Titanium CNC Machining

Elimold’s technical team has meticulously studied the unique properties of titanium and its alloys to achieve precision titanium machining. Their process-oriented approach and expertise enable them to precisely program CNC machine tools, resulting in optimal finished custom titanium parts. If you have any questions about our titanium CNC machining capabilities, please contact Elimold; our team of experts will be happy to assist you.

Looking for a reliable partner to bring your titanium project designs to life?

Are you looking for a reliable and technically skilled CNC machining center to outsource your titanium parts project? Elimold offers advanced titanium CNC machining services, a team of experienced experts, and state-of-the-art CNC equipment, enabling us to quickly and efficiently create ideal products with consistent quality and tolerances. Our materials offer unparalleled precision and performance, making them ideal for custom prototype parts or mass production. We take great pride in every product we create as if it were our own, and we are committed to using our expertise and care to make each product better. For more information, contact our experts today. You can also upload your CAD files or drawings directly online to receive a free, instant quote.

Elimold Offers Advanced Titanium Machining Services

Elimold is a trusted brand for providing advanced titanium machining services. Leveraging CNC technology and cutting-edge equipment, we are capable of performing complex machining operations on titanium materials. Our advanced machining capabilities encompass 4-axis and 5-axis machining, Swiss-type lathe machining, and even micro-machining. This allows us to manufacture parts with the highest precision and smallest tolerances. We can achieve tolerances as small as 0.0005 inches. Our team understands that every client’s project is unique, therefore we offer customized titanium machining services to meet specific client needs. Consequently, Elimold’s quality management team implements rigorous quality control processes to ensure that every precision titanium CNC machining project we provide meets the highest standards.

What is Titanium?

Titanium (symbol Ti in the periodic table) is a lightweight metal and the fourth most abundant metallic element in the Earth’s crust. It has an atomic number of 22, meaning it has 22 electrons and 22 protons; its atomic weight is 47.867 Daltons. Titanium’s electron configuration places it in the fourth period and fourth group of the periodic table. Titanium has two electrons in its fourth orbital, with an electron configuration of 1s² 2s² 2p⁶ 3s² 3p⁶ 3d² 4s². This metal possesses a wide range of practical properties, making it a preferred material for numerous applications.

Why use titanium?

Titanium has strength comparable to steel, but a much lower density. Its density is about 60% higher than aluminum, yet its strength is more than twice that of aluminum, with an ultimate tensile strength even surpassing most steel alloys. This makes it an ideal material for applications requiring high strength but limited by component weight. Titanium also exhibits better corrosion resistance than steel.

Furthermore, titanium possesses excellent ductility, is non-magnetic, and, due to its low thermal conductivity, is ideal for high-temperature applications. Because of its excellent high and low temperature resistance, its high fatigue limit allows for a long service life even in harsh applications and environments. Biocompatibility is another key property of titanium; it is non-toxic and not rejected by the human body.

Three Special Properties of Titanium

Shape Memory Function

This refers to the ability of Ti-50%Ni (atomic) alloys to recover their original shape under certain temperature conditions, hence the name shape memory alloy.

Superconductivity

When the temperature drops close to absolute zero, wires made of NbTi alloys lose their resistance. Even with a large current flowing through them, the wires do not heat up and therefore do not consume energy.

Hydrogen Storage Function

This refers to the ability of Ti-50%Fe (atomic) alloys to absorb large amounts of hydrogen. Utilizing this property of TiFe, hydrogen can be safely stored, eliminating the need for high-pressure steel cylinders. TiFe can also be used to release hydrogen under certain conditions, making it a type of energy storage material.

Titanium Material Properties

- High structural efficiency due to an elevated strength-to-density ratio

- High corrosion resistance, excellent resistance to seawater, chlorides, and acidic media that oxidize and sour

- This material is excellent at elevated temperatures (up to 600 degrees Celsius (1100 degrees Fahrenheit))

- Low density, roughly half the weight of steel, nickel, or copper alloys

- Fatigue strength is high in environments containing air and chloride

- Exceptionally high fracture toughness in chloride and air environments

- Low modulus of elasticity · Low coefficient of thermal expansion

- Erosive, corrosion-proof, and abrasion-proof

- The material is essentially nonmagnetic

- Cryogenic properties that are excellent

- Allergen-free, nontoxic, and fully biocompatible

- Ratio of ballistic resistance to density is high

- Exceptional intrinsic shock resistance

- Radioactivity with a short half-life

- An exceptionally high melting point

Titanium Alloy CNC Machining Material Grades and Properties

We offer one of the industry’s most comprehensive ranges of commercially available pure titanium and titanium-based alloy CNC machining materials, including many other materials that other companies cannot source or are unwilling to process. If you cannot find the material you need, we may be able to help you. Contact us today to speak with a titanium CNC machining expert!

Commercially Pure Titanium CNC Machining Materials

Titanium Grade 1 / CP4

A commercially pure metal with excellent corrosion and impact resistance, good formability, and high ductility.

Titanium Grade 2 / CP3

A commercially pure metal with superior corrosion resistance and excellent weldability and formability.

Titanium Grade 3 / CP2

A commercially pure metal with enhanced strength and mechanical properties compared to Grades 1 and 2.

Titanium Grade 4 / CP1

An alpha-beta alloy with high strength and exceptional corrosion resistance in a variety of environments.

Titanium Grade 7

A corrosion-resistant alloy with enhanced weldability and fabricability, especially in reducing acid environments.

Titanium Grade 11 / CP Ti-0.15Pd

An alpha-beta alloy with good weldability and formability, designed for enhanced resistance to corrosion in various chemical environments.

Titanium-Based Alloy CNC Machining Materials

Titanium Grade 5 /6Al-4V

An alpha-beta alloy with a perfect balance of strength, weight, and excellent corrosion resistance, suitable for high-performance applications.

Titanium Grade 6 / 5Al-2.5Sn

An alpha-beta alloy with excellent weldability, formability, and resistance to corrosive environments.

Titanium Grade 9 / 3Al-2.5V

An alpha-beta alloy with improved strength and corrosion resistance, suitable for elevated temperature applications.

Titanium Grade 12 / Ti-0.3-Mo-0.8Ni

A titanium alloy with outstanding corrosion resistance in oxidizing and mildly reducing environments.

Titanium Grade 23 / 6Al-4V ELI

A high-strength, alpha-beta alloy with excellent resistance to corrosion, fatigue, and crack growth.

Titanium 6Al-6V-2Sn / 6-6-2

An alpha-beta titanium alloy, known for its high strength, excellent corrosion resistance, and good weldability and formability.

Titanium 6-Al-2Sn-4Zr-2Mo / 6-2-4-2

A high-strength, heat-treated alpha-beta alloy, characterized by excellent corrosion resistance, high tensile strength, and good weldability.

Titanium 6Al-2Sn-4Zr-6Mo / 6-2-4-6

A high-strength, heat-treated alpha-beta titanium alloy with superior corrosion resistance and excellent weldability, often used in demanding aerospace and marine applications.

Titanium 8Al-1Mo-1V / 8-1-1

An alpha-beta titanium alloy with high strength, excellent weldability, and superior creep resistance, making it suitable for applications requiring high temperature and mechanical performance.

Need CNC Machined Parts in Titanium?

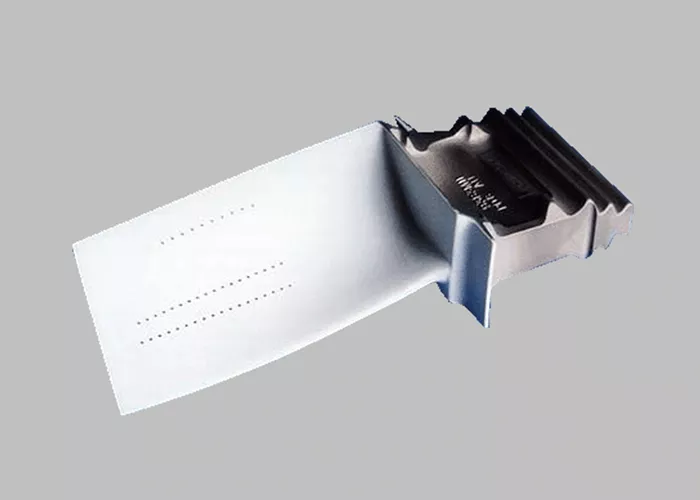

In-house Manufacturing and Equipment

Our comprehensive in-house operating model reduces overall costs and delivery times while ensuring professional handling from start to finish. Our 80,000-square-foot facility boasts over 136 state-of-the-art CNC machining centers, including several of the world’s largest, providing stable capacity, highly competitive pricing, and unparalleled CNC machining capabilities for titanium alloys. With our integrated in-house machining capabilities and robust supply chain, we can perfectly reproduce the most complex titanium alloy prototypes and production parts in a wide range of grades and surface finishes.

Titanium Alloy Parts Manufacturing Capabilities

Whether you need CNC machining for prototypes, small-batch production, or large-volume orders, our highly skilled and experienced team can easily handle projects of any size using state-of-the-art CNC equipment. We are capable of producing titanium alloy parts with a precision of up to 0.0002 inches. The size range of titanium alloy parts we can manufacture ranges from a minimum of 3 inches x 3 inches x 3 inches (or less than 1 pound) to a maximum of 150 inches x 92 inches x 48 inches (or up to 44,000 pounds).

Customized Solutions and Collaborative Engineering

Complex projects involving titanium alloys benefit from early collaboration between clients and machining suppliers. A dedicated service team provides concurrent engineering support, working closely with clients during the design phase to ensure manufacturability and optimize component performance. This proactive approach is crucial for mission-critical applications where any failure is unacceptable. Elimold’s customized solutions for complex projects fully embody this collaborative spirit.

Design Support & Effective Communication

At Elimold, we work alongside you from the outset to ensure every custom titanium CNC part is manufacturable, efficient, and meets your specific specifications. By combining early engineering support, advanced machining, and comprehensive post-processing, we make it easy for you to obtain finished titanium parts that meet your specifications.

DFM/DFA Guidance

Our engineers review your drawings and concepts, providing actionable feedback on wall thickness, tolerances, surface finishes, and cost drivers.

Flexible Production Scale

Whether you need a single prototype, small batch production, or full-scale production, we can adjust our processes and schedules to meet your deadlines while maintaining consistent quality.

Transparent Communication

From initial quotations to final shipment, we provide clear and up-to-date information at every stage. This includes videos, photos, inspection reports, and even assembly demos so you can verify quality before the parts leave the factory.

Surface Finishing Options for Titanium

As machined

Polishing

Sand Blasting

Tumbling

Electropolish

Alodine

Anodizing

Electroless Nickel

Painting

Powder Coating

Brushed Finish

Customization and Precision

Our team works directly with your team to transform CAD drawings into fully functional titanium alloy parts. We are capable of manufacturing parts with complex geometries, non-standard specifications, and extremely high tolerances. Whether you need deep holes, fine threads, or curved surface profiles, our machining equipment and expert team can handle the most complex designs. Our experienced team applies best practices, such as optimizing cutting speeds and coolant usage to reduce heat and work hardening, selecting appropriate tools for each process, and efficient chip removal.

Our Commitment to Quality

Elimold integrates quality control and assurance into all our titanium CNC machining operations. Our in-house testing laboratory conducts detailed dimensional, geometric, and hardness tests to ensure that every part meets customer and industry specifications. Whether our machined parts are used in aerospace, medical, defense, or automotive applications, we ensure our processes comply with all applicable regulations and performance standards. We are committed to providing our customers with consistent quality and reliability from the design phase to final part delivery.

Inventory Management Services

Elimiold offers inventory management services in addition to ensuring production quotas are met. We handle all aspects from procurement and production to assembly and delivery, maintaining sufficient inventory for your project without wasting valuable warehouse space—a delicate balance. Our inventory management capabilities include monitoring your existing inventory so we can automatically procure new materials and produce new parts in a timely manner to meet your project needs. With our streamlined virtual inventory system and consistently reliable delivery services, you’ll never have to worry about parts shortages again.

FAQs

The cost of CNC machining of titanium alloy depends on the complexity and size of the part, as well as the type of titanium alloy used. These factors affect the type of machine tool required, the machining time, and the cost of raw materials.

Titanium is a high-strength and versatile material after machining. Different surface treatment methods can be used to achieve specific effects.

One method is anodizing, which involves forming an oxide layer on the surface through electrolysis. This process can give the material color and prevent corrosion. Another method is polishing, which produces a smooth, shiny surface for decorative purposes. Titanium can also be plated with ceramic or diamond-like carbon. This coating makes the material more tough and wear-resistant, which is crucial for high-stress applications.

Choosing the right surface treatment technology depends on how you plan to use the titanium alloy part and what kind of appearance you want it to have.

CNC machining of titanium alloy is a precision manufacturing process that uses computer-controlled machine tools to remove material from titanium alloy workpieces, thereby producing high-precision, structurally complex titanium alloy parts. This process enables the manufacture of complex parts with extremely tight tolerances, ensuring consistent quality, precision, and repeatability in the final product.

Elimold utilizes efficient production planning and advanced CNC machine tools to minimize delivery times. Our streamlined processes and dedicated team ensure your parts are delivered on time while maintaining quality.

Carbide tools coated with materials such as TiAlN excel due to their high heat resistance and durability. These tools effectively remove chips and maintain the integrity of the cutting edge during machining.

Elimold employs full cooling and optimized feed rates to control heat buildup. This approach prevents material deformation and ensures stable machining performance.

Elimold combines precision machining with process quality inspection to meet stringent tolerance requirements up to ±0.005 mm. We also use high-precision tooling and fixtures to ensure stability and repeatability.

Elimold utilizes multi-axis CNC systems and Design for Manufacturing (DFM) advice to optimize machining performance. Our team collaborates with clients to improve designs while ensuring structural integrity.

Grade 4 titanium is generally considered the strongest pure titanium, but it has the worst ductility. It also has excellent corrosion resistance and outstanding ductility. Due to its low density, titanium is also lighter than some steels, such as stainless steel.

Titanium has low thermal conductivity and high strength, which leads to rapid tool wear, requiring specialized cutting strategies, equipment, and experience.

Yes. We can provide material certificates (COC), RoHS, REACH, and third-party inspection reports upon request.