Rapid Tooling Service

At Elimold, our rapid tooling services provide fast and reliable solutions for companies looking to quickly and efficiently produce high-quality prototypes and low-volume production parts. Utilizing a variety of advanced manufacturing technologies, we provide precision tooling that accelerates your production process, reduces lead times, and lowers costs, helping you get your products to market faster. With strong in-house factory manufacturing capabilities, lead times range from 10 days to 6 weeks. Contact us now for a free instant quote.

Experienced Rapid Tooling Manufacturer

Welcome to Elimold, we have a long history and rich experience in providing rapid tooling services, which means we are knowledgeable and skilled. We have been active in this market for a long time, with many employees, spacious production facilities and considerable monthly production. Our rapid tooling services are highly sought after. Strict testing standards, standardized production processes and comprehensive quality management practices ensure the excellent quality of our rapid tooling services. In addition, as experts in the industry, we have rich experience and a good reputation in rapid tooling services. Our partners include many partners from many countries around the world. If your project requires mechanical testing or design verification before mass production, we strongly recommend rapid tooling technology. This can avoid problems in potential future projects. With Elimold rapid tooling services, you will benefit from our rich plastic injection molding expertise and manage your projects efficiently.

Rapid Tooling Service Provider

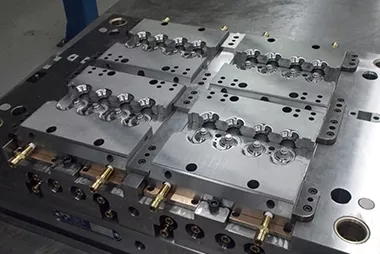

If you need to injection mold 1,000 to 5,000 parts, we recommend using rapid tooling to cut mold design and production time in half. This way, you can achieve the perfect balance between cost and time to market. Elimold is a leading provider of rapid injection molding and rapid tooling services, using a variety of technologies, including 3D additive manufacturing combined with traditional molding concepts to produce tools or molds from CAD models, often faster and cheaper than molds machined using traditional methods. All of our customer-facing staff are fully trained or have many years of experience in plastics manufacturing, so we always have the best advice for you. We can advise on material selection and the impact of a specific design on the manufacturing process, and even provide best practice design details to minimize production and material costs.

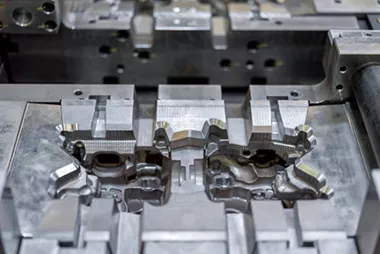

Professional Rapid Tooling Manufacturing Factory

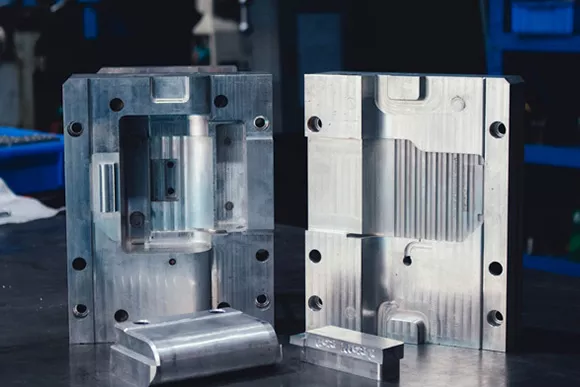

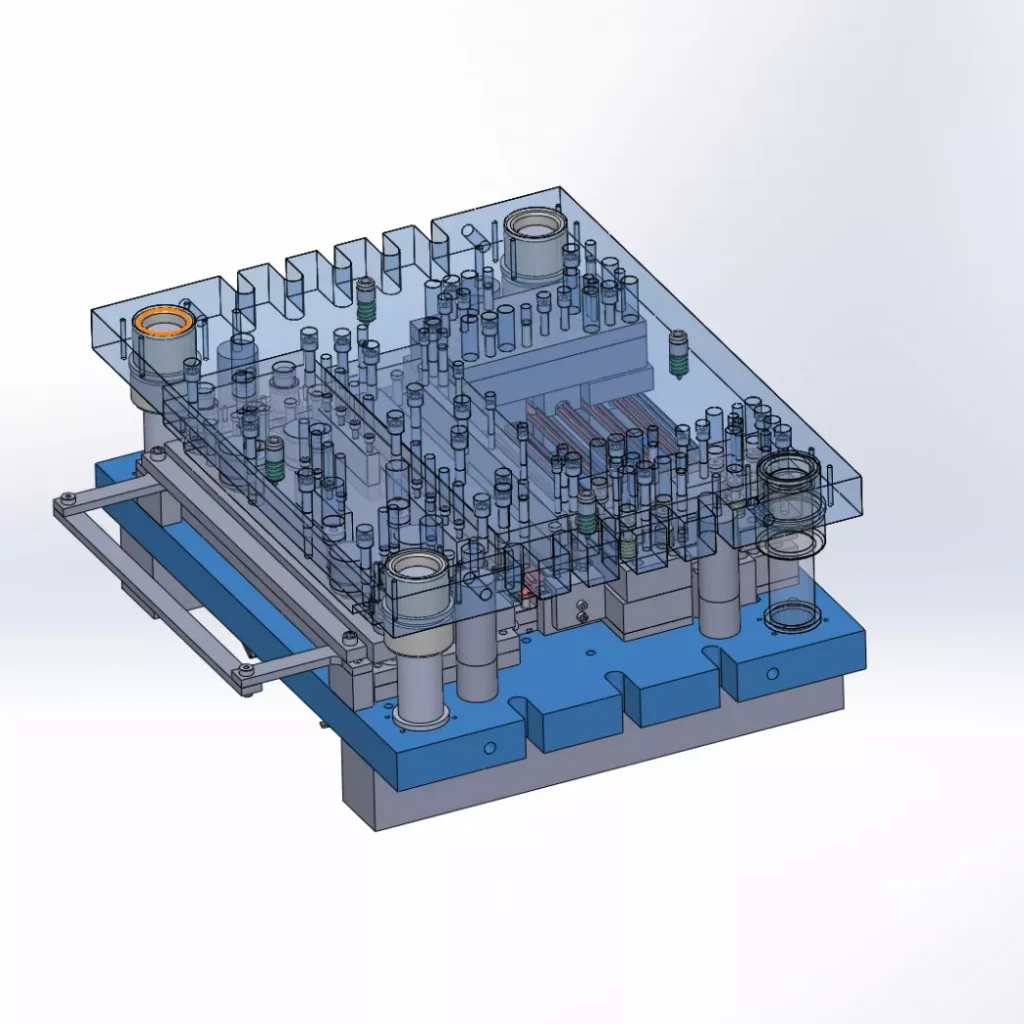

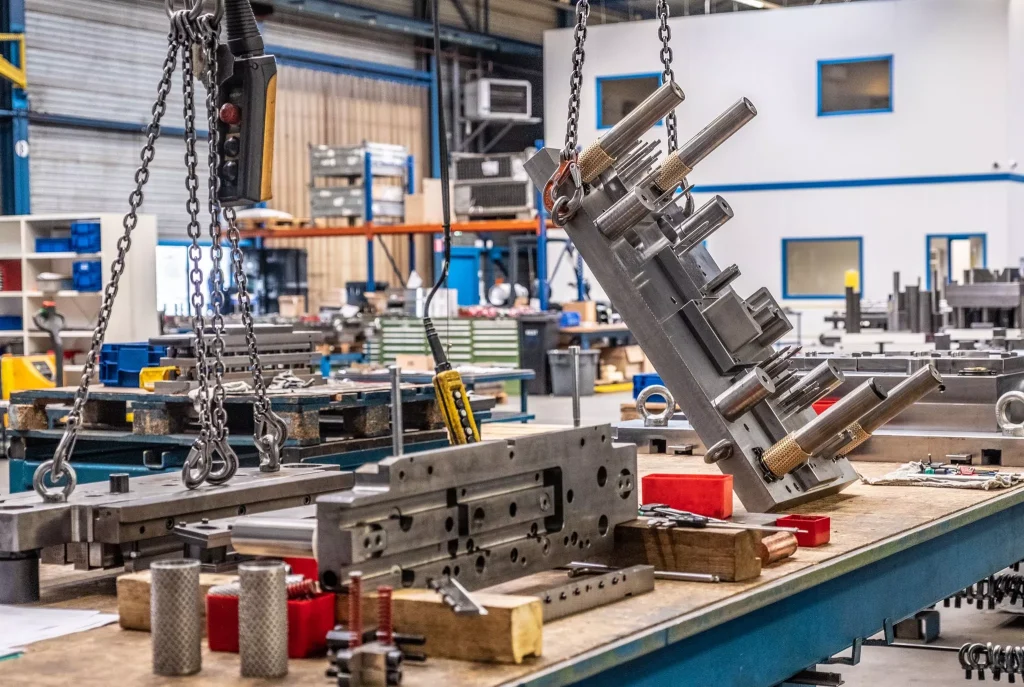

Elimold offers a one-stop, high-quality solution for your rapid tooling, plastic injection molding, and low-volume production projects. Our 22,000 square foot facility features a fully equipped in-house ISO-certified factory with tooling, molding, paint, and printing shops. Our dedicated team of engineers will assist you every step of the way, from product design to product delivery, ensuring that every step is optimized. You’ll experience Elimold’s exceptional customer service when you work with experienced team members at every stage of the process. You’ll find an estimating team that provides quotes on time, a simulation and design team that uses state-of-the-art software, experienced engineers, quality support with coordinate measuring machines (CMM), and a team of experienced toolmakers dedicated to molding a wide range of materials. Send us your project and we’ll provide you with a free quote.

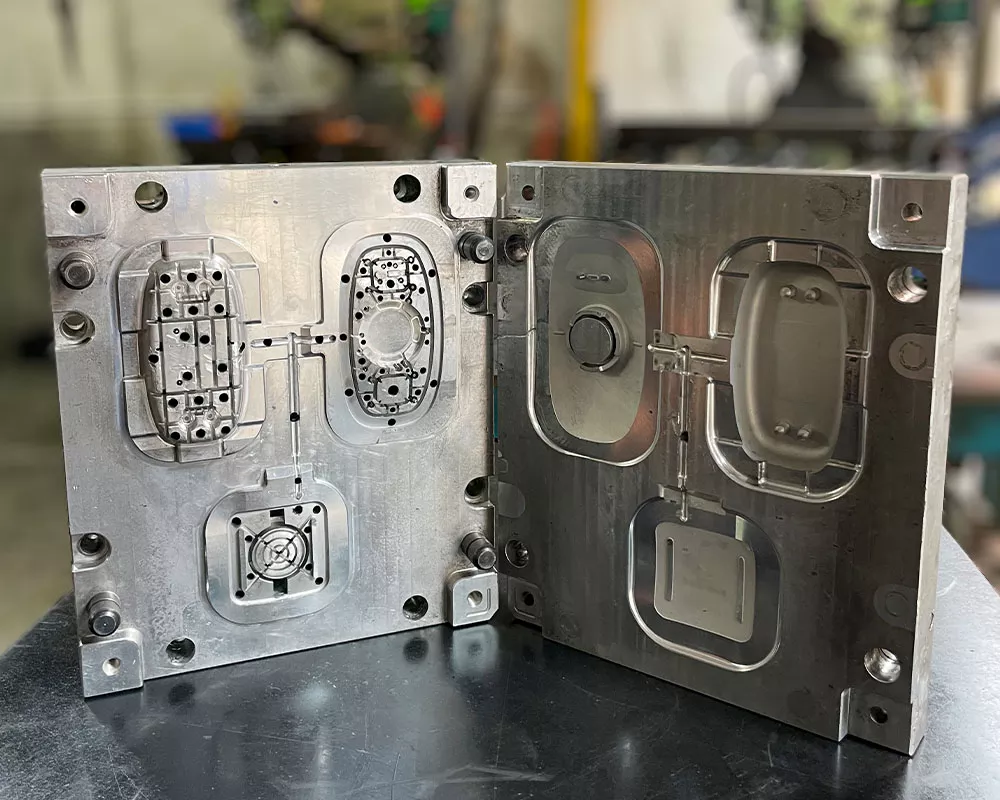

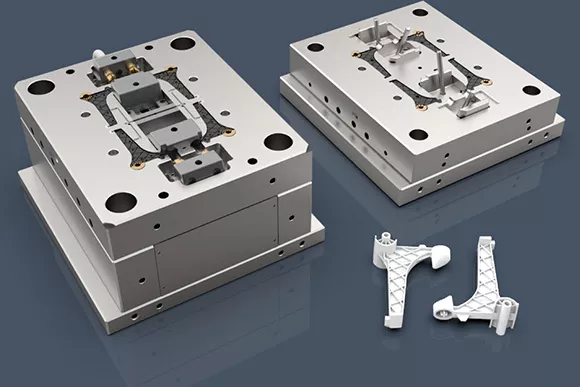

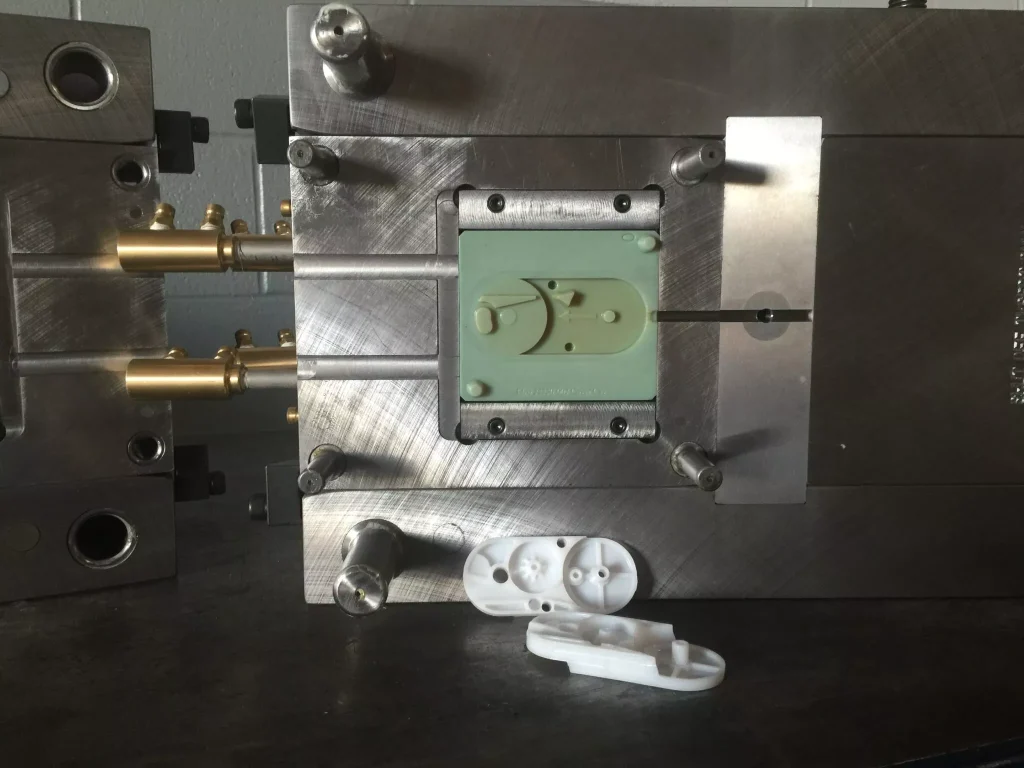

Unique Rapid Tooling System

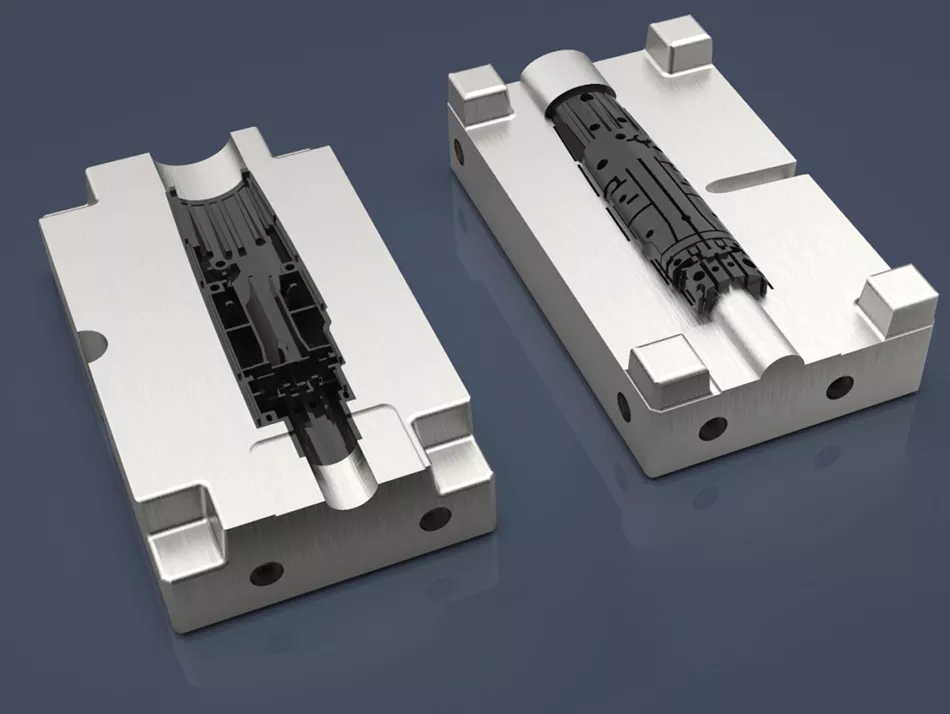

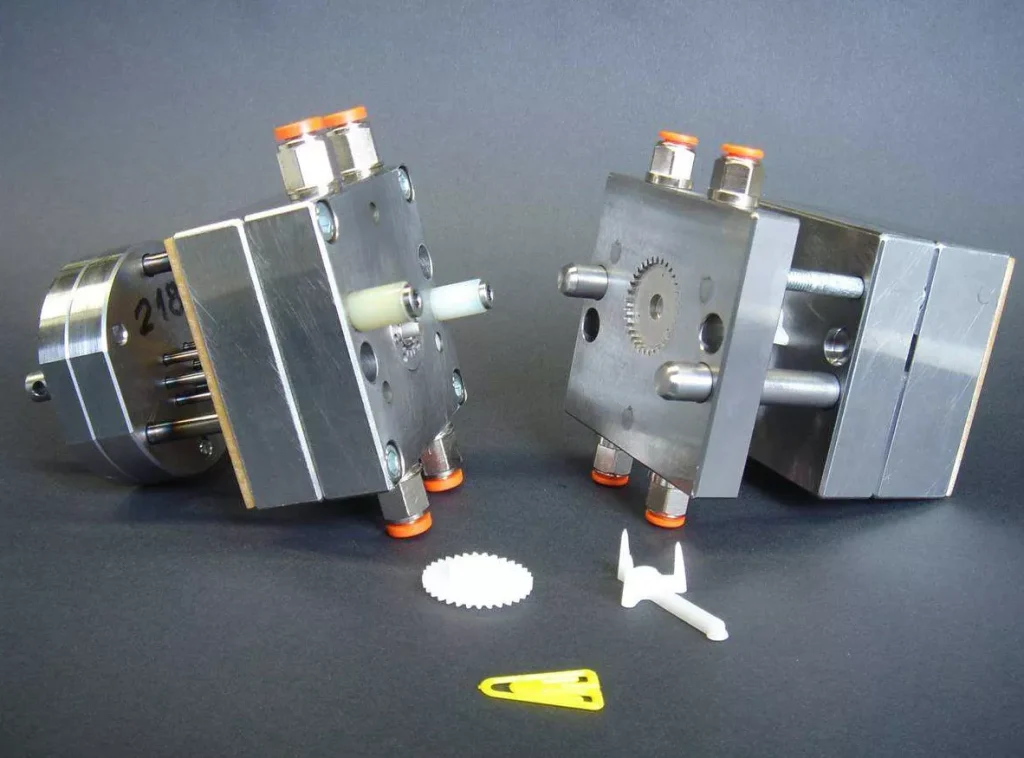

Elimold can provide a unique rapid tooling system. One engineer is responsible for the manufacture of your mold from start to finish. Using standard mold bases and suitable materials, machinists can produce finished molds in as little as ten days after the design drawings are approved. These molds use standard plastic resins and fillers to produce fully functional finished parts in relatively limited quantities. Rapid tooling has many advantages. Finished parts can be used for prototyping, product testing and certification, and as a bridge to larger volume production. Rapid tooling injection molding also helps our customers reduce the cost of new designs.

Ready to Start Your Rapid Tooling Projects?

Are you ready to start your next project? Let us help you deliver high-quality rapid tooling and parts in a short time. Get a free quote and start your project today.

A Trusted Rapid Tooling Company

Elimold provides excellent rapid tooling technology to meet small and medium-volume production needs at a low cost. Our rapid tooling process is optimized to produce high-quality injection molded parts with simple and complex shapes using real materials in the shortest time. And we can also provide manual loading inserts for very low production needs. We also provide comprehensive rapid tooling support and provide value-added solutions covering product design assistance (DFM), material selection, product structure optimization, mold detail design, flow analysis and other post-molding services (polishing, texturing and sandblasting) to help you bring your concept to market in just a few weeks.

Engineering Capabilities

Elimold offers professional support in design, technology and production. Our team can work closely with you from the initial design stage to provide engineering support to optimize part geometry, reduce cycle time and minimize tooling costs. By integrating DFM principles early in the process, we can help you avoid expensive changes later and provide durable and high-performance molds. In addition, our product development and prototyping solution project team is ready to meet your specific needs. We will provide you with the best insights on technology, materials and surface treatments to provide the best customer experience in product manufacturing. Our organization and follow-up processes will ensure that every step of production is strictly checked and monitored. Our team will be responsible for the project from beginning to end to ensure that the delivery of each order meets your expectations.

Rapid Tooling Material Options

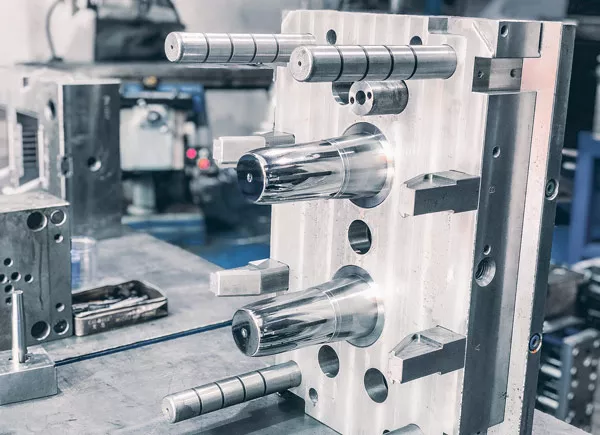

At Elimold, rapid tooling is done primarily with aluminum and steel alloys. Here are some of the properties of both materials:

Aluminum

Steel

Rapid Tooling Solutions

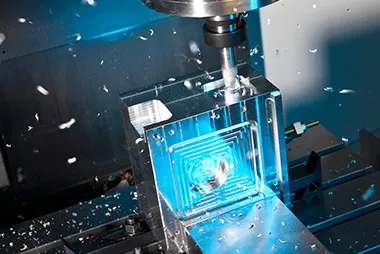

When you’re racing against a product launch deadline, you need to get true production-quality molded parts, fast. At Elimold, we understand the importance of speed and quality in the early stages of product development. That’s why our rapid tooling services are designed to bridge the gap between prototyping and full-scale production without sacrificing control, cost-effectiveness, or part integrity. That’s why we combine precision engineering, high-speed CNC machining, and design for manufacturability (DFM) expertise to deliver production-grade tooling in weeks, not months. Whether you’re launching into full production or need high-quality molded parts for functional testing, our processes help you reach your goals faster without cutting corners. Because we don’t just make tooling, we help make better products.

Custom Manufacturing from Prototyping to Production

Our process is based on the needs outlined by the customer and is designed to provide the most cost-effective solution. During the mold design process, we carefully review the part data you provide. If we have suggestions for part modifications to maintain mold integrity and part moldability, we will share them with you and obtain your consent before proceeding. Our molds are designed using advanced Cimatron CAD/CAM software, and the mold design data will be shared with you if required. Throughout the process, we work closely with you to discuss gates, ejection solutions, and mold construction to advance the project from the prototyping stage to the stage of manufacturing mass production molds when required. Elimold provides you with the entire value chain of customized production auxiliary tools or tooling with rapid tooling technology. From design and engineering, additive manufacturing or traditional manufacturing, to post-processing and finishing, we provide you with a one-stop service. Use it flexibly to benefit from our rapid tooling solutions for manufacturing auxiliary tools or tooling.

Low-cost Rapid Tooling Services

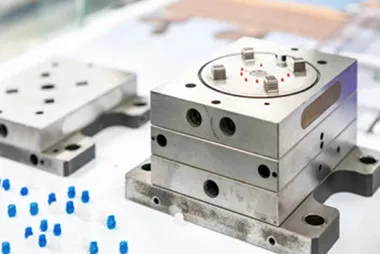

Elimold’s rapid tooling uses a variety of interchangeable mold bases to simplify complex mold structures. We use molds in a variety of materials, including aluminum, P20, NAK80, S136H and other materials. Depending on the geometry and simplicity of the part and the materials used, our tool life ranges from 5,000 to 500,000 times. Our in-house capabilities and experience also mean that we can deliver quality end-use parts faster and more economically. Rapid tooling can save approximately 40% to 50% in cost and time compared to traditional molding techniques. Depending on the final production product and mold structure, our mold delivery cycle is as fast as 5-20 days.

Optimized Design for Manufacturability (DFM)

We incorporate Design for Manufacturability (DFM) into every aspect of mold making and injection molding, from part design to injection molds, material selection and processing. No need to wait until production to discover design problems. Our optimized design for manufacturability ensures that parts can be manufactured and molded in a cost-effective manner, to scale. Therefore, Elimold provides Design for Manufacturability (DFM) services that cover all aspects of the injection molding process, from part design, mold design and material selection to processing. With more than 20 years of hands-on experience in traditional mold making and rapid prototyping, our engineers are able to integrate comprehensive interactive quotes and manufacturability analysis, and conduct design reviews to recommend the best technology for your custom prototype parts. For example, gate type and location, parting lines, draft angles, runner systems, slides and inserts, ejection, critical dimensions, tolerances and surface finish – all of which are critical factors in the production process.

Rapid Mold Category

We are able to manufacture a variety of standard rapid molds, as well as special molds using innovative and unique processing methods. We can easily select mold materials and simplify mold structure design according to different plastic materials, product surface requirements and product accuracy.

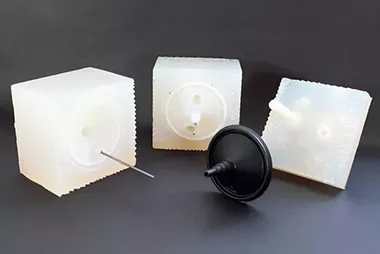

3D printed high temperature resin mold core

Rapid prototyping tool

Rapid production mold

Bridge tooling

Get started with a free quote

Are you working on a new plastic injection molding project? Want to get it to market as quickly as possible? Why not try our quick tooling service?

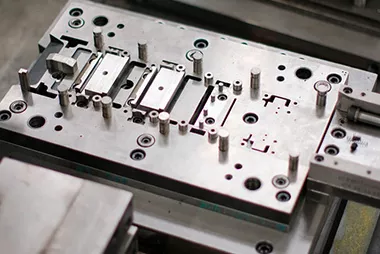

In-house Mold Making Shop

We offer a high-quality in-house mold shop for extremely fast turnaround. We leverage a global network of mold solution providers around the world. Our mold shop uses a paperless system to support the design, programming and manufacturing of your injection molds. We have a fully equipped mold production and repair shop. In addition, for customers who have already invested in molds, Elimold can also provide mold transfer solutions designed to improve part quality, service, production time and price. In addition, our production center is very spacious, providing ample space for our engineering and design teams to work on your project efficiently and freely. Our production and sales teams work closely together to ensure that the final product perfectly matches the original design and concept. We provide a tailor-made fast mold service and strive to provide you with high-quality injection molded parts in the shortest time.

Prototype Rapid Tooling Capabilities

During the prototype stage of product development, we face a lot of testing uncertainties. Elimold is able to flexibly meet customer requirements.

Injection Molding Tooling Surface Finish

- Polishing;

- High polish for glossy/high glossy;

- VDI sparking surface;

- MT texture equivalent;

- Mold-Tech texture

Plastic Injection Molding Color

- Pantone Color to follow;

- RAL Color to follow;

- Existing samples to follow;

- Samples with different colors available;

- Production with different color available;

Certified Quality Management

Our quality management system is ISO 9001 certified. Our production process meets the highest standards and has professional quality control. We are happy to discuss product improvements and customization. Each product is professionally certified and meets industry standards. Over the past few years, our organization has been marked by integrated advanced technology, which defines our professional approach. Therefore, Elimold can provide professional and affordable rapid tooling services worldwide. We continue to uphold the business spirit of quality, high quality is our life, and paying attention to customer needs is the source of the company’s survival. Customer satisfaction is our main goal. Therefore, whether your product development is simple or complex, we can provide you with comprehensive quality assurance and excellent product quality.

Machining Methods Used for Our Rapid Tooling Services

We offer a variety of manufacturing services and solutions to meet all your rapid tooling manufacturing needs. All your designs and ideas can be realized and transformed into products efficiently and safely in our factory. Elimold is a one-stop service, providing you with the ultimate convenience.

CNC Machining

Vacuum Casting

3D Printing

Tooling Transfer Services

- Eliminate supply chain disruptions

- Tool transfer teams that go through a 94 Point inspection

- Document incoming tool inspection

- Document part quality

- Document tool quality

- Document any potential issues (tooling or part)

- Improving part quality, service, and pricing

- Tool cleaning

- Tool review

- Tool maintenance

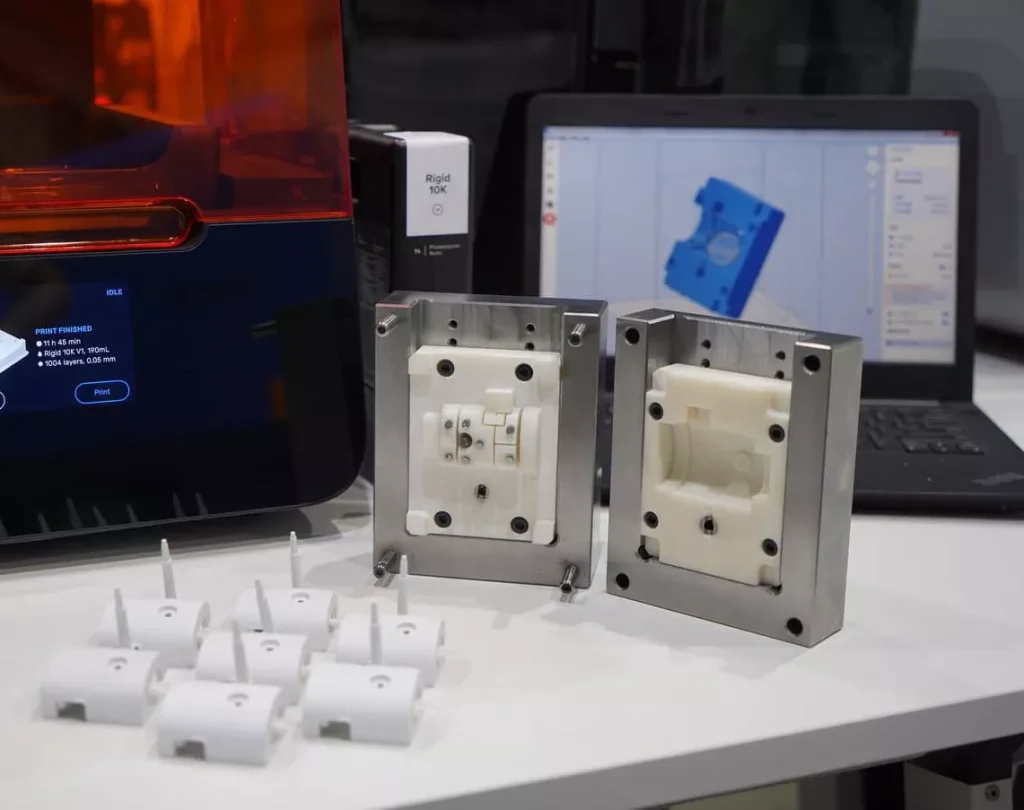

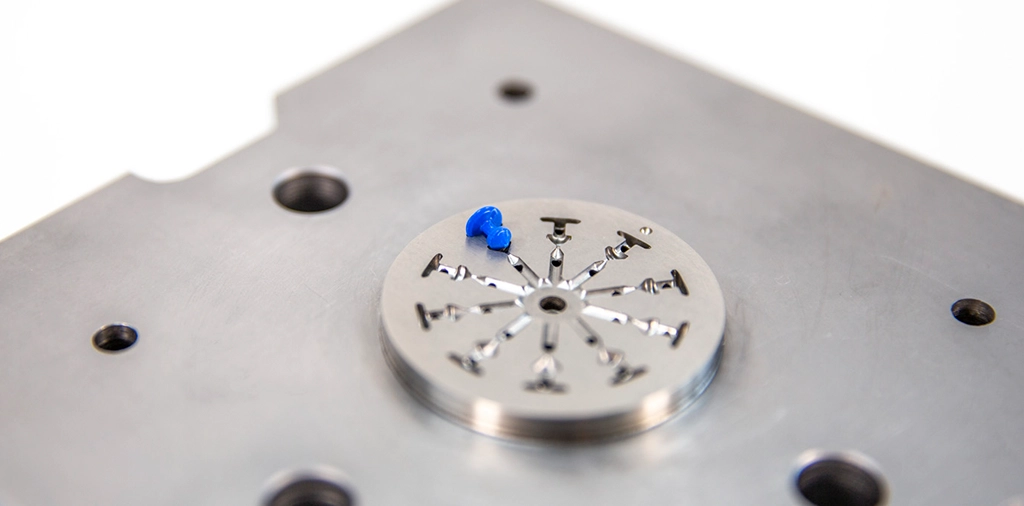

Why Use 3D Printing For Rapid Tooling?

Identify potential for improvement and optimize processes.Tool making with ablative or forming technologies, such as CNC milling or CNC turning, is subject to process-related limitations. Cooling channels created in injection-molded tools using machining technologies, for example, can be added to the material only in straight lines. The more complex a component’s geometry, the more difficult it is to maintain precise cooling along the contour of the tool. This can make the conventional production of sophisticated components extremely laborious and cost-intensive. Compared to traditional processes, additive manufacturing delivers a significant time saving and offers cost-effectiveness regardless of shape. Because each 3D-printed component is manufactured directly from CAD data, no additional tools are needed. This saves on labor and reduces the risk of errors in production.

Rapid Tooling Service for 3D Printing

Want to take advantage of rapid tooling? We will produce your tools and tool inserts on the Elimold within just a few days of receiving your order. Choose from six different 3D printing processes and over 30 materials to design your custom component.

- Selective Laser Melting

- Selective Laser Sintering

- Multi Jet Fusion

- Stereolithography

- PolyJet/MultiJet modeling

- Lithography-Based Ceramic Manufacturing

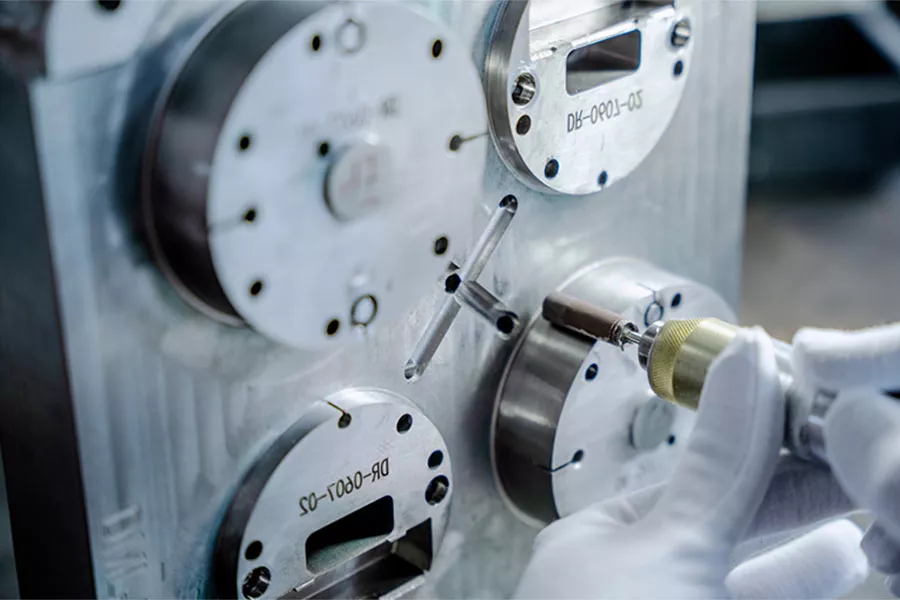

Tool Manufacturing Tolerances and Finishing Guidelines

Rapid tooling tolerance standards refer to the regulations on the allowable deviation range of mold cavity, part size and shape during the processing process, aiming to ensure the quality stability of parts during the processing process. Usually, rapid tooling tolerance standards are based on engineering drawing design requirements. For rapid tooling tolerance standards, we need to consider many factors, such as processing equipment accuracy, product size, surface treatment requirements, etc. Unless you specify otherwise, our standard tolerances comply with DIN-2768-1-fine standards. The surface treatment of mold cores and cavities can be carried out according to the classification system of the Plastics Industry Association and its general surface treatment guidelines. If you need the most refined rapid tooling services, please contact Elimold now.

What is Rapid Tooling?

Rapid tooling is a set of technologies used to quickly, cost-effectively, and efficiently create molds for use in traditional manufacturing processes to produce parts in a short time or in small quantities. Traditional molds are typically made of durable metals using techniques such as machining and metal casting. However, these processes are costly and are more suitable for large-scale production cycles. When used for mold iterations or to produce molds for only small batches of parts, costs rise and production cycles are significantly extended.

Incorporating rapid tooling technology into the product development process enables manufacturers to validate design and material selections before moving to mass production, thereby accelerating product development, rapidly iterating, and bringing better products to market. Rapid tooling technology enables engineers to use actual production-grade materials to evaluate the performance of parts in real applications and produce limited products for beta testing and verification testing. Rapid tooling technology can also help troubleshoot the manufacturing process before investing in expensive production tooling. This allows manufacturers to test market demand for new products, offer a wider range of products, or customize parts based on customer needs.

What is the advantages of rapid tooling?

- Reduce 40~50% cost compared with the traditional mold.

- Reduce 40~60% lead time compared with the traditional mold.

- The mold can be available for various of surface finish, such as: Texturing, Polishing, Sand blasting, etc.

- Soft steel make it easier to modify the tooling if the product design need to be changed.

- The mold can be made as family mold, so it can reduce the production lead time and keep the color consistency of the products.

- Rapid tooling is a good testing solution prior to huge volume production mold.

Our Material Verification

We measure the precise molecular composition of all raw materials used for your molds using X-ray fluorescence and spectrophotometry. You can be assured that we will deliver you a product that is exactly the same material grade as you specified. Our attention to detail does not stop with the final mold finish. We are not satisfied until your finished part has been fully verified in our modern quality control metrology laboratory.

Injection Molding Materials Supported by Rapid Tooling

Once rapid tooling is complete, a wide range of thermoplastics and elastomers can be used to mold functional prototypes or low-volume production parts. Elimold’s rapid tooling process supports injection molding with materials that closely match end-use properties, enabling precise testing, design validation, and low-volume production. Below are some of the most commonly used materials compatible with our rapid tooling solutions.

- ABS

- ABS/PC

- Acetal

- Acetal Copolymer

- Delrin

- ETPU

- HDPE

- LCP

- LDPE

- LLDPE

- Nylon

- PEEK

- PEI

- PET

- PETG

- PMMA

- Acrylic

- Polycarbonate

- Polypropylene

- PPA

- PPE/PS

- PS

- PSU

- TPU

- РВТ

- РС/РВТ

- Standard silicone

- Medical-grade silicone

- Optical-grade silicone

- Fluorosilicone

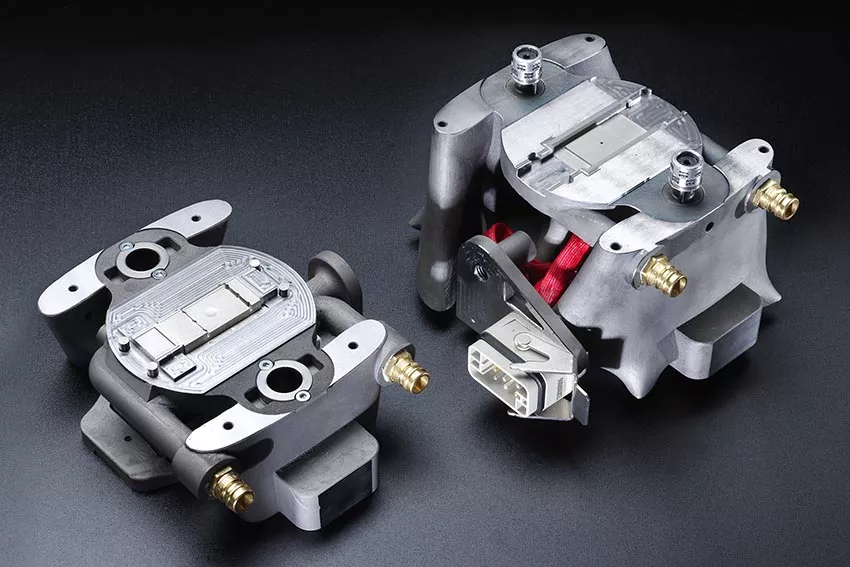

Other Mold Manufacturing Capabilities

In addition to plastic injection moulds, we can also manufacture sheet metal moulds, hydroforming tools, die casting tools, thermoforming and vacuum forming tools. Our extensive knowledge and craftsmanship means that we can always provide customers with better quality moulds at very competitive prices. The following are other types of moulds that Elimold often produces.

Sheet Metal Mold

Die Casting Mold

Compression Mold

Industries We Serve

Rapid tooling is used in nearly every aspect of industrial manufacturing, low-volume production, and product prototyping. The following industries use rapid tooling:

- Automotive

- Aerospace and Aircraft

- Construction

- Consumer Electronics

- Consumer Goods

- Military/Defense

- Energy and Power

- Medical

- Transportation

One-stop Rapid Tooling and Injection Molding Service

Elimold provides rapid delivery of prototype plastic injection molding services. Our engineers will consider technical issues, delivery cycle, quality and quantity requirements, and cost to provide you with the most suitable prototype injection molding solution. For technically innovative customers, we regard speed as the most important value. Our rapid response, deep insight into technical issues, collaborative and rapid mold manufacturing process, and professional project management will truly benefit our customers. We can provide a wide range of mold options based on customer standards such as resin type, mold life, part tolerance, and surface finish requirements. Depending on the complexity of the part and the type of mold, our rapid mold delivery cycle is typically 2 to 5 weeks.

Other Plastic Part Manufacturing Services

If you are looking for an experienced rapid tooling and plastic part prototype manufacturer, Elimold is the ideal choice. We have a strong team that can provide high-quality rapid tooling and plastic injection molding solutions. If you need more information or want to discuss your design needs with us, please feel free to contact us.

Plastic Injection Molding

LSR Injection Molding

Overmolding

Gas Assist Injection Molding

Insert Molding

Structural Foam Molding

Micro Molding

Production Tooling

Request Your Rapid Tooling Quote Today

After receiving your drawings, our engineers will analyze your custom parts right away. We actively work with you to clarify all details before providing a quote that is both economical and accurate.