Zinc Die Casting Services

Elimold is an independent, professional manufacturer of zinc die castings in China. We are a full-service zinc die casting company providing precision zinc die castings to customers worldwide. We utilize both standard and customized automated die casting machines to offer you competitive, high-quality products. Contact us now for a project quote.

Chinese Custom Zinc Die Casting Manufacturer

Looking for high-quality zinc die castings from an experienced and trusted parts manufacturer? As one of the leading die casting service companies, Elimold offers you the highest quality, most affordable zinc alloy die castings. We provide a one-stop custom zinc die casting service to the global market at highly competitive prices, offering a wide range of related services including engineering design, machining, finishing, and assembly. We can produce consistently reliable zinc die castings to meet your specifications. With advanced technology, a professional engineering team, and modern die casting equipment, we ensure our zinc die castings meet your requirements in terms of precision and production efficiency. To learn how our zinc die casting capabilities can meet your specifications, please contact us today for a quote.

Precision Zinc Die Casting Services Customized to Your Production Needs

Analysis

Custom Mold Solutions

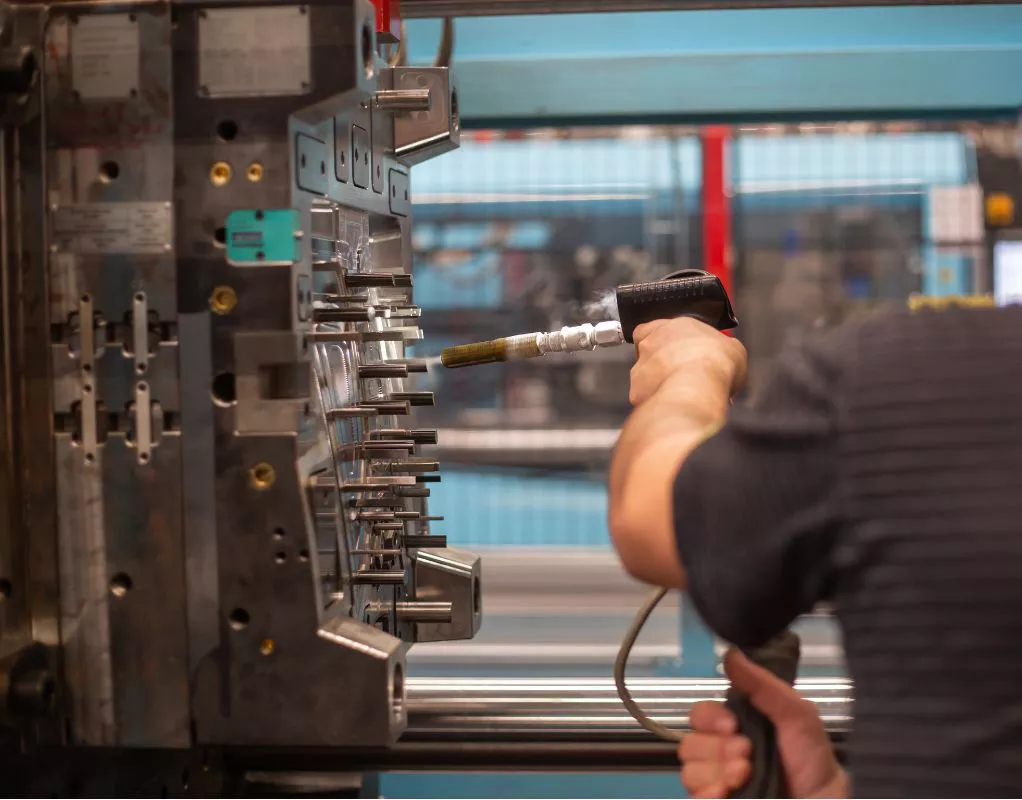

Die Casting Production

Finishing

Assembly

Packaging and Inventory

High-Quality Zinc Die Casting Services

At Elimold, we are committed to one-on-one communication with our clients and strive to provide the highest quality service. Our responsive, personalized service and support set Elimold apart from the competition. This has been our guiding principle since the company’s inception. We specialize in the production of zinc die castings and zinc die casting parts, ensuring high-quality results for every project.

Furthermore, our team understands that every project is unique and requires a tailored solution. Our team is ready to work with you, providing expert advice and guidance to ensure that the chosen casting processes and materials meet your specific requirements and exceed your expectations.

Collaborative Engineering Support

Our professional team of engineers is ready to assist you in optimizing your zinc die-casting design. We employ a collaborative approach to maximize throughput, minimize costs, and enhance product performance. Our engineering support includes:

- Design for Manufacturing (DFM) analysis

- Material selection and optimization

- Mold design consultation

- Technical problem solving and troubleshooting

Comprehensive In-House Die & Casting Services

Elimold offers comprehensive in-house services to streamline production processes and ensure quality control from concept to final delivery. Our service capabilities include:

- Tooling design and development

- Tapping and precision CNC machining

- Surface finishing and deburring

- Surface treatments include electroplating, powder coating, and painting

- Assembly and subassembly

- Logistics, packaging, and shipping

MagmaSoft® Zinc Mold Flow Testing

Elimold utilizes the internationally recognized MAGMAsoft® simulation technology to optimize mold design and zinc casting quality. MAGMAsoft®’s simulation capabilities help you gain a deeper understanding of many aspects of zinc injection molds, including filling, solidification, mechanical properties, thermal stress, and deformation. MAGMAsoft® features a fully menu-driven design, integrating a solid modeler, CASD interface, and a vast database, providing a complete solution for design, production, and quality departments.

Casting Zinc Alloy Material Grades

We offer a range of high-quality zinc alloy materials for die casting. Each alloy possesses unique properties suitable for various industries.

Zamak 3

Zamak 3 is the most common zinc die casting alloy in North America. Usually the first choice when considering an alloy for zinc die casting due to its excellent combination of mechanical and physical properties, and superb casting and finishing ability.

Zamak 2

Within the Zamak family of zinc die casting alloys, Zamak 2 has the highest strength and hardness due to its higher copper content (3%). Also known as Kirksite when making tooling for the stamping or plastic injection mold industries.

Zamak 5

Commonly used zinc die casting alloy throughout the world due to its combination of strength, ductility and fluidity. The 1% additional copper added to the alloy improves the alloy’s mechanical properties.

Zamak 7

Although magnesium is a useful element to combat corrosion effects of the alloy due to certain impurities, it was also found to reduce the alloy’s fluidity. In this alloy, nickel replaced magnesium, which helped improve the fluidity and casting ability of the alloy. The properties are similar to Zamak 3 with enhanced fluidity.

ZA-8

Zinc alloy with 8% aluminum. The most common of the ZA alloys due to its combination of strength, casting ability (cast in a hot chamber machine), and is often electro-plated.

ZA-12

ZA-12 has an excellent combination of mechanical properties and casting ability. Due to its elevated aluminum content this alloy is cast in a cold chamber die casting machine.

ZA-27

Zinc alloy with 27% aluminum. This higher aluminum content offers an alloy with exceptional mechanical properties as well as the lowest density of all the zinc die casting alloys.

EZAC

Zinc die casting alloy with the highest strength, hardness and creep resistance, along with exceptional fluidity.

ACuZinc

A zinc die casting alloy developed in the 1990’s by General Motors. ACuZinc is a zinc based alloy with approximately 5% copper and 3% aluminum. The combination AL/Cu/Zn in this alloy produces castings with exceptional mechanical and physical properties.

ZP0410

ZP0410 is a reliable and versatile zinc alloy that provides a good balance of properties for many die casting applications in the automotive, electronics and hardware industries.

ZP0430

ZP0430 is often referred to as ZP2 or Zamak 2. It’s a zinc alloy known for its exceptional strength and hardness.

BERIC

Superior zinc-based alloy in terms of wear resistance, tensile strength, hardness, and mechanical properties.

One-Stop Zinc Die Casting Shop

We specialize in providing you with a one-stop zinc die casting service. We have an experienced in-house team offering mold design engineering services, complete mold manufacturing, and mold maintenance. In addition to meeting a wide range of mold needs, our die casting department also has prototyping and mass production capabilities. This allows us to transform your ideas into the zinc die castings you require.

From Prototype to Mass Production

Turnkey Engineering Capabilities

Project Versatility

Ready to start your new zinc die-casting project with Elimold?

Whether you’re looking for precision, efficiency, or innovative solutions, the Elimold team is ready to bring your zinc die-casting project to life with their expertise and cutting-edge technology.

Zinc Alloy Die Casting Capabilities

Our presses range in tonnage from 100 to 2000 tons, capable of producing zinc alloy die castings suitable for both small and high-volume production. Elimold offers both hot-chamber and cold-chamber high-pressure die casting services. We utilize process monitoring, press-side imaging, robotics, MAGMAsoft® fluid simulation, permanent magnet molds, and mold maintenance solutions to extend mold life, shorten production cycles, reduce costs, and deliver high-quality die castings. From part design and prototyping to final assembly, Elimold provides all the integrated services you need on a unified platform, ensuring comprehensive support for your global manufacturing resources.

Hot Chamber Zinc Die Casting and Cold Chamber Zinc Die Casting

Hot chamber die casting and cold chamber die casting are two main methods in the die casting industry for producing precision zinc alloy parts. Each process has its unique characteristics, advantages, and limitations, making them suitable for different materials and applications.

Hot Chamber Zinc Die Casting

Cold Chamber Zinc Die Casting

Zinc Alloy Die Casting Plant

Elimold’s die casting plant in Shenzhen, China, boasts over 100 die casting machines in a 150,000 square foot facility with clamping forces ranging from 14 to 2,000 tons. This allows us to partner with leading companies seeking superior capacity and versatility while maintaining competitive pricing. We utilize both standard and custom-designed high-pressure die casting (HPDC) equipment. As the company grows, we continuously expand our production capacity to ensure we can meet diverse physical requirements. Currently, our annual zinc die casting parts production capacity exceeds 12 million pounds. The company continues to invest in new die casting equipment to further expand our capacity. We employ cutting-edge die casting technology to provide our customers with superior products.

Precision of Custom Zinc Alloy Die Casting Parts

Zinc die casting offers superior tolerances compared to aluminum and magnesium die casting. Elimold’s zinc die casting achieves repeatability of less than ±0.001 inches for small parts, a precision often comparable to machining. Few other processes can easily achieve such high net-shape accuracy. Many parts can be achieved net-shape through die casting without further machining. Due to zinc’s high-precision casting properties, many complex components can be redesigned and integrated into a single complex net-shape casting, significantly reducing costs.

Different Types of Zinc Casting Processes

Sand Casting

Permanent Mold Casting

Investment Casting

Lost Foam Casting

Centrifugal Casting

Low Pressure Casting

Vacuum Casting

Squeeze Casting

Gravity Die-Casting

High Pressure Die-Casting

Semi-permanent mold casting

Tilt Pour Aluminum Casting

Thin-Wall Zinc Alloy Casting Production Capability

All zinc die-casting alloys possess excellent casting fluidity, enabling superior thin-wall casting performance regardless of the casting process employed. At Elimold, we custom-make zinc die-castings with a minimum wall thickness of 0.040 inches (compared to 0.060 inches for aluminum die-castings). However, with our continuous improvement in die-casting and alloying technologies, we are now able to produce die-castings with wall thicknesses as low as 0.008 inches. Furthermore, zinc’s thin-walled characteristics and high strength allow us to manufacture zinc parts with the same strength and weight as aluminum die-castings, while also offering a cost advantage.

CNC Machining and Other Services for Zinc Castings

Elimold offers high-precision CNC machining services, including turning, milling, drilling, boring, and tapping. With high-quality zinc alloy die casting manufacturing and CNC machining services, Elimold is your one-stop solution provider for zinc alloy die casting and machining. In addition, Elimold offers a range of value-added services, saving customers time from obtaining multiple quotes and managing multiple suppliers. We have a large factory and experienced staff, enabling high-volume production and fast delivery. Through comprehensive testing and quality assurance processes, we ensure the delivery of the highest quality products and the most cost-effective services to meet your production needs.

Online Zinc Die Casting Manufacturing Service

Small Zinc Parts Castings

Medium Zinc Parts Castings

Large Zinc Parts Castings

Inspection and Surface Finishing Capabilities

In addition to Zinc die casting, Elimold offers a wide range of other services, including metallurgical composition analysis, process X-ray inspection, assembly and testing, heat treatment, Class A surface finishing (hand/surface finishing), coating, anodizing, electroplating, painting, and powder coating. With Elimold’s comprehensive value-added services, you can trust us to provide integrated solutions that meet all your manufacturing needs.

Quality Assurance

Quality is at the heart of everything we do. Every zinc die-cast part undergoes rigorous testing and quality control measures to ensure it meets or exceeds industry standards and customer expectations. Therefore, Elimold’s quality management team develops a personalized inspection plan for each part number to measure the effectiveness of our manufacturing processes. Simple parts require only basic inspections, while more complex parts require more comprehensive checks. We maintain a detailed database documenting every step we inspect throughout the entire process. This covers the entire manufacturing cycle—from liquid zinc to finished product. Each production stage has its unique inspection criteria to verify that we meet the specific requirements for that part. For example, we inspect casting, finishing, pouring, vibration finishing, and any machining processes.

Contact Elimold to learn how our team can support your project

The Elimold team is ready to help you achieve your production goals with precision-machined zinc alloy components. Contact us today to discuss your needs, and we’ll show you how to provide a durable, high-quality solution tailored to your requirements.