Short Run Injection Molding

At Elimold, our team has many years of combined experience designing and manufacturing high-quality custom plastic injection molded parts and products. This gives us all the knowledge and skills needed to assist with all stages of a short-run injection molding project. Need help with a short-run injection molding project? Elimold’s injection molding experts are here to help! We can assist you at every stage of your project, from design to prototyping to production, ensuring you receive the components you need, on time and as required.

24/7 Short-Run Plastic Injection Molding Service Provider

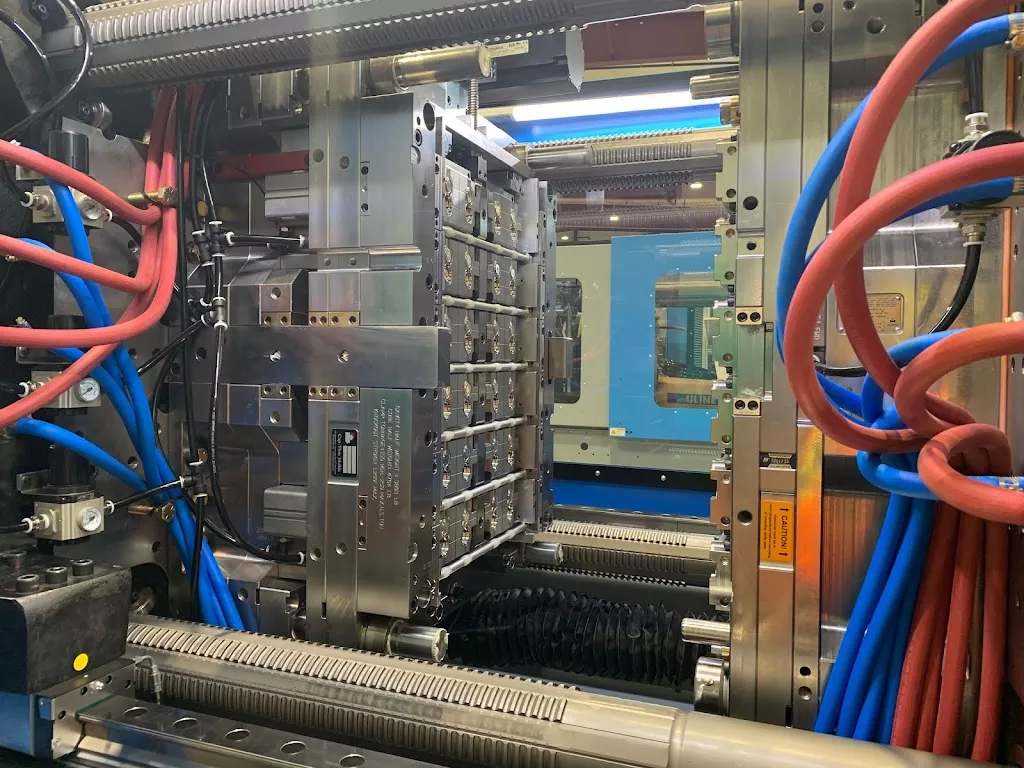

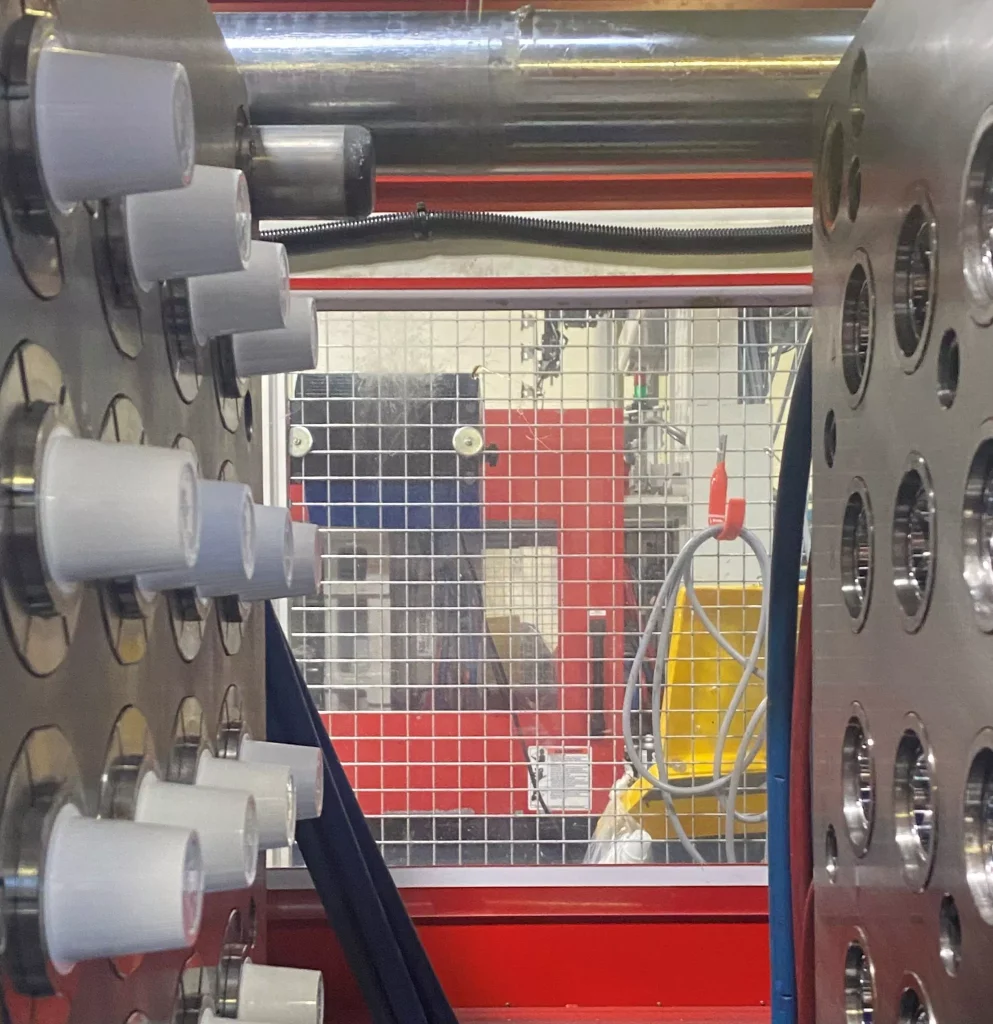

Welcome to our one-stop product development and manufacturing facility for custom precision injection molded products. Elimold has an integrated team of engineering designers and product manufacturing experts to seamlessly deliver your precision injection molded product or component on time, to quality specifications, and within budget. We specialize in short-run injection molding, close tolerance injection molding, UL certified injection molding, and medical injection molding. We also provide full tool and mold manufacturing capabilities. We can undertake short-run plastic injection molding production of all sizes. Our in-house facility has more than 100 pieces of various advanced equipment, and we are also very familiar with large-scale production tasks of millions of pieces and continuous production tasks around the clock (24/7).

Specialized Short Run Injection Molding Manufacturing Company

Elimold is a highly sought-after thermoplastic injection molding company that meets the growing demand for short lead times and low costs with innovative short run molding technology. In the manufacturing industry, it is critical to get products to market before your competitors. Elimold’s short run thermoplastic injection molding services not only help you outperform your competitors, but also help you meet your customers’ growing demands by providing you with custom plastic parts or assemblies at all stages of production.

At Elimold, short runs are not measured by the number of parts produced in a single run, but by the time it takes to produce each part. Typically, a run within 24 hours is considered a short run, which means that everything from 50 parts to 100,000 parts must be produced within 24 hours. Due to the growing demand for product customization and just-in-time delivery, the demand for our thermoplastic injection molding company and the entire short run industry is growing.

Elimold Short Run Plastic Injection Molding Capabilities

Below is a list of Elimold’s plant and molding capabilities:

- 90+ Molding Machines

- Ranging from 18 – 610 Ton

- Dedicated Production Cells

- With over 100,000 square feet of facility, we have the floor space to dedicate to your production project

- In-house injection mold making workshop

- Horizontal and Vertical Machines

- Atmospherically Controlled Facilities

- Insert Molding, Over-Molding, Post Molding and Decorating

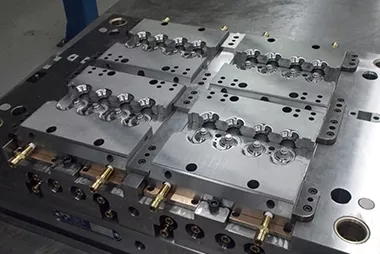

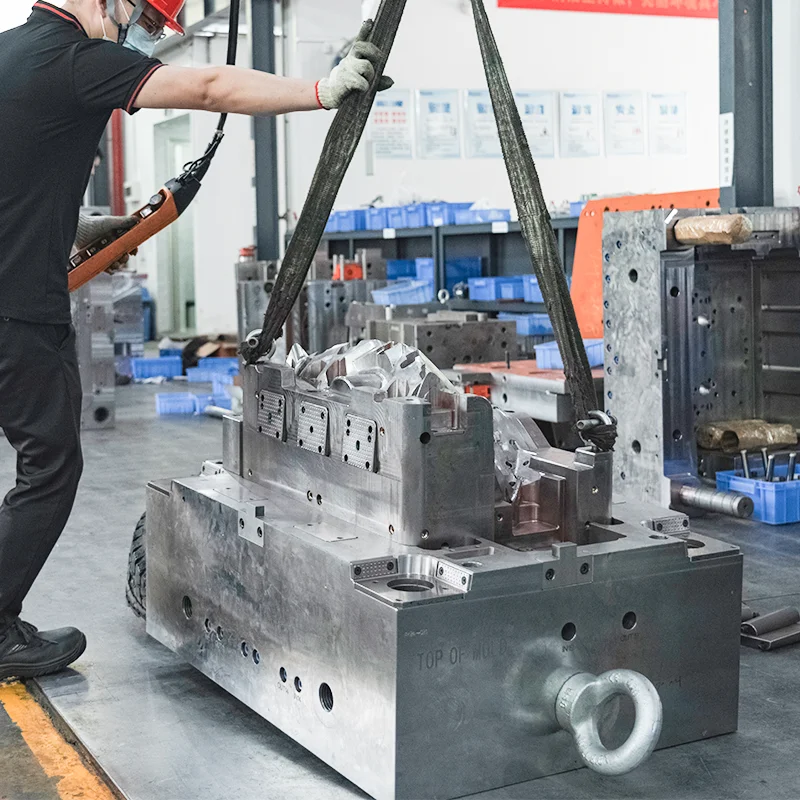

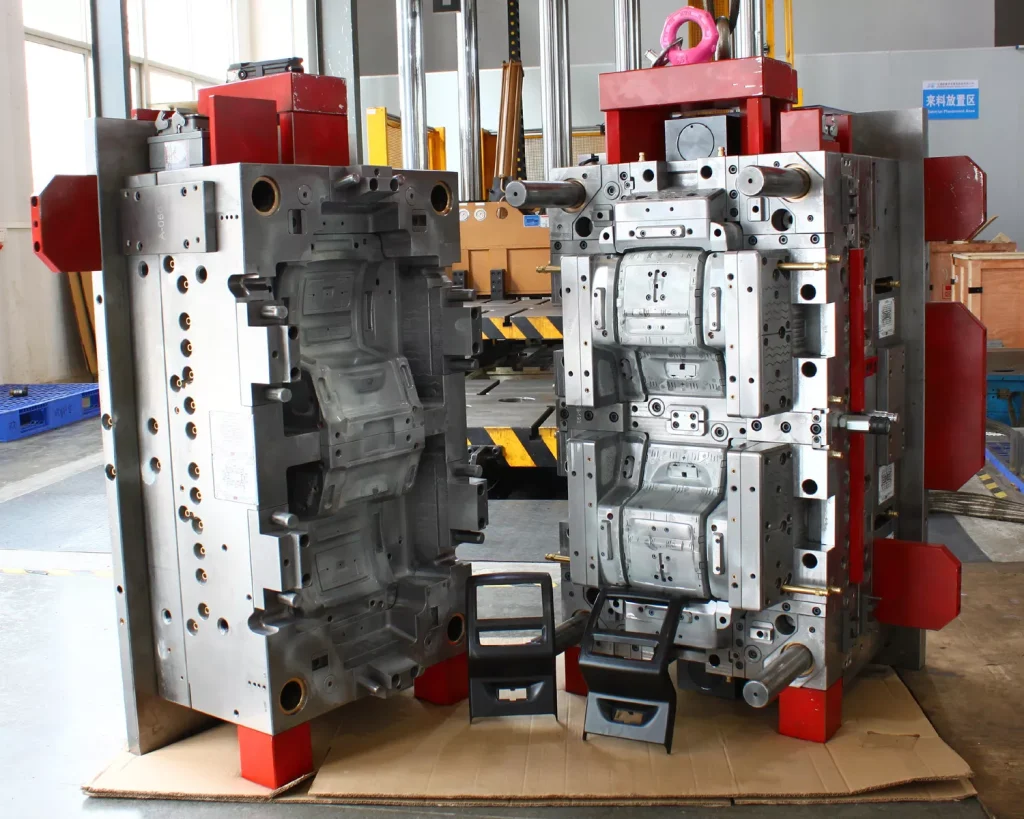

In-house Short-run Plastic Injection Mold Manufacturing Facility

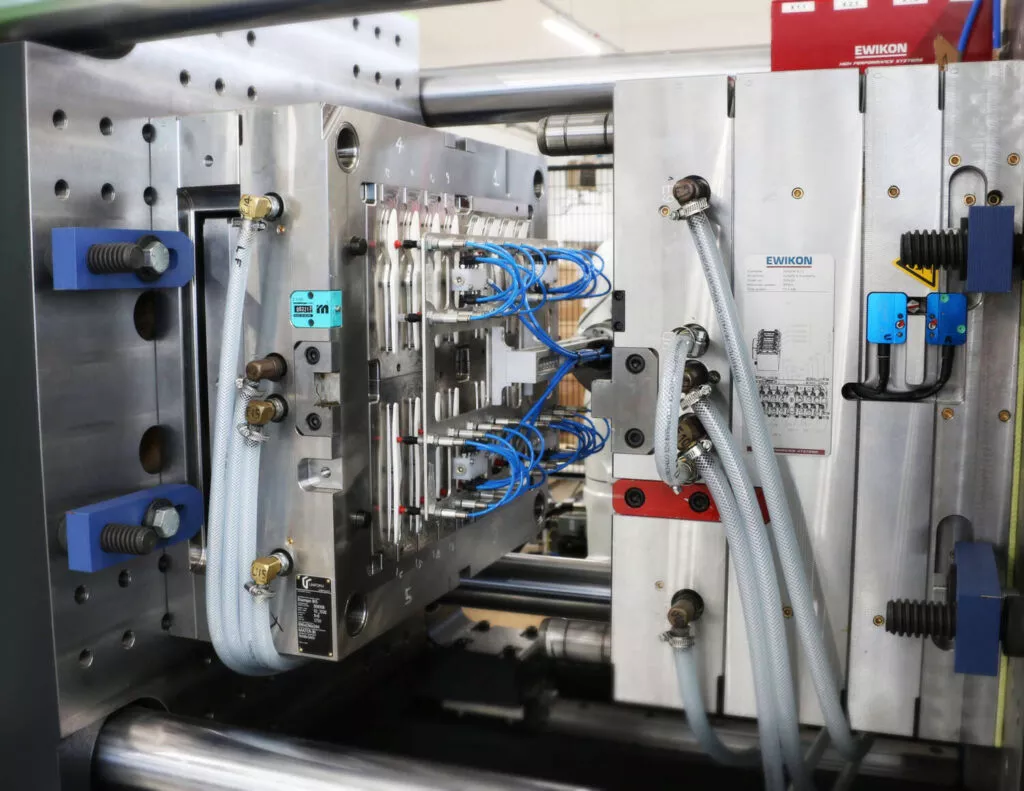

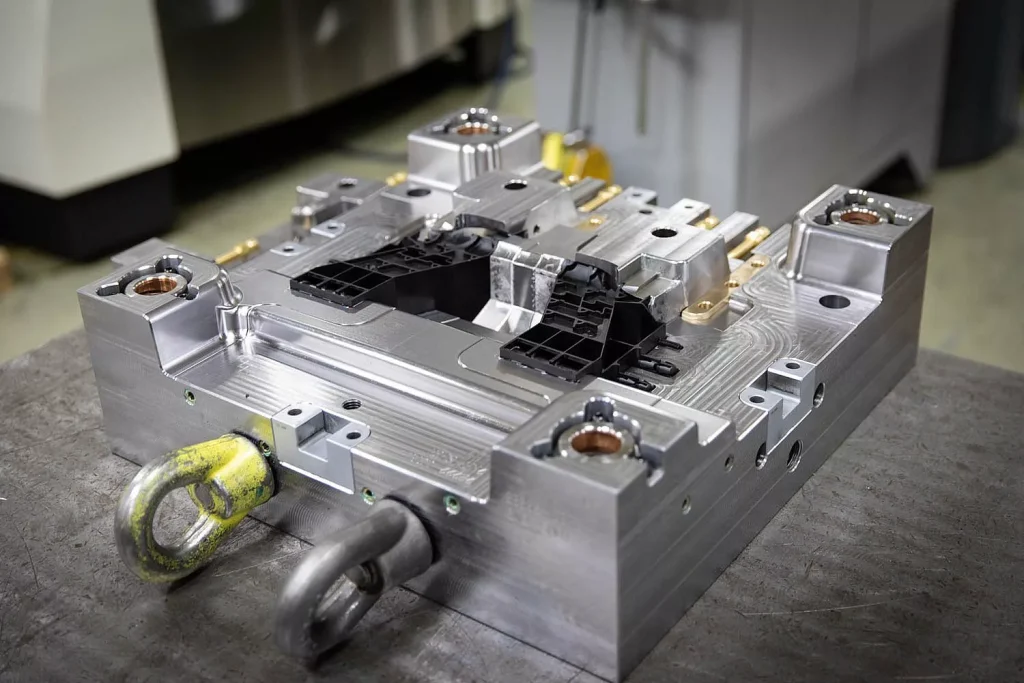

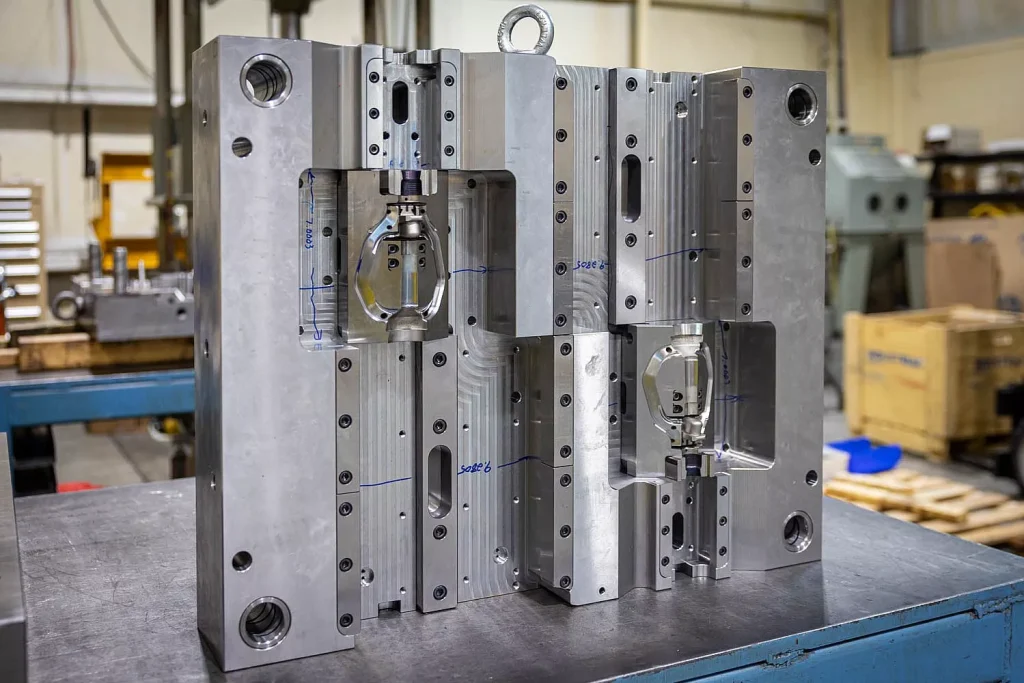

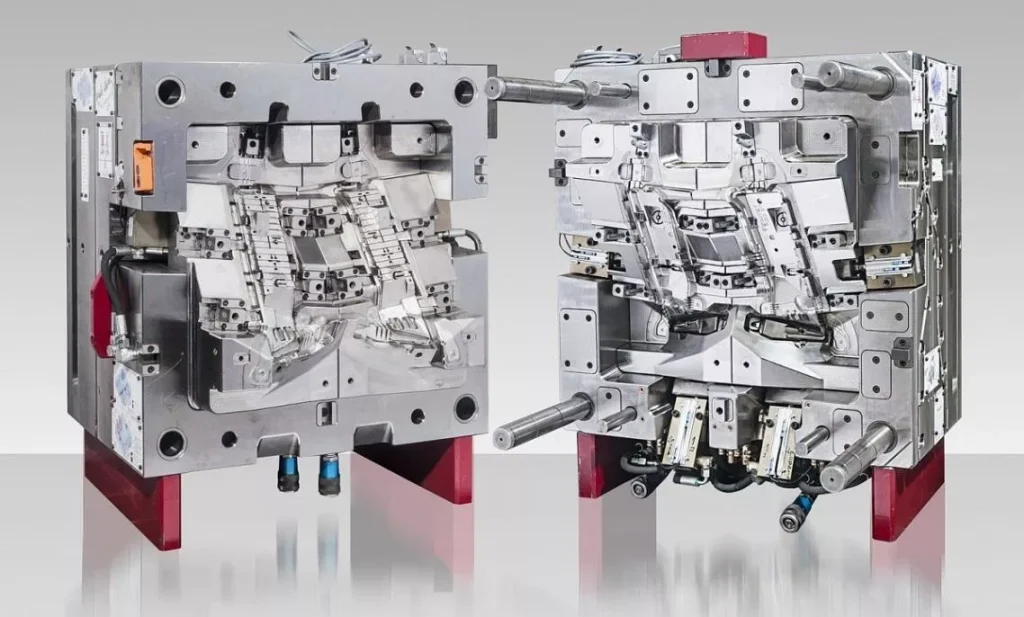

Elimold’s custom molds and high-volume plastic injection molding range from prototype to mass production. Our high-volume molds, whether short-run, high-volume or multi-cavity, are monitored and controlled, so you can be confident in every aspect of mold design and manufacturing. Attention to production detail ensures that goals, tasks and preset project results are met at every stage of the process. All high-volume molding, from design to manufacturing, is completed in-house and provides our customers with a competitive advantage in terms of cost, quality and lead time. In addition, we can work with customers to design and manufacture products and develop the most efficient high-volume molds to achieve cost-effectiveness. We specialize in high-quality high-volume molds for the plastic injection molding industry and provide a wide range of services. Elimold can coordinate your entire mold manufacturing project from design to delivery. With its quality assurance system, our mission is to provide molded products that fully meet or even exceed customer requirements and expectations. The company’s management is committed to continuous quality improvement. For excellent quality and efficient high-volume molding services, Elimold is the brand you can trust for short-run plastic injection molding services, please contact Elimold today.

Tooling & Engineering Services

Elimold’s Tooling & Engineering Services offers free quotes, part design reviews, and manufacturability analyses. We provide fast, cost-effective, short-run injection molding services. From start to finish, we are able to deliver most projects in 30 days or less.

Elimold is a short-run injection molding manufacturing company like no other, providing fast-delivery, low-cost molding and tooling services for a wide variety of plastic custom parts. No matter the industry, no matter how complex the part, we deliver fast. If you have your CAD files ready, we can provide you with a quote within 24 to 48 hours. If not, our dedicated engineering team can develop a CAD file for you. Our expert engineers and mold builders enable us to transform your 3D CAD model into a fully functional prototype or production part using true engineering grade resins, more consistently and affordably than any other rapid injection molding company.

Mold Design and Manufacturing Services

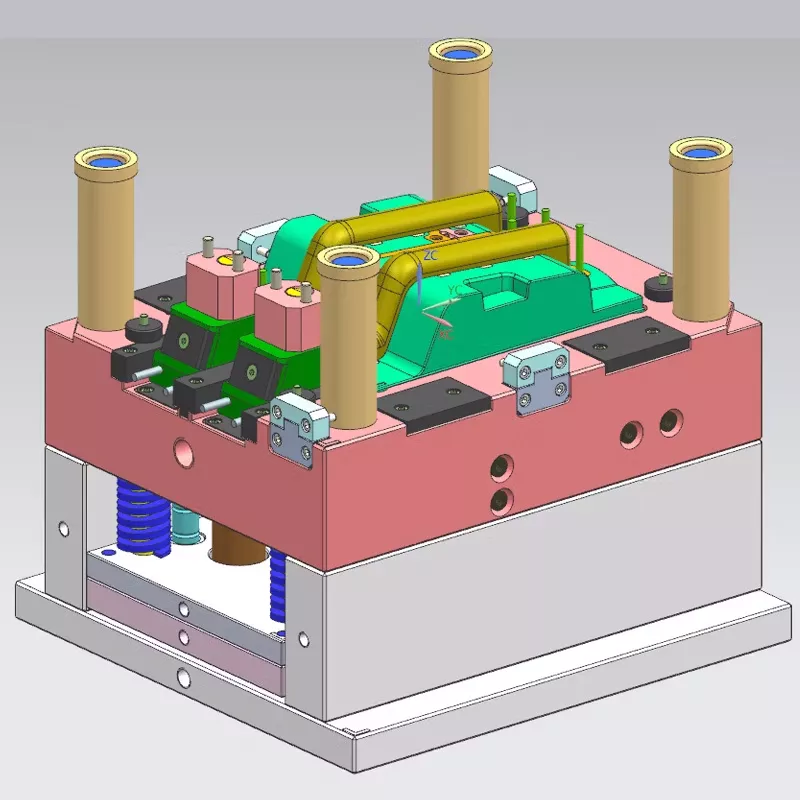

We use the most advanced technology and mold manufacturing techniques to produce devices that meet your product needs. We design molds based on your original drawings, schematics or models, or we can customize them for you. We are proficient in CAD software formats such as AutoCAD, SolidWorks, ProE, Cimatron and CADKey.

Our mold manufacturing team uses advanced CNC machining technology in our in-house mold processing factory to produce high-quality, dimensionally accurate molds in the shortest time after the injection mold design is completed. This is a fast custom mold service and capability. We are able to prototype and mass-produce plastic parts for a variety of thermoplastics.

Let's discuss your product goals and how our in-house expertise can help you.

At Elimold, our clients are our focus. We believe that a client-centric approach and excellent customer service are essential to the success of a project.

Comprehensive Short-Run Injection Molding Services

Elimold is different from other short-run injection molding facilities. We have the experience and equipment to provide unparalleled speed, flexibility and support. We apply our superior molding expertise to provide comprehensive technical guidance and mold selection for your project. We not only provide estimates for new projects, but also provide detailed quotes after understanding your needs. We pride ourselves on working closely with you from the beginning to ensure that the work specifications match your project goals.

We also pride ourselves on speed, providing fast-delivery injection molding services without sacrificing quality and precision. We are constantly improving our production processes, adopting new methods, reducing inefficiencies, and shortening our customers’ lead times. Whether you need short-run production, rapid mold making or prototyping services, we can help you find the best solution and deliver it quickly and efficiently.

One-Stop Short-Run Molding Services

Elimold has many years of experience in short-run injection molding services to meet a variety of plastic molding needs. Our in-house injection molding facility has advanced facilities that provide professional plastic injection molding, mold testing, small-batch production, and aluminum and steel mold manufacturing services. Our short-run molding services are ideal for prototyping, product development, and small-batch production with high flexibility and low upfront costs. This approach allows for rapid design iterations and market testing without a large capital investment.

At Elimold, we are committed to guiding you through the decision-making process to ensure that you choose the most effective molding strategy for your unique project needs. Our expertise in mold testing and short-run production allows us to support a wide range of industries, including automotive component manufacturers.

From initial planning to final production, we are your loyal partner, supporting you on your manufacturing journey with our expertise, quality service, confidentiality, and commitment to excellence. We also offer open mold trial hours! Are you ready to put your plastic molding project into practice?

Short-Run Injection Molding Service Types

If you have a production need but don’t know where to start, Elimold can help. Whether it’s a small batch or large-scale production, we can ensure you get the right process for your product. With decades of experience and cutting-edge technology designs, Elimold is a trusted leader in plastic injection molding. If you think injection molding is right for you, please contact us; we can answer all of your questions and help you get on the road to success.

Plastic Injection Molding

LSR Injection Molding

Overmolding

Gas Assist Injection Molding

Insert Molding

Structural Foam Molding

Rapid Tooling

Micro Molding

Production Tooling

Plastic Injection Molding Short Run Production Services

Elimold provides short run and low volume manufacturing services. For customers who need to produce precision injection molded parts in short runs, our processes combined with industry rapid tooling systems allow us to produce small runs without the need for large run production. Our in-house facilities are able to shorten product development cycles by providing short runs from 10 to thousands of pieces, significantly reducing lead times from prototype to low volume production.

We work with product developers, original equipment manufacturers (OEM) and tier suppliers to provide plastic injection molded parts that meet demanding specifications, schedules and budgets. As a result, our ideal short run injection molding customers highly value relationships with suppliers, understand that price is an element of total cost, and utilize Elimold as a preferred partner in plastic product development to solve problems, propose solutions and share best practices in tool design and optimized processing for repeatability from shot to shot. We encourage prospective customers to bring their next plastic development project to Elimold to experience firsthand what our team has to offer!

Quick DFM Report

While we check the feasibility of your design when we provide a quote, we can provide a quick and comprehensive DFM (Design for Manufacturability) report before production begins. In the DFM report, we identify any errors or issues that may cause problems in subsequent production.

As short-run experts, we will help you get the ideal molding solution. You can contact us and tell us what you need. Elimold has extensive expertise and experience in efficient and economical short-run injection molding production. If your project requires a prototype or production mold, please feel free to contact us. We will be happy to help you. And we can provide short-run injection molding material options for each injection molding material. Elimold can quickly build a short-run injection mold cavity and mold care plan based on your exact part quantity needs.

Fast Quotes for Short-Run Injection Molding Projects

Submit your files through our website, email, or by email. Our experienced engineers will quickly provide a comprehensive quote and manufacturability analysis. You can modify parameters such as quantity, material, surface treatment, etc. to find the perfect combination for your project and budget.

Competitive pricing and advanced processes enable you as a designer to quickly compare prices and find the best option for your manufacturing requirements. Once approved, your files will be sent to our team of injection molding engineers and we will begin making your mold based on the exact dimensions. Years of experience have enabled us to refine our processes and develop durable, precision injection molding molds to ensure you produce consistently high-quality precision parts.

Ready to get started on your short-run injection molding project? We’re here to help!

Elimold’s team commitment is to provide innovative and consistent quality in plastics. Do you have a problem part or design? Send us what you have, we will take a look and offer up some advice. To begin collaboration on your next project, arrange a meeting or tour our facility.

Rapid Prototyping

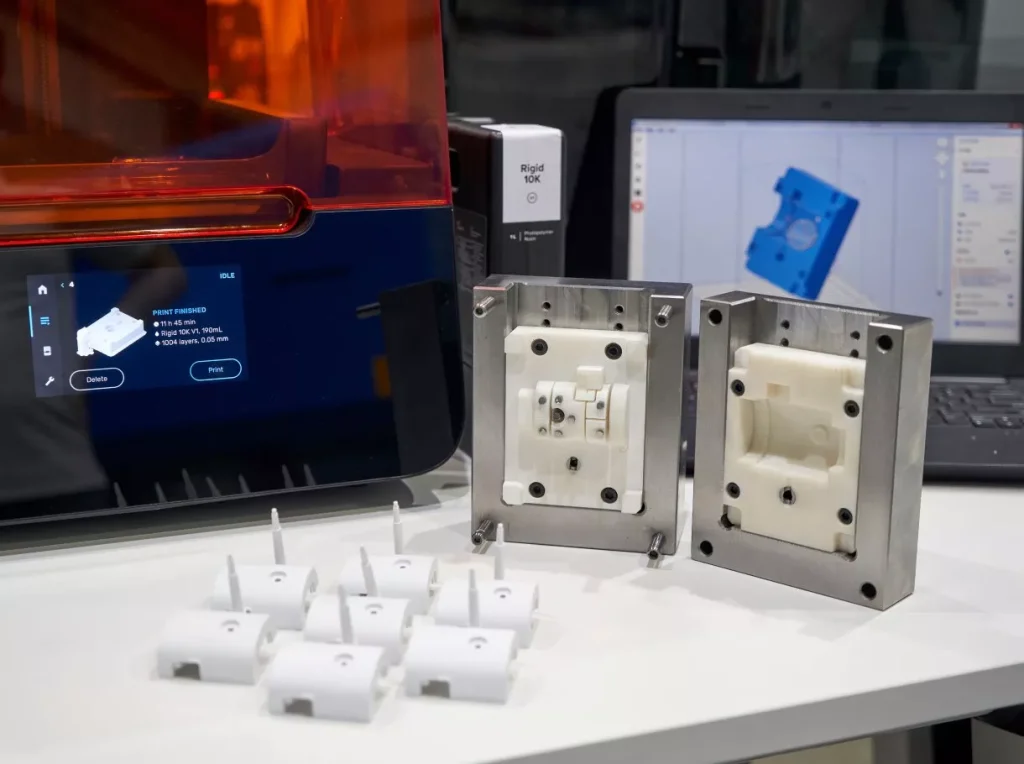

Prototyping with the intended production material is very beneficial. For prototypes and small batches, there are a variety of mold options, even for molding just two parts. However, the speed of rapid prototyping and part manufacturing can vary, and some can take days. This depends on the surface, material, and geometry of the structure to be coated. The delay is usually two to four weeks.

Some products need to be tested for fit, function, and life cycle before they can be mass-produced. Short-run injection molding makes this possible because it is fast and less expensive to produce. We use 3D printing technology to quickly build each part, ensuring it fits the mold shape and works properly before the injection mold is built. As a result, we can provide 3D printed prototype services in a variety of materials.

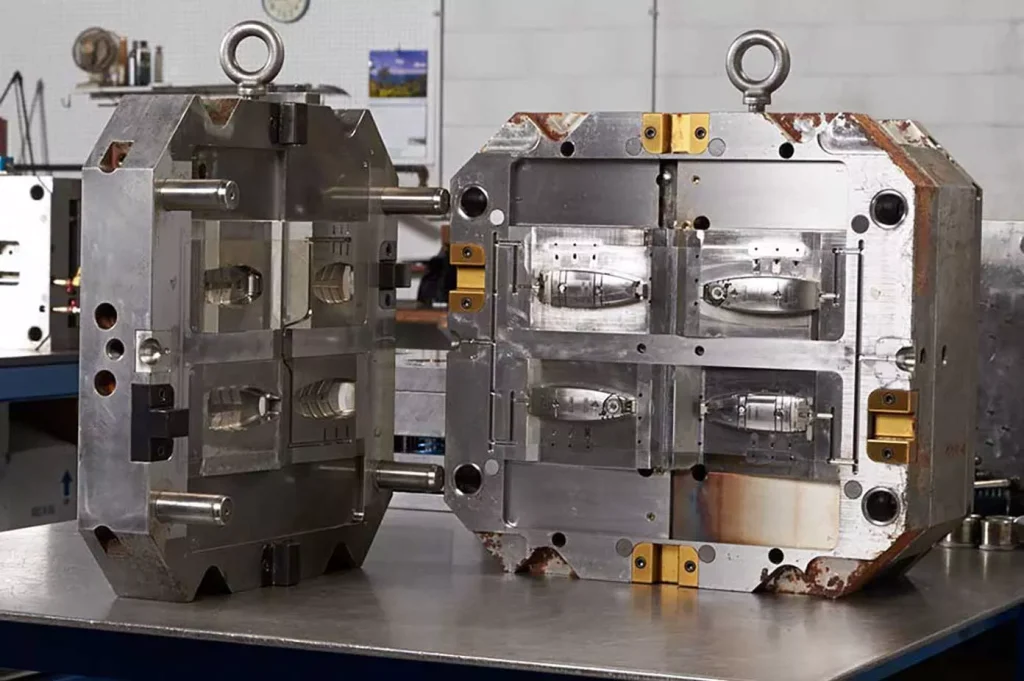

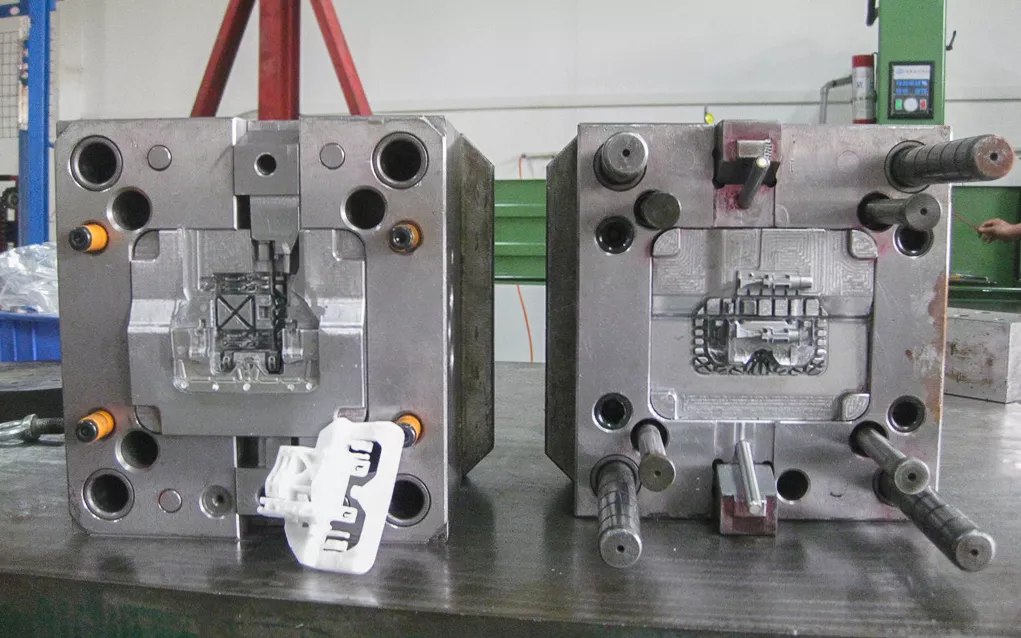

Transferring Existing Molds to Elimold

This happens more often than you might think, and there are two common scenarios. First, we have several major customers who are also large plastic injection molders that produce their own brand parts. They are very quality-conscious, so we are honored when they entrust us with their molds to produce their parts. Sometimes, they produce up to 50 molds at a time. Second, customers become dissatisfied with the performance of their existing supplier, usually due to product quality or delayed delivery, and begin looking for other suppliers. Elimold has often benefited from this situation. In either case, we are fully capable of quickly evaluating whether the mold is suitable for our equipment and making any necessary modifications, which are usually minor.

Samples and Large and Small Quantity Production

Elimold’s in-house injection mold making shop can design metal or plastic molds for injection molding manufacturing. We first design the molds using CAD files, and then use 5-axis cnc machining and EDM machining to turn them into reality. Once the molds are completed, we rigorously test the molds to ensure that the final product is flawless. Since we can provide one-stop injection molding services and have a dedicated injection molding shop to test the molds, we can also provide customers with sample, large and small batch production services. You don’t need to use your own machines or find a third-party company to do the injection molding for you, let us handle the manufacturing for you. It’s hard to find a company that is easy to work with when you need a fixed quantity of a product. At Elimold, we understand that you know your company best. We care about your bottom line budget and will provide the best quality molds and products for your company.

Key Features

- Flexibility: Short run injection molding allows for the production of small quantities, ranging from a few dozen to a few thousand parts, providing flexibility for prototyping, market testing, and limited-edition products.

- Rapid Turnaround: Our efficient processes and advanced machinery enable quick setup and fast production cycles, ensuring rapid delivery of your parts.

- Reduced Tooling Costs: We use cost-effective tooling options, such as aluminum molds or modular mold inserts, to minimize initial investment and reduce overall production costs.

- Customization: We offer tailored solutions, including custom part design, material selection, and surface finishes, to meet your unique requirements.

Applications

Our Short Run Injection Molding solutions cater to a wide range of industries and applications, including:

- Prototyping: Creating functional prototypes for product development and testing, allowing for design validation and iteration before full-scale production.

- Market Testing: Producing limited quantities of parts for market trials, enabling businesses to gather customer feedback and assess demand.

- Custom and Limited-Edition Products: Manufacturing specialized or limited-edition parts for niche markets, promotional items, or customized products.

- Bridge Production: Providing interim production solutions while long-term production tooling is being developed, ensuring continuous supply of parts.

Short-run injection molding costs for plastic part production

What you need to be aware of is that the cost of making a short-run injection mold and setup for producing a low-volume product is fixed and must be amortized over the order quantity. Generally speaking, short-run injection molding is suitable for 1 to 10,000 parts. At Elimold, we offer two mold options: prototype molds (usually with a warranty of at least 2,000 injections) and on-demand production molds (with a warranty for the life of the mold). If the mold is damaged, the company will replace it free of charge. Both options are quite inexpensive for production quantities. Other special services include first article inspection, capability reports, scientific molding process development reports, and production part approval process (PPAP). Some customers have realized that short-run molds can be used as final product molds. Alternatively, if production runs are in the millions, then production tooling may be more appropriate. On the other hand, if only a small number of parts are produced, 3D printing will be less expensive. Some manufacturers will use 3D printing to make prototypes first and then move on to low-volume injection molding.

Quality and Production Management

We have short-run injection molding capabilities from design to distribution and are committed to the same quality control and customer service as high-volume injection molding. We follow the same guidelines and operate in-house in the same facility, and we carefully manage the process, using quick-change tooling to reduce setup time and costs, thereby shortening lead times. Our advanced tooling, made from high-strength alloys, ensures fast processing, precision manufacturing, and close tolerance parts. With complete in-house capabilities, including mold decoration, hot stamping, ultrasonic welding, and contract assembly, our short-run injection molding follows the same stringent time-to-market standards and allows us to serve customers across a wide range of industries. This makes us a trusted partner for a wide range of industries seeking efficient and reliable injection molding solutions.

Just-In-Time (JIT) Delivery

Elimold’s injection molding process produces small batches of plastic molded parts cost-effectively. We ship these small batches of production parts using a Just-In-Time (JIT) delivery model.

Small batches and Just-In-Time (JIT) delivery minimize inventory costs and give customers greater flexibility to modify designs. We use high-quality, low-cost production alloy steel material molds that are capable of producing tight tolerance, consistent quality parts over thousands of cycles. In addition, this is a “generous by design” process, allowing for highly stylized surfaces and precise features in each part design.

If you are considering short run manufacturing projects, please consult us for more industry information and free quotation.

What is short-run injection molding?

Short-run injection molding is a manufacturing process designed to produce small to medium quantities of plastic parts, typically 100 to 10,000. The process injects molten plastic into a mold to create a part that meets design specifications. The “short run” refers to the fact that the process is optimized for small batches of parts, rather than mass production of tens of thousands or even millions of parts.

The molds used in short-run injection molding are typically simpler and less expensive than those designed for large-scale production. This is because short-run injection molding molds do not need to endure the same level of wear and tear as mass production molds, so they are cheaper and can be produced faster.

The Benefits of Short Run Molding

- No minimum order quantity: As specialists in short runs, we at Elimold do not require any minimum order for injection molding. This allows you the greatest flexibility in prototyping, iterating, testing, and controlling your inventory and production quantities.

- Lower costs: Short runs allow you to save costs in nearly every area of the injection molding process, including tool costs (with softer material such as aluminum, instead of stainless or tool steel), production costs (with only the quantity you need) and faster time to market.

- Long-lasting molds: Even with a softer mold material, our short run tooling is durable and long-lasting, with a 10,000-shot guarantee.

- Production-quality prototyping and testing: Other prototyping methods may be useful, and we offer other services to meet your needs — including short run CNC machining and 3D printing. However, if you need a production-quality prototype to guarantee performance and functionality, short run plastic injection molding should be your method of choice.

- Faster turnaround: With shorter production time, faster mold manufacturing and capacity dedicated to short runs, we are able to complete projects in as little as two days.

- Greater flexibility: As specialists in short runs, our machine capacity is dedicated to runs for prototyping and testing. This means that you can iterate on designs and see a new prototype in two days. Other injection molders (if they agree to a short run) will often keep unreliable timelines, not finishing your order until it is convenient for them. This creates an extended development process, with unmanageable timeframes for iterating on concepts and designs.

- Dedication and expertise: At Elimold, we specialize in short run manufacturing. We can assist you with material selection, tooling, production plans and schedules, and more — all backed by our extensive experience with prototyping and short run injection molding. Where other molders may not even return your RFQ or emails for low quantities, we specialize in working with customers just like you.

Short & Long Injection Molding Runs

We have the equipment and experience to meet your short-run, low-volume production needs. Our quick mold change system and master mold unit allow us to change molds efficiently, saving you time and money. We use a proprietary batch molding process to optimize every aspect of short-run production. From small batch procurement and drying to resource scheduling and shop sequencing, we provide excellent value from start to finish for short-run projects.

For companies that need high-quality, low-volume plastic parts, Elimold focuses on providing precise, durable and cost-effective short-run injection molding parts. Unlike large-scale production that requires large mold investments and high production volumes, our short-run injection molding services enable customized, flexible production to meet your specific project needs. Whether you need a prototype, replacement part or limited edition part, we can provide excellent precision and consistency while reducing lead times and overall production costs.

Quantities for Short-Run Injection Molding

Elimold understands that ten thousand pieces may not sound like a small order, but in fact, it is a significant order compared to the industry standard of one million pieces. Prototypes are produced quickly to a high standard to develop concepts and make them more affordable. Short-run injection molding is defined as beating the market. Niche markets such as small companies are profitable as small quantities of quality products are produced in small batches.

These products are often only produced in a few hundred pieces. Design adjustments can be made before large quantities are produced, resulting in considerable gains.

Material Options

- ABS (Acrylonitrile Butadiene Styrene)

- Polypropylene (PP)

- Polyethylene (PE)

- Polystyrene (PS)

- Nylon (Polyamide, PA)

- Polycarbonate (PC)

- Acetal (POM, Delrin)

- Thermoplastic Elastomers (TPE)

- TPU (Thermoplastic Polyurethane)

- PMMA (Acrylic)

- High Impact Polystyrene (HIPS)

- Low-Density Polyethylene (LDPE)

- High-Density Polyethylene (HDPE)

- Polyetheretherketone (PEEK)

- Polyphenylene Sulfide (PPS)

- Liquid Crystal Polymer (LCP)

- Polybutylene Terephthalate (PBT)

- Polyethylene Terephthalate (PET)

- Polysulfone (PSU)

- Polyvinyl Chloride (PVC)

- Acrylonitrile Styrene Acrylate (ASA)

- Ethylene Vinyl Acetate (EVA)

- Polyphenylsulfone (PPSU)

- Thermoplastic Polyimide (TPI)

- Styrene-Ethylene-Butylene-Styrene (SEBS)

- Polyoxymethylene Copolymer (POM-C)

- Polyoxymethylene Homopolymer (POM-H)

- Polytetrafluoroethylene (PTFE)

- Polyethylene Chlorinates (CPE)

- Polycyclohexylenedimethylene Terephthalate (PCT)

- Polyethylene Naphthalate (PEN)

- Thermoplastic Vulcanizates (TPV)

- Polyaryletherketone (PAEK)

- Polyetherketoneketone (PEKK)

- Polycarbonate/Acrylonitrile Butadiene Styrene (PC/ABS)

- Polypropylene Copolymer (PPC)

- Cellulose Acetate (CA)

- Polyimide (PI)

Value-added Services

We offer a range of surface treatments including textures, colors and surface coatings to enhance the functionality and appearance of your parts. Whether it is a simple finishing technique or a complex assembly, Elimold believes that adding value must be the way to do business in today’s manufacturing environment.

- Deflashing

- Degating

- Trimming

- Surface polishing

- Sandblasting

- Painting

- Pad printing

- Laser marking

- Ultrasonic welding

- Heat staking

- Chrome plating

- Anodizing

- Silk screening

- Assembly

- Inspection and quality control

Industries We Serve

Short-run plastic injection molding is used across a wide range of industries, including any industry that can produce using injection molding and requires short-run prototyping. Short runs are ideal for producing low-volume, highly specialized parts. Short runs are particularly useful when precision and part performance are critical, as is the need for production-quality prototyping.

- Automotive

- Aerospace

- Medical and Healthcare

- Consumer Electronics

- Industrial Equipment

- Home Appliances

- Robotics

- Telecommunications

- Agriculture

- Marine

- Defense and Military

- Sporting Goods

- Construction

- Toys Products

- Renewable Energy

- Packaging

- Wearable Technology

- Lighting

- HVAC

- Food Equipment

Industry and Parts

Our injection molded blanks, composites, parts, tubing, as well as stock and complex shapes save time, ensure consistent quality and give your supply chain peace of mind when manufacturing and processing short-run injection molded 4000 complex shapes. Application industries include medical, automotive and aerospace, but our services are not limited to these areas.

- assemblies

- bearings

- components

- connectors

- containers

- conveyor links

- diagnostics

- electronics

- enclosures

- fittings

- gears

- handles

- rods

- knobs

- microfluidics

- modules

- nozzles

- OEM

- parts

- pipes

- piston parts

- plugs

- products

- hinges

- housings

- instrumentation

- spools

- structural parts

- switch components

- switches

- tool parts

- tubes

- tubing

- valves

- washers

- pump parts

- pumps

- robot parts

- sockets

Alternative Processes for Short-Run Injection Molding

Elimold has extensive experience with short-term projects and can provide you with all of the advantages listed above. In addition to injection molding, we also provide short-term CNC machining and 3D printing services, whether you need complementary or supporting services for your injection molding project or a separate project, we can meet your needs. We exist only to solve the problems encountered in short-term injection mold procurement and manufacturing, and have helped thousands of customers move their projects forward quickly and efficiently, and take advantage of design and production expertise for unique requirements.

If you can’t wait to get physical samples of plastic parts as soon as possible, consider choosing Elimold as your rapid prototyping and prototype injection mold partner. We have the 3D printing technology to create and deliver your products quickly and easily. Contact us now to learn which process is best for your project.

Make the right choice for your project

The choice between short-term and long-term prototyping often depends on your specific project needs, budget constraints, and long-term goals. Short-term prototyping is the right choice when you need flexibility, fast turnaround, and low upfront costs. It is ideal for startups, product development phases, or niche markets with limited demand. Conversely, long-term prototyping is ideal for mature products with high and stable demand that focus on maximizing efficiency and minimizing unit costs.

Request Your Free Short Run Injection Molding Quote Today

After receiving your drawings, our engineers will analyze your custom Short Run Injection Molding parts right away. We actively work with you to clarify all details before providing a quote that is both economical and accurate.