Vertical CNC Turning

At Elimold, we offer industry-leading vertical CNC turning services. With state-of-the-art equipment that can handle a wide range of materials and part sizes, we are able to produce parts with unparalleled precision, making us the go-to solution for a wide range of industry needs. We tailor our services to your exact requirements and ensure that every part produced meets the highest standards of accuracy and reliability, helping you keep your project running smoothly. Contact us now for a free instant quote.

Professional Vertical CNC Turning Manufacturer

Elimold provides the highest quality CNC vertical turning services. With highly skilled CNC programmers and machinists and state-of-the-art vertical turning centers, we are committed to sound engineering, ethical business practices, and innovative design. We specialize in low-volume production and offer expedited and emergency services with fast delivery. We always strive to exceed our customers’ standards for precision, accuracy, and quality. If you need complex parts with tight tolerances and high precision, we have the equipment, knowledge, and experience to meet your exact specifications. Rapid CNC vertical turning is best used for rapid prototyping, form and fit testing, jigs and fixtures, and end-use functional parts. Trust Elimold’s experienced team to tailor a solution that meets your budget and deadlines without compromising standards. Eliminate the risk and cost of switching suppliers by choosing Elimold as an experienced partner.

Full Range of Vertical Turning CNC Machining Services

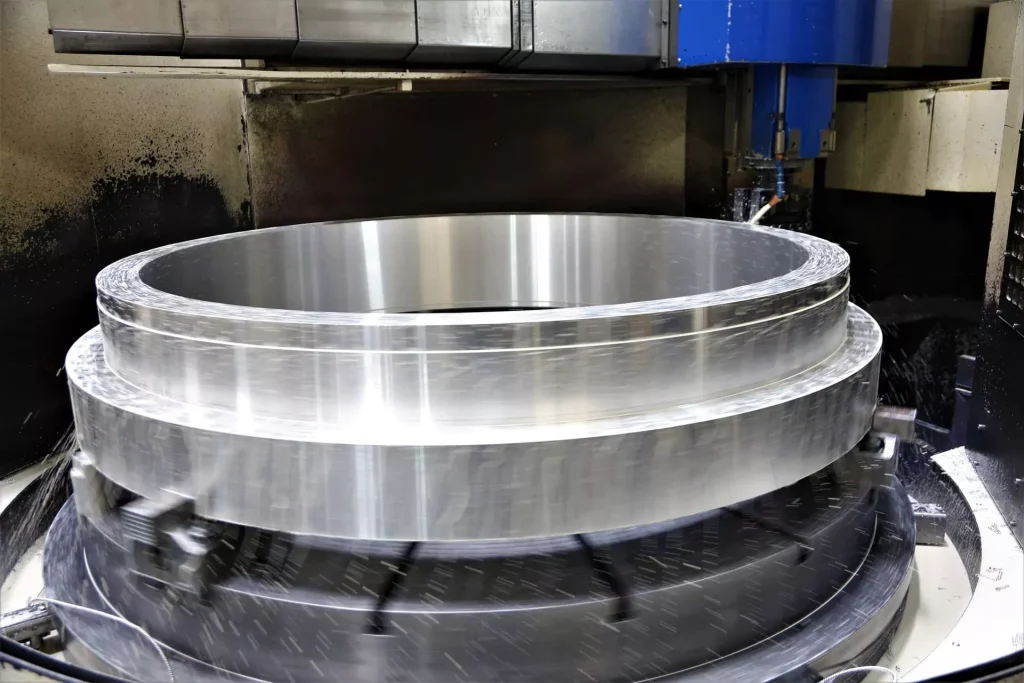

As a leading vertical CNC lathe shop, Elimold offers a full range of vertical turning CNC machining services. Our experienced technicians use advanced CNC technology to tailor precise and reliable parts for your industry. As an industry leader, we have the advanced equipment and technical experience to meet your most demanding vertical turning needs. Our innovative approach allows us to handle parts from a wide range of materials, from heavy and strong parts to thinner and less stable parts. We dare you to find a vertical turning application that is beyond our capabilities. Whether it is forging, casting or manufacturing, we have the professional talent and rich experience to solve your problems and complete them smoothly.

In-House Vertical Turning Shop Capabilities

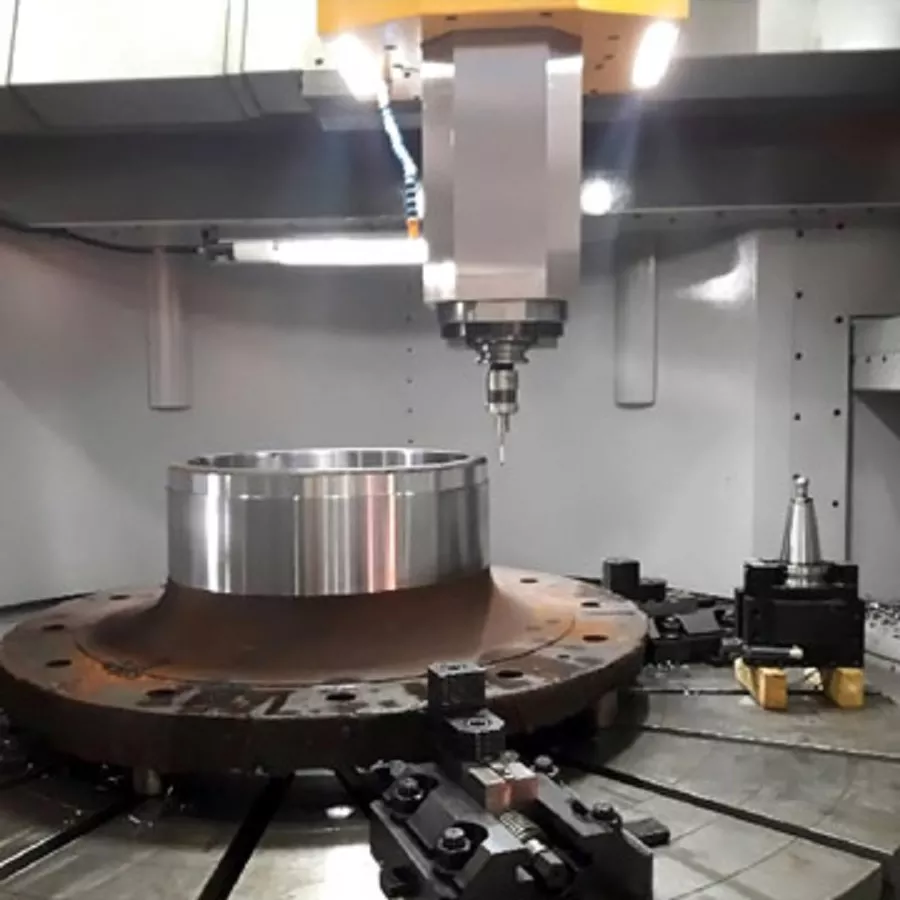

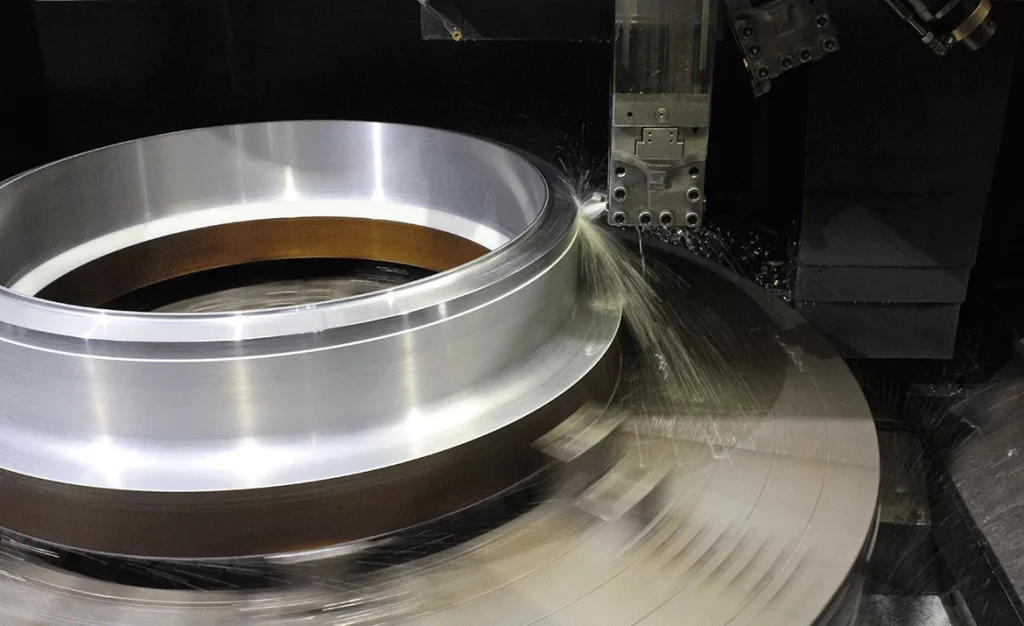

Elimold’s in-house vertical turning shop has the expertise and equipment to machine large parts from prototypes to mid-volume production runs, including experienced machinists, a temperature controlled shop, and the right measuring tools. Our wide range of CNC lathes can machine parts from 2” to 84” in diameter, up to 144” in length, and up to 20,000 lbs in weight, with tolerances of ±0.001. Our capabilities push the limits of shape, size, and complexity. In addition, we have a 35-ton capacity crane that easily transports large, heavy parts throughout the facility. Whether you need a part made from standard metals, high-performance alloys, or engineered plastics, we can meet your specifications, schedule, and budget.

In addition, our experienced in-house maintenance team maintains all machines to the highest standards. Our CNC vertical lathes are tested for accuracy using in-house equipment during regular preventive maintenance activities. Continuous machine accuracy assessments give you confidence that your parts meet specifications.

Vertical Turning Process Types

Turning Processes our machines can handle:

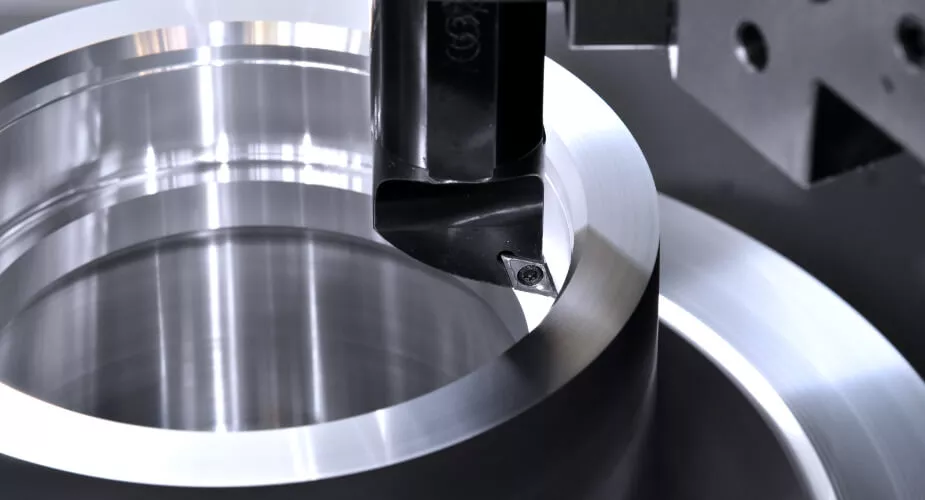

- Boring

- Cutting

- Drilling

- Facing

- Internal Forming

- Knurling

- Necking

- Parting

- Shoulder Facing

- Threading (external, internal)

- Turning (contour, form, taper, straight)

Large Vertical Turning Machining Services

Elimold offers vertical turning services for businesses that require precision conventional and CNC large-diameter turning of large, heavy and long parts. Our in-house facility features a wide range of vertical turning equipment, including vertical turning centers capable of handling large diameters and long designs. And, with a combination of manually driven machinery and CNC technology, we are able to provide the most efficient processes to cost-effectively meet your turning and milling needs for large-diameter workpieces and large manufacturing equipment components.

And, our expertise in handling complex materials and shapes gives us an edge over our competitors. We solve your machining challenges and find a solution for each one. From unique workholding to finding the right material, our machinists are committed to finding solutions, not excuses.

A Trusted Partner

Elimold believes that true partnership is the key to success. Since our founding, we have built lifelong relationships with numerous customers around the world by producing high-quality CNC machined parts.

Trust Elimold’s experienced team to design a custom solution that meets your budget and deadlines without compromising standards. Choosing Elimold as an experienced partner eliminates the risks and costs associated with switching suppliers.

Ready to start your next vertical turning project?

If you need vertical CNC turning and manufacturing services, we will provide you with high-tech solutions you can trust. Contact Elimold today and we will provide you with years of machining expertise and experience to help you achieve success.

What is Vertical Lathes?

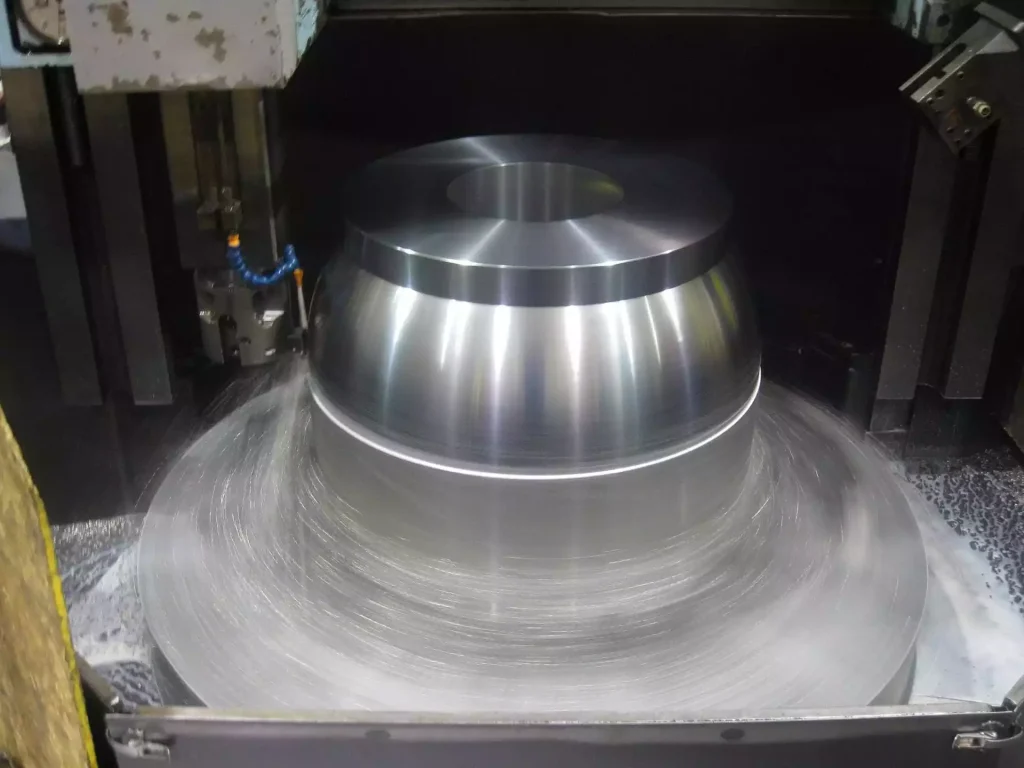

Vertical lathes orient the spindle in a fixed position in the vertical plane. The workpiece moves up or down to place it in line with the appropriate tool necessary for the desired operation.Vertical lathes are less complex than horizontal machines. They provide the best option for projects that focus on a single side, like large metal plates and sinking dies. They hold an advantage over horizontal lathes in circumstances where workpiece sagging might be a factor.

Advantages of Elimold's Vertical Turning Services

There are certain applications where a vertical lathe has advantages over other machining solutions. We use this to produce better quality parts and more efficient machined components. The advanced vertical turning equipment used in Elimold’s in-house facility is easy to install and fix when machining heavy workpieces. In addition, the lathe equipment has spindle self-loading and unloading functions, and is able to perform multi-tasking when machining and producing chucked parts, reducing customers’ processing time and turnaround time.

Our vertical lathes can accommodate larger and heavier castings better than horizontal lathes. We are able to safely perform heavier cuts without compromising tolerances. This shortens the machining cycle because we can remove material more efficiently. We can control the final surface finish from semi-finished to fine-finished, allowing customers to obtain excellent finished products without any grinding.

Material Options

We are capable of CNC vertical turning a diverse range of materials including:

- Aluminum

- Brass

- Bronze

- Cast iron

- Copper

- Inconel®

- Hastelloy®

- Nickel

- Steel

- Stainless steel

- Titanium

- Variety of Plastics

Surface Finishing Options

- Anodizing

- Electroplating

- Electroless Plating

- Phosphate Coating

- Passivation

- Nitriding

- Carburizing

- Thermal Spraying

- Black Oxide Coating

- Hard Coating

- Shot Peening

- Laser Surface Hardening

- Plasma Nitriding

- Hot-Dip Galvanizing

Rigorous Quality Inspection Process

Elimold is renowned in the industry for quality workmanship and reasonable prices. We have an ISO 9001:2015 certified quality management system. We uphold a culture of quality and perform a series of supervised and documented testing and inspection procedures at all key production stages. Customers can rest assured that any component will only leave the factory after it meets the highest quality standards. Elimold has established successful partnerships with top companies around the world with its superior quality, excellent performance and commitment to growth and innovation.

Value-added Services

In addition to our large diameter CNC vertical turning capabilities, we can also provide in-house secondary machining services including honing, thread forming, cylindrical grinding and phosphating. Our well-vetted, highly reliable outsourcing partners can provide services such as thermal spraying, flame hardening, Blanchard grinding, heat treating, ion or salt nitriding, carburizing, stress relieving and induction hardening. We provide turnkey services and take the lead in raw material procurement, processing, transportation and subcontracting for various projects.

Special applications

Vertical turning lathes find widespread use in various industries where precision and reliability are critical. Some of the applications we use our vertical turning machines for include:

- 4th Axis Machining

- 3D Profiling

- Casting Machining

- Bore Repair

- Valve Repair

- Part Mapping

- Press Plate Machining

- Production Runs

Industries We Serve

We are committed to providing excellent service to our customers and becoming a long-term partner to companies in various industries around the world.

- Semiconductor

- Aerospace

- Automotive

- Electronic

- Machine tool

- Medical

- Military

- Plumbing

- Food

- And more!

CNC Vertical Turning Applications

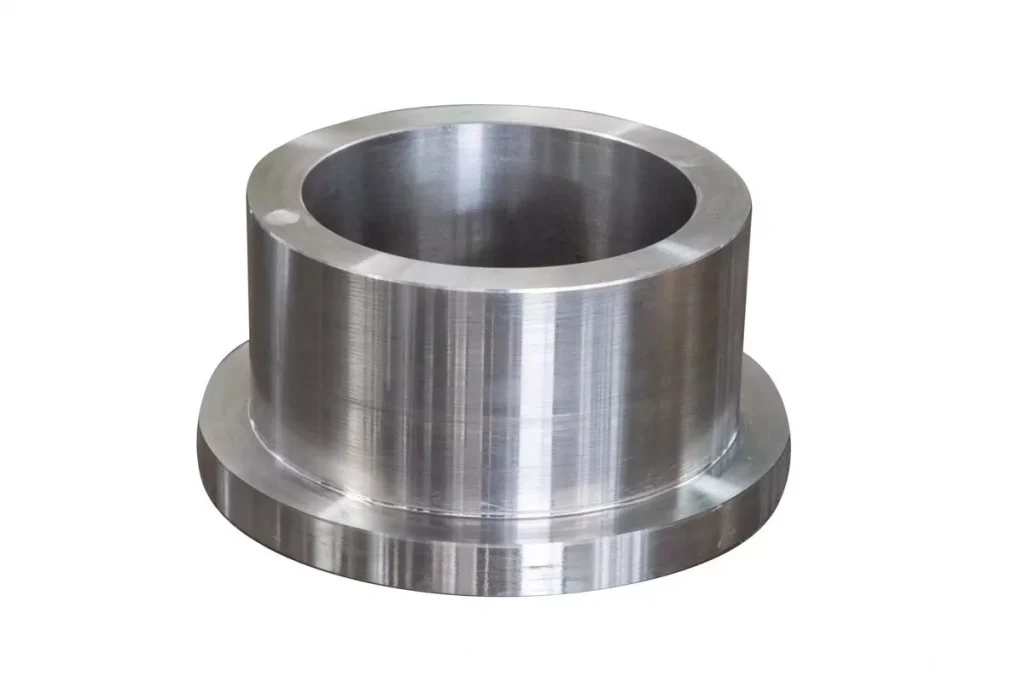

Elimold produces high-quality precision CNC vertical turned parts for a variety of industries around the world. We specialize in manufacturing complex parts with tight tolerances to meet your specifications.

- Brake discs

- Flywheels

- Pump housings

- Gear blanks

- Bearing housings

- Valve bodies

- Wheel hubs

- Flanges

- Couplings

- Large rings

- Turbine casings

- Pipe fittings

- Rotors

- Pulleys

- Cylinder liners

- Clutch plates

- End caps

- Compressor wheels

- Pipe flanges

- Slewing rings

- Seal rings

- Thrust washers

- Drum brakes

- Bearing covers

- Motor housings

- Turbine wheels

- Machine bases

- Hydraulic cylinder bases

- Pressure vessel ends

- Large washers

Other CNC Machining Services

Elimold is dedicated to providing a variety of exceptional CNC machining services for demanding, low tolerance industries. Our services range from simple drilling of production-level parts to the fabrication of complex designs.

CNC Milling

CNC Turning

3 Axis CNC Machining

4 Axis CNC Machining

5 Axis CNC Machining

CNC Prototypes

Wire EDM Machining

CNC Threading and Tapping

CNC High-Speed Drilling

Swiss Machining Service

CNC Routing Service

CNC Grinding Service

Request Your Free Vertical CNC Turning Quote Today

After receiving your drawings, our engineers will analyze your custom Vertical CNC Turning parts right away. We actively work with you to clarify all details before providing a quote that is both economical and accurate.