

Syndiotactic Polystyrene (SPS)

Compared to GPPS and HIPS, SPS has higher heat resistance and chemical stability. Its crystalline structure makes it widely used in engineering fields such as gears, bearings, and high-temperature or chemically corrosive components.

Expanded Polystyrene (EPS)

EPS (expanded polystyrene) is a lightweight material with excellent thermal insulation and cushioning properties, made from steam and gas-expanded polystyrene particles. It is commonly used in packaging materials, such as foam granules, building insulation materials, and disposable foam cups and saucers.

Extruded Polystyrene (XPS)

XPS has a higher density than EPS, a smoother surface, and better thermal insulation properties. Its closed-cell structure gives it superior moisture resistance. It is commonly used in building insulation boards, underfloor heating boards, and architectural models.

Polystyrene Foam Board (PSFB)

PSFB is a rigid, lightweight foam material with good thermal and sound insulation properties, suitable for wall and roof insulation and various building applications.

Injection Molded Polystyrene (IMPS)

IMPS achieves high precision, high strength, and a smooth surface finish through injection molding, making it ideal for automotive parts, medical devices, and high-precision tools.

Blow Molded Polystyrene (BPS)

BPS is a lightweight foam material processed through blow molding, commonly used in foam cups and lightweight packaging containers.

Cast Polystyrene (CPS)

CPS is a high-strength, high-precision material manufactured through a casting process. It is suitable for applications such as optical components and precision instruments.

Polystyrene Granules (PSP)

PSP consists of small beads or granules and can be used as a raw material for manufacturing other PS products, including insulation materials and various types of packaging materials.

PSMMA

Polystyrene-Co-methyl Methacrylate (PSMMA) is a copolymer with enhanced UV resistance, chemical stability, and optical transparency. It is commonly used in outdoor signage, optical lenses, and other high-transparency applications.

UV-Stable PS

Modified to resist degradation caused by UV exposure, it is recommended for outdoor applications.

What is the injection molding process for polystyrene?

The injection molding process begins by heating polystyrene material into a liquid state, which is then injected into a mold to form the desired shape. After cooling, the product is removed and placed in a hopper, subsequently sent to a post-processing stage for fine finishing. The advantage of using injection molding to produce polystyrene parts is that the mold, once made, can be reused repeatedly, enabling the mass production of high-quality polystyrene products.

Advantages of PS Injection Molding

- High Transparency and High Gloss: Parts produced have a glossy, glass-like surface, making them attractive to customers from the moment they hit the shelves.

- Excellent Rigidity: Provides superior structural integrity and rigidity, preventing parts from bending and failing under load.

- Low-Cost Material: One of the most economical polymer choices available, significantly reducing the cost per part.

- Ease of Processing: Excellent flow properties and fast cycle times improve production efficiency and output.

- Dimensional Stability: Maintains precise shape and dimensions after molding, ensuring consistent fit and assembly results.

Materials Engineering Capabilities and Procurement Services

Our designers, materials engineers, and manufacturing experts will help you determine if polystyrene plastics meet your application needs and specifications. Furthermore, Elimold maintains close partnerships with some of the industry’s most renowned resin suppliers, ensuring that our facilities use only the highest quality, high-performance thermoplastics. Standard polystyrene is available in various grades, such as free-flowing, medium-flowing, and high-temperature resistant resins. In addition, we offer high impact strength grades (PS-HI), which are elastomer-modified for improved impact resistance and pre-breakage deformation.

Ready to Quote Your New Project?

Planning to use polystyrene in your next project? Contact Elimold today! Our team of experts is ready to guide you through material selection and the production process, ensuring your project’s success.

One-Stop PS (Polystyrene) Injection Molding Service

Our one-stop service ensures timely manufacturing, sourcing, packaging, and shipping of PS plastic parts, even in urgent situations. We also offer design or reverse engineering services for your custom PS plastic parts. Our superior service and efficient production guarantee timely delivery and high-quality service; we are ready to take on new projects regardless of size or complexity. With transparent pricing, a long track record of success, and a team dedicated to your success, Elimold is undoubtedly the best choice for businesses that pursue excellence.

Your Leading Polystyrene Injection Molding Manufacturer

We have a strong and efficient team that can provide you with immediate and professional quotations. Our product managers will quickly provide you with a needs analysis based on your design drawings, standards, testing methods, and other requirements. With our deep technical expertise and extensive experience, we can meet your diverse needs and provide one or more solutions, allowing you to choose the most suitable one. Finally, our experienced in-house team manages the entire design process and provides a single contact person to ensure simple and smooth communication. From product design to full lifecycle verification, we ensure that every component meets your requirements and achieves the expected performance, because your success is our top priority.

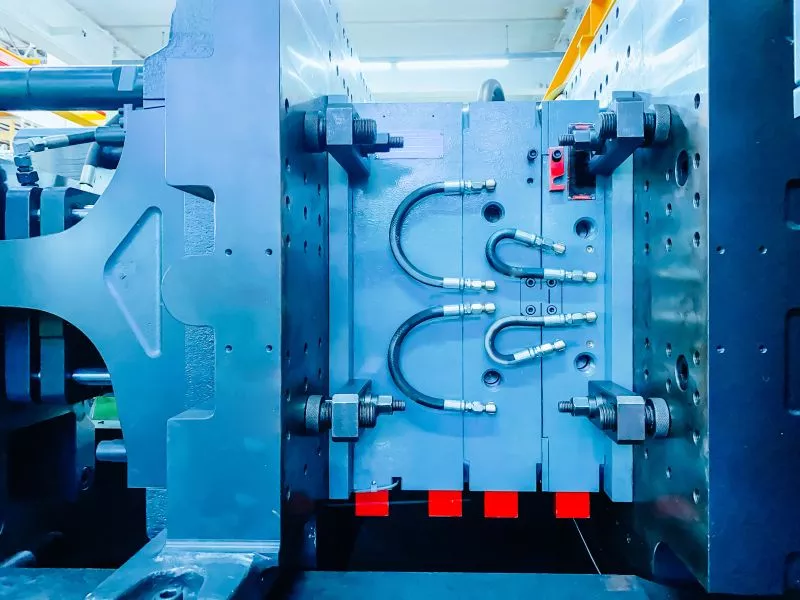

PS (Polystyrene) Injection Molding Factory

Our factory is fully equipped to meet your needs for rapid prototyping, high-volume, and high-speed production. We have over 130 injection molding machines, ranging in tonnage from 40 tons to 2200 tons, capable of producing parts weighing from fractions of an ounce to tens of pounds, ensuring every project meets the required precision specifications. In addition, we have a well-equipped mold-making workshop and CNC machining workshop for press maintenance, mold repair, and value-added services. Our in-house workshops not only produce large volumes of plastic parts but also maintain and repair molds, keeping them in optimal condition and extending their lifespan; some molds have been in use for over 10 years.

Cleanroom PS Injection Molding Workshop

We also possess a world-class, state-of-the-art cleanroom injection molding workshop that meets ISO Class 7 standards specifically for the production of PS plastic parts. This controlled environment minimizes airborne particulate matter and contaminants, ensuring your custom components are manufactured to the most stringent standards. This meticulous approach guarantees the integrity of the parts, thereby ensuring that the produced custom plastic products comply with regulatory requirements. Trust us to provide PS plastic parts of unparalleled quality and precision.

A Rigorous and Meticulous Quality Control System

Regarding product quality inspection, we have established a rigorous and meticulous quality control system. First, we use basic measuring tools such as calipers and micrometers to conduct preliminary measurements of the product’s key dimensions, quickly identifying products that clearly do not meet requirements. For products with high precision requirements, we use a coordinate measuring machine (CMM) for precise measurement, accurately obtaining three-dimensional dimensional data such as dimensional deviations and geometric tolerances to ensure that the product dimensions meet design requirements. Simultaneously, we utilize optical inspection equipment and image recognition technology to quickly inspect and compare the product’s appearance and dimensions, promptly detecting subtle dimensional differences and defects. By comprehensively employing multiple inspection methods, we strictly control product quality, ensuring that every product meets the requirements of your project.

Why Choose Elimold for Your PS Injection Molding Project?

To ensure customer satisfaction, we implement rigorous material management, including strict control over humidity, material density, and mixing ratios. Furthermore, we conduct internal checks every two hours during production. Therefore, we are able to meet our customers’ specific requirements for functionality, strength, durability, and color. Our manufacturing capabilities extend beyond cleanroom injection molding to include overmolding, insert molding, and in-mold labeling (IML). We have extensive experience producing multi-component Class A surface parts with complex geometries, undercuts, and thin walls.

Secondary Processing of Polystyrene Plastic Parts

Elimold not only offers easy decoration of polystyrene using pad printing and hot stamping processes, but also provides vacuum coating, which involves depositing a thin layer of aluminum onto the polystyrene surface. Furthermore, we can routinely process high-impact polystyrene post-forming processes, including drilling, tapping, turning, and milling. We also offer ultrasonic welding for polystyrene; when your project cannot be integrally molded using injection molding, we will use this process to weld the parts, ensuring both mechanical strength and aesthetic appeal.

PS Injection Molding at Elimold

Still unsure which process to choose? We offer free engineering consultations. Here, you’ll find inspiration, and we’re the ideal choice to meet all your project needs. The sooner you connect with our supplier, the more resources you’re likely to save. These resources could include time, money, functionality, or even entirely new ideas. We excel at tackling “tricky challenges”—projects that require extra attention, experimentation, or the use of new materials. For such projects, there’s no better mold-making company than Elimold.

FAQ

Our PS injection molding process allows for a wide range of customization options, including color matching, surface treatments, and complex geometries. It also supports overmolding and insert molding technologies to enhance product functionality.

Polystyrene (PS) is not considered an environmentally friendly material due to its poor biodegradability and difficulty in recycling. However, advancements in recycling technologies are improving its sustainability.

Polystyrene is not as durable as engineering plastics such as ABS or polycarbonate, but it is more affordable and easier to process. It is ideal for non-structural parts where cost-effectiveness and ease of production are primary considerations.

- PS vs. ABS: PS is more transparent, but its impact resistance is not as good as ABS.

- PS vs. PP: PS offers better rigidity and dimensional accuracy, while PP is more flexible and chemically resistant.

PS has limited heat resistance (it softens around 90-100°C), making it unsuitable for high-temperature environments.

Yes, PS can be molded into transparent parts, such as packaging and lampshades, depending on the application and material formulation.

Common defects include warpage, shrinkage marks, brittleness leading to cracking, and surface imperfections. These defects can be prevented by controlling wall thickness (keeping it uniform and moderate), using appropriate mold temperature and cooling time, employing suitable draft angles for easy demolding, and selecting the appropriate PS grade. Additionally, maintaining appropriate injection pressure and drying the material when necessary also helps avoid defects.

Get a Quote on Injection Molding Polystyrene Today

Elimold can work with you on the design and production of your polystyrene part. Get an instant quote today.