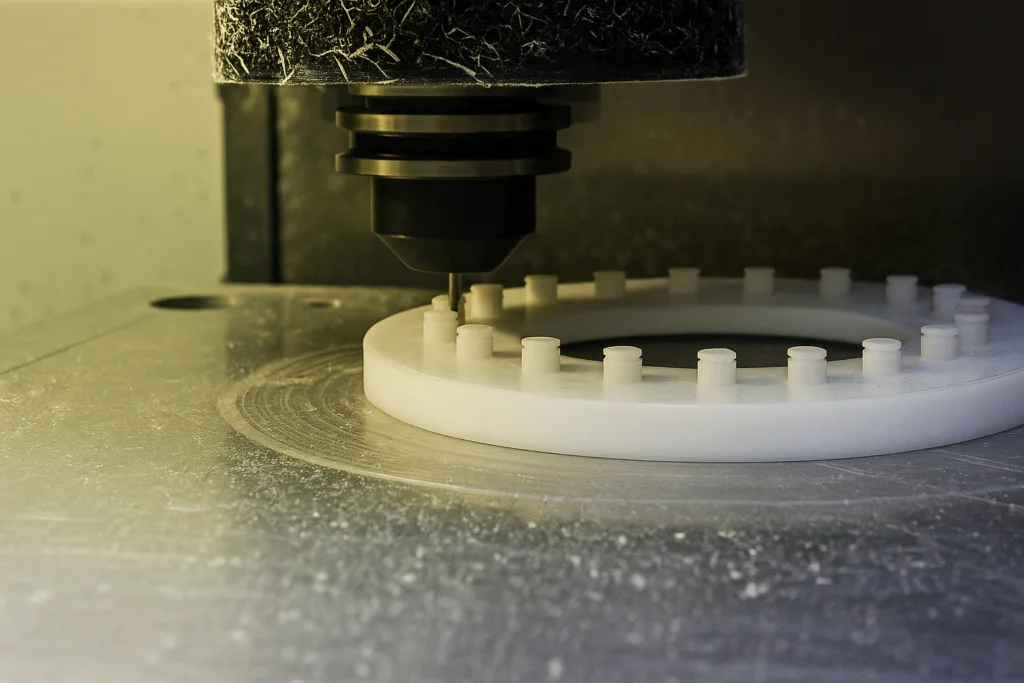

PTFE (Teflon) CNC Machining Services

Need high-quality PTFE CNC machining services? Elimold’s advanced equipment and experienced team of machinists ensure every job is precise, efficient, and of exceptional quality. From prototyping to mass production, we handle it all with ease. Contact us today to meet all your CNC machining needs.

Looking for Reliable PTFE CNC Machining Services?

Elimold is a leader in the design, manufacture, and supply of standard and custom-designed PTFE parts and assemblies. Whether you need prototyping or mass production, our advanced CNC equipment ensures tight tolerances, fast lead times, and consistent quality. From parts machining to complex assembly, we offer comprehensive services. Our team of engineers provides guidance and support at every step, working closely with you throughout the process to ensure products meet or exceed your specifications. Ready to get started? Contact us today to begin your PTFE CNC machining project.

What is PTFE?

Polytetrafluoroethylene (PTFE, also known as Teflon) is a fluoropolymer thermoplastic composed entirely of carbon and fluorine atoms. It is a versatile engineering plastic and a fluoropolymer synthesized from tetrafluoroethylene, renowned for its superior performance and properties. Teflon is the trade name for PTFE material. PTFE is a fluorinated solid, a polymer compound composed of carbon and fluorine. It is known for its extremely high heat resistance, capable of withstanding temperatures up to 260°C (500°F), and is also hydrophobic, meaning it is not wetted by water or aqueous substances. Additionally, Teflon has excellent corrosion resistance and the lowest coefficient of friction (0.05-0.10) of all solid materials. This characteristic ensures that PTFE parts have minimal resistance, making them ideal for applications requiring smooth, frictionless movement. Due to its fluoropolymer chemical composition, it also has excellent corrosion resistance.

Characteristics of Polytetrafluoroethylene (PTFE) Materials

- Withstands temperatures up to 250°C

- Maintains 5% elongation even at -196°C

- Resistant to strong acids, strong alkalis, water, and various organic solvents

- Best aging resistance among plastics

- Lowest coefficient of friction among solid materials

- Does not adhere to any substance

- Easy to process into complex shapes

- Chemically stable and corrosion-resistant

- Excellent dielectric insulation properties

- Safe and non-toxic, suitable for sensitive applications

- Can be used as a material for artificial blood vessels and long-term organ implants without causing adverse reactions

PTFE Material Properties

Polytetrafluoroethylene (PTFE), also known as Teflon, is a versatile engineering plastic commonly used in precision CNC machining. Its unique properties make it suitable for demanding applications across various industries. The table below lists the key processing-related characteristics of PTFE:

Mechanical Properties

| Tensile Strength | 1,500 – 3,000 psi |

| Tensile Modulus of Elasticity | — psi |

| Tensile Elongation | 100 – 200% |

| Flexural Strength | — psi |

| Flexural Modulus of Elasticity | 72,000 psi |

| Compressive Strength | — psi |

| Hardness | Shore D 55 |

| Izod Impact | 3.5 ft-lbs/in |

Thermal Properties

| Coefficient of Linear Thermal Expansion | 8.9 in/in/°F x 10-5 |

| Heat Deflection Temperature (66 psi/264 psi) | 250 / — °F |

| Max Continuous Service Temperature in Air | 500 °F |

Electrical Properties

| Dielectric Strength | 400 – 500 V/mil |

Machined PTEF Grades We Work With

Due to different additives, different grades of ptef materials have different properties, making them suitable for specific application requirements. We have machined various types of ptef and will select the appropriate material based on the specific requirements of your parts. Below are our commonly used PTFE grades for machining:

Pure PTFE

This is pure polytetrafluoroethylene (PTFE) without any additives. It has excellent electrical and chemical resistance and is commonly used for electrical insulation, sealing, and gaskets.

Mechanical Grade PTFE

Mechanical grade PTFE is a high-purity, virgin polycrystalline PTFE, ideal for mechanical parts requiring excellent chemical resistance and a low coefficient of friction. It is easy to process and can be used to manufacture seals, valves, bushings, and bearings requiring strength, creep resistance, and dimensional stability.

Glass Fiber Reinforced PTFE

Glass fiber reinforced PTFE is a composite material made by adding fine glass fibers to PTFE to improve its strength and stiffness. It retains the corrosion resistance of PTFE while improving wear resistance, dimensional stability, and load-bearing capacity. It is ideal for mechanical parts requiring higher mechanical strength.

Carbon-Filled PTFE

Carbon-filled PTFE is a composite material made by adding carbon filler to PTFE resin to improve conductivity and wear resistance. It improves hardness and load-bearing capacity while maintaining the coefficient of friction and chemical resistance of PTFE. It is commonly used in components requiring high conductivity and durability, such as bushings, seals, and valve seats.

Bronze-filled PTFE

Bronze-filled PTFE is a PTFE composite material reinforced with bronze particles, designed to improve strength, wear resistance, and bearing performance. It enhances mechanical properties while maintaining the corrosion resistance and low coefficient of friction of PTFE. Suitable for bearings, bushings, thrust washers, and other dry-running applications.

Graphite-filled PTFE

Graphite-filled PTFE is a composite material made by adding graphite filler to PTFE, improving thermal conductivity and reducing friction. It retains the chemical resistance of PTFE while improving wear resistance, lubrication, and heat dissipation. Suitable for bushings, bearings, valve seats, and other components requiring thermal conductivity.

Compliant with RoHS and Environmental Standards

Our polytetrafluoroethylene (PTFE) materials comply with the EU RoHS Directive (EU) 2015/863 and are free of restricted substances such as lead, mercury, cadmium, hexavalent chromium, polybrominated biphenyls (PBB), polybrominated diphenyl ethers (PBDE), and phthalates. All materials comply with global market environmental regulations. Material traceability information and batch documentation can be provided upon request.

PTFE CNC Parts Manufacturer

Finding a reliable PTFE parts supplier is no easy task. Elimold boasts an experienced design team capable of designing and manufacturing a wide range of PTFE products to your specifications. In addition to OEM projects, we also undertake ODM projects. We can modify and customize machined PTFE parts according to your design requirements, including material selection, dimensions, surface treatment, and color. Our products cover a wide range of colors, including white Teflon, black Teflon, and clear Teflon, to meet diverse customer needs.

PTFE CNC Machining Workshop Capabilities

Our 36,000-square-foot machining workshop is equipped with over 100 3/4/5-axis milling machines, lathes, and engraving machines. Utilizing the latest technology and equipment, we achieve the most precise and efficient custom Teflon machining. From parts processing to routine machine maintenance, we strive for excellence in every aspect of our work.

For PTFE materials, our in-house factory offers a dust-free, temperature-controlled production environment to prevent PTFE parts from deforming due to temperature variations, thus avoiding any impact on product machining accuracy. However, what truly sets Elimold apart is our team’s unwavering pursuit of excellence. We are a group of experienced craftsmen, each dedicated to perfecting the quality and craftsmanship of our custom Teflon products.

From Prototype to High-Volume Production

We manufacture strictly to your specifications, quickly prototyping parts as needed, and handling both low-volume and high-volume production. Leveraging our in-house CNC machining capabilities, we can produce standard and near-net-shape parts, enabling efficient machining of customized PTFE parts. When you place an order with Elimold, we will review your part details, tolerances, quantity, and delivery requirements, and provide a timely quote. For customers with recurring part requirements within a specific timeframe, we offer bulk purchase orders with multiple delivery dates.

Engineering and Design Services for Custom CNC Parts with PTFE

Our end-to-end service includes assistance with design. If you already have design files, you can send them to us. After fully understanding your needs, we will use various software such as CAD and CAM to help you with drafting and design. Based on your design drawings, we will create complex and high-precision mechanical parts. No matter how unique the shape and size of the part, we can find the best solution using advanced equipment and experience. Our team is ready to work on your project. Once you send your project files, our designated team will assess your needs and provide the solution that best meets your expectations. If you have PTFE or other plastic projects, please contact us today for a quote.

Surface Treatment Solutions for CNC-Machined PTFE Parts

To enhance both appearance and functionality, we offer a variety of surface treatment services for your CNC-machined polytetrafluoroethylene (PTFE) parts.

As-Machined

Standard finish with visible tool marks; suitable for functional prototypes and internal components.

Smoothing

Removes machining marks and evens out surface texture; ideal for prototypes and parts where appearance is not critical.

Power Coating

powder coating provide colorful, durable, and corrosion-resistant finishes.

Surface Printing

Adds logos, text, or identification marks via silk screen or pad printing, ideal for branding or part tracking.

Brushed Finish

A brushed finish adds a distinct texture to PVC surfaces. It’s a less common choice but can provide an interesting aesthetic for parts where a unique look is desired.

Painting

PVC can be painted to achieve different colors and appearances, giving it a customized look. This is useful when parts need to blend into specific environments or for branding purposes.

Quality Management Processes

All parts we manufacture undergo rigorous quality control processes designed specifically for this material with its unique properties. Each component is tested using measurement procedures that fully consider the temperature sensitivity and mechanical properties of PTFE. Our quality management system ensures consistent results through comprehensive process documentation, well-trained personnel, and calibrated equipment. Material traceability remains consistent throughout the manufacturing process, and the material characteristics of each batch are recorded for future reference.

Alternatives to Teflon

While PTFE (polytetrafluoroethylene) offers many advantages, several other materials serve as better alternatives, including:

Ethylenechlorotrifluoroethylene (ECTFE)

This is a copolymer of ethylene and trifluorochloroethylene, a semi-crystalline fluoropolymer. It is a fluoropolymer similar to Teflon, a fluorocarbon compound containing multiple carbon-fluorine bonds. This semi-crystalline thermoplastic offers better corrosion and chemical resistance than Teflon. Therefore, manufacturers often use it as a substitute in applications requiring higher chemical and corrosion resistance.

Polychlorotrifluoroethylene (PCTFE)

This material is an alternative to Teflon, but unlike Teflon, it is a thermoplastic chlorofluoropolymer. It boasts the lowest water vapor transmission rate of all plastics and extremely high water resistance.

Perfluoroalkoxy (PFA)

PFA and Teflon are both fluoropolymers with similar chemical corrosion resistance. However, PFA has poorer abrasion resistance and is softer than Teflon. Therefore, manufacturers rarely use this material in structural components.

FAQ

Compared to metals, PTFE's softness and flexibility require extra care during such machining to avoid deformation and dimensional errors, which can be caused by improper handling when machining PTFE parts.

Tolerances for precision machining of PTFE vary depending on the specific application and manufacturing process. However, PTFE machining tolerances are typically around +/- 0.005 inches or 0.127 millimeters. This means that the final dimensions of a machined PTFE part may deviate from the expected dimensions by up to 0.005 inches or 0.127 millimeters.

Yes, untreated PTFE parts can have rough edges if they haven't undergone proper finishing. To achieve the desired smoothness and surface finish, post-processing, including grinding or polishing, should be performed on machined PTFE parts.

Typically, Teflon can be machined to a thickness of up to 0.063 inches (1.6 mm). However, to ensure accuracy, always consult the manufacturer of the equipment you are using, as there may be limitations for specific products or applications.

While machined PTFE parts are stable and non-toxic at lower temperatures, they begin to deteriorate at around 260°C (500°F), decompose above 350°C (662°F), and undergo pyrolysis at 400°C (752°F).

Yes, it is approved by the U.S. Food and Drug Administration (FDA), but is typically used in the food and pharmaceutical industries.

Yes, we value intellectual property protection and are happy to sign a non-disclosure agreement with you before reviewing documents.

The unique challenges of machining PTFE include its extremely slippery surface, low thermal conductivity, and tendency to cold flow under pressure. The material's slipperiness makes workpiece clamping difficult, requiring specialized clamping solutions. Its low thermal conductivity (1.7 BTU·in/ft²·hr·°F) leads to heat buildup during machining, necessitating the use of a cold air cooling system. PTFE's tendency to deform under pressure also requires distributed clamping and minimizing cutting forces.

The four main components of Teflon thermoplastic are water, chloroform, fluorite, and hydrofluoric acid. These components are mixed in a chemical reaction chamber, where the temperature is precisely controlled between approximately 590 and 900ºC (1094 to 1652ºF).

Pure PTFE exhibits excellent chemical resistance and remains stable in most corrosive media. However, PTFE components can react with certain liquid or dissolved alkali metals, fluorine, and other strong oxidizing agents.

Due to its non-stick properties, untreated PTFE cannot be bonded using conventional adhesives. However, surface treatments such as sodium naphthalene etching or plasma treatment can create adhesive surfaces. Etched PTFE can then be bonded to metals, plastics, and elastomers using epoxy, silicone, or specialized fluoropolymer adhesives. For critical applications, mechanical fastening or encapsulation often provides a more reliable connection.

Need Teflon (PTFE) CNC Machined Parts?

Simply send us your 3D CAD files, and our customer service engineers will review your design, assess its manufacturability, and ensure the parts meet your expectations and budget requirements. Contact us today for a free quote.