Waterjet Cutting Services

We have an in-house water jet cutting factory and have many years of experience in this field. Elimold is customer-centric and will do our best to meet your needs whenever you need us. We are able to deliver quickly and are flexible depending on the job needs. In addition to speed, we also provide cost-effective quality for each part. Our team can handle a wide range of parts from prototypes to mass production. Let us help you with your next project, we won’t let you down.

Professional Waterjet Cutting Manufacturer

Our factory currently has an independent waterjet cutting workshop that can meet the production needs from single prototypes to large projects lasting several months. We know that your project schedule is critical, and we are willing to work around the clock to meet your fast deadlines. We continue to invest in waterjet technology to ensure that we always have the most advanced waterjet technology. In addition, our in-house full-service manufacturing plant can provide a variety of sheet metal production and CNC machining services in addition to waterjet cutting services. The complete service capabilities enable us to transform your ideas and designs into complete projects, and pay attention to details and service every step of the way.

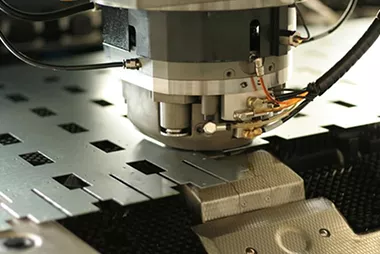

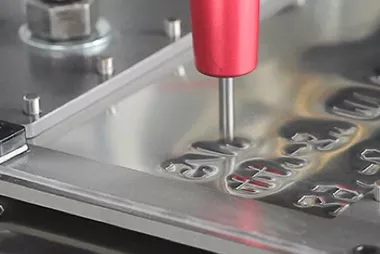

In-House Advanced Waterjet Cutting Factory

Elimold has a state-of-the-art manufacturing factory and is one of the most innovative in the industry. Our 15,000 square foot shop is equipped with a wide range of advanced waterjet cutting equipment. From one-piece projects to mass production, we treat every job with the same high standards and meticulousness. In addition, we have 27,000 square feet of warehouse space, and currently have more than 2,000 custom parts for customers in various industries, and the inventory continues to grow. It’s one of the reasons why more than 30,000 companies around the world choose us as their metal solutions provider. We have no minimum order requirements and most orders can be shipped the same day, while the industry standard is usually 5-7 days. And no matter the size of the project, Elimold can take it. No matter the size, from small to large, from industrial to craft, from basic to complex, our team will ensure that your custom waterjet cutting project is completed and delivered according to your needs and timeline.

Elimold Waterjet Cutting Service Capabilities

Our waterjet cutting equipment provides unlimited flexibility in our operations. We can cut materials up to 12 inches thick or as thin as 0.001 inches. Our waterjet cutters can cut materials from 0.06 inches to 160 inches wide and 0.06 inches to 320 inches long. Waterjet cutting provides an excellent edge finish from 1-5 grades while holding tolerances to within +/- 0.005 inches. For harder materials, we can cut workpieces up to 120 inches x 300 inches with our abrasive waterjet cutters. Our abrasive cutters can handle materials up to 10 inches thick.

Full-Service Waterjet Cutting Parts Supplier

Elimold is a comprehensive supplier of waterjet cutting and other services. We will work with you from the beginning to determine the best manufacturing process, all the way to selecting a high-quality finishing company. We are committed to providing high-quality services at every stage of production, from excellent customer service to meticulous communication, to advanced technology and industry expertise, we strive to exceed your expectations. And we undertake a variety of business from prototypes to mass production, with fast lead times and can provide rush orders and pre-expedited orders. We are committed to customer satisfaction and provide personalized service to each customer. In addition to laser and waterjet cutting, we also provide a wide range of value-added services, including reverse engineering, electroplating, welding, assembly, kitting, special packaging, warehousing and customized shipping solutions. For more details on precision waterjet cutting services or other auxiliary services, please contact us directly.

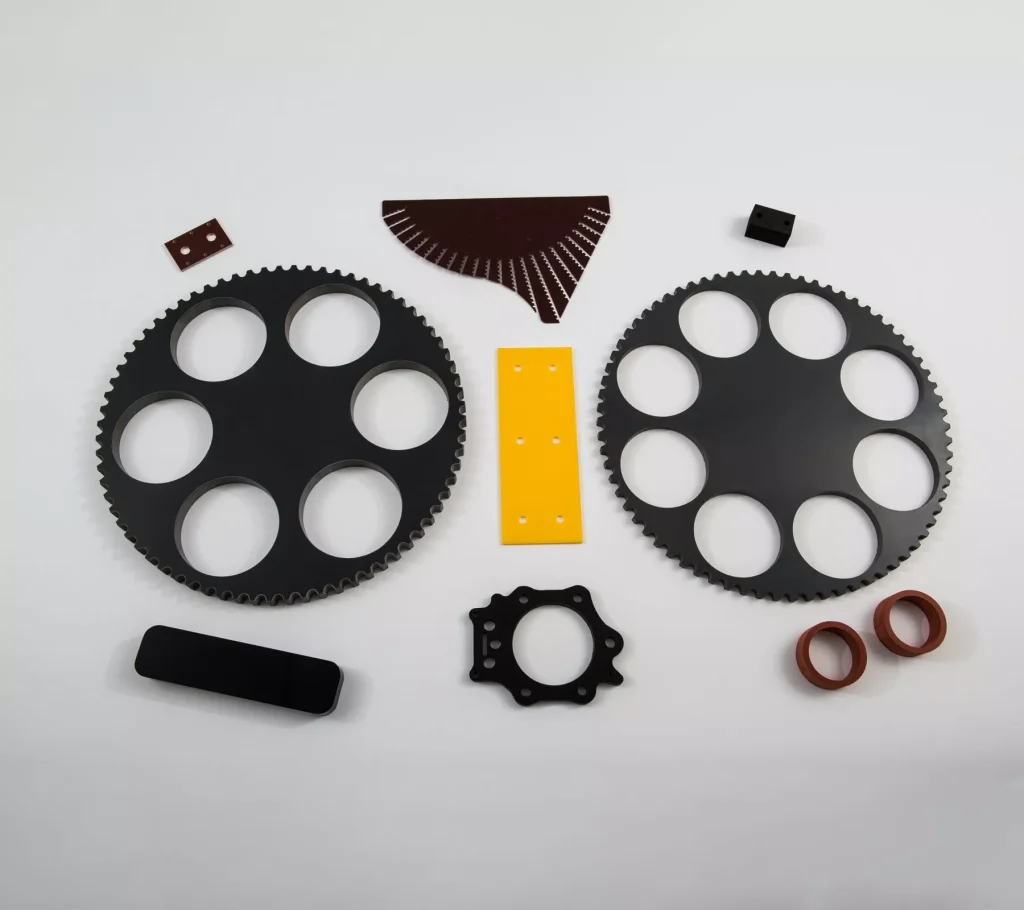

High Quality Waterjet Cut Parts

We always put our customers first and make sure to treat them with the utmost respect, because we believe that every detail matters. Therefore, during the custom parts inspection process, we ensure the quality and integrity of your metal components by using calibrated inspection equipment, precision tools and strict quality systems, including providing a variety of testing and inspection procedures (such as surface and dimensions, ultrasonic testing, visual inspection, etc.). As a result, we can achieve the best results on your parts, components or prototypes. We use tested and repeatable techniques and have a well-trained and dedicated staff to ensure that your work or ideas are of the highest quality. Elimold adheres to its core values and is determined to exceed the expectations of each customer.

Ready to get started on your waterjet quote?

Start your project today! Upload your CAD design and get an instant quote for custom waterjet cut parts.

Precision Waterjet Cutting & Fabrication

We provide waterjet cutting services from prototypes to high-volume production. With our multi-axis cutting capabilities, we can create everything from 2D shapes to complex 3D shapes in a single operation while maintaining high precision. Our powerful waterjet cutting capabilities are suitable for nearly all materials and produce smooth edge surfaces, often without the need for further processing. Our waterjet cutting services are competitively priced and come with fast turnaround and on-time delivery.

Whether you require small or large batches, we can meet your specific needs. Our ISO 9001:2015 certified facility can produce products ranging from 1 to 100,000 pieces depending on your size requirements. We also adhere to a variety of industry standards to ensure that your custom parts have superior performance and quality.

Engineering & Design Services

Our team of experts is ready to provide exceptional customer service and assist you with any simple or complex part design. Our experienced CAD design team can import most drawings. If you are unsure of your needs, our design team can help you create cutting designs and nest items for optimal use of materials. We also assist customers with design and layout to ensure proper installation. Whether you are an entrepreneur with a big idea or a manufacturer in need of a prototype part, our team is ready to turn your concept into a usable part. We provide cost-effective waterjet cutting services that fit your budget, are 100% traceable, and are ISO 9001:2015 quality certified.

Secondary Operations Service

- Assembly

- Powder Coating

- Welding

- Riveting

- Bagging/Kitting

- Tapping

- Plating

- Heat Treating

- Deburring

- Stress Relief

- Swage

- Reaming

- Counterboring

- Spot Facing

- Fabricating

Value-added Services

In our state-of-the-art facilities, we use the most advanced waterjet cutting technology to produce the near-net or net-shape products you need. In addition, we offer value-added services such as bending, boring, centerless grinding, double-disc grinding, grinding, drilling, forming, heat treating, rolling, stamping and nesting to help you produce a complete finished part. To learn how our waterjet or laser cutting services can help you complete your next project, contact us today or request a quote online.

Quality Management

Elimold proudly offers water jet cutting services, and we are able to cut steel plates to your exact specifications. All inventory is 100% traceable, and all water jet cut parts are produced in accordance with our ISO 9001:2015 certified quality system. We can perform a material takeoff based on your drawings, replicate your parts using SolidWorks, nest your project within our plate inventory, and then perform high-quality custom machining. Our company is committed to exceeding expectations and meeting industry standards in terms of lead times and product availability. To learn more about our water jet cutting services, please contact us today to discuss your design needs.

Waterjet Cutting Material Options

Elimold offers a wide range of waterjet cutting materials in various thicknesses for you to choose from. What materials do you need custom cutting?

- Steel Hard Rolled

- Steel Mild

- Steel Tool

- Tantalum

- Tin

- Titanium

- Tungsten

- Wrought Iron

- Zinc

- Armor Plate

- Hastalloy

- Hardened Steel

- Hot Rolled Steel

- Inconel

- Magnesium

- Mild Steel

- Nickel Alloys

- Stainless Steel

- Steel Alloy

- Steel Hardened

- Alloy Steel

- Aluminum

- Armor Plate

- Brass

- Boron

- Bronze

- Cast Iron

- Cobalt

- Copper

- Exotic Alloys

Surface Treatment Options

Choose Elimold for a full range of services to meet all of your project needs, from prototype to full assembly, we have you covered. We have over 15 finishing options, an extensive hardware catalog, and more!

Cutting Methods

Custom laser cutting, waterjet cuttingand CNC routing. We’ll cut your partswith the method best suited for yourmaterial.

Bending & Forming

Add dimension to your projects with ourprecision CNC bending services

Countersinking &Tapping

Quickly and easily add threading to yourparts, or allow hardware to sit flush.

Hardware Insertion

Select from our catalog of PEM press-fithardware to add nuts, studs, andstandoffs.

Anodizing

We offer Class ll anodizing services toadd durability and character to your lasercut parts.

Plating

Increase rust prevention, wear resistance,and strength with zinc and nickel plating.

Powder Coating

Give your laser cut parts a bold, long.lasting finish and protective layer in oneof 7 colors.

Tumbling

Reduce the surface blemishes andhandling scratches found in rawmaterials.

Design tips for waterjet cutting

- Tolerances:+/-0.005″ on most parts. By running slower feedrates, certain parts the tolerance can be +/-0.002″.

- Minimum hole size of 0.090″ diameter.

- Square inside corner geometry will cut to a 0.020″ radius.

- Larger inside or outside radius corner will cut slightly faster (less cost).

- Maximum material thickness is 6″.

- Maximum sheet size that can be cut is 6′ x 12′.

Custom Waterjet Cutting Manufacturing Solutions

Discover the power of customization with Elimold’s custom waterjet cutting manufacturing services. We specialize in custom parts made to your unique specifications. From design to assembly, our experienced team is committed to providing quality, durable, and efficient solutions. If you have special needs or challenges, please discuss how we can turn your ideas into reality. Whether you need to cut materials that do not conform to traditional processing methods or you are looking for reliable and accurate cutting for your product prototype design, we can help you! All you need to do is provide your CAD file, or if you have a design, our CAD experts can draw up a drawing for you. With our precise waterjet cutting technology, we are able to quickly deliver your unique product. Contact our qualified team today for cost-effective waterjet cutting services!

What is water jet cutting?

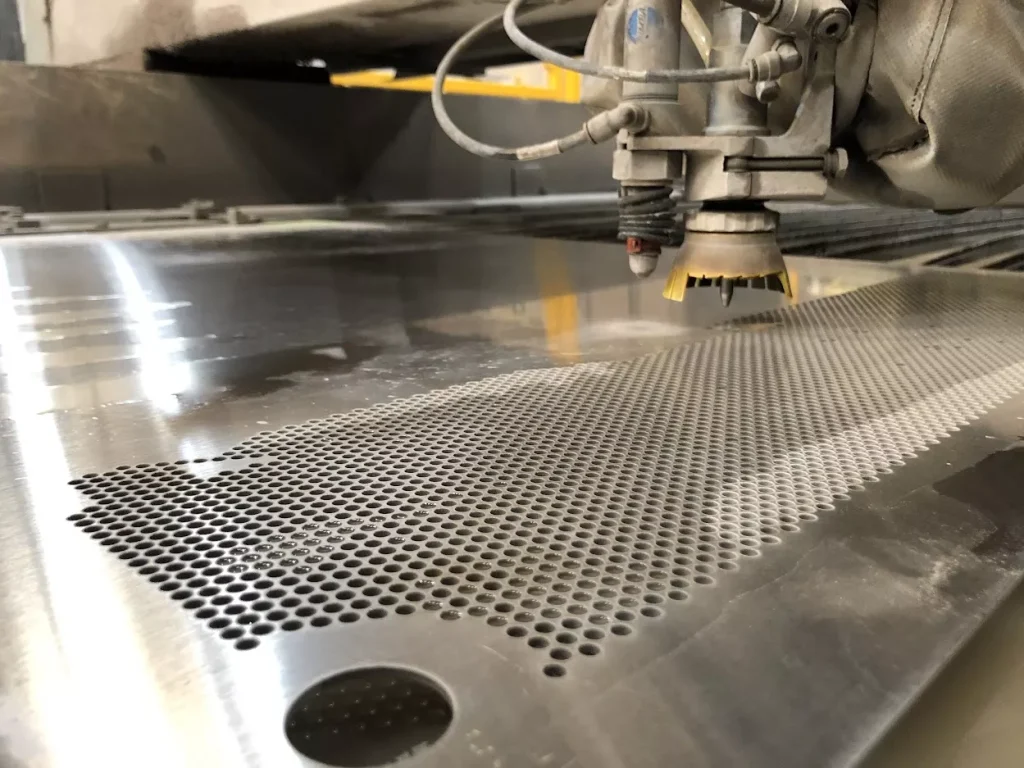

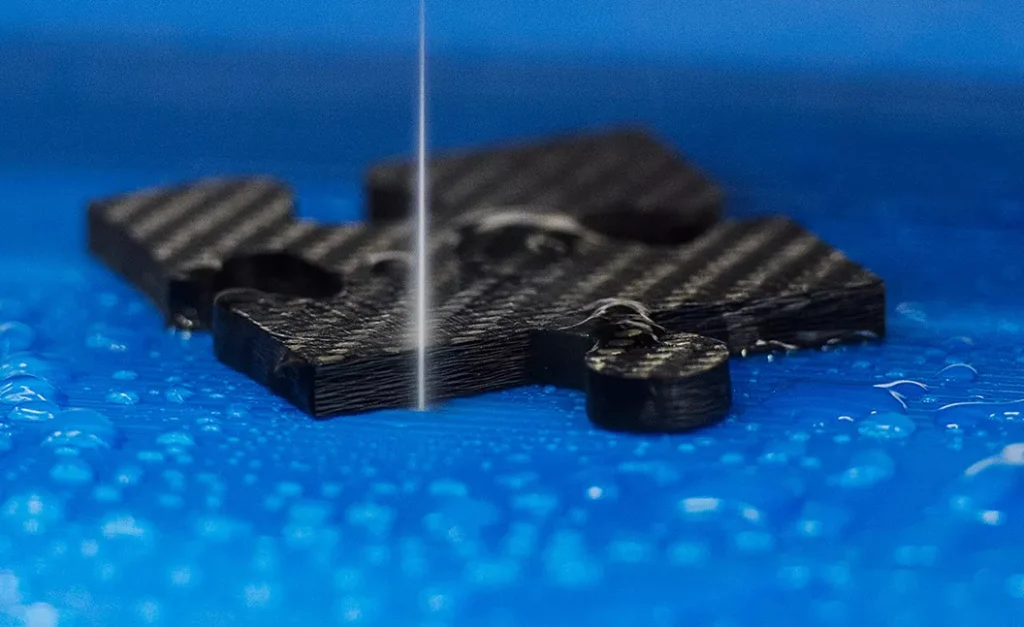

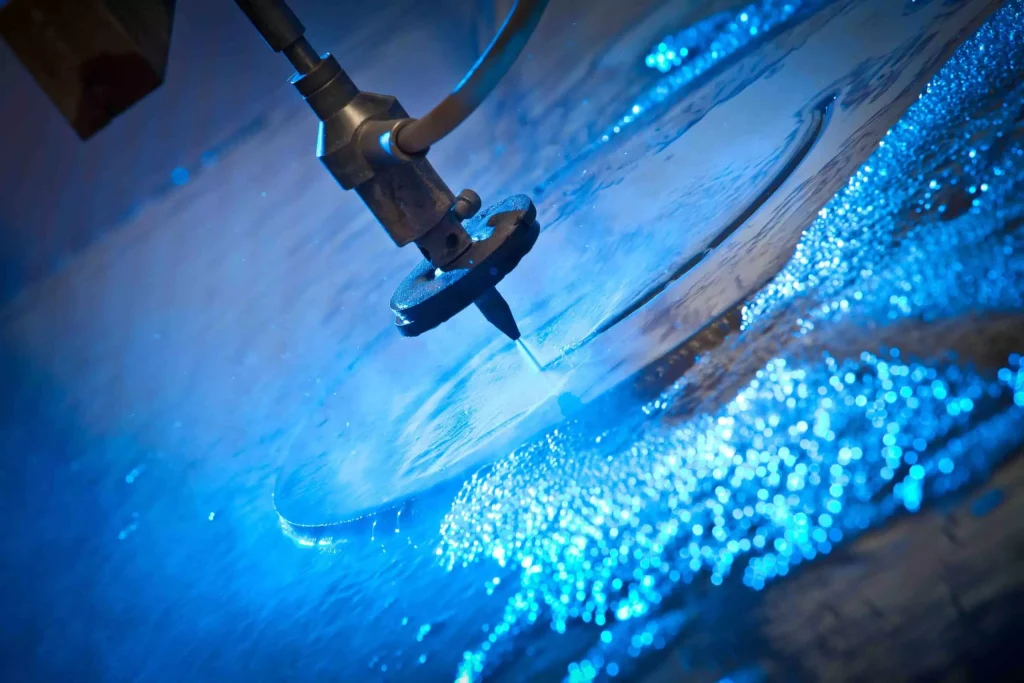

Waterjet or water jet cutting, is a manufacturing process that’s best described as a controlled, accelerated erosion process. A waterjet is an industrial cutting machine used to make flat-cut parts out of relatively thin, flexible/semi-rigid materials using a nozzle to focus high-pressure water through a very small hole and into a high-pressure stream or jet.

Unlike more traditional die cutting methods, a waterjet has no spinning metal rotors or die blades so a waterjet won’t change the physical structure of the material being cut. A waterjet can make parts with fine details and complicated shapes and unlike laser and plasma, waterjet cutting doesn’t produce any harmful waste or byproducts like noxious fumes or gases that could harm operators or the environment.

Advantages of Water Jet Cutting

- It can be used with many types of materials

- No thermal impact on the material structure

- Incredible accuracy with low set-up cost

- Variable speed to maintain the vertical edge quality

- Minimal kerf width

- Minimal secondary finishing

- Efficient material usage

- Cost-effective

- Produce complex shapes

- Quick turnaround (6-8 business days)

Industries We Serve

Waterjet cutting services are able to precisely cut and shape countless materials and small parts, making it the method of choice for many industries and applications, including:

- Aerospace

- Automation

- Automotive

- Biomedical

- Commercial

- Communications

- Consumer Goods

- Electrical

- Electronics

- Energy

- Food Production

- Laboratory

- Machinery

- Marine

- Medical

- Nuclear

- Optical

- Pumps

- Railroad

- Robotics

- Semiconductor

- Specialty Machinery

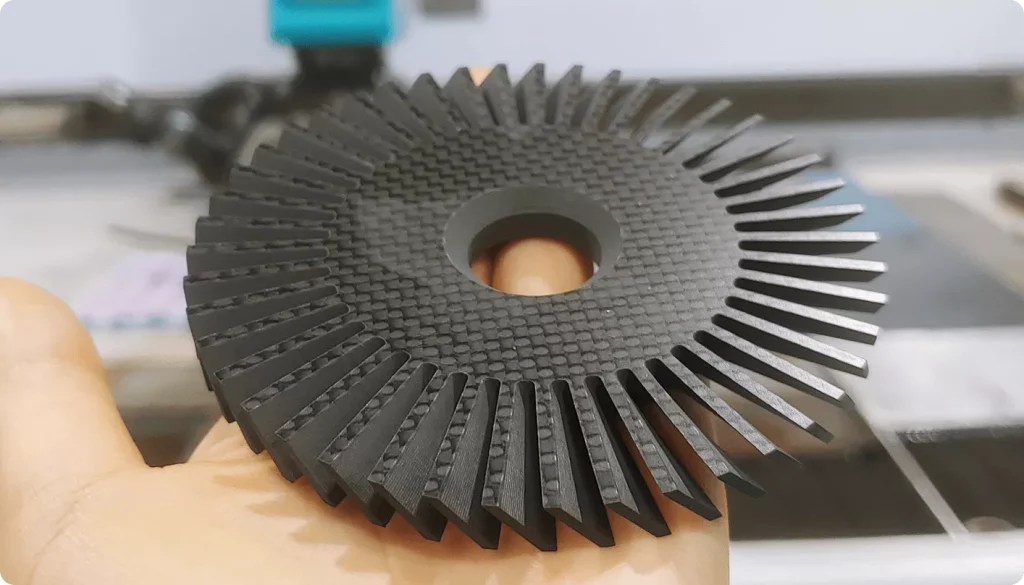

Waterjet Cutting Applications

Elimold continues to improve its already high standards and workmanship by adopting the latest and most successful technologies and tools. We manufacture a wide variety of parts for customers in a wide range of industries. Our extensive industry experience means you can expect the quality and commitment you expect from your supplier. We pride ourselves on personal service, which is a refreshing change in today’s tough business environment.

- Gaskets

- Brackets

- Flanges

- Panels

- Enclosures

- Signage

- Decorative screens

- Machine components

- Chassis plates

- Structural supports

- Mounting plates

- Gear blanks

- Control panels

- Shims

- Custom artwork

- Heat exchanger plates

- Valve plates

- Aerospace components

- Automotive parts

- Architectural features

- Conveyor parts

- Tooling fixtures

- Electronic enclosures

- Pipe clamps

- Custom grills

- Base plates

- Cover plates

- Instrument panels

- Turbine blades

- Insulation panels

- Support brackets

- Elevator panels

- Pump housings

- Nameplates

- Knife blanks

- Spacer rings

- Ventilation grilles

- Furniture components

- Chassis frames

- Machine guards

Waterjet Machining Contract Manufacturer

We know your time is valuable. That’s why our experienced team of waterjet cutting professionals is committed to processing your order quickly. While every project has unique needs, you can count on Elimold to deliver your waterjet cut parts with minimal downtime, without sacrificing quality. And we provide innovative solutions to our customers based on the specific needs of each project. We will work closely with you to determine the cutting method that best meets your goals, from waterjet cutting to our other advanced sheet metal production services. When you choose Elimold for your custom sheet metal part processing needs, you can trust that we will take the time to understand your unique application requirements. Our waterjet cutting services are unmatched in high-precision cutting of custom sizes. Superior quality reduces the need for additional machining operations to further finish the part, minimizing the total production time and cost for many projects. If you need a reliable waterjet cutting solution, Elimold has it.

Other Sheet Metal Fabrication Services

Our sheet metal production services offer unmatched precision and reliability, especially for projects that require meticulous detail. Whether you need to process foam, rubber, metal or composite materials, Elimold can meet your custom sheet metal part needs. Below are the various sheet metal fabrication services we offer.

Laser Cutting

Plasma Cutting

Punching

Stamping

Die Cutting

Bending and Forming

Welding

Extrusion

Embossing

Request Your Free Waterjet Cutting Quote Today

After receiving your drawings, our engineers will analyze your custom Waterjet Cutting parts right away. We actively work with you to clarify all details before providing a quote that is both economical and accurate.