Tube Laser Cutting

Our advanced tube laser cutting services provide you with seamless and precise cutting. Whether you need square, round or rectangular metal tube parts, we can produce them in large quantities. With our wide range of tube laser cutting machines, we are able to serve you at every stage of your project. We know that your time is valuable and we are committed to providing efficient services to help your business reach its full potential. Contact us now for a free instant quote.

Professional Tube Laser Cutting Manufacturer

At Elimold, we specialize in providing best-in-class tube laser cutting services to meet the precise needs of our customers. Our advanced technology provides unparalleled precision, speed, and flexibility when cutting tubes of different diameters and lengths. From rapid prototyping to mass production, we provide custom metal tube laser cutting solutions to help you improve product quality, efficiency, and cost-effectiveness. We pride ourselves on our commitment to quality control and innovation, ensuring that each of our products meets the highest standards of excellence. While we can handle orders of any size, we prefer large orders so that we can take full advantage of economies of scale and optimize production processes. You can trust Elimold’s tube laser cutting services with precision, reliability, and expertise.

Comprehensive Tube Laser Cutting Services

We are a trusted metal fabrication partner for OEM and Tier 1 suppliers. We manufacture and assemble medium to high volume tube and sheet metal components with our proven technical capabilities. Our capabilities include welding, painting, laser cutting, assembly, forming and prototyping services to deliver prototypes and first-article designs. We work with our customers’ existing design and internal engineering departments to streamline proof-of-concept and production processes. We specialize in providing fully outsourced, end-to-end services and everything that comes with it. As a true one-stop shop, we offer unmatched in-house services and trusted partners to ensure the job is completed quickly. Contact us for a range of key services provided by our trusted partners.

Custom Tube Laser Cutting Solutions Provider

For Original Equipment Manufacturers (OEM), a substandard part can negatively impact the performance, safety, and reliability of the end product. Elimold’s CNC tube laser cutting services ensure you get parts that meet the expected size, shape, and function. We are a custom parts manufacturing solutions provider located in Shenzhen, China, specializing in turnkey tube laser cutting services for Original Equipment Manufacturers (OEM) and their supply chain partners. For large-scale production, we also provide everything you need. Including planning, drawing tubes up to 8 inches in diameter, and putting them into the tube laser for processing. Since order quantities can range from 1 to more than 100,000 pieces, the process varies from day to day.

At Elimold, you will find a team dedicated to providing excellent service. Consistently providing fast, accurate, and reliable service is our top priority. We are committed to helping you stay ahead of production, giving you extra time, manpower, and warehouse space to focus on other projects. Want to add a tube laser processing job to our schedule? Elimold’s team is ready to help you!

Tube and Profile Laser Cutting

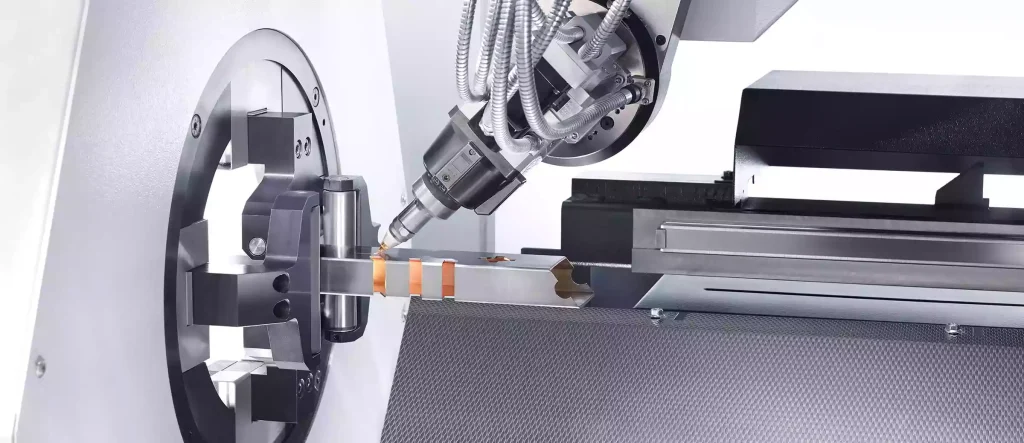

Our laser tube cutting services cover all major tubes and profiles, including large tube laser cutting, and can easily cope with a variety of special profile cutting needs. Continuous investment ensures that we can always provide customers with the most comprehensive solutions to help them stay ahead of the curve.

Take advantage of online bevel and countersink cutting, as well as FlowDrill and tapping technology provided by Laser Cutting Company. Orders will be received fully weld-ready, including 45° chamfers on internal and external contours.

High-Quality Tube Laser Cutting Services

As one of the leading tube laser cutting service companies, Elimold’s in-house facility features an impressive suite of advanced laser cutting equipment that operates 24/7. With its in-house design team and end-to-end processing services, our tube laser cutting services are unmatched.

Whether your cutting needs are large or small, simple or complex, we can secure your project. Tube laser cutting (also known as 3D cutting) can reduce material costs, increase downstream production efficiency, and provide a competitive advantage. Utilize our multi-axis tube laser cutting capabilities to open up new design possibilities, optimize parts, and achieve efficient manufacturing.

Sizes and Tolerances

- Tube processing system ByTube 130

- Min. Tube length (with automatic loading) : 8.2 ft

- Max. Tube length : 21.3 – 27.8 ft

- Max. Tube weight : 11.42 lbs/ft

- Tube sections round,square, rectangular , oval , semi-oval , elliptic

- Dimensions round sections (min. – max.) : 0.39 x 0.39 – 5.1 x 5.1 inch

- Dimensions rectangular sections (min. – max.) : 0.39 x 0.39 – 5.1 x 5.1 inch

- Dimensions other sections (min. – max.) to be inscribed in box with

- Positioning Precision* +_ 0.004 inch

- Number of controlled axis : 6

Unlimited Design

We can provide our customers with precision products that go beyond traditional shapes. Our ability to switch from cutting flat parts to cutting complex tube or box profiles is what makes our laser cutting technology stand out from many in the industry. When you work with Elimold to get a final product that truly lives up to your design promise, you can’t leave anything to chance. We focus only on customer satisfaction. From investing in cutting-edge laser cutting technology to training elite experts, we do everything we can to meet your needs. You can even place orders in small or large quantities, so there are no limits to your design.

Engineering Design Services

Elimold’s team of experienced engineers can work with you to develop innovative designs to improve aesthetics, enhance functionality, and bring new products to market faster. When you work with us, our team will work with you to design a solution tailored to your specific needs. We will gain a deep understanding of your part’s current production process, evaluate its application or end use, and work with you to identify and meet your specific needs

Ready to start your laser tube cutting quote?

Want to learn more about what Elimold can do for you? Contact us today for a consultation. We are here to help!

Fast Turnaround Laser Tube Cutting Services

We machine custom tubing parts for manufacturers who only need a handful of parts, as well as large OEM who need thousands of parts. Our commitment to every project is to maintain fast lead times so that you get the best quality parts faster, and your project is completed faster. With tube laser processing, our average lead time is 2 to 5 days, making us the regional industry speed leader. With our state-of-the-art equipment and experienced team, we can cut and custom round, square, rectangular, and even shaped tubing with the highest tolerances on the market. You can send a simple hand-drawn sketch or a SolidWorks STP file with your project specifications, or our team can create a drawing for you, run it through the dedicated ArTube software, and fabricate it for you in our in-house facility.

Quality Management

Elimold offers a vertically integrated, turnkey custom tube parts manufacturing process. Our fully automated tube laser equipment represents state-of-the-art technology. Our in-house facilities are ISO 9001:2015 certified with strong capacity and manufacturing redundancy. We collaborate on new and existing products using a Value Analysis/Value Engineering (VA/VE) process. This allows us to validate the manufacturing process prior to production, saving development time, reducing costs, and consistently delivering on time.

One-Stop Laser Tube Cutting Services

Lasers have opened up new design possibilities in the tube manufacturing industry. Elimold is able to laser cut tubes in ways that would be unimaginable by hand, resulting in stronger, more precise, and more innovative parts. We pride ourselves on being a one-stop shop, with almost all operations, including the tube laser cutting equipment, being performed in the same facility. Our cross-disciplinary expertise allows us to maintain consistency and accuracy throughout the entire production process. With our extensive knowledge of tube and sheet metal processing, we are able to provide you with a complete solution from start to finish.

Experts in Tube Laser Fabrication

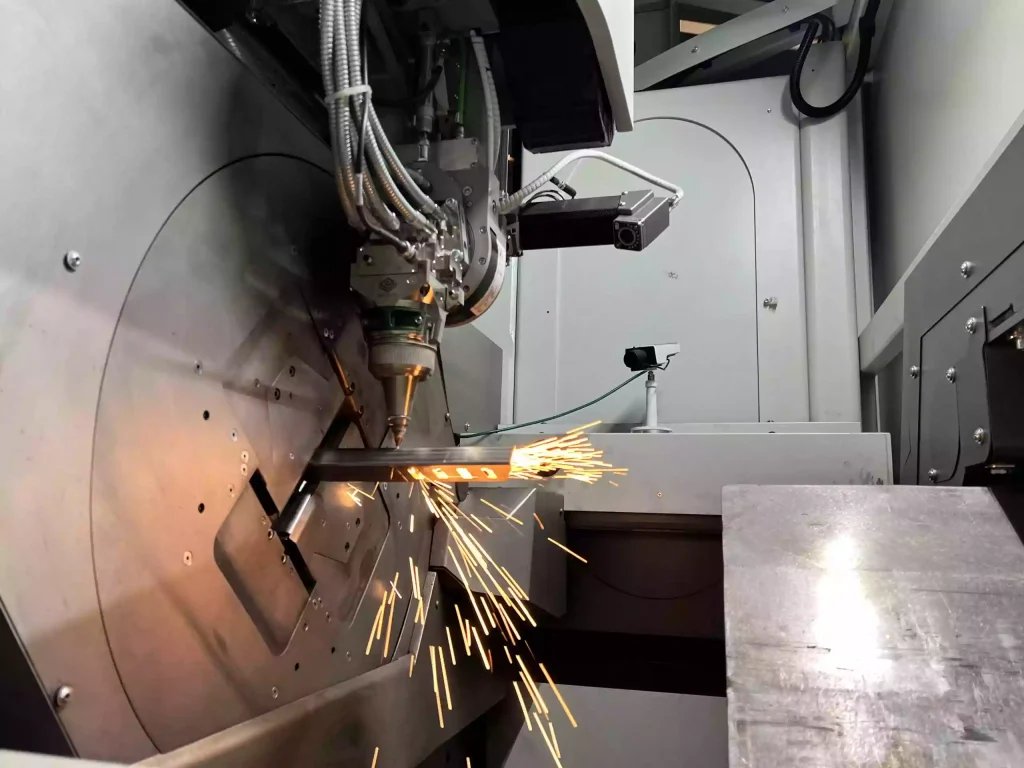

When it comes to fabrication, experience and attention to detail are critical. This is especially true when using tube laser technology, which is revolutionizing the metal fabrication industry. Tube lasers offer unprecedented precision and flexibility in metal cutting and shaping, enabling complex shapes and tight tolerances that were once impossible. However, this level of technology requires skilled and experienced technicians to operate and maintain it. Therefore, it is critical to choose a fabrication shop like Elimold that has years of experience and a consistent commitment to quality. By working with our tube laser experts, you can be sure that your fabrication needs are met with precision and efficiency.

Materials Processed

You can directly provide the required materials, or Elimold will select suppliers based on your needs, ensuring that you receive the highest quality, highest quality materials on the market. The materials we most commonly process include:

- Mild steel

- Aluminum

- Stainless steel

- Angle iron

- Channel steel

- Round pipe

- Flat bar

- I-beam

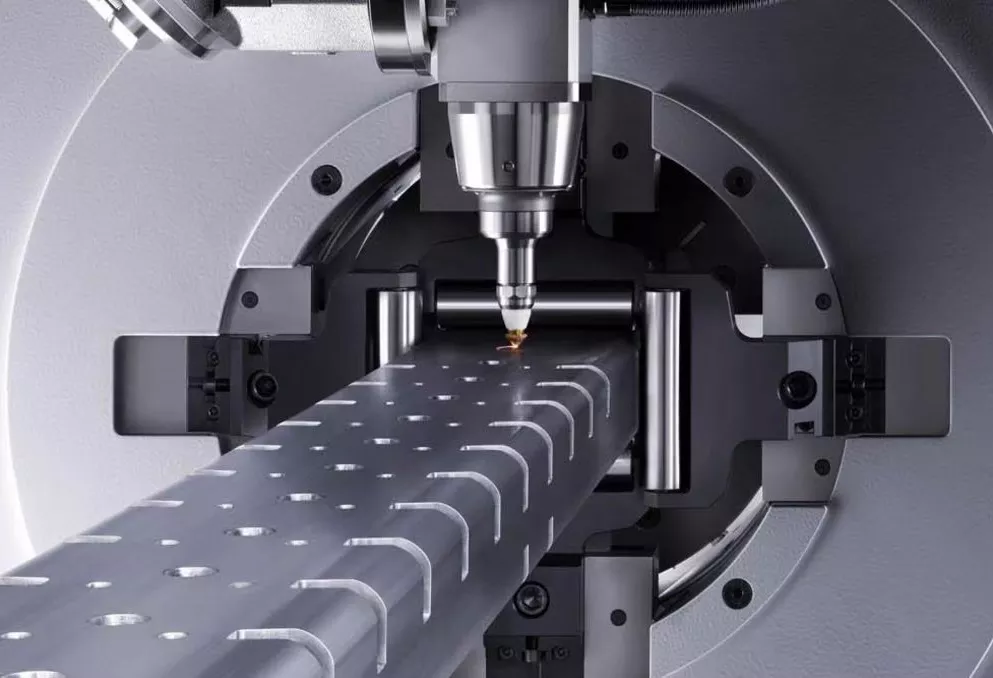

Six-axis Tube Laser Cutting

Elimold is achieving unprecedented levels of part optimization efficiency thanks to the application of six-axis 3D laser cutting technology. The wide application of tubes and profiles provides a wide range of opportunities for improving design efficiency. Reducing materials, reducing processes such as welding, and reducing assembly time all open up a path to new markets for manufacturers. Usually, operations such as cutting, welding, milling and deburring will increase project costs. Utilizing Elimold’s tube laser cutting service means that designers can reduce operations, thereby shortening lead times and reducing costs. The average cost reduction is about 50%, and it is common to reduce 85%. Need help? Maximize efficiency through design with Elimold’s in-house design services. We can fully optimize part design for efficient manufacturing and subsequent assembly.

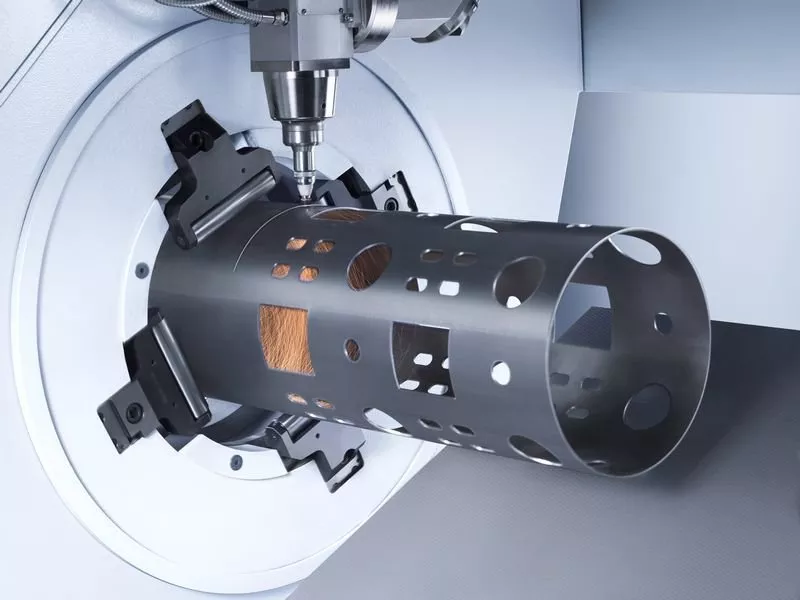

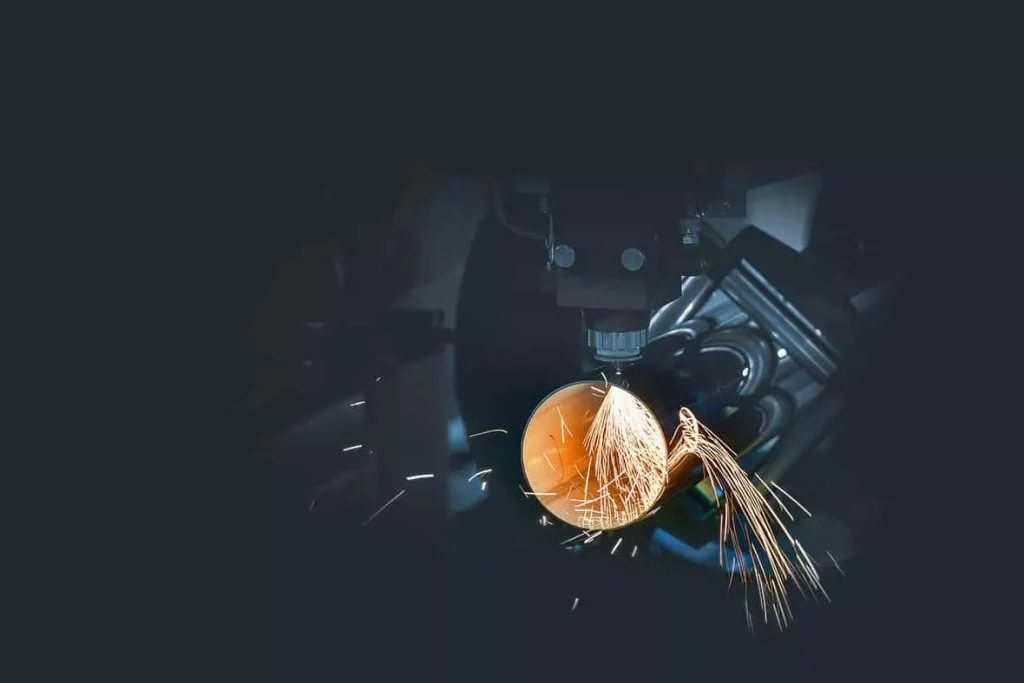

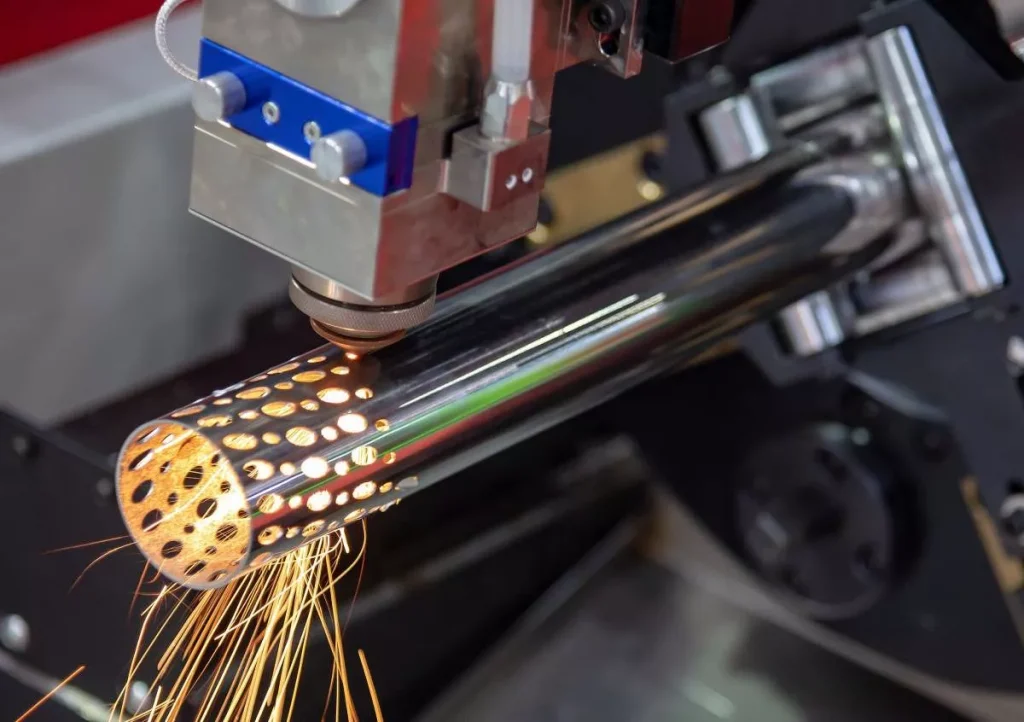

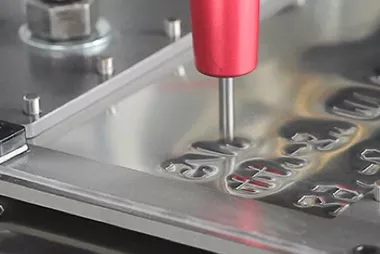

What is Tube Laser Cutting ?

Tube laser cutting is a method that employs a high-precision laser to cut or engrave tubes and pipes into desired shapes and patterns. The process involves securing the tube in a rotating mechanism, allowing it to turn in sync with the laser’s path. This technology enables the creation of precise holes and channels within the material, down to the minimum thickness of its walls.It’s particularly useful for preparing tubes for subsequent processes like bending and welding, facilitating the manufacture of complex tube structures.

Benefits of Tube Laser Cutting Services

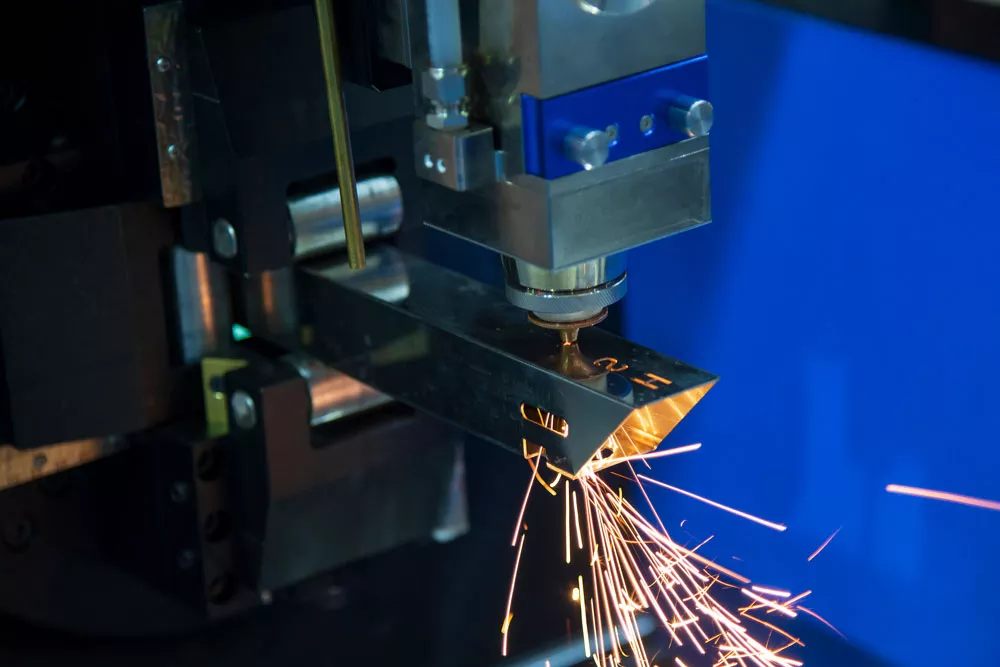

- Perfection, Every Time: Our lasers are engineered to be precise and accurate on every single tube, whether it’s cutting it to a certain length or making incisions within the tube itself. The extremely hot beam of the laser also allows for smoother and tighter cuts, leaving no excess metal to get in the way of the pipe fitting.

- Quick Cuts: The automated robotic movements of our robotic laser allow us to make cuts quickly. We’ll compute a set of movements that the laser will use to create the exact cuts and incisions in a fraction of the time it would take to do it by hand.

- Satisfaction: All of our laser-cut tubes have smooth, polished edges. We pride ourselves in creating high-quality product for low prices. We also strive to deliver every product in a timely manner—we want to ensure the customer is highly satisfied when it arrives.

Industries We Serve

Elimold provides tube laser cutting services for a broad range of industries, including:

- Construction

- Industrial fabrication / manufacturing

- Military and Defense

- Automotive

- Recreational Vehicles

- OEM

- Agricultural

- Furniture

- Communications/telecom

- Alternative Energy

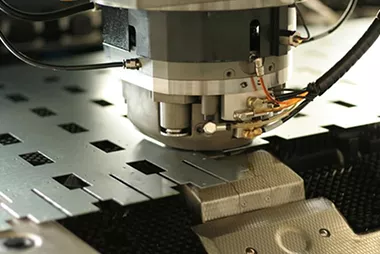

Metal Tube Laser Cutting

At Elimold, we continually invest in the latest equipment and technology in our in-house facility to provide the highest quality tube laser cutting services. Our advanced software and equipment provide our customers with a unique advantage, producing high quality, high precision parts at extremely fast speeds.

Our tube laser cutting machines can cut shapes such as tubes, structural parts or channels, and add complex cutouts and holes in one go. The system can cut virtually any geometry, including open and special shapes. With a skilled team and the right equipment, we can easily cut even the most complex parts. Submit your 3D CAD file through our platform and we will respond within 24 hours.

Other Metal Fabrication Capabilities

Elimold is committed to providing unparalleled quality and consistency in laser tube cutting manufacturing. With our extensive metal fabrication capabilities, we ensure that every project is delivered with consistently excellent results. With this in mind, we are committed to providing our customers with even more precise on-time delivery commitments.

Laser Cutting

Plasma Cutting

Punching

Stamping

Die Cutting

Bending and Forming

Welding

Extrusion

Embossing

Request Your Free Tube Laser Cutting Quote Today

After receiving your drawings, our engineers will analyze your custom Tube Laser Cutting parts right away. We actively work with you to clarify all details before providing a quote that is both economical and accurate.