Contract Manufacturing

Get full project management from our team, customizing our services to optimize the cost, quantity, and quality of your order. Explore custom OEM components and parts with Elimold’s best-in-class OEM contract manufacturing team. Contact our dedicated team of OEM parts manufacturers.

A Contract Manufacturing Company Providing End-to-End Solutions

Elimold is a contract manufacturing company dedicated to helping original equipment manufacturers (OEM) streamline their production processes, reduce costs, and improve product quality. Our in-house facility in China and global supply chain network provide manufacturing, assembly, and finishing services to help you maintain a smooth supply chain and shorten lead times.

We partner with companies in the aerospace, energy, and industrial equipment manufacturing sectors to bring complex builds to life. Whether you need a small number of components or a complete product assembly, we deliver with precision and speed.

We offer a range of custom manufacturing services designed to meet the toughest production challenges. Furthermore, each service is tailored to your goals. Whatever your priority, whether it’s accelerating production, tightening tolerances, or reducing the number of suppliers, we’re committed to helping you.

What is Contract Manufacturing?

Contract manufacturing is a collaborative model between a brand owner and a contract manufacturer. The brand owner controls product design, branding, and sales channels, while outsourcing production to a third-party manufacturer with the necessary equipment, personnel, and experience.

This model offers significant advantages. For the brand owner, it saves the costs of building its own factory and purchasing equipment, while leveraging the OEM’s economies of scale to reduce production costs. The brand owner can focus on core businesses like R&D and marketing, while flexibly adjusting orders and product specifications. For the contract manufacturer, it can fully utilize idle production capacity and accumulate technology and experience by serving different brands. The process involves: the brand owner determines the product design and specifications; the two parties sign a contract that includes key terms such as production quantity, price, and delivery time; the brand owner oversees production and controls quality; and the contract manufacturer delivers the product and provides after-sales service.

Elimold's In-House Contract Manufacturing

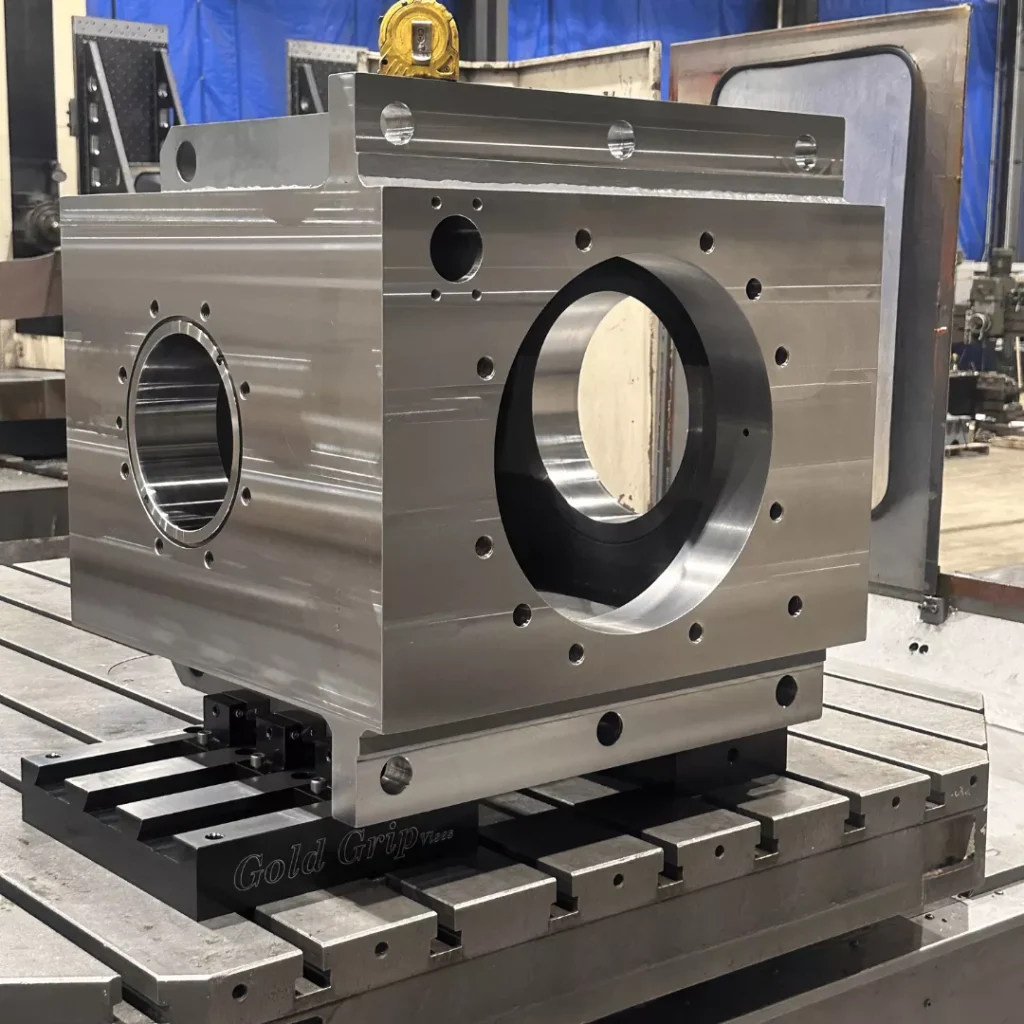

Our contract manufacturing facility, comprised of a team of engineers, project managers, and contract manufacturers, offers unparalleled innovation. We take on a wide range of tasks requiring tight tolerances, large-scale material handling, or rapid product development, adapting to your unique needs. From prototyping to full production, we support every stage of your manufacturing process.

In addition, we have an 185,000-square-foot in-house facility dedicated to comprehensive manufacturing. With a 15-ton lifting capacity and a 13-foot hook height, we can perform nearly all processes in-house. This means faster delivery times, fewer delays, and better quality control. From raw custom part manufacturing to finished product assembly, Elimold offers a full-service manufacturing partner.

Expert Design and Engineering Consulting

Elimold has over 100 design and engineering experts ready to provide design support, from simple part modifications to highly customized assemblies with complex geometries and specialized functionality. Our experts will assist you every step of the way, from initial design and new product introduction to scaled production. We’ll work with your team to develop a design that’s cost-effective, meets production deadlines, and adheres to industry requirements and required tolerances. Our regional offices offer extensive component design and engineering capabilities, including CAD modeling, CAE analysis, black-box testing, and rapid prototyping.

How We Help Bring Products to Market

Low-Volume Production

Ramp up production to get quality end-use parts to market fast and use batch production to reduce financial risk with no order minimums and low total cost of ownership

Mass Production

Order quantities up to 1 million+ parts with volume pricing built to fit your budget

On-Demand Production

Build agility into your supply chain by ordering quick-turn parts when needed

Your Strategic Manufacturing Partner

We have a team of manufacturing experts working behind the scenes to fulfill your production order—we manage the entire process and keep you updated along the way. We support you with:

- A dedicated account manager with production expertise

- CAD and cost-reduction advice from in-house applications engineers

- Logistics fulfillment from operations specialists

- On-site quality control

- Assistance with platform and file uploads to help navigate orders with complex bills of material (BoMs) and sourcing from both Elimold and its network partners

Manufacturing for Quick-Turn Prototyping and Full Scale Production

Elimold is a full-service global manufacturing service that can help you onshore your supply chain no matter where you are in the world. Our in-house manufacturing factories and global manufacturing network of more than 250 suppliers around the world enables a responsive supply chain for sourcing custom parts.

CNC Machining

Injection Molding

Sheet Metal Fabrication

3D Printing

Extrusion

Die Casting

Vacuum Casting

Wire EDM

Class 100 Cleanroom

Through contract manufacturing, our customers benefit from a comprehensive range of manufacturing services under one roof, saving time and resources. Companies across a wide range of industries rely on us for both individual parts and complete systems.

Our Class 100 cleanroom ensures high purity levels, while outsourcing testing, inspection, and certification processes to us allows customers to reduce production costs and eliminate on-site testing. Elimold’s Class 100 cleanroom is designed for ultra-high-purity manufacturing, enabling us to produce components and assemblies that meet stringent cleanliness standards. This is particularly important for gas and chemical delivery systems used in semiconductor and life science applications.

Quality Controls, Inspection Capabilities, and Certifications

Our industry-standard procedures and certifications guarantee quality and regulatory compliance.

- CMM inspection report

- Full dimensional inspections

- Material test reports and certifications

- REACH and RoHS Certificates of Conformance (CoC) First Article Inspection (FAI)

- Industry certifications: ISO 9001, AS 9100, ISO 14001, and ISO TS16949

- PPAP quality management system

Talk to a Contract Manufacturing Expert Now

If your business is looking to leverage the advantages of contract manufacturing and fabrication in your production process, contact Elimold today to speak with an expert.

How our Contract Manufacturing Services Work

Our process is built for precision, flexibility, and speed—ensuring every project moves seamlessly from concept to completion.

Discovery & Requirement Analysis

Engineering & Design Support

Sourcing & Planning

Manufacturing & Assembly

Quality Assurance

Packaging & Delivery

From concept to consumer and from design to full-scale production

From design to full-scale production, Elimold offers comprehensive contract manufacturing, design, and commercialization solutions, giving you access to the latest technologies and a team of experienced designers and engineers.

With over 10 years of experience in the design, development, and utilization of high-tech products and instruments, Elimold is well-equipped to turn your ideas into reality. When you work with Elimold, you’ll be assigned a dedicated project management team to coordinate all your needs, from custom prototypes to large-scale production projects, as well as all aspects of sourcing, shipping, and ongoing marketing.

Materials

Find all the materials you need for product development across industries. Common materials are shown above. You can explore our Material Lists for more options. Need specific material? Contact our specialists.

Metals

- Aluminium

- Copper

- Brass

- Bronze

- Steel

- Stainless Steel

- Magnesium

- Titanium

Plastics

ABS

PC

PMMA

POM

PA

PE

PEEK

HDPE

HIPS

LDPE

PBT

- PP

- PAI

- PEI

- PET

- PPS

- PS

- PVC

- Teflon

- UPE

- Bakelite

- FR-4

Surface Finishing

As Machined

Anodizing

Brushed Finish

Sand Blasting

Heat Treatment

Teflon Coating

Black Oxidize

Electroless Plating

Electroplating

Painting

Powder Coating

Electrophoresis

Tumbling

Alodine

Electropolish

Passivation

SPI Finish

Advantages of Contract Manufacturing

Contract manufacturing services offer substantial advantages, encompassing cost-effectiveness, technology, and production adaptability.

In terms of cost-effectiveness, contract manufacturers can achieve economies of scale by purchasing raw materials in bulk, lowering prices. Furthermore, with their operational expertise, contract manufacturers can help clients avoid significant capital investments in production equipment and effectively manage production costs.

In terms of technology, they possess extensive production capabilities and experience, implement strict quality control systems, adhere to industry standards to ensure product quality, and continuously invest in technological advancements.

In terms of production adaptability, contract manufacturers are able to quickly respond to market demand, flexibly adjust production plans, and quickly scale up or adjust production capacity based on order fluctuations.

Get Automation for Contract Manufacturing and Fabrication from Elimold

Automation is becoming increasingly important in the contract manufacturing and fabrication sectors. We understand the importance of automation in improving operational efficiency and productivity. Therefore, we’ve invested in state-of-the-art automation technology, enabling us to produce high-quality products with greater speed and precision for our custom contract manufacturing clients.

Our team has the expertise to design, develop, and implement automated systems to meet our clients’ specific needs. We can incorporate automation into every stage of any manufacturing process, from design and prototyping to production and assembly. This enables us to produce products with greater precision, consistency, and efficiency.

Risks and Considerations

While contract manufacturing can bring a lot of benefits to the table, it’s crucial to be aware of the potential risks and how to tackle them. At Elimold, we prioritize transparency, teamwork, and open communication to ensure that every partnership is built on a strong foundation.

Loss of Process Control

When you outsource manufacturing, you’re essentially handing over a piece of your production process. If you don’t choose the right partner, this can lead to miscommunication, quality problems, or delays in timelines. That’s why we focus on thorough planning, regular updates, and meticulous process documentation allowing you to keep control without having to micromanage every detail.

Intellectual Property (IP) Concerns

When you share your designs and proprietary methods with an external manufacturer, trust is key. At Elimold, we take confidentiality seriously at every step, and we’re more than willing to work within NDAs or contractual IP protections to keep your innovations safe.

Quality Variability

One of the biggest worries when collaborating with new manufacturing partners is inconsistent quality. Our ISO certification, in-house testing capabilities, and reliable cleanroom processes ensure that your specifications are met consistently whether it’s your first project or your fiftieth.

Hidden Costs

If expectations aren’t clearly laid out, scope creep and change orders can lead to unexpected costs. We help our customers steer clear of surprises by providing detailed quotes, clarifying deliverables, and offering insights into optional services like testing, kitting, or specialty materials.

Dependency and Supply Chain Complexity

Relying on an external manufacturer means you need to align schedules and manage supply chain logistics. We work closely with your team to forecast demand, manage lead times, and stay ahead of material shortages keeping your production on track.

Continuously Building Team Confidentiality

At Elimold, we continuously build a sense of confidentiality within our team, enabling our team to identify and address risks associated with contract manufacturing from the outset. We help clients minimize uncertainty and build lasting, stable partnerships.

Applications of Contract Manufacturing and Fabrication

Contract manufacturing and fabrication have numerous applications across a wide range of industries. We offer custom contract manufacturing and fabrication services that cater to the specific needs of our clients in various industries.

One of the main custom manufacturing applications is in the electronics industry. We specialize in producing electronic enclosures, control panels and cable assemblies that meet the exacting standards of our clients. Our team has the expertise and experience to design, prototype and manufacture electronic components that are tailored to meet the needs of our clients in the electronics industry.

Another key application of contract manufacturing and fabrication is in the medical industry. We understand that the medical industry requires high-precision components that meet stringent regulatory requirements. We specialize in producing components for medical devices, surgical instruments and implants. Our state-of-the-art facility is equipped with the latest technology, and our team has the expertise to produce components that meet the highest standards of quality and performance.

The aerospace and automotive industries also rely heavily on contract manufacturing and fabrication. We have the expertise to produce complex components for aircraft and automobiles that require high-precision and tight tolerances. Our team has the experience and knowledge to produce components that meet the specific needs of our clients in these industries.

Start your production project today with dedicated support from our manufacturing team.

Whether you need a custom manufacturer for short-term production or a long-term manufacturing partner for comprehensive manufacturing, Elimold can serve you. With advanced tools, a skilled team, and a strong focus on quality, we can help you solve your toughest manufacturing challenges. Contact us to get started on your next project.