PVDF Injection Molding Service

Elimold is a China-based PVDF plastic product manufacturer supplying PVDF injection molded parts to manufacturers requiring prototype part validation, on-demand production, and customized high-volume parts. Working directly with the source factory reduces certification risks and supports long-term supply plans. Contact us today for free PVDF injection molding consultation.

Chinese PVDF Plastic Product Manufacturer

Elimold is a vertically integrated PVDF injection molding solutions partner serving a wide range of industries. We support the entire lifecycle of PVDF plastic products, including rapid prototyping, mold development, validation, production molding, and automated secondary processing.

Our diverse range of advanced PVDF plastic product manufacturing solutions includes micro-injection, multi-material injection molding, and insert molding. Our scalability ensures you achieve your goals on time, whether you need to design and develop new products or scale up immediately for high-volume production. Elimold works with you to bring your products to market and optimize your supply chain. We consistently deliver superior products on time.

A Comprehensive PVDF Plastic Product Production Support Team

We have a professional PVDF plastic parts manufacturing team working behind the scenes to meet your production order needs. We manage the entire process and keep you updated on the latest progress.

Engineering & DFM

Mold Making

Injection Molding

Surface Treatments

Quality and Compliance

Assembly and Shipping

What is PVDF?

Polyvinylidene fluoride (PVDF) is a semi-crystalline fluoropolymer. This thermoplastic exhibits excellent chemical resistance, mechanical properties, and thermal stability. PVDF is composed of repeating vinylidene fluoride units, and its strong internal carbon-fluorine bonds give it a unique combination of properties.

Typical applications for this material include corrosive environments that require both the chemical resistance of fluoroplastics and higher mechanical properties than polytetrafluoroethylene (PTFE) or polytetrafluoroethylene (PCTFE). PVDF can be used at temperatures up to 300°F (approximately 149°C). PVDF is white and is available in a variety of sizes.

PVDF Properties and Material Options

Homopolymer PVDF

Copolymer PVDF

PVDF Injection Molding Principle and Process

Inside the injection molding machine barrel, PVDF material melts into a flowing molten material under the action of heat and shear force. This molten material then flows into the closed mold cavity under the thrust of the plunger or screw for molding. After cooling and solidification, the mold is opened and the product is removed. The key to the molding process lies in heat transfer under pressure and melt flow, which are closely related to factors such as the viscosity, thermal stability, thermal conductivity, crystallinity, and moisture content of the PVDF material.

PVDF injection molding typically uses screw-type injection molding machines with a screw length-to-diameter ratio of 20:1 to 25:1. Parts in the injection molding machine that frequently come into contact with the molten resin should be made of corrosion-resistant materials. The diameter of the main mold channel should be approximately 1 mm larger than the nozzle, ideally thick and short, with uniform mold cavity wall thickness and avoidance of sharp corners to reduce flow resistance.

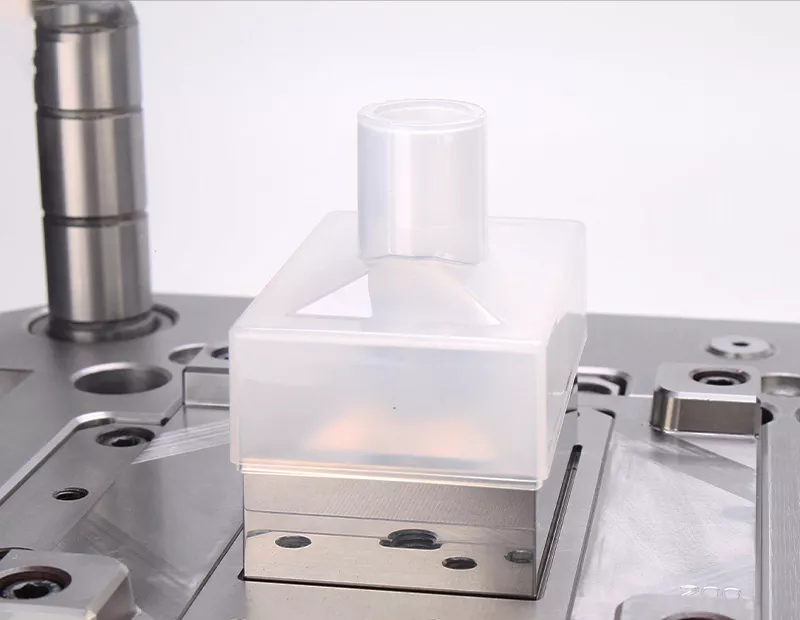

PVDF Injection Molding and Molds

Our in-house injection molding plant utilizes state-of-the-art machinery, equipment, and mold technology to process PVDF, ensuring superior performance of finished PVDF components. We ensure precise and gentle processing of PVDF materials. PVDF melt must never come into contact with boron-containing products (screws, barrels, certain glass fibers) or molybdenum disulfide (MoS₂), as this will cause spontaneous melt decomposition. Therefore, all PVDF polymers and compounds are fed directly into the injection molding machine and processed in specially coated screws and injection units.

One-Stop PVDF Injection Molding Solution Provider

Elimold’s PVDF injection molding processes deliver the highest industry standards through JIT, EDI, FIFO, and lean manufacturing processes—strategic components of our commitment to meeting customer needs. Furthermore, when designing custom PVDF injection molded parts, our engineering team assists customers throughout the entire lifecycle, from customer requirements and design, prototyping, mold making to final production. We also offer design improvements for PVDF parts to facilitate production and assembly. Even in emergency situations, we can produce, package, and ship parts on time, making Elimold your one-stop PVDF injection molding solution provider.

Ready to Get Started?

Elimold’s team is dedicated to providing innovative and consistently high-quality PVDF plastic products. If you encounter any issues with parts or designs, please send us your information, and we will assess and provide advice. To collaborate with us on your next project, please arrange a meeting or visit our factory.

PVDF Injection Molding Factory

Our factory is located in Shenzhen, China, covering an area of over 10,000 square meters. Our PVDF injection molding production line boasts over 130 fully electric injection molding machines equipped with appropriately sized barrels, minimizing heat treatment time during the PVDF molding process and thus maximizing the performance and consistency of each injection molded part. Our injection molding machines range in tonnage from 15 tons to 2200 tons, meaning we can produce PVDF parts weighing from 0.1 grams to 3600 grams. All machines are equipped with an RJG system, enabling us to monitor cavity conditions and develop the most reliable PVDF molding processes for specific parts. We apply scientific molding principles to the PVDF injection molding process.

ISO Class 7 and 8 Cleanrooms for Healthcare Clients

Elimold manufactures and assembles a wide range of medical devices and components, a process that typically requires molding and assembly in cleanrooms. These operations are conducted in custom-built ISO Class 7 (10,000 sq ft) and ISO Class 8 (100,000 sq ft) cleanrooms exceeding 20,000 sq ft, including spaces for plastic and silicone molding as well as assembly work areas. Our services are suitable for highly regulated safety, security, and protective products. We are ISO 13485:2016 certified for medical and government contract manufacturing and assembly.

PVDF Injection Molded Parts Reverse Engineering Services

No part design drawings? Only part samples? No problem! Our team can reverse engineer PVDF plastic products and parts, providing you with suitable alternative designs. For your custom PVDF parts reverse engineering, our superior service and efficient production ensure timely delivery and high-quality service. In addition to reverse engineering, we also offer emergency manufacturing and delivery, engineering, and other value-added manufacturing solutions.

How Long Does it Take to Make a PVDF Injection Mold?

Our mold-making department takes an average of 35 working days to complete the production of one mold. After production, we conduct mold testing. Some adjustments may be necessary. Finally, after the plastic parts pass quality control, we perform surface texturing or polishing. Sending a final sample to the customer for acceptance is our standard procedure.

Once the sample passes inspection, mass production begins immediately. The entire process takes approximately 20 days. Therefore, the production of each order is carefully planned. If raw materials are out of stock, our purchasing department will handle the procurement. Using the same molds, we can complete an average of 150,000 to 500,000 injection molding cycles per day. After injection molding, we inspect the parts, remove burrs, and package them before shipping.

Custom Options for PVDF Injection Molding

PVDF injection molding requires specialized, customized solutions to meet demanding application requirements. Elimold focuses on optimizing materials, molds, and processes to withstand extreme high-temperature environments. Our solutions ensure your parts maintain structural integrity and performance at high temperatures.

Surface Finishes and Post-Processing Options

From Rapid Prototyping to Full-Scale Production

Our Quality Management and Inspection Capabilities

Every PVDF part produced in our factory undergoes First Article Inspection (FAI). Our plastics quality control and engineering team conducts FAI based on a quality checklist and customer-approved standards. Together, we determine the criteria for acceptable parts and develop part specifications. Part inspection includes dimensional accuracy, functionality, critical features, and appearance defects. Non-conforming parts are isolated, reground, and recycled. Once the customer approves the sample parts, we schedule production or begin production immediately. Once products are in production, we conduct in-process inspections at predetermined intervals. We randomly select parts for inspection to verify compliance with part specifications.

Ready to Get Started on Your PVDF Injection Molding Project?

Contact Elimold’s custom PVDF injection molding experts today; we look forward to the opportunity to work with you and contribute to the success of your projects.