TPE (Thermoplastic Elastomer) Injection Molding Service

Your TPE Molding Expert: Developing high-quality, custom-molded TPE components. From mold design to final product manufacturing, Elimold offers a comprehensive, one-stop solution for thermoplastic elastomer (TPE) injection molding to meet a wide range of diverse needs.

Elimold's TPE Injection Molding Services

Are you looking for a material that combines the flexibility of rubber with the processability of plastics? Then TPE (Thermoplastic Elastomers) are the ideal choice. Elimold is one of the industry’s leading manufacturers of TPE plastic injection molding services, having completed over 10,000 TPE injection molding projects to date. Therefore, our extensive experience allows us to provide you with durable, flexible, and customizable molded elastomer parts to meet your specific needs. Leveraging our expertise in thermoplastic elastomers (TPE), we will help you transform your product ideas into a production-ready reality. Furthermore, we offer material selection and purchasing services. If you want the best results with a low-risk TPE product development strategy, choose our professional solutions.

A Comprehensive TPE Plastic Product Manufacturing Support Team

We have a professional TPE plastic product manufacturing team working behind the scenes to meet your production order needs. We manage the entire process and keep you updated on the latest progress.

Engineering & DFM

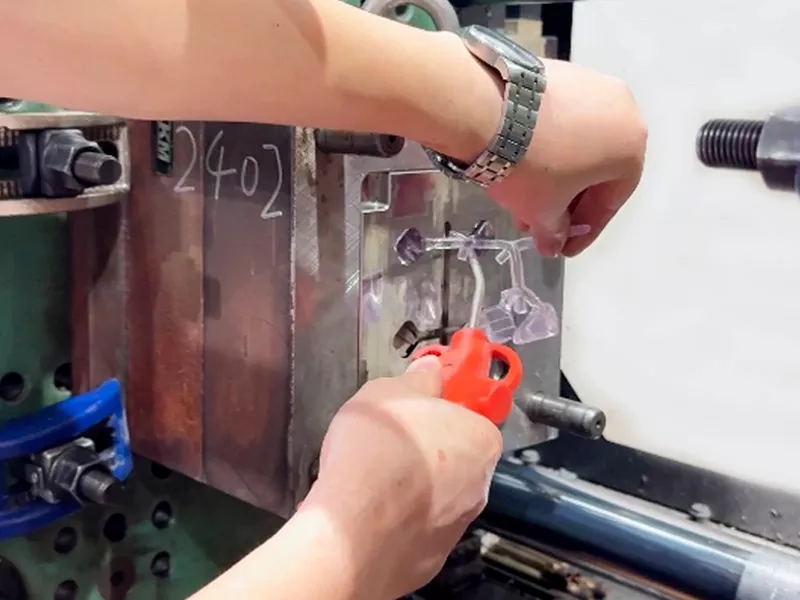

Mold Making

Injection Molding

Surface Treatments

Quality and Compliance

Assembly and Shipping

What Are TPE Materials?

Thermoplastic elastomers are block copolymers or physical blends with phase-separated structures. Their molecular chains contain both hard and soft segments, combining the flexibility of rubber with the processability of thermoplastics. They can be repeatedly melt-molded and recycled. They exhibit excellent elongation, tear resistance, and abrasion resistance, and are resistant to grease, certain solvents, and UV radiation. However, their heat resistance is typically only 100-150°C, and they are prone to permanent deformation under prolonged pressure. Some grades of thermoplastic elastomers require drying before processing, which increases their cost compared to ordinary plastics. TPE materials are popular because their superior properties can be easily achieved by simply changing the composition of the mixture, the viscosity of the components, and the composite composition.

TPE Material Categories

TPE are divided into two main categories: copolymer blends and block copolymers. This distinction is based on structural composition.

Copolymer Blends (TPE)

Block Copolymer TPE

Modification and Reinforcement of TPE Plastics

Thermoplastic elastomers can be modified to enhance their properties and make them more suitable for specific applications. Elimold offers modified materials including:

Blending with Other Polymers

Blending involves combining TPE materials with other polymers to achieve a desired balance of properties. This modification can enhance a variety of properties, such as stiffness, impact resistance, and thermal stability.

Polypropylene Blends

Blending thermoplastic elastomer (TPE) plastics with polypropylene (PP) improves stiffness and heat resistance. These blends are commonly used in automotive applications where structural integrity and heat resistance are critical.

Polyethylene Blends

Blending thermoplastic elastomers (TPE) with polyethylene (PE) improves impact resistance and flexibility. These blends are suitable for applications such as packaging, consumer goods, and sporting goods.

Nylon Blends

Blending TPE with nylon improves toughness and chemical resistance, making it ideal for demanding applications such as automotive under-hood components and industrial parts.

Thermoplastic Elastomer Material Grades

Thermoplastic elastomers come in various types, each with specific properties and applications in different industries. Below are the TPE material types commonly used by Elimold:

Styrenic Block Copolymers (TPE-S)

This styrene block copolymer is also known as TPE-S or TPS. It consists of rigid styrene blocks and soft rubber portions, resulting in excellent flexibility, suppleness, and grip.

Thermoplastic Polyolefins (TPE-O)

Thermoplastic polyolefins, also known as TPE-O or TPO, are a combination of thermoplastic and rubber materials. These materials are high in strength, weather-resistant, and UV-resistant.

Thermoplastic Vulcanization (TPE-V)

Thermoplastic vulcanizate rubber (TPE) is a vulcanized form of TPE. This type of rubber material is partially cross-linked, resulting in higher elasticity and greater durability. TPE-V is particularly suitable for components susceptible to wear, high temperatures, or mechanical stress.

Thermoplastic Polyurethanes (TPE-U)

Thermoplastic polyurethane (TPE-U), also known as TPU, is a material with excellent abrasion resistance, superior mechanical properties, and chemical resistance.

Thermoplastic Polyesters (TPE-E)

Thermoplastic copolyester (TPE-E), also known as COPE or TPC, is a combination of a polyester portion and a rubber portion. Therefore, these materials exhibit excellent abrasion resistance and heat resistance.

Thermoplastic Polyamides (TPE-A)

Thermoplastic polyamide (TPE-A) is composed of a polyamide component. They perform well in applications requiring high strength and flexibility.

Material Selection and Sourcing Services

To provide our customers with the soft, flexible injection-molded products they require, we utilize a variety of TPE materials. These elastomers are specially formulated for injection molding, enabling us to manufacture high-precision parts that meet our customers’ designs. We supply TPE elastomers in various hardness grades, from Shore A 30A to 90A and above. (The lower the number, the softer the material.) If you are unsure which material or Shore A hardness is suitable for your product, please contact us, and we will discuss your material requirements with you. Elimold’s team of experts will help you select the elastomer that meets your application and performance requirements.

Are You Ready To Work With Elimold on Your TPE Injection Molding Project?

Get an estimated quote for your custom project within 4 hours!

TPE Injection Molding Process

In the injection molding process, TPE granules enter the machine through a hopper and then into a heated barrel. The heat in the barrel melts the material into a liquid resin, which is then injected into a closed mold under high pressure. After the molten polymer cools, the finished product can be removed from the mold. Injection molding is a high-volume process with high mold costs. The advanced properties of our TPE compounds can shorten the production cycle, thereby enabling rapid production of parts.

Custom TPE Molding Solutions

With over 10 years of experience, we offer a full range of injection molding services, from mold design to final production. In addition, we provide custom TPE formulations and PMS color matching services to meet your specific needs. Whether your specifications require ergonomic comfort, compliance, or high-volume processing, Elimold’s TPEs are custom-formulated and lab-validated for practical applications. Each TPE material is tailored to your part design, equipment, and end-use requirements and validated in our in-house laboratories.

Professional TPE Injection Molding Factory

We offer a wide range of injection molding, mold making, and assembly services to meet your specific TPE project needs. Located in Shenzhen, China, we have a modern, integrated injection molding and mold making facility spanning 136,000 square feet. Our technicians, engineers, and mold makers have over 20 years of experience in the plastics industry, and we are committed to meeting your plastics needs with superior innovation, quality, and service.

Cleanroom TPE Injection Molding Workshop

Our high-tech injection molding plant serves industries with stringent tolerance and regulatory requirements. We possess modern Class 10,000 (ISO/Class 7) and Class 100,000 cleanrooms. We combine traditional experience with modern scientific injection molding principles to provide you with high-quality TPE injection molded parts. Elimold’s in-house plant is ISO 13485:2016, ISO 9001:2015, and AS 9100 REV D certified and ITAR registered, complying with FDA regulations. We strictly adhere to Good Manufacturing Practices (GMP) and comply with all applicable FAA and MIL SPEC regulations.

Secondary Processing and Surface Treatment Options

TPE is available in a variety of colors and hardness (softness/hardness). It typically has a matte rubber texture, but certain grades of TPE can be modified to achieve a glossy finish or special textures. Furthermore, TPE supports a variety of post-molding processing techniques, depending on its grade and application:

- Overmolding on rigid substrates such as ABS or PP

- Pad printing or laser marking

- Heat sealing and ultrasonic welding (depending on the grade)

- Assembly with other plastic or metal parts

Our Quality Control

We are committed to providing the highest quality TPE products through rigorous quality control measures. We strictly adhere to quality control standards to ensure that every TPE molded part meets stringent standards in terms of performance, reliability, and customer satisfaction. Raw materials are carefully inspected before entering the production line. During production, technicians conduct regular quality checks to ensure product consistency and compliance with specifications. Finally, each product is completed after passing inspections for quality, functionality, and customer compliance.

Reverse Engineering Services for TPE Plastic Products

No design drawings, only product samples? No problem! Our team can reverse engineer the parts you need and provide suitable alternative designs. For the reverse engineering of your custom thermoplastic elastomer injection molded parts, our superior service and efficient production ensure timely delivery and high-quality service.

TPE Injection Molding Alternative: 3D Printing

TPE polymers are compatible with 3D printing methods such as FDM (Fused Deposition Modeling) and SLS (Selective Laser Sintering), enabling the production of flexible parts with complex geometries. 3D printing with TPE plastics allows for rapid prototyping and production of custom parts without the need for molds. This method builds parts by stacking molten TPE material layer by layer, providing high design flexibility and rapid turnaround time.

Ready to Quote Your New Project?

We offer a one-stop TPE injection molding solution, from design and mold making to material selection and manufacturing. Contact our professional team today to solve your problems.