Sheet Metal Forming Service

Elimold specializes in sheet metal forming, providing precise, efficient and cost-effective solutions to meet your unique needs. With advanced technology and an experienced team of experts, we are able to provide high-quality metal processing results that meet the most stringent industry standards. Our professional sheet metal services can help you transform your designs. Get a quote now and save more on your project!

Sheet Metal Forming Manufacturer

Elimold provides high-quality custom sheet metal forming services to a wide range of clients, meeting their diverse and demanding needs. Services range from prototypes to short and long production runs. We have developed unique, cost-effective and breakthrough technologies to better serve our customers. In addition, our in-house facility features advanced sheet metal forming equipment, CNC programming, and a team of highly trained and skilled craftsmen to provide customers with products of excellent quality, on-time delivery, and at competitive prices. In addition to our strong technical capabilities, we are also proud of our commitment to customer service. From the initial consultation to the final product delivery, we work closely with you to ensure clear communication and a deep understanding of your project needs. Our flexible approach allows us to accommodate small and large-scale production runs, providing reliable delivery times and competitive prices. When choosing our sheet metal forming services, you will gain a partner committed to providing excellent quality and value to help you achieve your manufacturing goals accurately and efficiently. You can trust our company to provide fast, accurate quotes and engineering solutions for all your sheet metal forming needs.

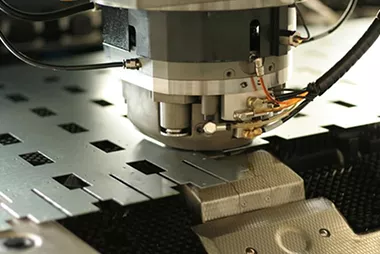

Elimold's In-House Sheet Metal Forming Manufacturing Facility

At our 30,000 square foot sheet metal facility in Shenzhen, China, our team is able to provide high-quality, professional steel and metal forming services for a wide range of materials. Our in-house facility features advanced equipment to produce custom metal molds and components. In addition, our expert machinists are dedicated to ensuring that the products we deliver are of the highest precision. Our goal is to create unparalleled results. Our experienced engineering team is able to handle all aspects of the sheet metal forming and bending process, including design, manufacturing, assembly, and surface treatment. We provide more than just metal forming services, we provide a one-stop service to ensure that the final product exceeds your expectations. And our passionate team of engineers will provide you with guidance on product design, surface treatment, welding, and many other aspects of the sheet metal forming process. From concept to finished product, we will ensure that every step meets your needs and ensures that the final product you are proud of and satisfied with.

Precision Metal Forming Capabilities

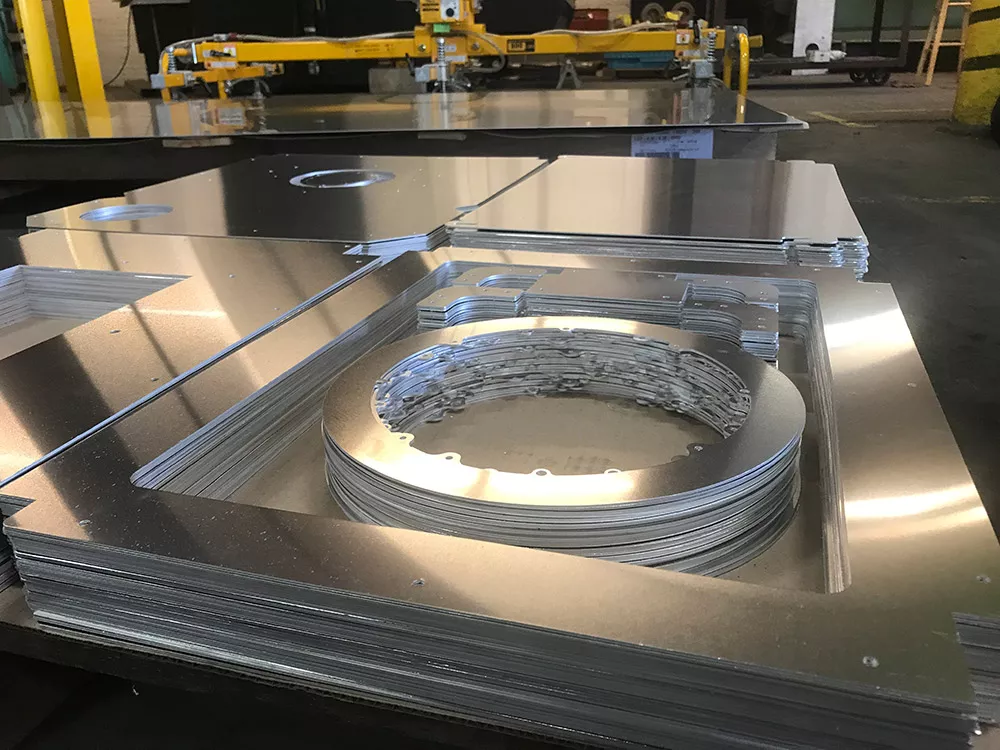

We offer metal forming services up to 34 feet long and up to 1.5 inches thick, with a maximum thickness of 6 inches. Depending on the specification, we can meet tolerances of +/- 0.005 inches and +/- 0.010 inches, depending on the characteristics required. Our standard delivery time is one week. Expedited delivery can be completed in as little as one day.

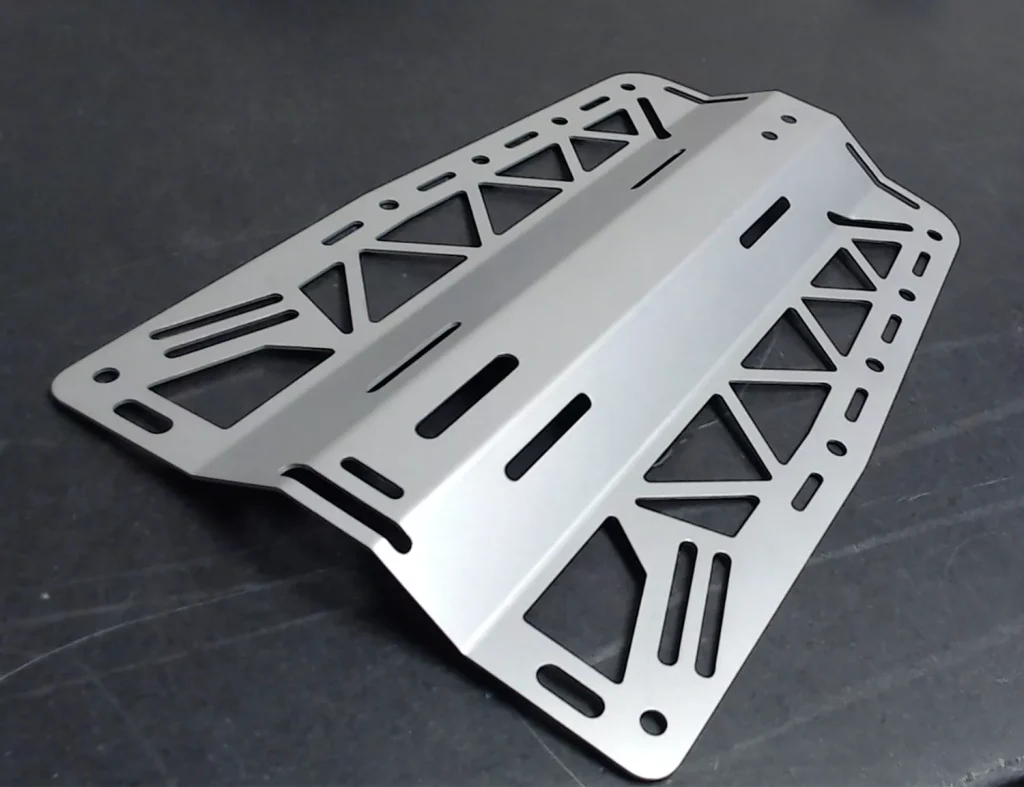

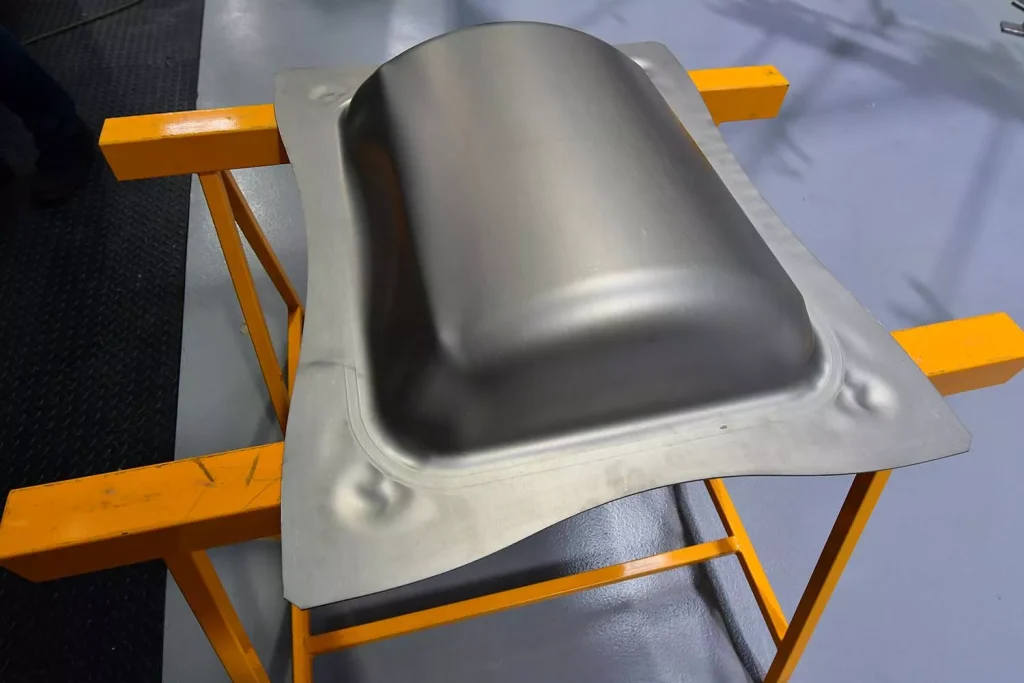

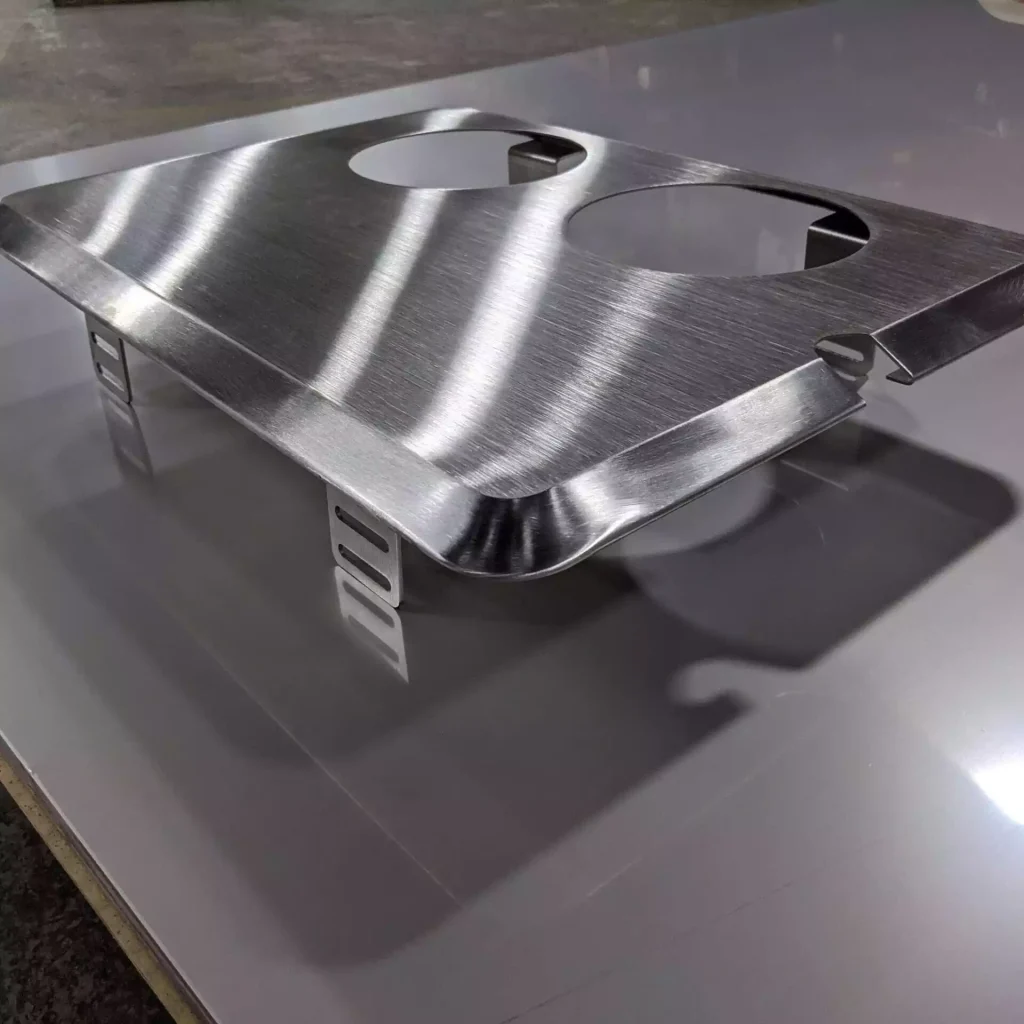

Our experienced team and in-house facility are fully equipped to handle any of your sheet metal forming needs. Our state-of-the-art equipment allows us to easily stamp, coin, bend, and form your metal parts. So, no matter what type of part your project requires, we have the expertise and resources to meet all of your needs. From the most delicate sheet metal to thicker and more complex sheets, we have the necessary tools and machinery to ensure that each part is perfectly formed. Our advanced tooling and CNC machines allow us to precisely form each part, ensuring that your project meets the highest standards of quality and precision. No matter how complex your sheet metal forming project, you can trust the experts at Elimold to get the job done perfectly, every time.

In-House Sheet Metal Forming Die Fabrication Shop Capabilities

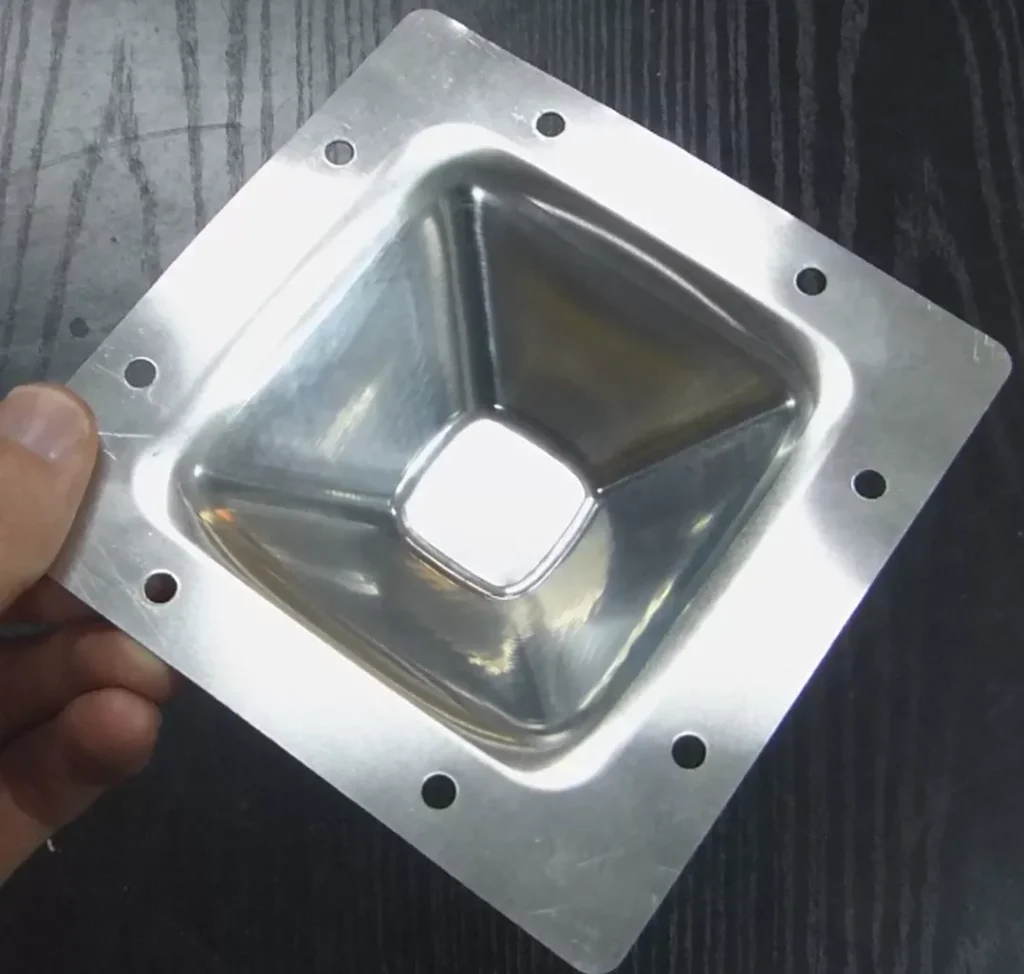

In the world of sheet metal forming, custom forming is an important technique for creating parts with specific shapes and properties. At Elimold, our forming services are able to guarantee precision and repeatability, ensuring that each part meets the specifications required for your project. This saves time and cost in rework and improves the overall functionality of the final product. In addition, our in-house die fabrication capabilities allow us to quickly design and manufacture custom dies for unique formed sheet metal projects, providing a cost-effective solution for special parts. With a combination of expertise and advanced equipment, we are able to provide high-quality forming services that add value to your project.

Our in-house facility can provide metal forming services from 250 to 250,000 pieces, and we offer an exclusive lifetime die preservation service. Elimold’s in-house die fabrication shop is known for providing high-quality dies, from the simplest shapes to the most complex custom stampings. This makes Elimold an ideal partner for almost any metal forming project. Our extensive experience, advanced precision forming equipment, and extensive die inventory provide us with everything we need to create quality parts and products that meet or exceed the most stringent customer specifications and standards.

High-Speed, High-Volume Metal Forming Service

Elimold offers a full range of metal forming services with fast delivery. We manufacture all of our tooling in-house to ensure quality and lead time control. Our forming systems feature simple tooling that is built quickly and economically. We are able to deliver metal forming projects quickly, knowing that our customers are often working to tight deadlines and tight deadlines. Our equipment is built to exacting tolerances and supports highly repeatable manufacturing processes. Our batch sizes range from single pieces to over 5,0000 pieces. Our carefully crafted manufacturing processes have proven to be more cost effective than metal stamping or plastic tooling, even for shipments well in excess of 5,00000 pieces. By streamlining the sheet metal forming process, Elimold is able to complete high volume orders with amazing speed and quality. Our extensive metal forming equipment and experienced operators ensure exceptional precision on every project.

Types of Metal Forming Services

Elimold offers a wide range of metal forming services. Whether you need a simple custom part or a complex part for a special project, we have earned a reputation for being able to do projects that many other manufacturers are reluctant to complete. Depending on the type of metal you are working with and the size of your project, our team utilizes a variety of metal forming techniques:

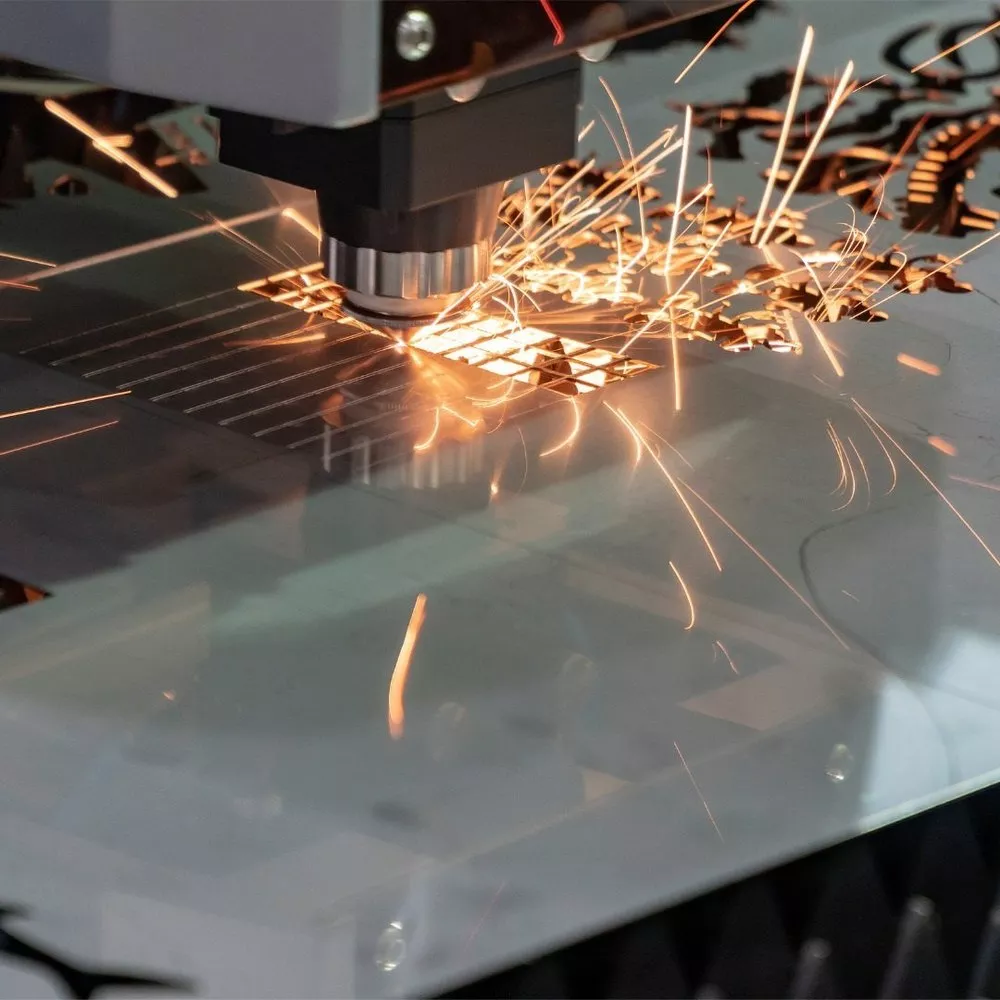

Laser Cutting

Plasma Cutting

Punching

Stamping

Die Cutting

Bending

Welding

Extrusion

Embossing

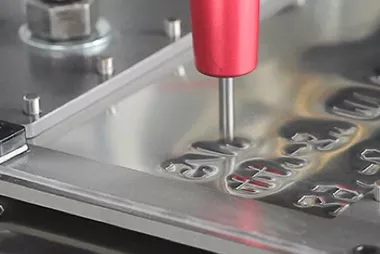

Digital Sheet Metal Forming Services and Capabilities

Elimold offers high-quality sheet metal forming services for a wide range of custom metal projects. With thousands of projects under our belt over the years, we are trusted for our superior workmanship and extensive industry knowledge. Digital Sheet Metal Forming (DSMF) is one of the latest advancements in our field, and it offers many benefits to companies looking to streamline their production processes and reduce manufacturing time. Compared to traditional sheet metal manufacturing methods, the benefits of DSMF include shorter lead times, faster production, no need for expensive tooling and die manufacturing, and a lower overall cost compared to traditional part stamping processes. Additionally, digital sheet metal forming has virtually no minimum order quantity (MOQ) restrictions, meaning it is ideal for unique projects and rapid sheet metal prototyping.

Ready for a free quote?

We proudly serve locations around the world. It only takes a minute! Select the services you would like, upload your design, and one of our team members will get back to you with a free quote as soon as possible. If you don’t have a design mockup, or need some help with your design, we’d love to help! Simply contact us and one of our team members will be happy to answer any questions you may have.

Sheet Metal Forming Solutions

Traditional sheet metal forming is often a laborious and time-consuming process. Thanks to Elimold’s significant advancements in technology and the integration of digital tools, what used to take days or even weeks can now be done in just hours.

At Elimold, we proudly own and operate the most advanced digital sheet metal forming systems in the world. Our process is simple: select materials according to customer specifications, cut to size, upload digital files, and leave them to our advanced forming systems. Think of it as printing a component exactly as you requested, or even better than expected. With our systems, there is no room for human error, no long waiting periods, and no calculation errors.

Currently, global customer demand for first-class, accurate, and efficient sheet metal components continues to surge. To meet this demand, Elimold has designed a sheet metal manufacturing system designed to optimize the production of complex precision components. Our system perfectly combines innovative technology with intelligent automation to improve efficiency, precision, and versatility. With a user-friendly interface and rugged construction, our sheet metal manufacturing system is a full-service solution to meet your diverse sheet metal manufacturing needs. By implementing computer-controlled sheet metal forming processes, our advanced technology ensures consistent results and minimizes human intervention. The end result is a carefully crafted part that meets precise specifications, helping you achieve the ultimate in quality.

From Prototype to Production

Our extensive experience in digital sheet metal forming enables us to meet the needs of our customers across a wide range of industries. We have successfully delivered custom prototypes and final products that exceeded our customers’ expectations, fully demonstrating the versatility and effectiveness of this manufacturing method.

Whether it is rapid prototyping or high-volume production, our expertise in digital sheet metal forming enables us to provide our customers with cost-effective and timely additive manufacturing solutions. With Elimold’s support, you can be confident in the quality and reliability of our delivered products. Whatever part you need, Elimold can provide a cost-effective and on-demand solution to meet your manufacturing needs. We have the same cutting-edge technology as other companies, without sacrificing excellent customer service. We promise to work with you to create products that exceed your expectations.

Experts in Custom Sheet Metal Forming Services

Our metal forming services precisely machine parts to the tightest tolerances and final shape. Metal forming is another way we work with our customers to create added value for each part by flexibly producing parts with simple or complex geometries. Starting with blank development, our staff considers material hardness, grain orientation, bend radius, and material tensile properties to provide the most accurate parts that meet your dimensional tolerance requirements. Throughout the manufacturing process, we follow the requirements of the forming process to ensure that the sheet metal parts always maintain the design tolerances during the forming process.

Expert Team of Metal Forming Engineers

We continue to provide programming, forming and manufacturing services for custom shapes for a variety of applications. Our team consists of project managers, computer programmers and shop fabricators. As a full-service metal forming manufacturer, we work with your staff to develop concepts and build prototypes. Once the design is approved, production can begin. Our team supports customers in a wide range of industries. Our area of expertise is in forming metal profiles for you according to your specifications, drawings or purchase order requirements. We also welcome collaborations with unique ideas that have not yet been reviewed. Whether you have a complete dimensional drawing or need engineering support, our engineering team can work with you to help you design the blanks and molds you need. We are proficient in etching and bending parts to achieve the final shape and provide fully functional parts so that you can start using them immediately.

DFM Services

By involving us early in your design process, we can help you identify opportunities to reduce part weight and labor costs. We gain a deep understanding of the form, fit, and function of your parts to determine which manufacturing process will produce the best results. Our team not only operates the machines, but also works with you to ensure that the final product is optimized in both design and function. We are experts in Design for Manufacturing (DFM), and our engineering team works with customers to optimize production cost efficiency. Our engineers also use DFM to reduce the number of assembly parts while retaining assembly function and design. This value-added design service helps match the fit, form, and function of the equipment to help customers get the best solution at the best value and cost.

Commitment to Quality

Elimold offers a vertically integrated turnkey manufacturing process, including full in-house metal forming capabilities. Our fully automated metal forming equipment represents state-of-the-art technology. Each in-house facility is ISO 9001:2015 certified and has strong capacity and manufacturing redundancy. We collaborate on new and existing products using a Value Analysis/Value Engineering (VA/VE) process. This allows us to validate the manufacturing process prior to production, saving development time, reducing costs, and consistently delivering on time. Our quality control processes ensure that components meet the high standards we set. A lean manufacturing environment allows us to provide the highest level of service to all of our customers and consistently exceed our customers’ expectations.

- PPAP (Production Part Approval Process) – All Levels

- FAIR (First Article Inspection Report)

- Capability Studies (Statistical Process Control)

- CMRT (Conflict Minerals Reporting Template)

Full-service Sheet Metal Forming Services

Our full-service approach allows us to gain a deep understanding of our customers’ needs and the role each project plays in their overall business. This understanding means we work as a genuine partner, providing professional services rather than just meeting specific one-off needs. We have sophisticated CNC metal forming equipment that can manufacture the highly complex and detailed parts our customers require. Our advanced equipment can be programmed manually and automatically, or through angular 2D and 3D graphic simulations. As a result, we are able to quickly mass produce while ensuring the highest quality from the first piece to the last.

As a result, our sheet metal forming and manufacturing services can meet your diverse needs and provide high-quality, precise and efficient solutions for all your projects. We use advanced equipment and processes to process sheet metal into a variety of shapes and specifications, ensuring that each product meets your precise specifications. Whether you need bending, stamping or deep drawing, our team of experts has the knowledge and experience to handle the most complex needs. Our optimized process ensures the production of consistent high-quality products, reduces material waste, and improves overall production efficiency.

Have a metal forming project coming up?

Are you ready to work with a dedicated team of metal forming experts? Contact us today to learn more about our solutions and get a free instant quote!

What is Metal Forming?

Metal forming is one of the most widespread and vital manufacturing processes in today’s society. During this process, materials are physically deformed through a variety of techniques. At its core, it involves applying forces that exceed the material’s yield strength, which results in strain hardening.

Metal forming is an umbrella term that encompasses all manufacturing processes that involve forming and reshaping solid metal into a desired shape. These processes can occur when the material is above its recrystallization temperature (hot working) or below its recrystallization temperature (cold working), depending on the specific part and production specifications. The shape of the material (i.e., whether its surface area to volume ratio is high or low) also affects the process and equipment used for the forming operation.

Advantages of Precision Metal Forming Process

- Speed: Parts can be formed in as little as one day

- Precision: Tolerances can be held as tight as +/- 0.001” (0.025mm)

- Cost: Tooling cost is minimal

- Flexibility: Multi-station tooling allows geometries not otherwise achievable with progressive dies

- Reliability: All parts are made to Elimold’s exacting quality and craftsmanship standards

- Growth: Short prototype runs can smoothly transition to mass production runs

Material Options

We can provide metal sheets, plates, coils and bars, and our state-of-the-art factory in Shenzhen, China has sufficient inventory and a large stock of materials to shorten metal forming lead times and reduce customer costs.

- Abrasion Resistant Plate

- Aluminum

- Architectural Metal

- Brass

- Bronze

- Carbon Steel

- Copper

- Heat Resistant Metals

- Heat Resistant Steels

- Coil Steel

- High Temperature Alloy

- Iron

- Light Metal

- Perforated Metal

- Sheet Metal

- Stainless Steel

- Steel

- Steel Plate

- Structural Steel

- Titanium Alloy

Metal Finishes for Formed Parts

We provide value-added services to support our precision metal forming manufacturing capabilities, ensuring your finished metal parts are of the highest quality. Our value-added services include:

- Anodizing

- Electroplating

- Powder Coating

- Painting

- Polishing

- Buffing

- Sandblasting

- Shot Peening

- Heat Treatment

- Passivation

- Galvanizing

- Pickling

- Deburring

- Etching

- Chromating

- Burnishing

- Chemical Coat

- Custom Finishes

Industries We Serve

Elimold serves a wide range of industries and applications. Our commitment to high-quality, precision metal products has earned us the trust of many customers around the world. These industries include:

- Architectural

- Commercial

- Communications

- Concrete Precast Molds

- Fabricated Metal Products

- Food Processing Equipment

- General Construction

- Hydro-Electric

- Industrial

- Marine

- Power Transmission

- Power Generation

- Printing

- Pulp and Paper

- Semiconductor

- Utility

- Steel Service Centers

- Stainless Steel Service Centers

- Special Industry Machinery

- Architectural Design Firms

- Sign Companies

- Machine Shops

- Paint Colorant Dispensing Equipment

- Paint Blending Equipment (shakers)

- Engineering Companies

- Awning Manufacturers

- Oil Exploration and Drilling

- Art

- Radio Wave Transmission

- Television Broadcasting

Common Applications of Metal Forming

Metal forming is an efficient and economical production process that is used in a wide variety of fields. Fortunately, we understand our customers’ needs and are able to produce a wide range of parts with tight tolerances and complex shapes. With this versatile and flexible manufacturing process, we can easily design and develop some hard-to-get parts.

- Brackets

- Mounts

- Enclosures

- Covers

- Panels

- Frames

- Displays

- Stands

- Carts

- Boxes

- Weldments

- Assemblies

- Electrical Cabinets

- control boxes

- enclosures

- Chassis

- heat exchangers

- vending machines

- Lockers

- RV door panels

- Drawers & Shelves

- Light Fixtures

- Refrigeration Equipment

- Appliance doors and panels

One-Stop Sheet Metal Forming Services

Elimold has in-house capabilities to form, trim, machine, laser cut, and heat treat a wide range of materials. We offer a complete one-stop service from design to manufacturing. By controlling all processes in-house, we can work together to ensure high-quality parts for a variety of industry applications. As we continue to expand our in-house services and invest in our employees, this capability will continue to help our customers reduce production time and costs. When your project requires a one-of-a-kind sheet metal part, you need a team you can trust. Elimiold provides professional sheet metal forming services for a variety of applications, from prototype development to high-volume production. Our industry-leading technology can meet the production needs of both small batch orders and large-volume parts.

The Value of Outsourcing Forming at Elimold

Cost Benefits

Outsourcing metal forming operations can save manufacturers money. Contracting with a specialized metal forming provider often provides access to advanced technology and expertise without the need for a large upfront investment in machinery, equipment, and skilled labor.

Expertise and Specialization

Metal forming service providers often specialize in a specific process such as stamping, bending, or extrusion. By outsourcing to an expert in the field, manufacturers can benefit from the expertise and skills of professionals focused on metal forming, resulting in higher quality products and increased efficiency.

Focus on Core Competencies

Outsourcing allows manufacturers to focus on their core competencies, such as product design, marketing, and overall business strategy. Metal forming can be a complex and specialized process, and by outsourcing this portion of production, companies can streamline operations and improve overall efficiency.

Flexibility and Scalability

Outsourcing provides manufacturers with greater flexibility and scalability. Metal forming needs can vary depending on market demands, and outsourcing allows manufacturers to quickly scale up or down production without the challenges that come with maintaining an in-house metal forming facility.

Access to Advanced Technology

Metal forming service providers often invest in state-of-the-art technology and equipment to stay competitive. By outsourcing, manufacturers can take advantage of the latest advances in metal forming without having to continually invest in upgraded equipment.

Reduced Lead Time

Specialized metal forming suppliers often have streamlined processes and workflows, which results in shorter product lead times. This is critical for manufacturers facing tight production schedules or dealing with changes in market demand.

Risk Mitigation

Outsourcing metal forming operations helps mitigate certain risks associated with in-house production, such as equipment maintenance, skilled labor shortages, or market fluctuations. Service providers are often equipped to handle these challenges, allowing manufacturers to focus on their core business.

Global Sourcing Opportunities

Outsourcing provides an opportunity to explore the global metal forming services market. Manufacturers have access to a wider range of suppliers and may benefit from lower labor costs, a diverse skill set, and a diverse material supply.

Request Your Free Sheet Metal Forming Quote Today

After receiving your drawings, our engineers will analyze your custom Sheet Metal Forming parts right away. We actively work with you to clarify all details before providing a quote that is both economical and accurate.