Sheet Metal Bending Services

We provide custom sheet metal bending services to exceed customer expectations at competitive prices. From prototype design to sheet metal bending manufacturing, we rely on our experienced team and advanced production equipment to ensure that you get high-precision, stable sheet metal bending parts. Free sheet metal quotation and DFM review within 1 day. The fastest delivery cycle is 3-5 days.

Metal Bending Manufacturers

At Elimold, we are experts in metal bending. We offer metal bending services from low-volume prototypes to high-volume production. We can cut and bend any type of sheet metal to create durable products. We have advanced sheet metal processing equipment to produce both functional prototypes and end-use products. Whatever part you need, Elimold has a cost-effective and customizable solution to meet your manufacturing needs. We use the same cutting-edge technology as other companies without sacrificing excellent customer service. We promise to work with you to create products that exceed your expectations.

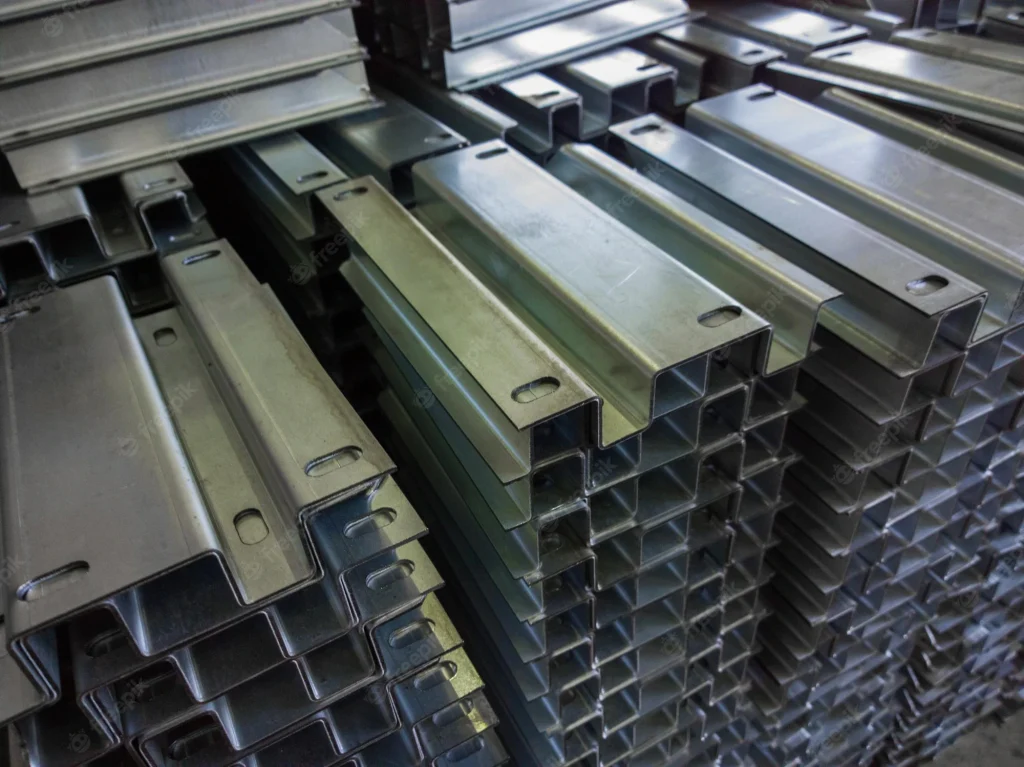

Metal Bending Shop

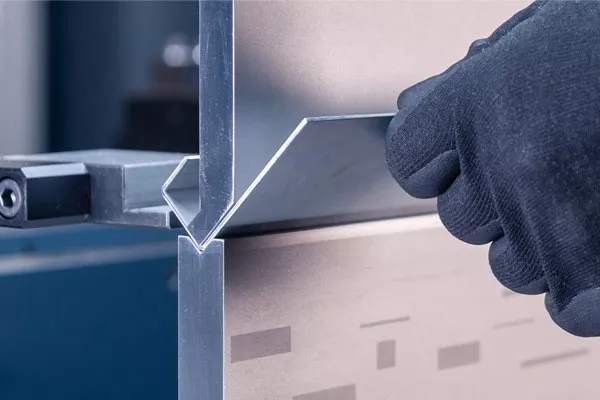

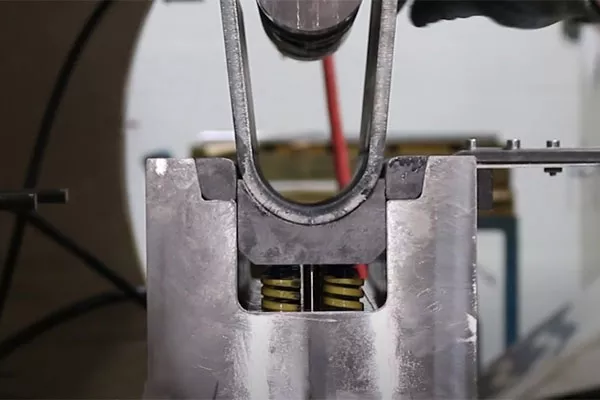

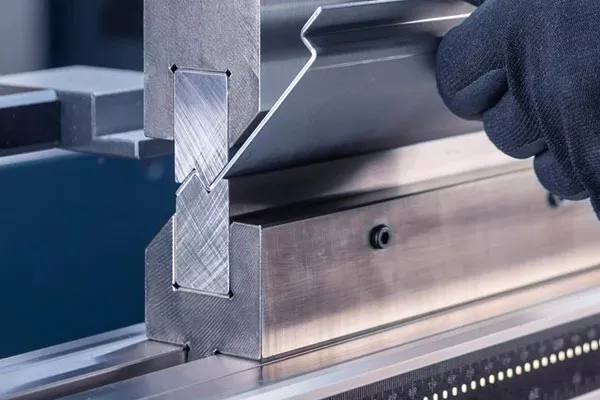

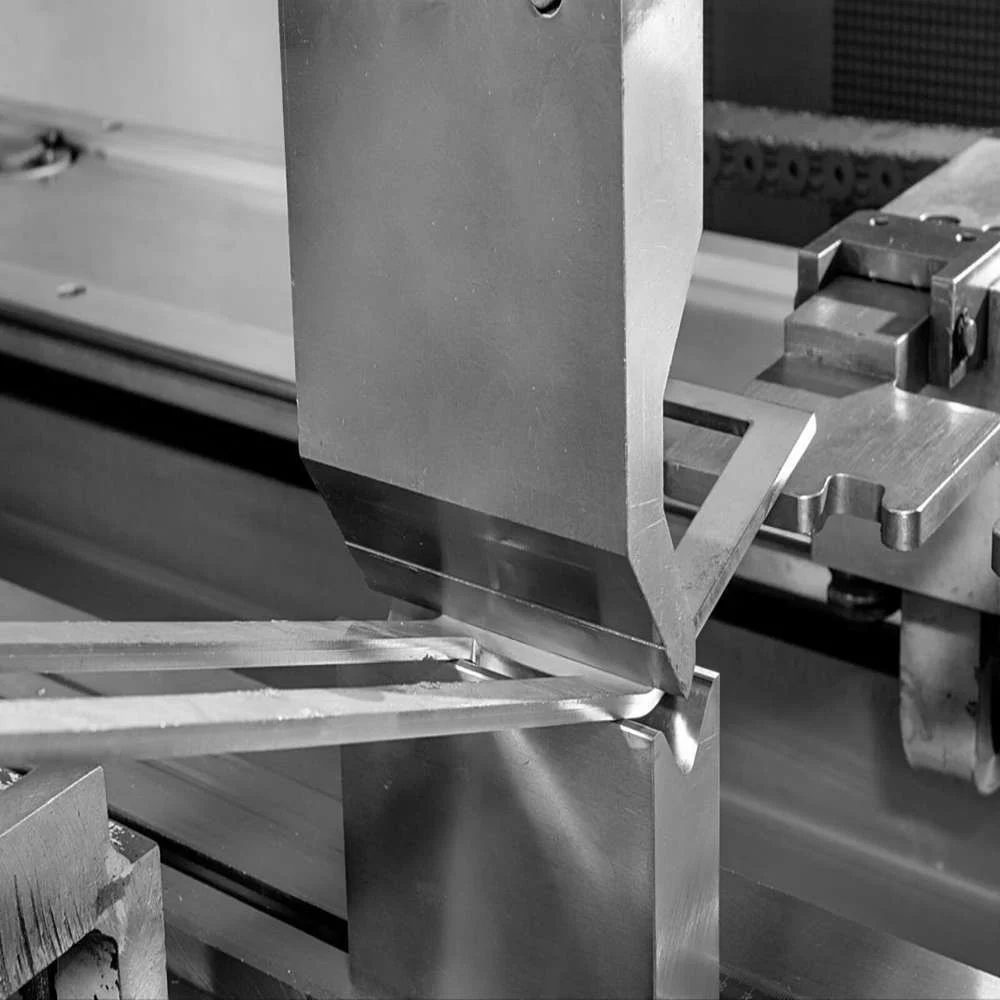

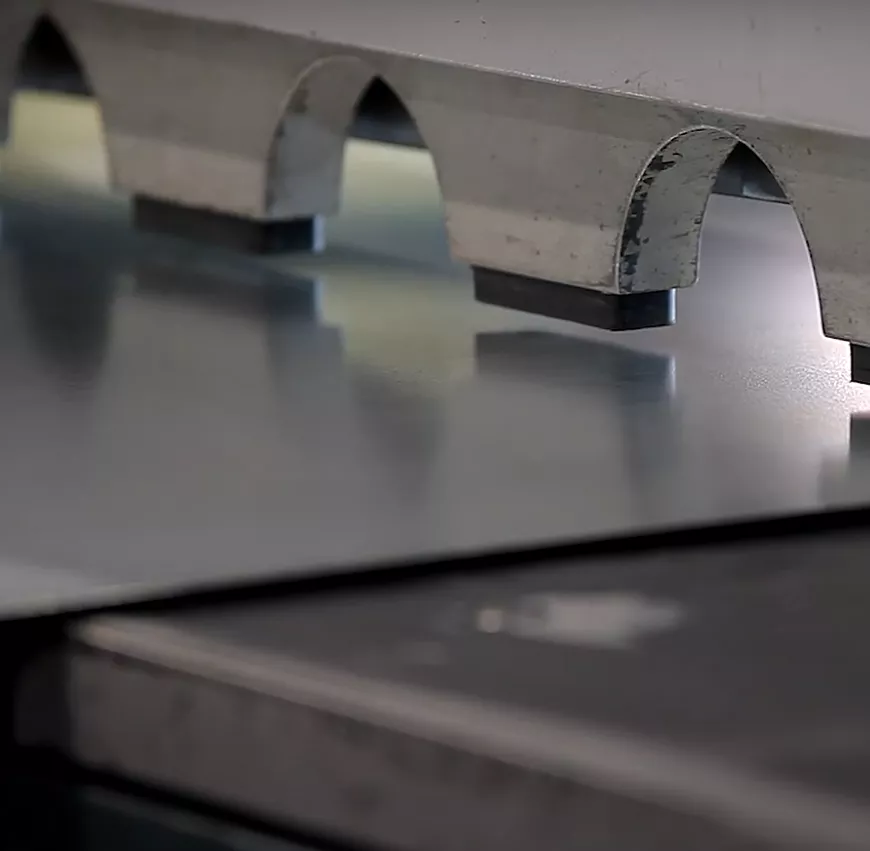

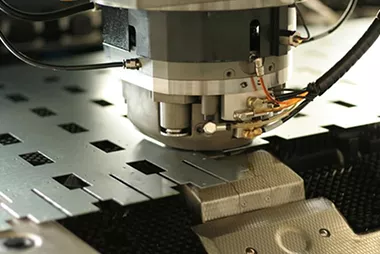

The metal bending process converts flat sheets into 3D shapes by applying precise forces, using advanced mechanical equipment to bend at specified angles. Before bending, the flat sheets must be pre-processed using cutting methods such as laser cutting to ensure high precision. At Elimold, our 30,000 square foot sheet metal fabrication facility has more than 100 skilled employees and a core engineering team with more than 15 years of experience. We are committed to providing precision sheet metal processing and custom manufacturing solutions to innovative companies around the world. Our processes use high-tonnage equipment with a maximum load capacity of up to 200 tons and can handle materials up to 3200 mm in length. Each bend is performed using precision tooling from R3 to R50 to ensure processing tolerances within ±0.1 mm. Elimold’s team is able to provide high-quality, professional steel and metal forming services for a variety of materials. Depending on the type of metal you are using and the size of your project, our team uses a variety of metal forming technologies, so we provide custom metal bending services that can provide customized solutions with high precision and consistency.

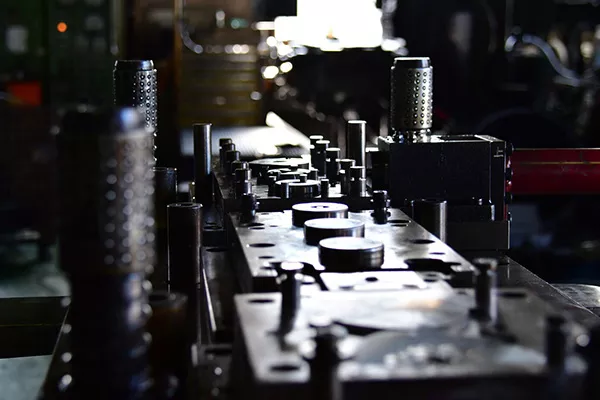

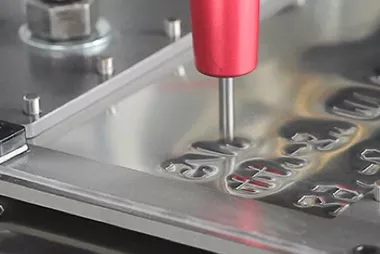

In-house Metal Bending Die Manufacturing Capabilities

Elimold has invested heavily in an in-house die manufacturing shop with advanced manufacturing equipment and a team of fast-response die design and manufacturing engineers, enabling us to quickly deliver the parts and quantities you need. If the die is designed and manufactured by us, all metal bending dies are produced in our in-house die manufacturing facility with advanced processing equipment. Elimold’s responsibility is to ensure that your order is completed on time, and our team will perform DFM analysis for your project before the die is opened and promptly inform you of any problems that your design may encounter in mass production. Our in-house sheet metal bending die manufacturing capabilities can save you time and cost in die modification.

Precision Bending

With backgauge positioning with an accuracy of +/- 0.0001 inches, real-time material thickness measurement and compensation, and high-precision punch placement, our equipment produces parts with a high degree of accuracy and repeatability, with a standard bend angle tolerance of +/- 1.0 degrees.

Precision is not just a goal, it is a guarantee. Our advanced sheet metal bending services combine cutting-edge CNC technology with superb expertise to provide bends to your exact specifications, ensuring high-quality custom sheet metal parts are delivered with precision and efficiency. We pride ourselves on being able to deliver custom metal parts quickly and efficiently. Whether you are working on a small complex part or a large project, Elimold’s expertise in tight tolerances and large sizes ensures that your sheet metal bending needs are met with precision and excellence. Our commitment to quality and attention to detail make us a trusted partner in sheet metal fabrication.

One-Stop Sheet Metal Bending Services

Working with us gives you full control over your needs and a customized experience. For example, you can choose to send us your own metal materials for bending, or we can provide the materials you need. If the metal parts are too large, we can also cut them to the size you want and bend them with a press brake. The unique advantage of our sheet metal bending services is that we can bend metal up to 32 feet long cleanly. Our flexible services, coupled with responsive customer service, will bring you the best results and experience for your project. As a true one-stop sheet metal bending shop, orders are delivered complete and ready for assembly with sheet metal bending services. With comprehensive in-house analysis services, sourcing high-quality, accurate parts has never been easier.

Get instant pricing for bending now!

All it takes is a quality design, a few days, and a little bit of our manufacturing magic to bring your ideas to life. Get started today with instant pricing.

Sheet Metal Bending Process

There are many different types of metal bending techniques, and the correct bending procedure depends on the material and thickness of the sheet metal that needs to be bent. Our team will also analyze your project needs and determine the best method to achieve the best results. The basic types of metal bending that Elimold can perform include:

Air Bending

Bottom Bending

Hem Bending

Large Radius Bending

V Bending

U Bending

Z Bending

Roll Bending

Coining

Wipe Bending

Rotary Bending

Step bending

Prototypes and Low Volume Production

At Elimold, we are dedicated to meeting all of your bending needs, no matter how big or small. We understand the importance of rapid prototyping and low-volume production for product development and testing. With our expertise in metal bending, we can help you efficiently create prototypes and produce low-volume production runs. Our team works closely with you to ensure precise bending specifications, allowing you to evaluate and refine your designs before committing to large-scale production. With no minimum order quantity, we can support you from a single prototype to a large-volume production run. We are committed to providing consistent, high-quality service for orders of all sizes.

Engineering Design & Manufacturing Services

Accuracy is critical when designing sheet metal bending parts. Elimold understands the challenges that can arise during the design phase and offers a streamlined drawing creation service to assist you. Our team of experts can review your design to ensure it is suitable for bending and make any necessary adjustments. This collaborative approach saves you time and ensures your parts are manufactured correctly from the start.

We specialize in providing you with excellent sheet metal bending, fabrication, and welding services to help you get the job done right. We offer complete manufacturing and assembly services for medium to large volume orders. You can also contact our engineering team for prototyping and first-article projects.

Fast Turnaround Time

Delivery time for sheet metal bending depends on the size and complexity of the project, and we can deliver in as fast as 2-4 weeks (expedited fees may apply). We are committed to providing fast and efficient service, ensuring timely delivery and maintaining communication with you throughout the process. Elimold has the ability to minimize the turnaround time for even the most complex projects with an experienced team of skilled sheet metal craftsmen, advanced equipment, computer-based processes, efficient internal procedures, and strong office and shop management. In addition, we also provide emergency services to provide you with the custom sheet metal bending parts you need in a short period of time.

Ready to get started on your metal bending quote?

When you choose Elimold, you get a trusted partner who values speed, quality, flexibility and collaboration. We will help you turn your ideas into tangible parts and components, laying the foundation for a successful product launch or mass production.

On-Demand Custom Metal Bending Services

The design of precision bent parts can be complex. During the bending process, radius, K factor and part geometry are limited by the factory tooling and materials. The final design often requires long back-and-forth communication with the factory, which increases costs and lead times. Elimold takes a unique approach to bending to meet the needs of our customers, whether it is a simple or complex design. From drawing to delivery, you can choose the right metal bending process according to your needs without having to do it yourself. Our on-demand manufacturing services are designed to reduce downstream processes and simplify assembly, further improving efficiency. Our capabilities are not limited to bending; we also provide a wide range of post-processing options to ensure that the parts you receive are not only perfectly bent, but also ready for use in prototypes or final products.

Quality Control and Inspection

At Elimold, quality is at the heart of everything we do. We implement a multi-level quality control program to ensure that every part produced is up to specification and meets industry standards. From dimensional control to surface quality control, we guarantee that your product will always be in top condition. Therefore, after the bending process is completed, all parts are quality checked to ensure that all specifications and requirements are met. To check the size, angles and surface finish of the parts, our quality control team uses advanced sheet metal bending tools to ensure that the parts meet the quality specifications of international industrial standards and customer expectations.

Quality Testing standards for Sheet Metal Bending Services

Bend Performance Analysis

Forming Limit Diagram (FLD)

Tests the material’s ability to withstand deformation without failure or cracks.

Material Flow Test

Optical Strain Measurement /Digital lmage Correlation

Measures how the material flows during bending,ensuring uniform deformation.

Residual Stress Measurement

X-ray Diffraction/Neutron Diffraction

Tests the residual stress patterns in the material after bending,impacting part durability.

Heat-Affected Zone (HAZ) Testing

Metallographic Analysis / Microscopy

Examines the microstructure changes in the material after bending, especially when heated during forming.

Surface Integrity Testing

Surface Profilometer/Microscopy

Measures any micro-cracks, scratches, or deformations in the surface after bending, which could affect functionality.

Angle Reversal Test

Digital Protractor/coniometer

Measures the precision of angle reversals after bending, ensuring consistent results in multi-axis bending.

Bend Fracture Testing

Microscopic Crack Analysis

Detects cracks or fractures at the bend area under high magnification, ensuring the integrity of the bend.

Tensile Strain Localization

Strain Gage/Digital lmage Correlation

Tests the localization of strain around the bend zone to ensure uniform distribution of deformation.

Elastic Modulus Measurement

Stress-Strain Curve /Tensile Test

Measures the material’s ability to return to its original shape after bending, impacting part flexibility.

Work Hardening Rate

Stress-Strain Testing

Tests the material’s resistance to deformation, ensuring it doesn’t weaken excessively during bending.

Bend Orientation Test

Optical lmaging /Digital Protractor

Evaluates how material behaves when bent along different axes (e.g., longitudinal vs.transverse), ensuring flexibility in design.

Bend Geometry Verification

3D Scanning/Laser scanning

Ensures the 3D geometry of the bent part matches the design specifications with high accuracy.

Intergranular Corrosion Testing

Electrochemical Testing /Salt Spray Test

Ensures that the material can resist corrosion along grain boundaries after bending, especially for high-alloymetals.

Sheet Metal Bending Material Options

Elimold offers a wide range of sheet metal bending capabilities. Our experienced team can bring your designs to life using a wide range of materials, from standard steels to aluminum alloys to specialty alloys. We have the equipment and expertise to meet your sheet metal needs, no matter their complexity or material. If your project requires a material that is not on the list, let us know! We can accommodate other material needs, but quotes may take more time while we source the materials.

- Aluminum

- Steel

- Stainless Steel

- Brass

- Copper

- Titanium

- Zinc

- Nickel

- Bronze

- Galvanized Steel

Surface Finishing Options

Reasonable surface treatment of metal parts can improve the durability, corrosion resistance, heat resistance, conductivity and decorative appearance of the material. Below are some of the surface finishing options we provide. If you need special surface finishing options, please contact us.

- Mirror polishing

- Wire drawing

- Galvanizing

- Anodizing

- Black oxide coating

- Chrome plating

- Machining

- Electroplating

- Powder coating

- Sandblasting

- Laser engraving

- Pad Printing

- Heat Treat

- Broaching

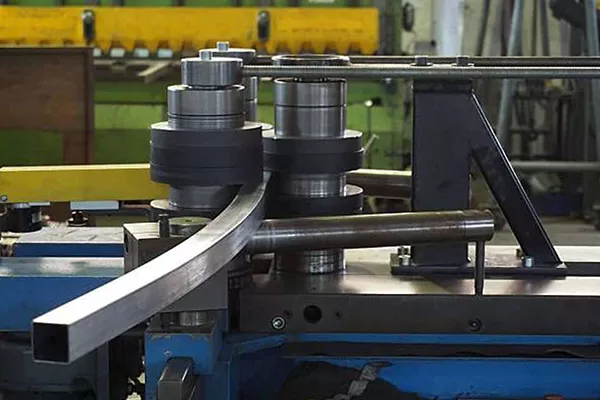

Sheet Metal Bending Technologies and Shapes

As a full-service manufacturing company, one of Elimold’s many specialties includes custom metal bending of pipe, bar, beam, and tubing. We can take your custom prototype or design and turn it into a reality based on your specific project and needs. Our talented staff has an average of nearly ten years of experience and prides itself on maintaining an unparalleled level of quality. Your product will be precisely formed, delivered on time, with minimal distortion and consistency. Our experienced and skilled metal bending machines are capable of handling a wide range of different materials. No matter what the material is, we can bend it to the desired shape and radius based on your needs.

Tube Bending

Rectangular Tube Bending

Bar Bending

Beam Bending

Channel Bending

Pipe Bending

Structural Steel Bending

Mandrel Bending

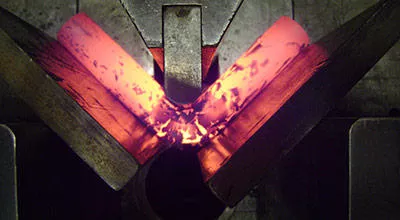

Hot Bending

Bulb Flats

Angle Bending

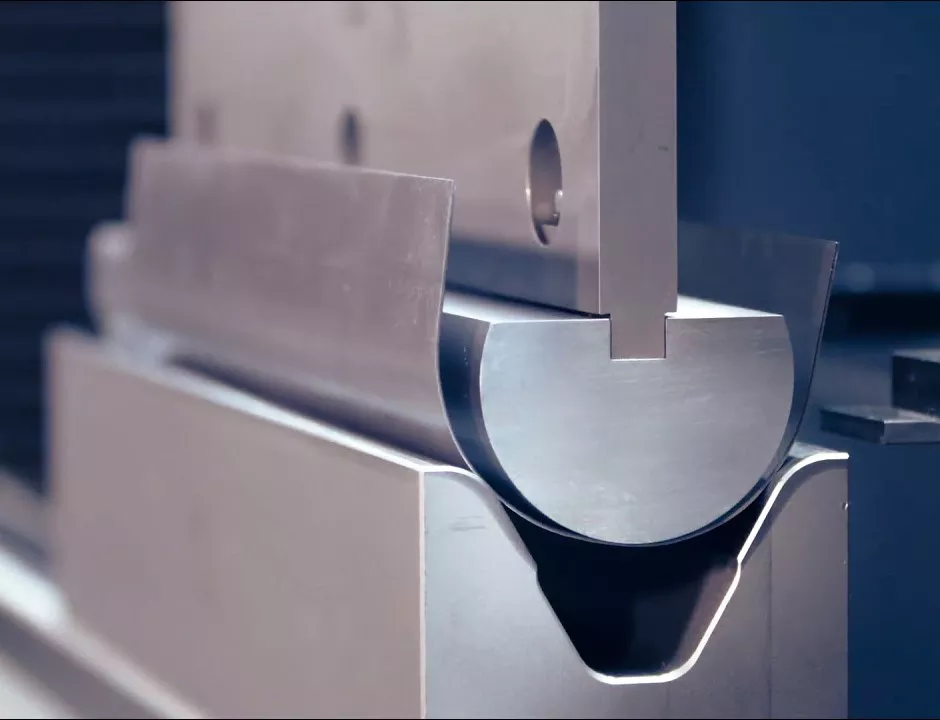

What is Sheet Metal Bending?

Sheet metal bending involves shaping a sheet of metal into a desired shape or angle by applying force at specific points, creating a permanent bend or arc. It is a standard metal forming process that requires the use of a variety of tools and machines to manipulate the sheet metal. During the bending process, the sheet metal is typically clamped between a punch and a die, and then pressurized to bend it to a specific angle. The amount of force required to achieve the desired bend depends on a variety of factors, including the type of metal used, the thickness of the sheet, and the angle of the bend.

There are a variety of methods for bending metal, including air bending, bottom bending, stamping, roll bending, and V-bending. Each technique has its own unique advantages and can be selected based on the specific circumstances of the project. After bending, technicians use a variety of processing techniques, such as trimming and cutting, to remove excess material.

Metal Bending Advantages

While welding is inevitable in many cases and bending cannot substitute it everywhere, we recommend choosing metal bending services whenever possible. The advantages of metal folding are:

- Aesthetics: Although in engineering functionality comes first, design follows closely behind. The lack of weldments guarantees a nice visual for your project.

- Coating: A smooth surface is a great canvas for coating procedures, leaving a better result.

- Fewer mistakes: Welding needs more manual labour. Manual labour, in turn, leaves more room for mistakes. Automatic CNC bending systems provide accurate results.

- Fewer parts: It is more convenient to re-work your parts in CAD, if needed. But it’s also easier to keep your workfloor nice and tidy with fewer parts laying around.

Industries We Serve

At Elimold, we support diverse industries with our metal bending services, including:

- Agriculture

- Architecture

- Chemical

- Construction/cranes

- Defense

- Energy

- Marine

- Mining

- Transportation

- Trailers/truck bodies

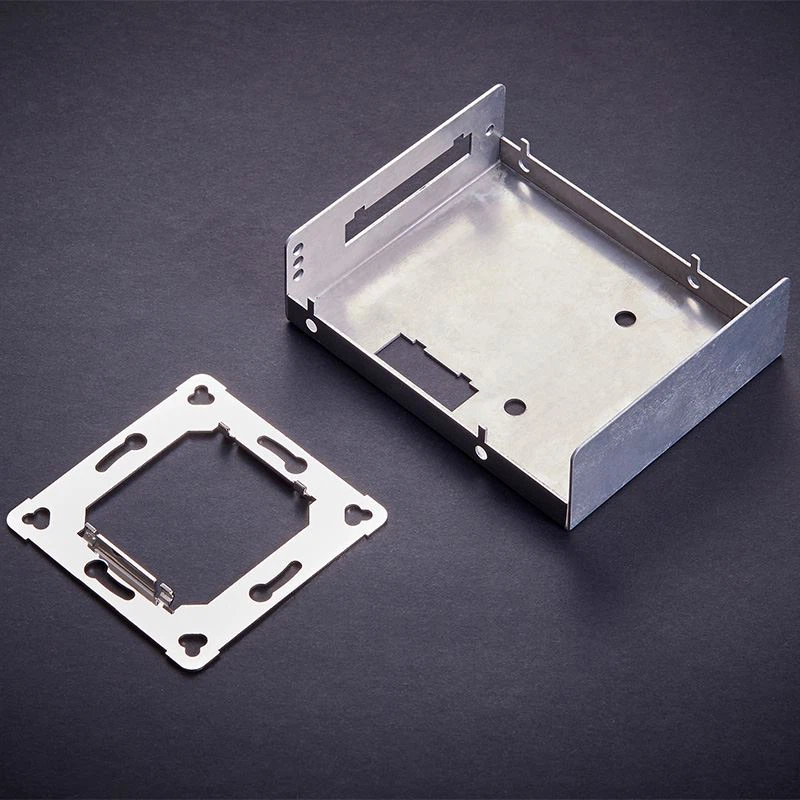

Our Sheet Metal Bending for Various Applications

Elimold is always committed to developing new technologies to meet the needs of various industries. We are well aware of the changing needs of our customers and the range of industries we serve is constantly expanding. No matter what industry you are in, we can provide the necessary equipment and skilled workers to accurately and reliably meet your needs.

- Brackets

- Enclosures

- Chassis

- Panels

- Clips

- Mounting plates

- Housings

- Flanges

- Ducts

- Frames

- Gussets

- Covers

- Boxes

- Channels

- Trays

- Hangers

- Louvers

- Cabinets

- Shields

- Reinforcements

- Bezels

- Stiffeners

- Knockout panels

- Transition pieces

- Cable trays

- End caps

- Filter frames

- Battery holders

- Pedestals

- Vent covers

Other Metal Fabrication Services

Elimold has been providing quality bending and sheet metal fabrication services to customers around the world. We offer a wide range of services, from simple repair and fabrication projects to complex custom fabrication projects with special specifications that require specialized equipment. Our team of experts has the skills and experience to complete the work on time and on budget. For our team, no matter how big or small the project is, we can meet all of your fabrication needs!

Laser Cutting

Plasma Cutting

Punching

Stamping

Die Cutting

Forming

Welding

Extrusion

Embossing

Why choose Elimold for your next sheet metal bending project?

Elimold is a top sheet metal production company that can provide high-quality services for your next project. With years of experience in the industry, we have become a trusted partner for clients from a wide range of industries. Our company uses state-of-the-art equipment and technology to ensure precision and accuracy in our sheet metal bending services. We also have a team of experienced and skilled professionals who can provide guidance and support at every step of the process. Our company’s commitment to quality, competitive pricing, and on-time delivery make us an excellent partner for any sheet metal project, from prototyping to mass production. Ultimately, choosing us means working with a trusted partner who will help you achieve your project goals efficiently, effectively, and maintain the highest quality.

Request Your Free Sheet Metal Bending Quote Today

After receiving your drawings, our engineers will analyze your custom Sheet Metal Bending parts right away. We actively work with you to clarify all details before providing a quote that is both economical and accurate.