Vapor Smoothing Services

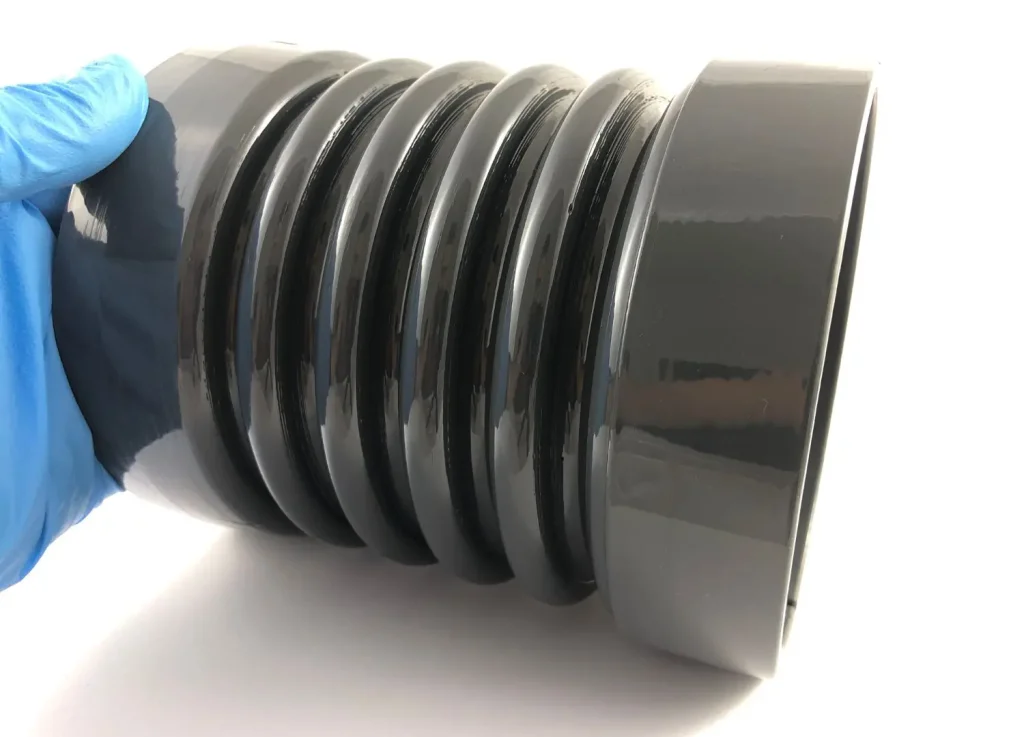

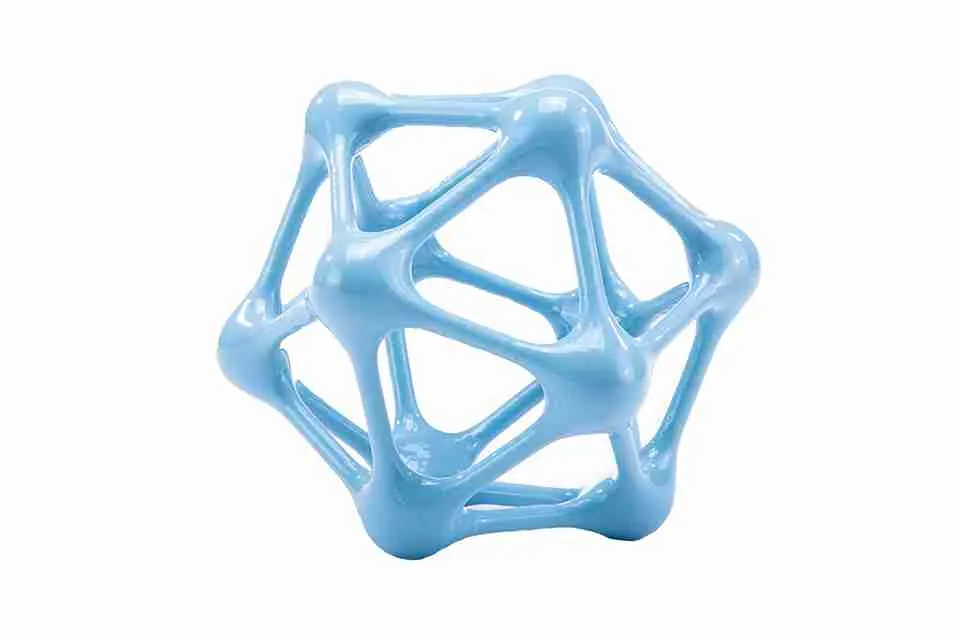

Post-processing 3D printed parts with vapor smoothing allows parts to become watertight, stronger, and smoother. This is possible without the degradation of mechanical properties. Post vapor smoothing, you can expect a surface finish extremely close to injection molding.

Vapor Smoothing for 3D Printing

Fully automated surface treatment technology smoothes and seals the surface of 3D-printed polymer parts. Achieve a surface finish with an injection-molded look and feel.

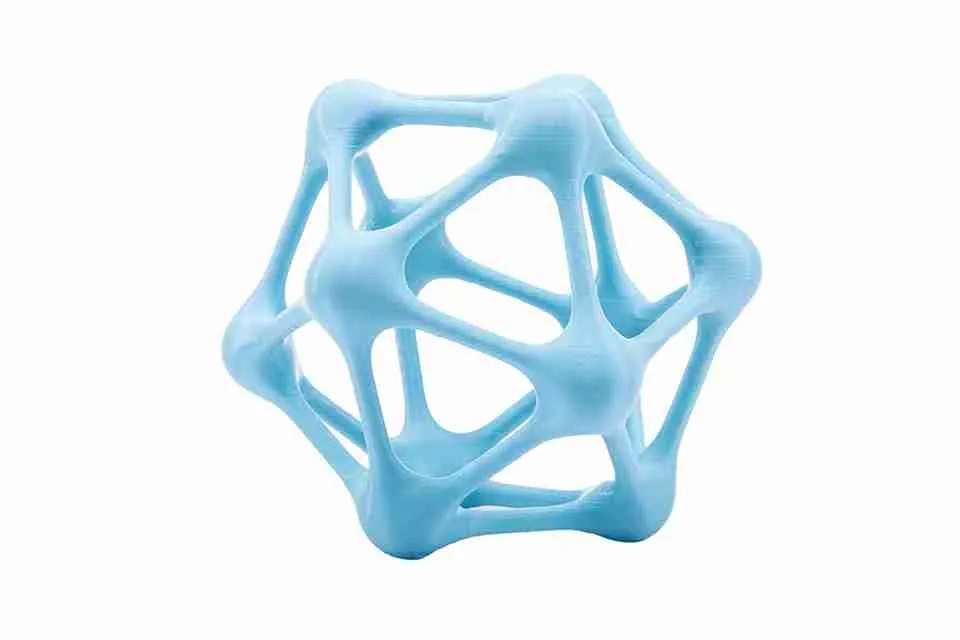

The process is non-line-of-sight, so complex geometries and cavities of thermoplastic parts can be smoothed without degrading mechanical properties. Steam smoothing can create a polished, consistent finish on your 3D parts. Traditional injection molding for mass production takes parts directly from the mold with a mirror or textured finish. No post-processing is required, and the parts can be packaged and shipped to their destination after cooling. Molders use polishing techniques with brushes, felt, stones, and other tools to achieve this complete finish.

From Prototype to Production

Fully automated surface treatment technology that smooths and seals the surfaces of 3D printed polymer parts. Achieve a surface finish that has the look and feel of an injection molded product. Steam smoothing with Elimold is the ultimate solution for enhancing the appearance and quality of your 3D printed parts. Our advanced systems use advanced steam smoothing technology to create a flawless, glossy surface that truly shows off the intricate details of your design. This innovative process takes your printed parts to a whole new level, from rapid prototypes to professional-grade finished products. The process is non-line-of-sight, so it can smooth complex geometries and internal cavities of thermoplastic parts without compromising their mechanical properties. The patented Elimold Steam Smoothing technology is UL and CE certified and recommended by leading additive manufacturing companies around the world.

Tailor Your Vapor Smoothing Experience

Discover the ideal finishing solution that aligns with your specific needs and budget. to ensure maximum quality our specialists will carry out a preliminary set-up testing on one of your sample.

Direct Vapor Smoothing

Manual Finishing + Vapor Smoothing

Stand-alone Vapor Smoothing

Steam Smooth 3D Printed Parts

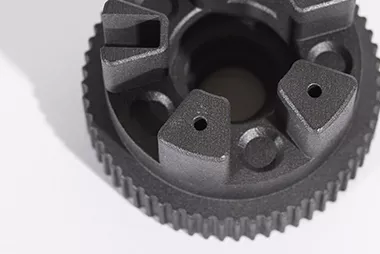

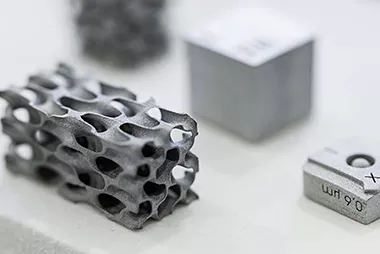

3D printing is one of the best ways to get products in small batches. However, plastic 3D printing often involves an important trade-off: rough-surfaced parts. Powder bed fusion processes such as Selective Laser Sintering (SLS) and HP Multi Jet Fusion (MJF) leave a matte sugar cube-like surface finish. Fused Deposition Modeling (FDM) shows different layer lines. In the past, post-treatment surface finishes such as abrasive media tumbling, hand finishing, or coating have slightly improved the surface finish of 3D printed parts. Engineers may opt for other processes entirely, such as injection molding, CNC machining, or polyurethane casting.

With the introduction of chemical vapor smoothing, a technique that smoothes 3D printed surfaces and improves mechanical properties by vaporizing a solvent, 3D printed plastics are now more suitable for low-volume production than ever. Chemical vapor smoothing works with most 3D-printed polymers and elastomers.

Applications of Steam Smoothed Parts

You can get instant pricing and lead times for Steam Smoothing at Elimold based on the most common processes, materials, quantities and part geometries. Because the process is batch-based, the cost per part is relatively low and decreases with larger order volumes. Elimold typically extends lead times for Steam Smoothing by 1-5 business days.

Increased Mechanical Properties

Due to the removal of surface porosity, extensive testing demonstrates that vapor smoothed demonstrated no loss in Ultimate Tensile Strength (UTS) with an increase in Elongation at Break (EAB).

Injection Molding-Like Surface

Using a series of predefined parameters, this process achieves for the first time a surface finish that matches injection molding techniques with an RA of less than 1 micron.

Dimensional Accuracy

The process does not degrade the mechanical properties of the parts. After the treatment, parts exhibit no more than a 0.4%-dimensional change, irrespective of the desired finish level.

Seals Against Liquid & Gas Intake

The treatment completely seals the surface, eliminating liquid or gas intake. As a result, parts become watertight and airtight.

Enhances Colour

Vapor smoothing enhances the color consistency and hue of the colored part. Additionally, parts with color, such as HP MJF 580 parts, do not bleed in 3D machines.

Reduction in Bacteria Growth

Tests have shown the reduction of bacteria growth and attachment on parts that have been chemically vaporing smoothed.

Vapor Smoothing Creates a Polished Part In Seconds

Vapor Smoothing is a fast, effective way to achieve a smooth finish for your 3D Printed Objects. By using the Vapor Smoothing System, 3D printed parts can be finished to a fine smoothness without losing the detail of the original printed part.

- Consistent, uniform results to every part that is vapor smoothed.

- Significantly reduced processing times from hours to minutes.

- Smoothing of parts with complex geometries and intricate angles.

- Easy removal of small layer lines.

- Smoothing of most FDM thermoplastics, including ABS and ASA.

- Elimination of the use of flammable solvents like Acetone and THF.

Get an instant quote on your 3D printing design.

Are you ready to unleash the full potential of 3D printing? Elimold offers a comprehensive range of 3D printing and post-processing services to meet your specific needs. Our team of experts can guide you in material selection, recommend the most appropriate post-processing techniques (steam smoothing, vibration polishing, and more!), and handle the entire production process with precision and care.

Why use vapor smoothing?

Additive manufacturing is often used for small-batch production, offering unparalleled flexibility and speed. However, industrial powder bed fusion technologies such as Selective Laser Sintering (SLS) and Multi Jet Fusion (MJF) produce parts with a grainy surface texture reminiscent of a strong minty flavor. The advent of chemical vapor smoothing marks a major turning point in this field. This innovative technology not only smoothes and seals the surface of 3D printed parts, but also enhances their mechanical properties. With vapor smoothing, 3D printing polymers is more suitable than ever for small-batch production.

What is Vapor Smoothing?

Vapor Smoothing is a post-processing technique used in 3D printing to improve the surface finish of printed parts. The process uses the heat and condensation of steam to smooth and level the surface of the part, thereby reducing common defects in the printing process.

Vapor Smoothing is performed in a special sealed chamber equipped with a heating and steam supply system. The 3D printed component is placed in this chamber. Then, vapor generated by the heating of the solvent is injected into the chamber. The vapor condenses on the surface of the part, a phenomenon that causes the surface of the material to partially soften and smooth it through surface tension. This effect smoothes and evens out the characteristic porous surface caused by multi-jet fusion printing, resulting in a smooth and uniform surface. The processing time depends on the material, component size and the desired surface finish.

Steam Smoothing Workflow

The steam smoothing process is carried out in a special sealed chamber equipped with a heating and steam delivery system. The 3D printed part is placed in this chamber. The steam generated by the heating of the solvent is then injected into the chamber. The steam condenses on the surface of the part, causing the surface of the material to partially soften and become smooth due to surface tension. This effect evens out the porous surface caused by multi-jet melt printing, resulting in a smooth and uniform surface. The processing time depends on the material, part size and the required surface finish.

Benefits of Vapor Smoothing 3D Printing

Vapor-smoothed parts improve the appearance and rival an injection-molded surface finish. The surface roughness of standard SLS parts is typically greater than 250uin Ra but can be improved to below 125uin Ra and as low as 40uin Ra by chemical vapor polishing. Chemical vapor smoothing can improve material surface by 800%-1000%. It is important to note that chemical vapor smoothing redistributes the surface material to provide a sealed, smooth surface but does not produce a polished surface. There will still be visible surface topology and minimal layer lines.

Chemical vapor smoothing can significantly improve the viability of 3D printing in food processing, medical devices, and consumer products and is recommended for end-use applications in these industries.

Which 3D printing materials can be vapor smoothed?

- Nylon 12

- Nylon 12, Glass Bead

- Nylon 11

- Thermoplastic Urethane, TPU 88A

- Polypropylene (PP)

- Nylon 11 EX

- Nylon 12, Carbon-Filled (CF)

- Nylon 12, Aluminum-Filled (AF)

- Nylon 12, Mineral-Filled (HST)

Other benefits of chemical vapor smoothing include

- A uniform, sealed surface, on 3D printed parts

- Improved tensile, elongation, and flexural performance

- No extra coatings; the surface is the part's material

- Significantly reduced moisture absorption

- Closed loop, repeatable processing results

- Ability to polish non-line-of-sight features

- Retains features and dimensional accuracy

- No residual chemicals or media in features

- Improved cosmetics and enhanced colors

Design Tips for Vapor Smoothing 3D Prints

- Add radii to sharp internal corners to prevent rounded voids

- Keep wall and feature thicknesses above 0.040" (1 mm) to avoid distortion or defects

- Keep wall thicknesses uniform, similar to injection molding

- Be mindful that orientation-specific build lines may still be present, but smoothed

- Racking marks may be visible depending on how the work was held during processing

- Flexible materials, like TPU 88A, may have more surface imperfections versus rigid materials

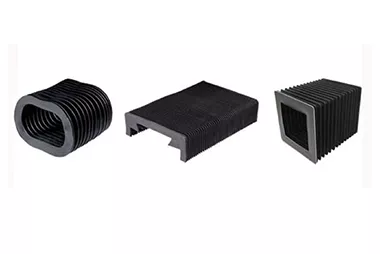

Applications for Vapor-Smoothed Parts

Vapor smoothing on printed medical parts enables aesthetic designs that are comfortable, easy to clean, and sweatproof. It’s also ideal for automotive and industrial machinery as it produces smooth, tactile, leak-proof 3D-printed parts. These properties allow for a wide range of applications, from concept modeling to prototyping testing and end-use parts.

Typical use cases include:

- custom medical devices

- wearables

- liquid reservoirs and tanks

- fluid transfer pipes and manifolds

- ducts

- valve covers

- oil sumps

Integrated Post-processing

If you want to fully exploit the potential of additive manufacturing while achieving the high-quality surface finish typical of injection molding, the professional Elimold steam smoothing process is the ideal solution for you. This post-processing technology matched to Elimold materials enhances the aesthetics and mechanical properties of 3D printed parts, making them not only visually attractive but also more durable. In addition, we can also provide CNC machining services CNC machining can be applied to additively manufactured parts with steam smoothing for complex geometries and precise finishing to ensure that parts meet strict specifications.

3D Printing Services by Elimold

Elimold offers a variety of different 3D printing service types. And our team of engineers will consider the material, desired finish, part complexity, and safety factors to choose the best option for your project. With the right technology, your 3D print will go from a rough prototype to a beautiful masterpiece, ready to impress.

Stereolithography (SLA)

Selective Laser Sintering(SLS)

PolyJet

Multi Jet Fusion (MJF)

Digital Light synthesis(DLS)

Fused DepositionModeling (FDM)

Direct metal laser sintering (DMLS)

P3 technology (DLP)

Solidscape (wax deposition)

Micro 3D Printing

Wire Arc Additive Manufacturing (WAAM)

Metal Binder Jetting

Request Your Free Vapor Smoothing Quote Today

After receiving your drawings, our engineers will analyze your custom Vapor Smoothing parts right away. We actively work with you to clarify all details before providing a quote that is both economical and accurate.