Sheet Cutting Services

Elimold specializes in a range of precision sheet metal cutting manufacturing services that can produce long, complex, close tolerance and customized parts. Our services include sheet metal cutting, CNC plasma cutting, flame cutting, laser cutting, water jet cutting and metal sawing. Elimold is your one-stop supplier for all your sheet metal part cutting needs. Contact us now for a free instant quote.

Sheet Cutting Manufacturers

At Elimold, our cutting services cover a wide range of projects from prototypes to large-scale serial production, with advanced prototyping capabilities. We can provide precision sheet cutting services to customers in a wide range of industries, and provide material selection, part design advice and processing guidance. Our ISO 9001:2015 certified facility is equipped with a wide range of cutting equipment. As for the materials we offer for our custom sheet cutting services, we are proud to tell you that we have a wide variety of metal and plastic sheet materials for you to choose from. Professional processing guidance is also an important part of our custom sheet cutting services. No matter what processing plan, material selection or surface treatment you choose, our professional team can provide you with a full range of services.

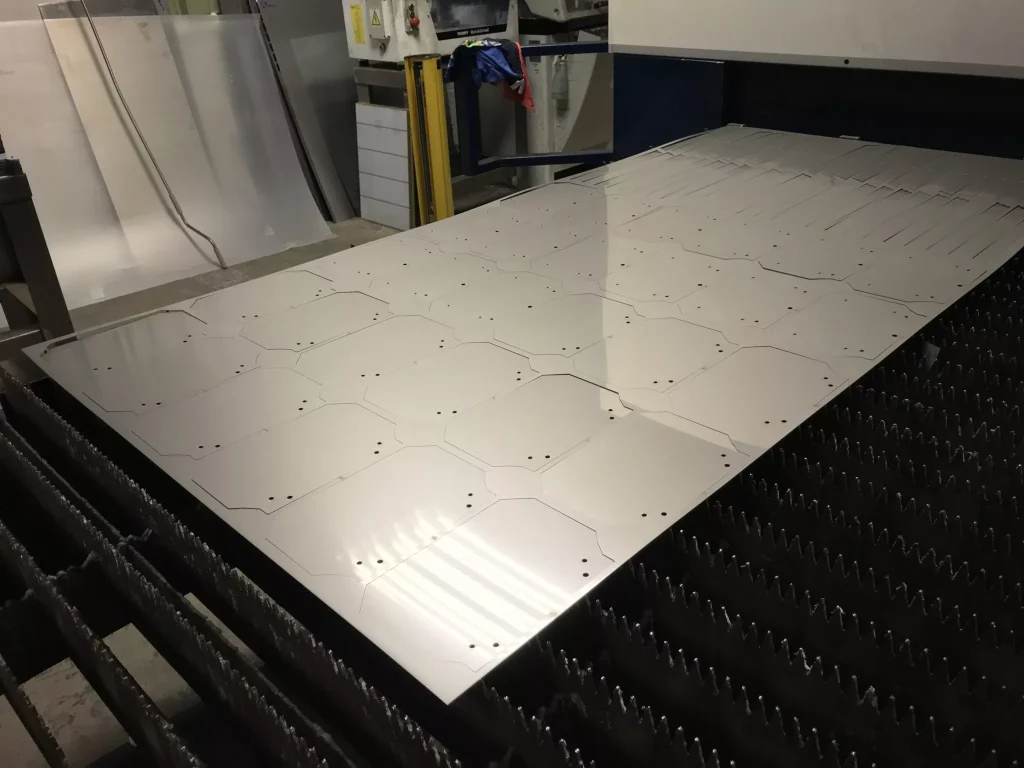

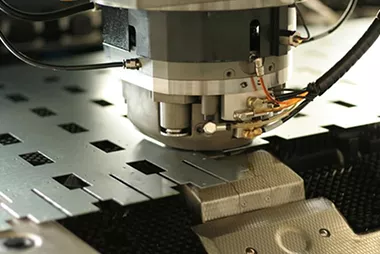

In-house Sheet Cutting Facility

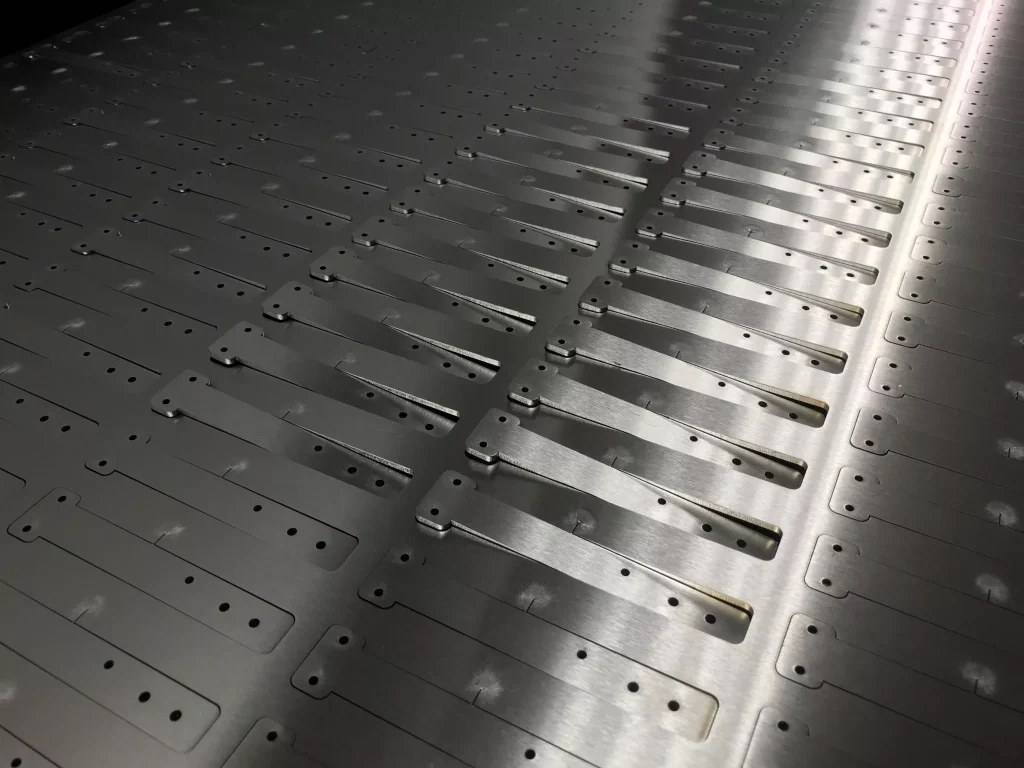

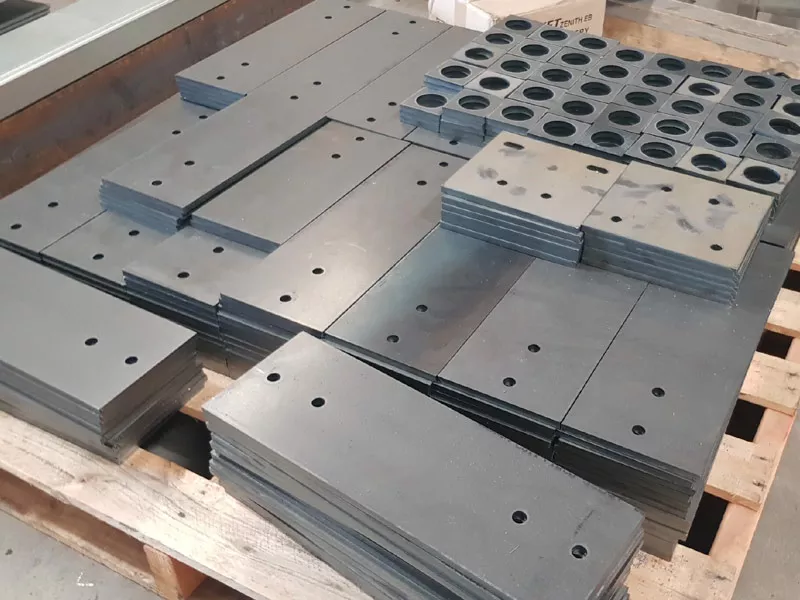

Our 135,000 square foot state-of-the-art facility is capable of handling a wide range of production tasks, from one-off prototypes to large-volume or multi-year production runs. Elimold’s in-house AS9100D certified facility has 46 cutting machines of various types, capable of producing highly complex parts with fully automated unattended production capabilities, providing you with a one-stop custom cutting service to reduce production costs and shorten lead times. In addition to the above services, we also provide services such as punching and slotting. Our high-precision cutting and processing capabilities can save you time and money on your project. And we can also provide fast turnaround times and same-day service, and carry a wide range of materials and sizes in stock. We provide local delivery and JIT (Just-in-Time) services, and we have stock when you need it, without clogging your shop. We can cut a variety of materials with bevel cuts according to your needs. So no matter the size of the order, no matter the quantity, Elimold can meet your needs.

Our Capabilities

- Blank Size: Elimold has access to platforms up to 10’ x 20’ for laser cutting and waterjet cutting. However, many sheet stock sizes commonly cap out at 48” x 96” (4’ x 8’) or smaller.

- Standard Lead Time: 3 business days

- Sheet Thickness: 0.020″ up to beyond 1.00″ depending on materials. Thinner or thicker stock may be possible through manual quoting.

- General Tolerances: Edge to edge tolerances of +/- 0.010” nominal on the top-cut surface. Thicker materials may have a tolerance deviation on the bottom face due to tapers inherent in laser cutting, waterjet cutting, or plasma cutting.

Fast Turnaround Sheet Cutting Services

We specialize in metal cutting services and have years of expertise in custom sheet cutting. Sheet cutting is the process of shaping sheet or thin metal into nearly any shape you need. We use the most advanced technology in the manufacturing industry. We have a wide range of advanced equipment that allows us to quickly and efficiently customize sheet metal parts for customers in regions around the world.

In addition, our team has been dedicated to perfecting the art and science of custom metal cutting services. Our team of highly trained, skilled and experienced precision metal cutting experts produces tens of thousands of parts every day, meeting not only the tight deadlines but also the strict tolerances required by high-tech equipment manufacturers. With our advanced equipment and extensive in-house inventory, we are always ready to handle the most demanding specifications and production schedules.

Our Sheet Metal Cutting Service Solutions

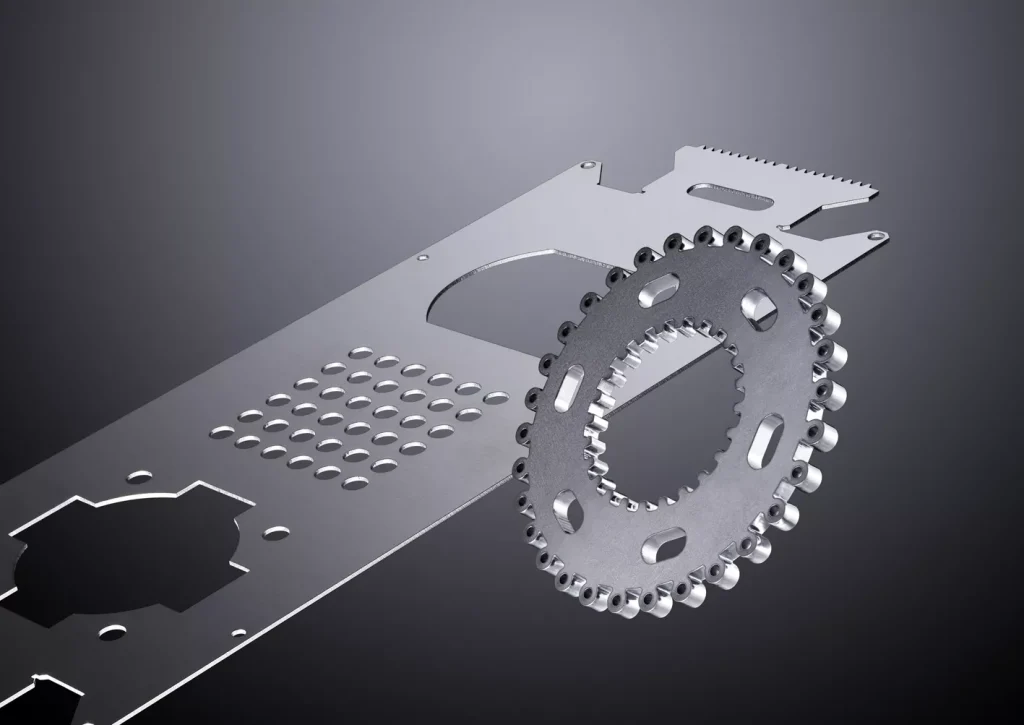

Whether you need a small, complex part or a high-volume, formed sheet metal part, Elimold has you covered. Our team of experts has decades of expertise and unmatched innovation to help you move your sheet metal fabrication project from prototype to production quickly and efficiently. Below are a variety of metal cutting services we offer.

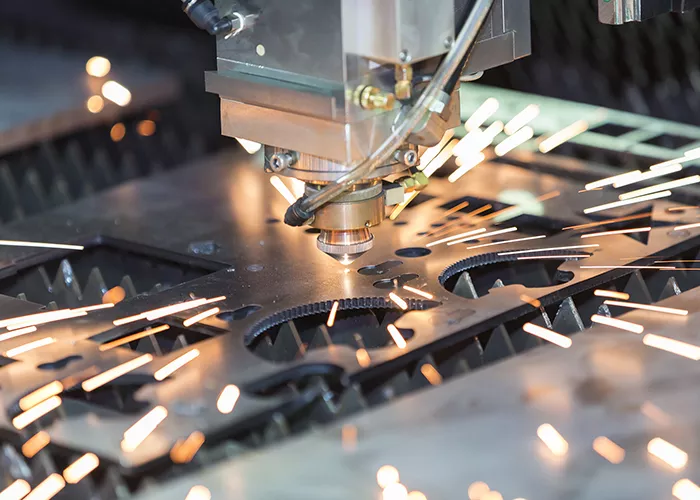

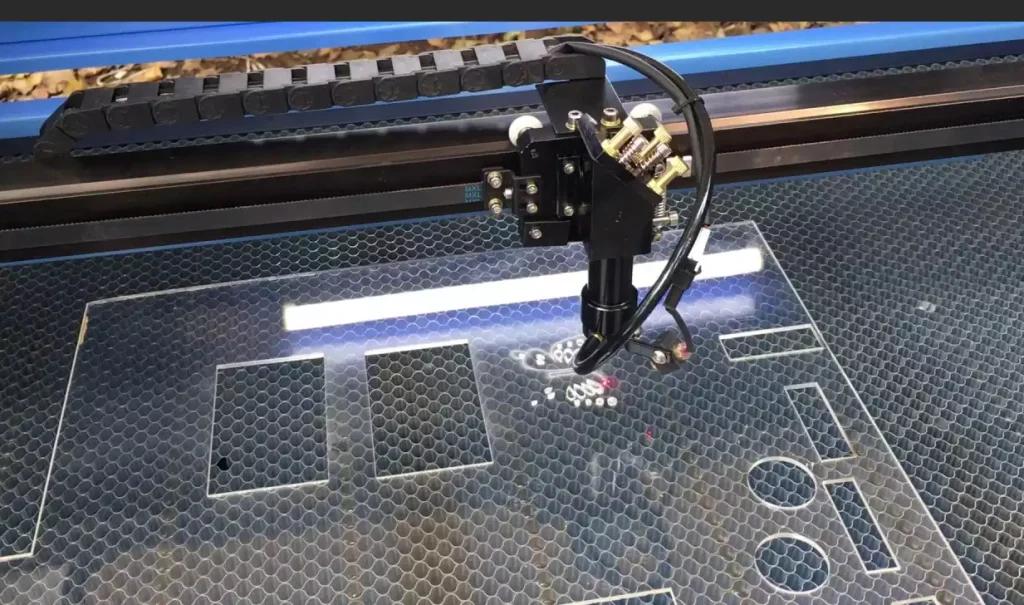

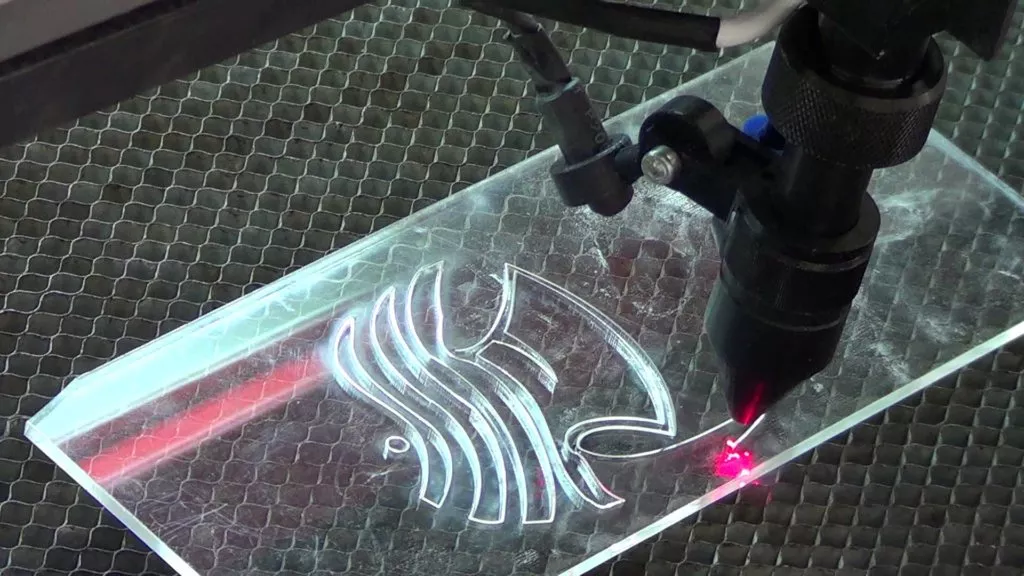

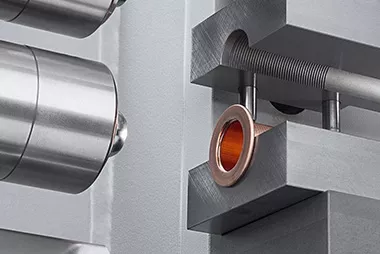

Laser Cutting

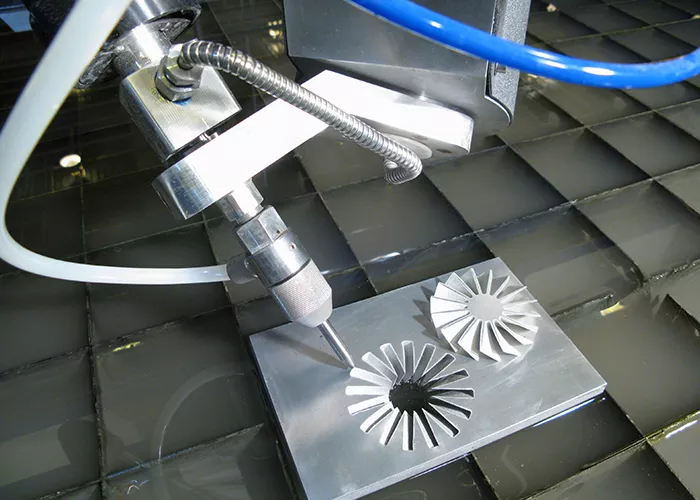

Waterjet Cutting

Plasma Cutting

Sheet Metal Prototyping

Sheet Metal Fabrication

Micro Waterjet Cutting

Sheet Cutting Service Provider

We have a talented team, state-of-the-art equipment, and years of industry experience. The Elimold team is focused on providing high-quality, custom metal products, providing you with a full range of services from design to order execution. Our investment in advanced sheet cutting technology reflects our determination to enhance and improve the quality of customer service. As a result, we can serve a wide range of OEM manufacturers who want to outsource their manufacturing operations through trusted contract manufacturing services. Our high-quality workmanship enables us to provide tight tolerance parts that meet the most demanding requirements of our customers. In addition, precision metal cutting is our foundation, and our metal cutting experts are constantly improving their methods to ensure the quality and precision our customers require. Consistent cutting results require mastering many variables. In the field of metal cutting, we integrate technology, tools, equipment and methods every day to achieve precise and repeatable results.

How do laser cutting and water jet cutting differ?

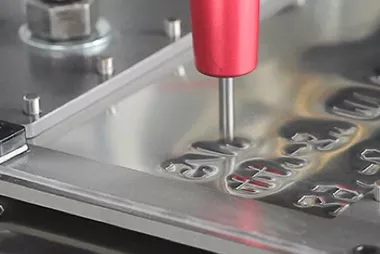

Laser cutting is the most common form of blanking, which is the creation of a contoured cut of a two-dimensional shape in a common material. It uses a laser to concentrate heat and carve a path through the material. The thickness of the carved path is called the kerf, and is typically less than 0.010 inches. Unlike lasers, water jet cutting takes advantage of the fact that water is incompressible, so when a thin stream of water is ejected from a nozzle at very high pressure, it can cut almost anything.Waterjets have an advantage when cutting certain thicker metals because they do not generate excessive heat, which can affect hardness. Waterjets can cut kerfs from 0.040 inches to 0.050 inches thick, but both waterjets and lasers have the same general tolerance of +/- 0.010 inches. Compared to lasers, waterjets are better suited for soft materials such as foams or gaskets because they do not compress or burn. This is also important for materials such as PVC, PC, and even galvanized metals, which can only be cut with waterjets to avoid exposure to high temperatures that can create harmful fumes such as fluorine, chlorine, or zinc. Lasers offer the advantages of speed and availability, as they can process most plastics and thinner metals quickly and deftly. Lasers are also used for engraving and part marking.

Design Tip: Minimum Feature-to-Feature Distances for Laser and Waterjet Cutting

Feature Description (MT = Material Thickness)

- Minimum Hole to Edge Distance = 2X MT or 0.125”, whichever is smaller

- Minimum Hole to Hole Distance = 6X MT or 0.125”, whichever is smaller

- Minimum Relief Cuts = 0.010” or 1X MT, whichever is greater

- Minimum Corner Fillets = 0.5X MT or 0.125”, whichever is smaller

- Minimum Tab Thickness = 0.063” or 1X MT, whichever is greater

- Minimum Slot Thickness = 0.040” or 1X MT, whichever is greater

Quality and Service You Can Trust

Elimold offers a wide range of plate cutting services to meet a variety of manufacturing needs. We have advanced technology, extensive expertise and extensive experience to ensure that every product we produce is of high quality. You can be assured that we have the knowledge, quality and skills required to entrust you with the development of your products. We are committed to providing excellent results and are able to handle every step from concept to creation with the utmost care and attention to detail. We work hard to control the quality of each production step, but our quality department has the final say on whether a part is shipped, or needs to be scrapped and re-cut. Once your parts have been inspected and approved, they will be packaged, labeled and boxed. Each shipment you receive will include a packing list listing which parts are packed in each box.

Choose Lead Time and Shipping

Once you work with Elimold on a custom sheet cutting parts project and confirm full package pricing, you can choose your lead time and shipping options. Depending on the size of your job, available materials, and capacity, we can offer lead times as fast as same-day delivery. Please select the lead time option that best fits your time and budget. Standard lead time for prototypes or low-volume laser cut parts is 2 business days (at no additional charge).

Ready to Get a Sheet Cutting Quote?

If you need precision plate cutting services to support your project, the Elimold team can help. We can handle projects of almost any size, quantity, material, thickness and design and look forward to speaking with you. Please leave a message and we will contact you as soon as possible.

What is Sheet Cutting?

Sheet cutting is a category of processes that slices into flat stock material following a profile to produce a shape. Sheet stock is cut using a high-powered CNC laser or waterjet. The material’s gauge determines the thickness of the part. From a one-off batch to mass production, custom designs can be cut in various materials ranging from plastics, elastomers, composites, metals, and more. Sheet cutting is also typical for blank preparation in other manufacturing processes like sheet metal fabrication or metal stamping.Elimold’s sheet cutting service can cut just about any material using lasers and waterjet capabilities. From clear acrylic panels to thick tool steel, Elimold’s manufacturing marketplace offers a one-stop-shop solution for any project with instant quoting and a wide selection of materials.

Sheet Cutting Materials

Our team works with an array of metal options in our plate and sheet metal cutting services, allowing us to create diverse products per our clients’ specifications. The metals we cut include, but are not limited to:

- Alloys

- Aluminum

- Carbon steel

- Inconel

- Monel

- Stainless steel

- Steel

Surface Finishing Options

In addition to polishing surfaces to a smoothness of Ra 0.010 µm, Elimold also offers a range of custom metal finishing services as final preparation for parts after cutting. Complying with the latest ASTM A967 standards.

- Painting

- Powder Coating

- Anodizing

- Plating

- Galvanizing

- Brushed Finish

- Polishing

- Bead Blasting

- Laminating

- Embossing

- Etching

- Passivation

- Vinyl Coating

- Brush Finish

- PVD Coating

- Heat Treating

Value-added Services

In addition to our sheet metal cutting services, we can provide a variety of value-added services, including punching, undercutting, forming, threading and engraving. Our sheet metal punches do it all with precision, and all tools can rotate 360 degrees. We can also provide hollowing. Perforation. Beading. Imprinting your logo. It’s up to you. Whether you need threading, stamping or special cutting, we can meet your needs.

Industries We Serve

In this way the pieces are ready to be used in a variety of sectors:

- Aerospace

- Agriculture

- Construction

- Contract manufacturing

- Energy

- Military

- Mining

- Electro-Mechanic

- Medical

- Robotics

- Lighting Fixtures

- Home Appliances

- Vending

- Gas Distribution

Why Choose Elimold for Your Next sheet Cutting Project?

Elimold is a top provider of sheet cutting services. There are many reasons why customers choose Elimold for their next plate cutting project. First, Elimold has many years of experience in this industry, which means we have refined our processes, allowing us to produce high-quality and precision parts. Second, we have state-of-the-art equipment and facilities that allow us to process a wide range of materials and thicknesses. Third, Elimold is committed to customer satisfaction, which is reflected in fast turnaround times, competitive pricing, and the ability to produce custom parts to meet unique customer needs. Finally, Elimold has a team of experienced engineers and technicians who work closely with customers to ensure their needs are met and successful. By choosing Elimold, customers can be assured of receiving the highest quality sheet cutting services.

Other Types of Sheet Metal Fabrication Services

Sheet metal has a wide range of applications in different manufacturing fields. But how do you make your sheet metal parts? Sheet metal parts need to be custom according to your needs. This is where our engineers can help you. We can provide the following sheet metal manufacturing processes to help you custom sheet metal parts.

Punching

Stamping

Die Cutting

Bending

Welding

Extrusion

Embossing

Forming

Riveting

Request Your Free Sheet Cutting Quote Today

After receiving your drawings, our engineers will analyze your custom Sheet Cutting parts right away. We actively work with you to clarify all details before providing a quote that is both economical and accurate.