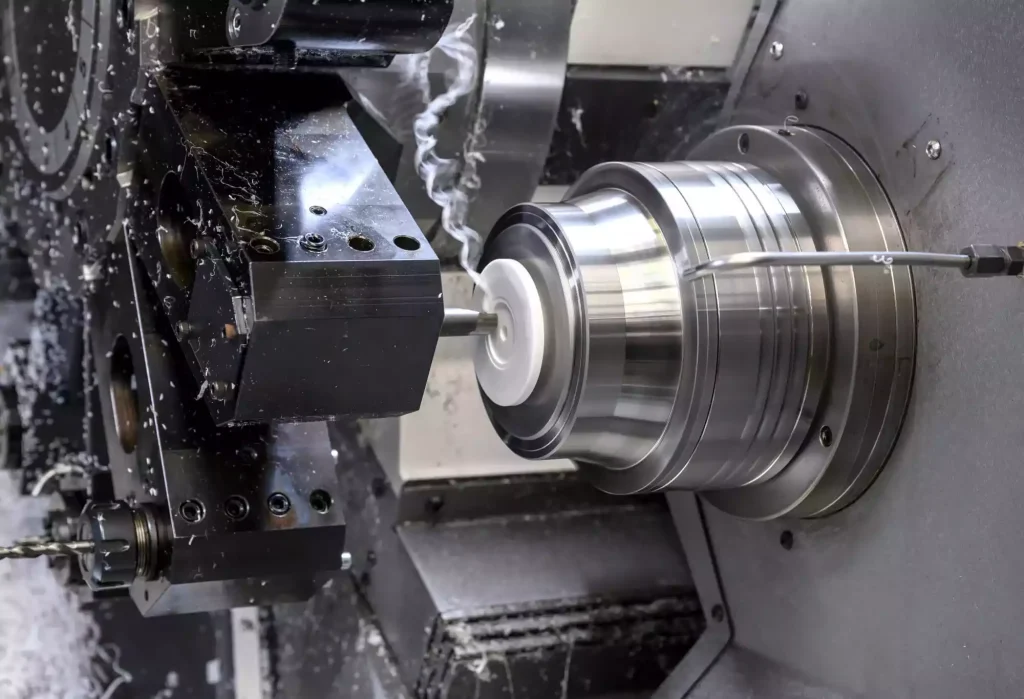

PVDF CNC Machining Services

Elimold can custom-machine PVDF parts according to your specifications, samples, or drawings. We manufacture high-quality, precision PVDF parts in a wide range of sizes. Whether it’s a single prototype or large-volume production, we can meet your specific needs in a cost-effective manner. Contact us now for a quote.

Are You Working on a CNC Project that Requires the Exceptional Performance of PVDF Materials?

The demand for CNC machining services of fluoropolymers such as Kynar® PVDF is growing across various industries worldwide, driven primarily by the increasing popularity of specialized, small-batch production of custom parts and components. For companies developing prototype products, partnering with a fluoropolymer parts manufacturer like Elimold is incredibly convenient. Elimold’s extensive experience in custom engineering plastics ensures that we consistently meet our customers’ evolving needs with the same innovative spirit and dedication, and are committed to creating new value in fluoropolymer applications.

What is PVDF?

Polyvinylidene fluoride (PVDF) is a semi-crystalline fluoropolymer, commercially known as Kynar®, whose basic unit is the repeating vinylidene fluoride (VDF) monomer, with the chemical formula (C₂H₂F₂)n. The free-radical polymerization of VDF produces molecular chains composed of alternating -CH₂- and -CF₂- groups. This polymer structure gives PVDF its unique polarity, making it extremely useful in applications requiring excellent thermal stability and electrical properties.

It is a high-purity thermoplastic made from high molecular weight fluorocarbons. It possesses efficient piezoelectric and pyroelectric properties. These characteristics make it widely used in sensor and battery applications. PVDF has a glass transition temperature (Tg) of approximately -350 degrees Celsius, and its crystallinity is typically 50-60%. It is one of the toughest fluoroplastics, with the lowest coefficient of friction, and excellent corrosion resistance, aging resistance, weather resistance, and radiation resistance. In addition, PVDF exhibits high mechanical strength and toughness.

Properties of Polyvinylidene Fluoride

The widespread use of polyvinylidene fluoride (PVDF) is due to its excellent physical and chemical properties. Among the most important properties are:

- Inertness to food contact

- Excellent compression, creep, and impact resistance, and high rigidity

- Unaffected by strong acids and bases

- Hydrolysis resistance and high water resistance

- Excellent sliding properties

- Ability to withstand weathering and UV radiation

- Easy to maintain desired dimensions

- High tolerance to temperature variations (up to +150°C)

- Low flammability

- Ease of plastic and mechanical processing

CNC Machining Grades of PVDF Material

Polyvinylidene fluoride (PVDF) is available in two formulations: homopolymer and copolymer.

- Homopolymer PVDF plastic has higher strength, stiffness, and better thermal deformation properties than copolymer PVDF plastic.

- Copolymer PVDF plastic has lower stiffness than homopolymer PVDF plastic, but offers higher impact resistance and stress crack resistance.

Comprehensive Production Support Team

We have a team of experienced manufacturing experts working behind the scenes to fulfill your production orders. We manage the entire process and keep you updated on the latest progress.

Account Manager

Application Engineers

Logistics

Quality Control

Professional PVDF CNC Machining Service Provider

With over 10 years of engineering experience, we are committed to providing the highest quality PVDF CNC machining and other products. We also offer custom part design and reverse engineering services. Our exceptional service and efficient production ensure timely delivery and superior quality. In addition to custom design and reverse engineering, we also provide value-added manufacturing solutions such as expedited manufacturing and delivery, engineering, high-volume production, assembly, and packaging.

Looking for a Professional PVDF Plastic CNC Machining Manufacturer?

With leading-edge automated manufacturing equipment and computer-aided design processes, Elimold specializes in manufacturing custom PVDF CNC parts in a variety of shapes and sizes. We go beyond the limitations of our competitors, with our engineers and technicians working closely with clients to create precise plastic parts based on their unique design requirements. Furthermore, Elimold uses only the highest purity PVDF materials that fully meet the performance requirements of each project. Our custom PVDF parts are suitable for precision applications in the biomedical, pharmaceutical, and semiconductor industries.

PVDF CNC Machining One-Stop Solution

When designing custom PVDF CNC machining solutions, Elimold’s team assists clients throughout the entire lifecycle, from customer requirements and design to prototyping, mass manufacturing, and final production. We also provide suggestions for design improvements to your desired custom parts to facilitate installation, cleaning, and maintenance. Furthermore, even in urgent situations, we can produce, source, package, and ship parts on time, making Elimold your one-stop machining solution provider.

From Prototype to Mass Production

We manufacture high-quality, precision PVDF CNC parts in various specifications. Whether it’s single-piece prototyping or large-volume production, we can meet your specific needs in a cost-effective manner. From your initial inquiry to the delivery of finished parts, our engineering team members will work with you to ensure your parts meet or exceed your specifications. Furthermore, Elimold utilizes the latest technology and the highest quality standards, and provides exceptional customer service, delivering finished parts that meet or exceed expectations for every customer, on time and within budget.

CNC Machining Capabilities for Custom PVDF Parts

Our advanced CNC equipment allows for machining tolerances of ±0.03 mm (±0.0012 inches) for PVDF components. Even tighter tolerances can be achieved for specific features using appropriate tooling and fixturing. The key is using sharp tools, proper cutting speeds/feed rates, and sufficient cooling to prevent thermal expansion during machining. Additionally, our technical experts can provide professional advice to ensure you receive the best product made from the right materials, meeting your end-use specifications and providing a long-term solution.

PVDF CNC Machining Factory

Elimold’s production facility in Shenzhen, China, is equipped with over 100 state-of-the-art design and manufacturing machines of various types. Our engineering team is capable of producing a wide range of PVDF plastic products. Our latest CNC machines, advanced CAD/CAM software, and modern tooling allow us to produce parts with excellent surface finish and within the tightest tolerances permitted by the material. We are happy to manufacture and quote parts based on various drawings (from 2D paper drawings to 3D CAD models), and we can also perform reverse engineering based on existing parts. So contact us today and tell us your requirements. Our professional team is ready to meet any challenge. Elimold – helping you succeed.

FAQ

While polytetrafluoroethylene (PTFE) offers excellent chemical resistance, polyvinylidene fluoride (PVDF) surpasses it in terms of mechanical strength, stiffness, and dimensional stability. PVDF is also easier to process and weld, making it more cost-effective in many applications. Its piezoelectric properties and flame retardancy set it apart among fluoropolymers.

Absolutely. PVDF exhibits exceptional UV resistance and weatherability, maintaining its performance even after decades of outdoor exposure. It is widely used in applications such as construction, outdoor chemical storage, and solar panel components. This material resists degradation from sunlight, rain, and temperature cycling.

PVDF can be effectively welded using techniques such as hot air welding, extrusion welding, or butt fusion welding. While bonding can be challenging due to PVDF's low surface energy, surface treatments can improve adhesion. We offer comprehensive PVDF welding and assembly services.

Yes, PVDF is widely used in semiconductor, pharmaceutical, and ultrapure water applications. The material exhibits extremely low levels of extractables and particulate generation. Natural PVDF contains no additives or stabilizers that could contaminate sensitive processes. We also offer special high-purity grades for the most demanding applications.

PVDF is an excellent choice for applications requiring a high-purity engineering thermoplastic with good chemical resistance, UV stability, flame retardancy, and abrasion resistance, and it offers good weldability using thermoplastic welding equipment.

Need custom CNC machined PVDF parts?

Whatever type of custom machined PVDF components and precision manufacturing services you require, our team is ready to provide solutions that exceed your expectations.