Wire EDM Machining Services

Elimold has cutting-edge facilities equipped with advanced wire EDM machines, providing exceptional capacity and flexibility for both R&D and high-volume wire EDM processes. Explore our comprehensive range of services, from wire EDM to turnkey manufacturing solutions, and learn how we can take your project to new heights of success.

Professional Wire EDM Manufacturer

Elimold has a full-fledged wire EDM shop capable of producing custom parts with tight tolerances. We have wire EDM, small micro-hole EDM and traditional EDM, countersinking and other technologies. We offer fast lead times and very competitive pricing. We have a well-trained, skilled and dedicated workforce who go the extra mile to exceed your expectations. We manufacture custom parts that far exceed the standards of our customers and clients and have a reputation for the fastest turnaround times and very competitive prices. Contact us today for a free estimate and quote. Email or fax us your prints, drawings, files or questions so we can help you turn your idea or product into reality!

Comprehensive Turnkey Wire EDM Services

In addition to wire EDM services, we offer comprehensive turnkey solutions for all of your manufacturing needs. With over four decades of experience, our team is well-versed in all aspects of custom mechanical services. We work with customers across a wide range of industries to produce high-quality parts and assemblies to meet their specific needs. Whether you require wire EDM services, precision cnc machining, welding, assembly, or design and engineering assistance, we have the expertise to deliver exceptional results. Elimold is continually improving our processes and capabilities. Our state-of-the-art facilities are equipped with the latest technology and equipment to deliver quality parts that meet the highest standards. Whether you require precision machining or complete assembly, we can provide efficient and reliable services custom to your specific requirements.

In-House Wire EDM Shop Capabilities

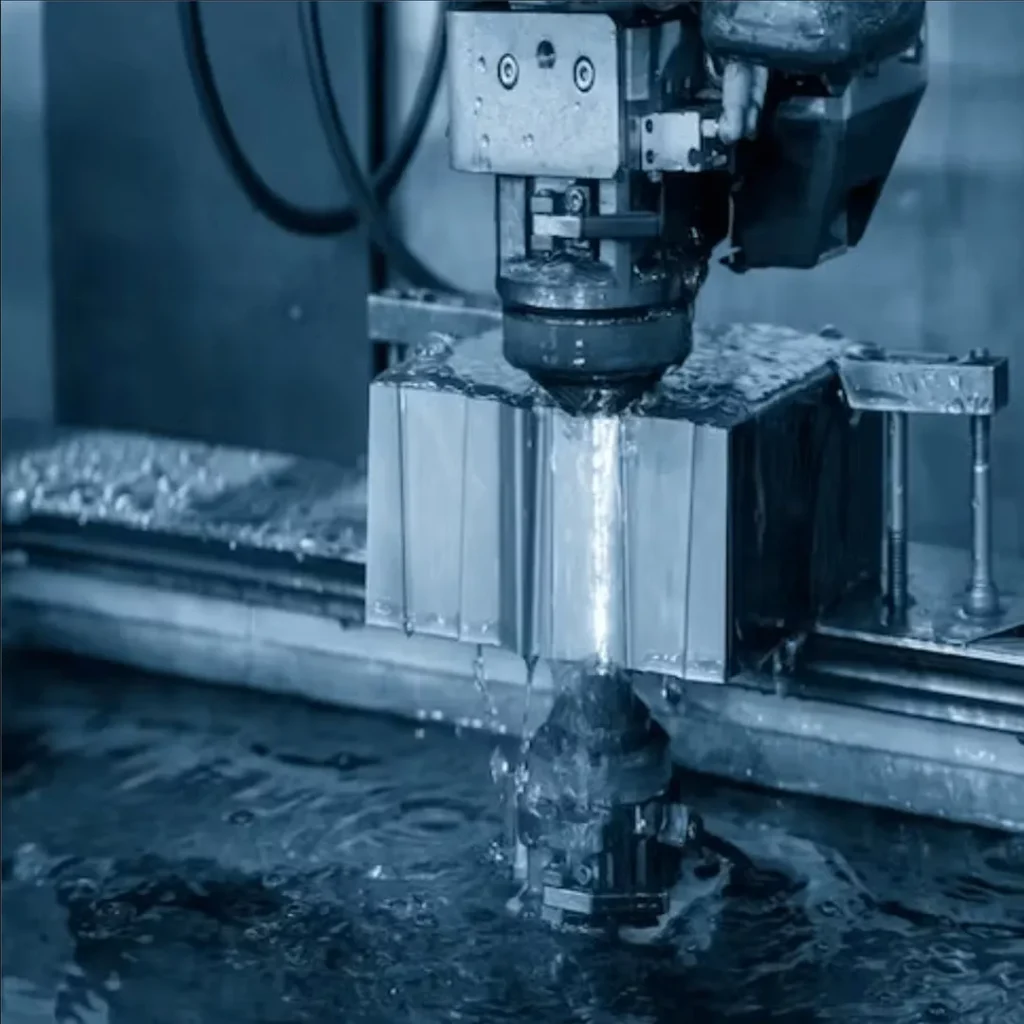

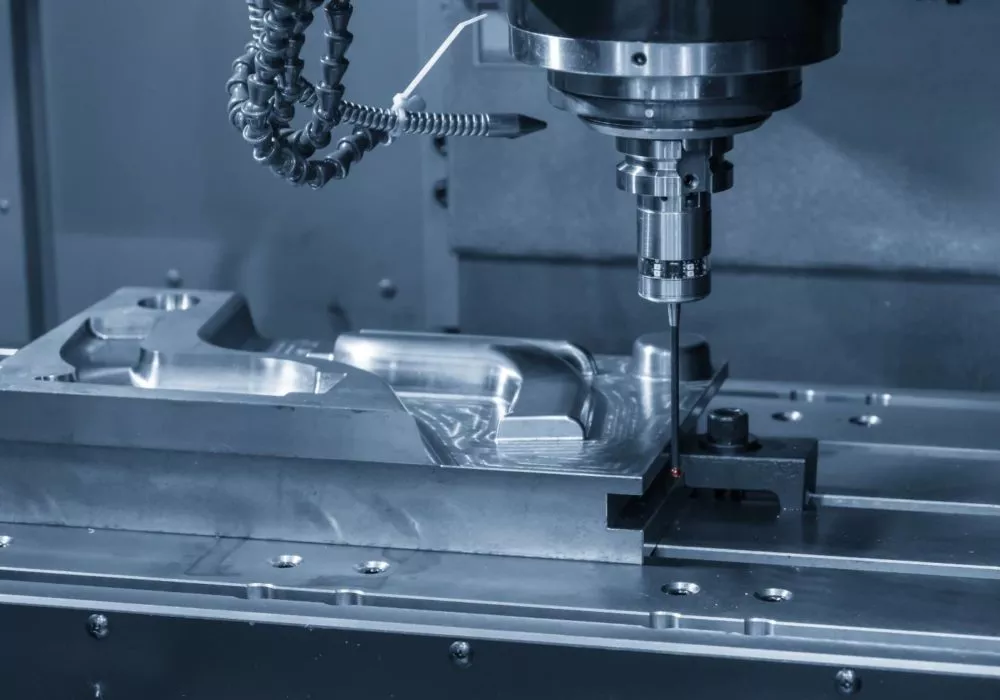

Our in-house CNC machining shop is equipped with 22 wire EDM machines, allowing us to easily handle high-volume production and the most complex EDM processes. Our state-of-the-art equipment features 5-axis cutting capabilities, a 49.2″ x 40.1″ x 32.0″ work envelope, and the ability to machine even parts with a 45-degree taper. In addition, we can wire EDM with 0.002″ wire, allowing for precision cuts and complex geometries, including inside corners with radii less than 0.0015″, a maximum taper of 17° at 4″ material thickness, and the ability to accommodate larger projects than the average wire EDM shop, with a workpiece weight capacity of up to 6,600 lbs. Partner with Elimold to help you overcome your production challenges. Our reliable performance and superior quality are unmatched. With a 99.7% on-time delivery rate and the resources to provide you with a ready-to-go product.

Wire EDM Cutting Specifications

Wire EDM provides higher cutting accuracies and tighter tolerances than standard cutting processes:

- 5-Axis

- Wire diameter: .004~.012 in.

- Tolerance: .0001 in.

- Maximum taper angle: 30º @ 8 in. material thickness

- Position accuracy .0001 in. (.003mm)

- Feature and contour accuracy +/- .0001 in.

- Kerf width .006-.014 in.

- Maximum workpiece dimensions 27 x 40 in.

- Maximum workpiece thickness (may be stacked sheets) 15 in. thick

24/7 Wire EDM Production Service

Elimold has the most fully equipped professional wire EDM workshop. Therefore, we can undertake any size and type of wire EDM project and deliver it on time. Modern wire EDM machines are equipped with automatic needle threading devices and use three shifts, so they can achieve 24/7 production. We always insist on constantly acquiring new programming, machine tools and inspection equipment to ensure that we can provide the latest technology, the highest precision and the highest output. This enables us to choose the most suitable equipment according to different part characteristics and production requirements, thus achieving a wide range of production capabilities. Our team is composed of industry experts who are familiar with industry requirements, standards and practices. Direct production of custom parts without strict pre-production review usually leads to higher costs, lower production and substandard piecework. Let our experts discuss your needs in depth and ask the right questions based on years of production experience.

Additional EDM Services Offered by Elimold

We offer more than just wire cutting machine processing. Our in-house factory can provide you with the following EDM processing services, providing you with almost unlimited production capabilities, whether you are producing simple or complex parts.

CNC Sinking EDM

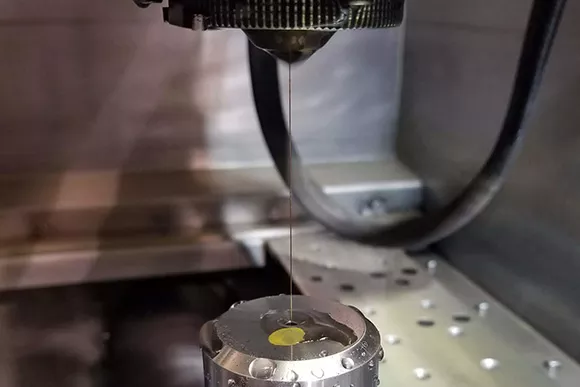

Micro-hole EDM

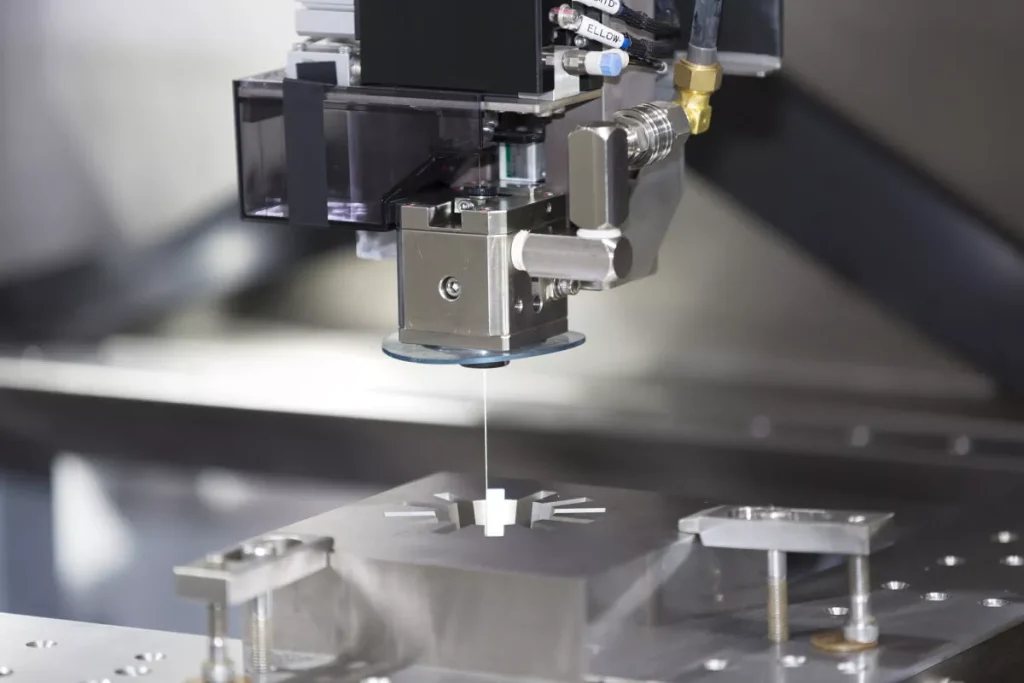

Hole Popper (or Fast Hole) EDM

Fast Hole EDM

Wire EDM Outsourcing Provider

Elimold is a leading Wire EDM Outsourcing Provider and Wire EDM Service Provider. Our team works with partners across a wide range of industries to provide high-precision prototypes, mid-volume production, and long-term, high-volume EDM component production services. As an experienced wire EDM provider, we understand the benefits of working with customers upfront on projects. Elimold can provide extensive design for manufacturability advice to improve production speed, accuracy, and finished product quality. In addition, we continue to invest in technology, people, and equipment to continuously improve our capabilities and provide a wide range of wire EDM services. As a result, we can provide the highest quality precision machining services with fast delivery cycles, competitive pricing, and excellent customer service.

Engineering Design Services

Elimold has earned a strong reputation for its ability to quickly and economically produce ultra-fine parts that exceed traditional manufacturing techniques. Engineering assistance with full CAD/CAM support is provided at every step of the development process to ensure cost-effective Wire EDM designs are created. Once the design is approved, the project is entered into our computerized planning and scheduling system. This system allows us to closely monitor project progress, provide timely status reports, and maintain tight control over delivery schedules.

Quality Management

Our Micro EDM services are provided by a temperature controlled inspection department equipped with coordinate measuring machines (CMM) and optical measurement capabilities. We have earned a strong reputation for consistency and accuracy. Each project we accept is carefully reviewed based on the customer’s requirements and expectations, and an inspection plan is developed to ensure that all requirements are met. No matter which EDM service you require, rest assured that Elimold has the experience and capabilities to exceed your expectations.

Contract Wire EDM Services

Customer satisfaction is Elimold’s top priority. Advanced technology and a highly qualified engineering team enable us to quickly and efficiently deliver parts to exacting tolerances. We specialize in custom wire EDM services for demanding applications. Our team of experts will work with you, using a proven consultative approach, to tailor the best manufacturing solution for your needs, addressing performance, fit, life, and safety. Materials are sourced from reputable suppliers and verified for compliance upon arrival. Our quality control team uses sophisticated testing and inspection equipment to ensure every part produced exceeds customer specifications. All orders are reviewed for accuracy prior to shipment.

Why choose our precision wire EDM services?

Quality Assurance

Elimold is known for precision machined parts and adheres to the highest quality standards, sometimes even exceeding them, which is why our customers choose our wire EDM services. We continue to maintain and continuously improve the quality of our parts, which is the key to our customers’ trust. With advanced technology and first-class wire EDM equipment, we are committed to providing you with top-quality parts with excellent performance.

Pursuit of Precision

We are passionate about the work we do and the service we provide. This is one of the reasons why we are fully committed to successfully machining your complex custom parts. Most importantly, Elimold always keeps its promises and is passionate. Honesty is the essence of this job, and we will not make promises that we cannot keep.

Quality Control

Elimold has advanced quality control systems and a team of well-trained professionals to ensure that your parts are machined the right way. Our advanced wire EDM equipment and superb craftsmanship enable us to continuously improve and enhance the quality of your parts. The deep knowledge of our engineers helps us ensure that your work is completed according to your specifications.

Reliable On-Time Delivery

At Elimold, our experienced staff, equipped with advanced monitoring equipment, monitors the progress of every job related to wire EDM part production on a daily basis. Our fully optimized scheduling and processing processes allow us to increase production in a cost-effective manner. Our ability to resolve any potential problems before they arise is a key factor in our ability to provide you with consistent, reliable on-time delivery.

Superior Capabilities

The most commendable thing about Elimold is that we only provide the highest quality products and parts. The parts we machine are excellent and stable. With our superb material selection ability, our parts can maintain excellent performance for a long time, helping your business to improve efficiency and productivity. Rapid Manufacture can meet all your wire EDM-related needs.

Excellent Service

Our team is the key to our success. We respond quickly and provide all wire EDM-related information, including specifications, data sheets and dimensions. Our experienced team of professionals is ready to help you with your project. Whether you need design and engineering assistance or precision machining services, our experts will work closely with you to ensure that your needs are met.

Ready to get started on your wire EDM machining project?

Elimold has the experience, expertise and technology to deliver custom parts with tight tolerances for your project. Request a quote for Wire EDM services today, or contact us for more information.

Full Range of Wire EDM Solutions

Elimold offers a full range of wire EDM solutions. We can produce custom precision EDM parts that exceed your expectations for quality and performance. As customer needs change, our engineers can provide guidance on the best manufacturing process based on part geometry, material and production volume. We can provide additional finishing, coating and assembly services as needed. We are committed to building long-term business relationships with our customers and are committed to providing services that enhance our core machining and manufacturing capabilities. And we provide fast delivery cycles to ensure that your tasks are completed on time. We understand that every project is unique, so whether you need a prototype or small or large-scale production, we provide tailored solutions. Our team is committed to meeting your needs and providing excellent customer service. Our focus on providing quality Wire EDM services and customer satisfaction makes us the best choice for your project.

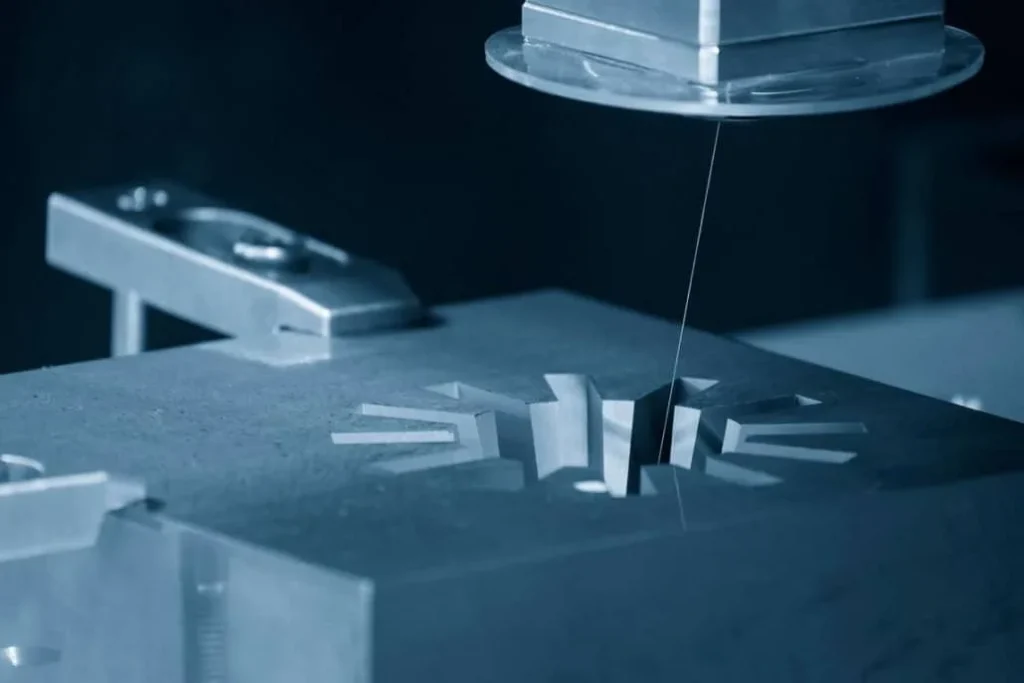

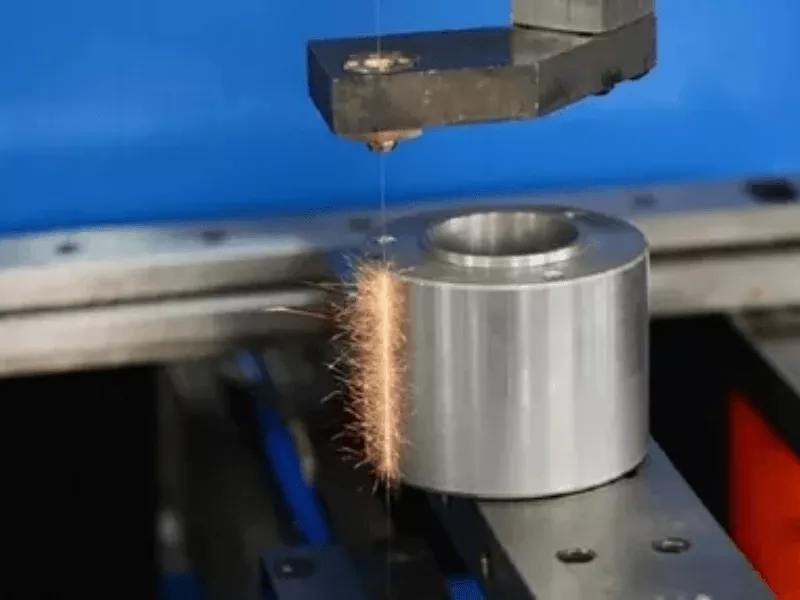

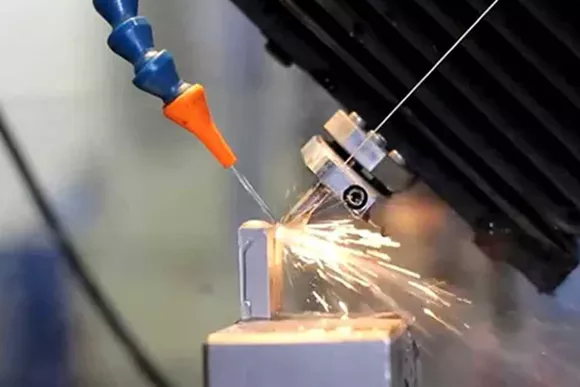

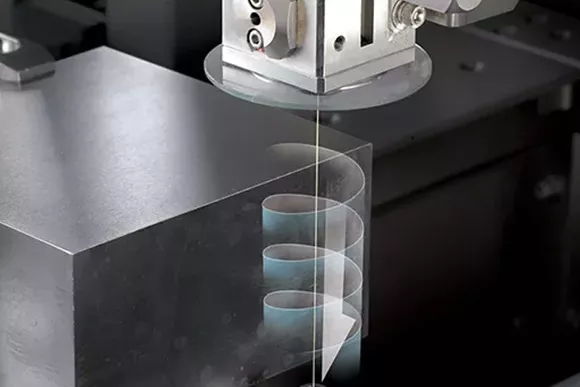

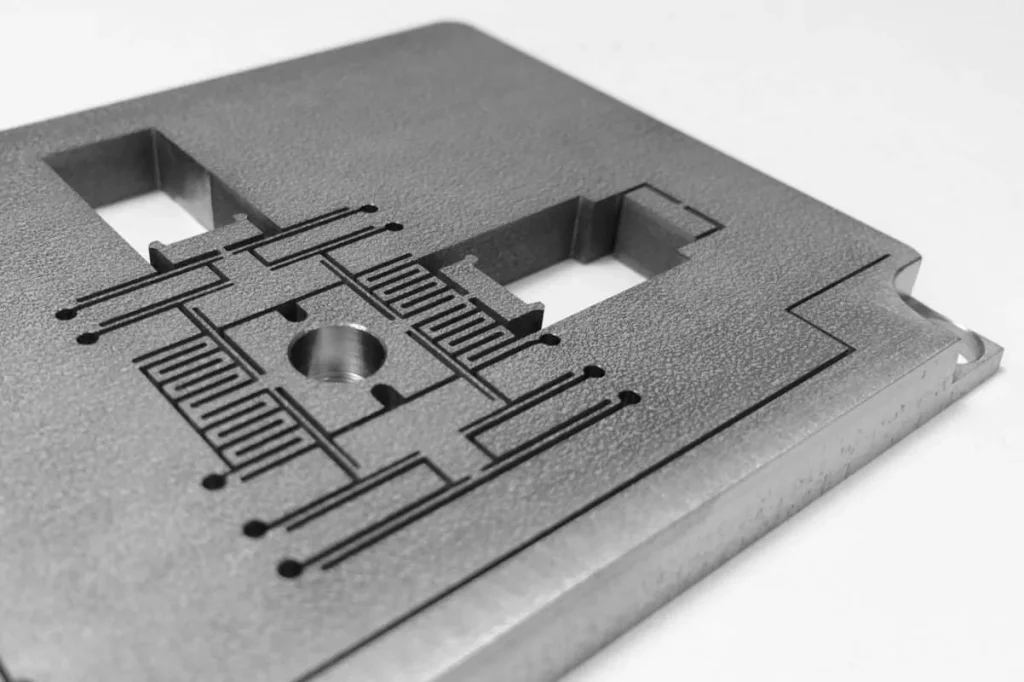

What is Wire EDM?

Wire EDM is a machining process that uses an electric spark to melt or vaporize metal materials for cutting. The cutting process is achieved by using an electrical discharge between two electrodes separated by a dielectric fluid and with different voltages applied. Wire EDM is a machining method used to create complex and precise shapes and contours on parts that are not possible with traditional CNC machining methods. One of the advantages of Wire EDM is that it can be used to machine parts made of materials that are usually difficult to machine with high precision and quality control using standard methods, such as heat-treated steels, alloys, and exotic metals. The Wire EDM process is capable of machining complex shapes with extremely close tolerances. It can also accurately machine narrow slots and small holes, making it a valuable tool for manufacturers and other engineering applications and industries.

Advantages of Wire EDM

Compared to other precision metal cutting processes, wire EDM has many advantages:

- No custom tooling required – delivery times are short

- No cutting forces present – virtually no burrs generated

- Workpiece material hardness does not affect cutting speed

- Improved surface finishes – no additional finishing or polishing needed

- Tools & metal parts are machined after heat treatment – dimensional accuracy is maintained

- Highly repeatable with no deformation

- Ability to stack, string & nest multiple parts

- Ideal for delicate & complex parts

- Tight tolerances & precise fits

- Small corners & radii

- Narrow slots & thin walls

Material Options

Elimold offers a wide range of materials suitable for wire EDM machining. We have an extensive inventory of high-performance alloys and specialty metals to meet the most demanding specifications. Whether you need a precision part or a complex geometry, our team of experts can help you select the best material solution for your project. If your project requires a material that is not on the list, please let us know! We can meet other material needs, but quotes may take more time while we source the material.

- Alloy steels

- Aluminum

- Brass

- Carbide

- Carbide substrates

- Carbon steel

- Cobalt

- Cobalt chrome

- Conductive ceramics

- Copper

- Gold

- Graphite

- Hardened steels

- Hastelloy

- High-performance alloys

- Inconel

- Iron

- Kovar

- Lead

- Magnesium

- Molybdenum

- Monel

- Nickel

- Niobium

- Platinum

- Polycrystalline diamond (PCD)

- Rhenium

- Silver

- Stainless steel

- Superalloys

- Tantalum

- Titanium

- Tungsten

Surface Finishing Service Options

Elimold offers a range of value-added and finishing options to ensure your project is closer to the production finish line. We have the resources to provide you with ready-to-use components no matter your needs, including:

The finish option with the quickest turnaround. Parts are left with visible tool marks and potentially sharp edges and burrs, which can be removed upon request. Surface finish is comparable to 125 uin Ra finish.

The part surface is left with a smooth, matte appearance.

This is a batch-based process that tumbles vibrating media to remove sharp edges and burrs on machined parts. Tumbling can remove machine marks on exterior surfaces. Parts over 8” may require a manual review.

Type II (MIL-A-8625, Type II) creates a corrosion-resistant finish. Parts can be anodized in different colors—clear, black, red, and gold are most common—and is usually associated with aluminum. Type III (MIL-A-8625, Type III, Class 1/2 “hardcoat”) is thicker and creates a wear-resistant layer in addition to the corrosion resistance seen with Type II.

A surface finish for titanium per AMS-2488 Type 2 specification. Also called Tiodize, this finish increases fatigue strength and the wear resistance of a part. Titanium anodized parts are common in aerospace and medical device manufacturing. Non-pigmented titanium anodize finishes will dull shine.

A hard coat anodize process that embeds PTFE to create a self-lubricating, dry contact surface with Type 3 hard coat’s protective properties. This finish can be used on aluminum alloys or titanium and increases the service life of the product. This finish conforms to the AMS-2482 Type 1 Hard Coat Anodizing with Teflon (Non-Dyed).

Provides corrosion resistance and good conductivity properties. Can be used as a base for paint. Can leave surface yellow/gold. Adds very little thickness, about 0.00001”-0.00004”. Chem film will conform to MIL-DTL-5541, TYPE I/II.

Improves corrosion resistance for 200 and 300 series and precipitation hardened corrosion-resistant steels. Thickness is negligible, about 0.0000001”. Conforms to ASTM A967, AMS-QQ-P-35, MIL-STD-171, ASTM A380, or AMS 2700.

This is a process where powdered paint is sprayed onto a part that is then baked in an oven. This creates a strong, wear- and corrosion-resistant layer that is more durable than standard painting methods. A wide variety of colors are available to create the desired aesthetic.

An electrochemical process cleans steel parts to reduce corrosion and improve appearance, by making the metal brighter. Removes about 0.0001”-0.0025” of the metal. Conforms to ASTM B912-02.

Provides uniform nickel coating which offers protection from corrosion, oxidation, and wear on irregular surfaces. The finished part will be brighter. Thickness starts at .0001”. Conforms to MIL-C-26074.

Silver offers high solderability and electrical conductivity but is susceptible to tarnish. Conforms to AMS QQ-S-365D. Thickness is about 0.00002” – 0.0003.”

Gold Plating provides good corrosion and tarnish resistance with excellent solderability. Default application specification is MIL-G-45204 and ASTM B488, CLASS 00, 0, OR 1. Thickness is about 0.00002″ – 0.00005.”

Provides uniform zinc coating which offers protection from corrosion, oxidation, and wear on irregular surfaces. Conforms to ASTM B633-15.

Industries We Serve

Our engineers and machinists have extensive knowledge of optimal wire EDM machining practices and materials as they apply to many different industries, including but not limited to:

- Aerospace

- Agricultural

- Automotive

- Appliance

- Construction

- Electrical

- Electronics

- Fire Suppression

- Food & Beverage

- Furniture

- Manufacturers

- Medical

- Military/Government

- Motorcycle

- Semiconductor

- Marine

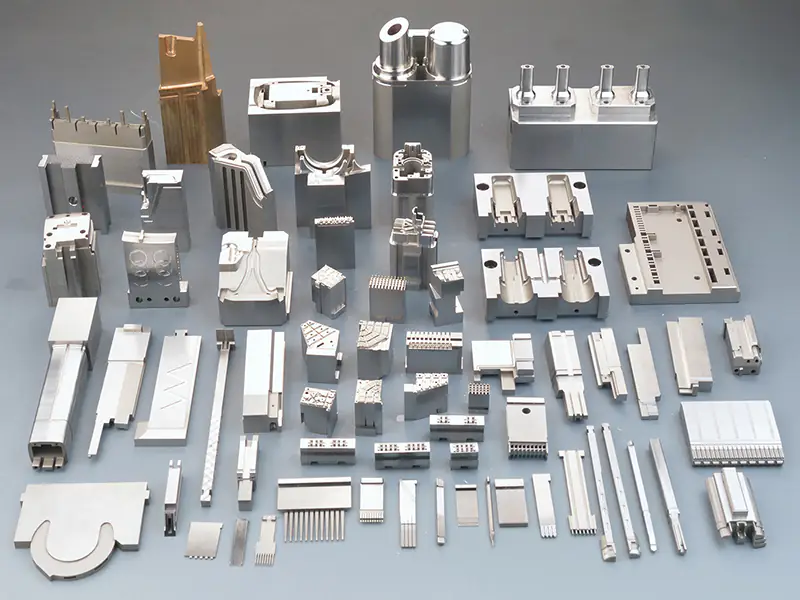

Wire EDM Parts & Applications

Manufacturers of complex, critical and precision products rely on wire EDM service capabilities to deliver the parts they need at the highest quality, fastest speed and best comparable price. Partnering with an experienced and certified wire EDM service shop can provide a wide range of manufacturers in a variety of industries with the high-quality components they need.

- Dies and punches

- Extrusion dies

- Injection mold components

- Gears

- Splines

- Keyways

- Surgical instruments

- Turbine blades

- Nozzles

- Aerospace components

- Fuel system components

- Fine blanking tools

- Fixtures and jigs

- Precision washers

- Electronic connectors

- Custom brackets

- Thread gauges

- EDM electrodes

- Heat sinks

- Microfluidic components

- Stamping dies

- Forming tools

- Laminated core stacks

- Optical tooling components

- Precision shims

- Indexing plates

- Wear plates

- Carbide inserts

- Retainer plates

- Backing plates

- Medical implant components

- Wire guides

- Sensor housings

- Aerospace brackets

- Valve components

- Microelectronic packages

- Cutting inserts

- EDM starter holes

- Thin wall structures

- Battery tabs

Precision Wire EDM Machining with Elimold

At Elimold, we have the power of wire EDM (EDM) to deliver precision engineered parts to our customers. Our wire EDM services are ideal for precision machining applications. Our technology ensures that every cut is accurate and of the highest quality. Our commitment to precision and quality is built on our advanced wire EDM equipment and our team of experienced, professional technicians. These strengths make us a leader in wire EDM, able to deliver parts that meet the exacting requirements of any industry. We also pride ourselves on our ability to meet customer deadlines, including the ability to meet some rush orders. It all starts with our fast 4-hour quote. Once you upload your part file, we will put together a quote for you.

Other CNC Machining Services

CNC machining is one of our key services. We have completed tens of thousands of CNC machining projects over the years. CNC Machining Smart Solutions Manufacturing Services stand out from the competition because we are able to maintain micron-level tolerances while offering globally competitive pricing and delivery times. With our extensive knowledge of CNC machining technology and decades of industry experience, we are confident that we can produce the most challenging parts to your precise specifications. To learn more about Elimold’s services, please contact our manufacturing team and request a quote.

CNC Milling

CNC Turning

3 Axis CNC Machining

4 Axis CNC Machining

5 Axis CNC Machining

CNC Prototypes

Jig Grinding Services

CNC Threading and Tapping

CNC High-Speed Drilling

Swiss Machining Service

CNC Routing Service

CNC Grinding Service

EDM vs. Conventional Machining

EDM and conventional machining are two different manufacturing methods, each with its own advantages and uses. EDM uses electrical discharges to wear away material, making it ideal for machining fine and intricate shapes. In contrast, conventional machining uses mechanical tools to cut through material, making it more flexible to accommodate different part sizes and materials. When choosing a manufacturing method, consider important factors such as part complexity, material, and your production needs. These decisions will help you find the best solution for your project. If you have any questions about the best option for your project, contact our team!

Request Your Free Wire EDM Machining Quote Today

After receiving your drawings, our engineers will analyze your custom Wire EDM machining parts right away. We actively work with you to clarify all details before providing a quote that is both economical and accurate.