Engineering & Design Support

From concept to production, Elimold makes your designs manufacturable. Speed Your Time to Market with Our Diverse Team of Engineers, Designers and Builders.

An Unmatched Breadth of Engineering Expertise

Our team of engineers boasts decades of engineering experience and expertise spanning a wide range of technical fields. Whether you need prototyping, transitional solutions, small-batch or high-volume parts production, our team can help you turn concepts into reality and streamline your supply chain with practical parts design and manufacturing solutions.

Elimold’s professional team of engineers and designers strives for excellence in every project. As the Elimold team continues to grow, we have expanded our ancillary services, further enhancing our comprehensive engineering and design capabilities. Therefore, we are able to provide solutions to virtually any engineering and design challenge our clients encounter throughout the project lifecycle.

Expertise to Support All Your Prototyping and Production Needs

When collaborating with external companies to produce components, top-tier engineering is crucial. Producing consistently high-quality components at reasonable prices involves numerous factors, including part design, manufacturing methods, material selection, manufacturability, advanced prototyping, and the design of efficient production processes.

Hiring an inexperienced partner is risky. It can lead to part quality issues, cost overruns, and endless delays, negatively impacting your reputation as a supplier with your customers. On the other hand, experienced engineering partners can help you avoid these problems. They anticipate potential challenges based on the part’s geometry and have a thorough understanding of the advantages and disadvantages of each manufacturing method. They can help you find the perfect balance between design, materials, manufacturing methods, and surface treatment options to produce parts that meet all your requirements and avoid the pitfalls of a lack of systematic approach.

Elimold’s engineering and design team has decades of experience and expertise in additive manufacturing, injection molding, sheet metal fabrication, and CNC machining. You can contact us directly or read our case studies to see how we help clients save time and money on critical projects.

How We Help Our Clients

With our globally standardized working methods, we not only deliver high-quality service but also integrate global best practices and knowledge to ensure your projects achieve optimal results. Elimold is a people-centric company; however, what truly sets us apart is not just the skills of our employees and our global knowledge-sharing approach, but also our passion for excellence and our relentless pursuit of creating the highest value for our clients. Elimold offers a wide range of service capabilities, integrated according to the specific needs of the project team, to provide a tailored portfolio of expertise, delivering comprehensive design and engineering services for any type of asset.

How does Elimold's multidisciplinary approach improve your mechanical design and manufacturing processes?

Elimold’s expert engineers and industry specialists facilitate the smooth progress of mechanical engineering projects with robust design support, testing, and analysis services. Our expertise covers all mechanical components and systems across a wide range of products, from industrial equipment and consumer goods to medical devices.

Our consultants across various engineering disciplines provide best-in-class expertise and leverage Elimold’s extensive testing capabilities and advanced modeling knowledge to conduct cutting-edge research to evaluate mechanical designs and improve the reliability and performance of prototypes and final products.

Elimold's Design Engineering Support Process

Design engineering support services provide technical support at every stage of the design, adaptation, and manufacturing of complex units, parts, and mechanisms in an engineered product. Elimold’s team offers comprehensive design support: from early-stage design support (including technical and economic fundamentals analysis and production planning for specific units) to final design compliance verification and expert consultation, we provide expert services.

Our skilled technicians focus on all stages of product development, providing support to the entire design and development department, from prototype creation to final production delivery. By contracting with Elimold, you will be able to integrate advanced technologies and modern design and engineering tools into your business activities.

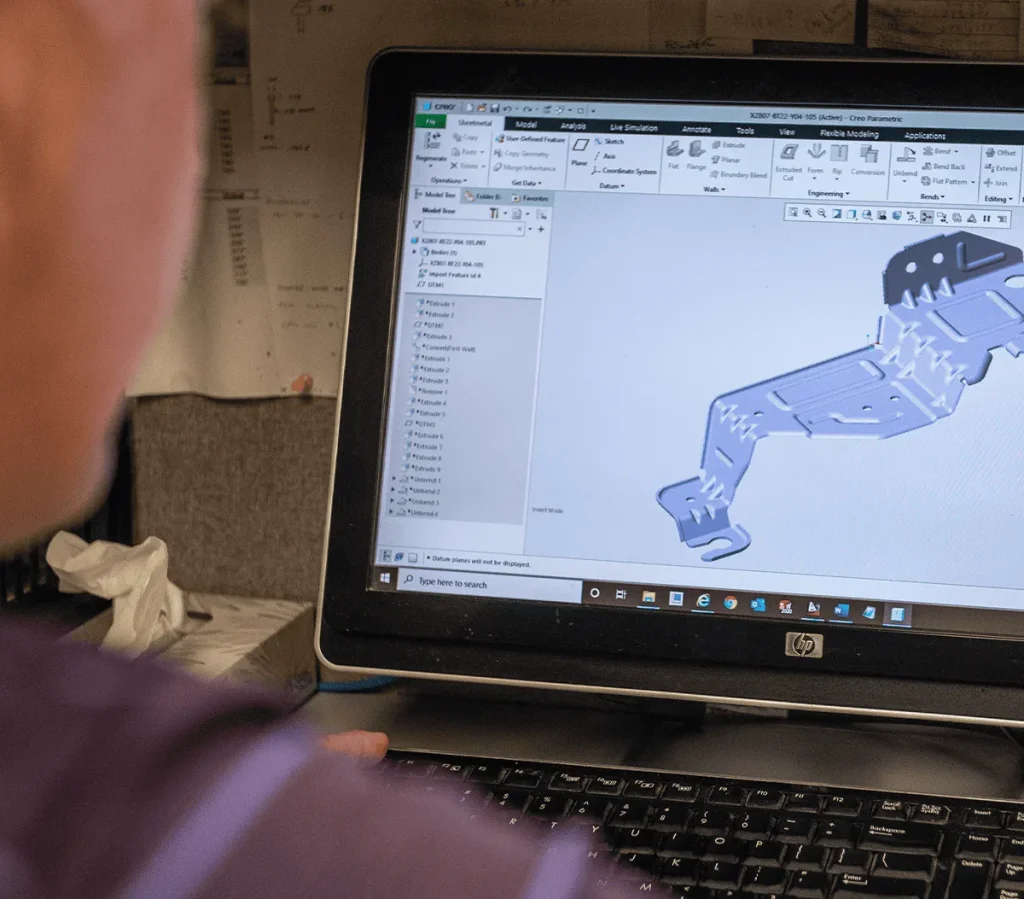

1. Creation of 3D models.

Thanks to the reduction of the design term using of practical 3D tools, you can accelerate the product launching process by 50%. Besides, three-dimensional models given to us will be suitable for you in future – they are convenient for making presentations, participation in tenders and competitions.

2. Reverse engineering.

In the process of reverse engineering, you will be able to restore the lost design documentation completely, which is necessary for manufacturing and modelling of the product you are interested in. Restoration, but not building from scratch, allows preserving from 10% up to 30% of project budget, which the company may redirect for other business tasks.

3. Documentation development.

As a result of the development of new design and technical documentation, you will get all necessary assemblies and parts drawings, specifications, including accompanying instructions. Availability of the full package with initial electronic data permits to modernize and improve products two times faster and to simplify the project reconciliation process between subcontractors.

4.Selection and calculation of material costs.

Optimal selection of design components and precise analysis of the budget cost estimate permit saving up to 32% of the budget due to avoidance of technical collisions and additional expenses for the lost (rejected) share of materials

5.Establishment of libraries.

Let us work with a list of specific and standardized parts. In several days you will get a personal library, where all units most frequently used in your production will be located under a suitable procedure. In future, it will simplify the drawing making process by your engineering department.

6.Operation with parametric elements.

You will be able to keep and repeatedly use structural elements designed by us in other projects. It allows accelerating projects reconciliation at least by 17% and decreasing human factor errors almost by 90% due to the single internal standard.

Up to 75% savings on design and engineering support budgets.

Furthermore, working with Elimold’s team of engineering experts avoids project delays caused by bureaucratic obstacles such as overtime, public holidays, and labor unions. We believe this is crucial for the manufacturing industry, not only due to supply chain constraints but also during the digital transformation. Moreover, our team is ready to provide solutions tailored to your specific needs.

In addition to the above advantages, thanks to remote collaboration and the engineers’ backgrounds, working with Elimold can save you up to 75% on your design and engineering support budget. For example, according to Deloitte, 59% of companies choose outsourcing to save money and reduce costs, including reducing spending on full-time staff. You can verify this for yourself with our experience and capabilities.

Five Ways to Leverage Our Expertise

The Elimold engineering team can support you throughout your product development and manufacturing process in the following five ways:

Additive Manufacturing Expertise

Elimold provides extensive know-how to help their customers optimize the part designs and material selections to improve manufacturability, save money and improve part quality. We can help you identify and solve geometry- and process-specific problems that DFM algorithms tend to miss.

- Use design optimization with generative tools specific to additive.

- Apply direct digital manufacturing (DDM) tools and development processes.

- Utilize extensive knowledge of additive materials and processes.

- Development of advanced prototyping processes tailored to the project.

- Access to in-house additive printing equipment.

Design For Manufacturing (DFM) Guidance

Elimold’s in-house production capabilities are paired with a large network of equally skilled in-house specialists. Depend on our knowledge and resources to inform key design decisions—especially manufacturing nuances for your part’s unique geometry. Our team works collaboratively, so we can carefully identify risks earlier in development and effectively meet your design and manufacturing requirements.

- Assembly fixture and jig design

- Design for injection molding

- Tool design and refinement

Mechanical Concept Development

Elimold offers creative yet simple design solutions to meet your product’s functional goals with the best production processes for each stage of development.

- Device and enclosure development

- Component integration

- Large-scale fabrications

- Experts in multiple CAD software formats

- Iterative design using in-house equipment

- Methods to increase speed and decrease cost of development

Advanced Prototyping

Work with Elimold to build a prototype to ensure your part is designed with final production in mind.

- Expedited prototyping with on-site additive manufacturing services for fast turnarounds on parts

- In-house CNC machining, turning, casting, molding and cutting

- Rapid prototyping and iterative testing

- Functional, aesthetic or fully-integrated prototypes

Production Support

Anyone can build a prototype part. Engineering a product so it can be mass-produced requires a different set of skills that require technology expertise so that guidelines may either be followed or creatively managed to simplify your unique production output.

Elimold’s engineering staff can help you improve the manufacturability of your parts, ensuring that they can be made cost-effectively at a consistently high level of quality and that they will perform well in their end-use applications. Whether you need bridge, low or full production parts, we can design a production solution that is cost-effective and practical.

- Optimize designs for manufacturability

- Suggest design changes that will streamline the manufacturing process (e.g., eliminating overhanging part features to eliminate the need for side actions for injection mold tools)

- Suggest alternate approaches to minimize the need for post-processing

Design Solutions for All Industries

Concept Development

Are you in the concept development phase and want a separate design team to work in parallel with yours? We can provide an independent look at your project to come up with alternative solutions and approaches to your design challenges. You can then combine those with your internal design efforts to create a blended design solution created from a larger group of engineering minds. Alternatively, we can work directly with your sales and marketing team combined with your customer inputs and knowledge base to lead and complete the concept development phase. Once concepts are approved, we would move into design and development for your product. And then follow through to production implementation.

Design Team Augmentation

We are also available to augment your own internal design department. As you are aware, much of the time consuming work involved with mechanical product design involves prototype design iteration, production drawing layout, tolerance stacking, model/drawing checking. Let 3D Engineering Solutions improve your time to market by application of our services to bolster your capacities at the right times and in the right places in your design process. Use our strengths in certain parts of your design process or continuously throughout.

Design for Manufacturing Support

Do you have a design that has been through the concept development phase and want to have it fleshed out into a manufacturing design? 3D Engineering Solutions can help you satisfy your product development needs. Our practical engineering design background can help you design products that can be manufactured in quantities from thousands to millions of parts per year. And with our tolerance stacking work, those parts will be able to be manufactured and assembled with little difficulty. We are experts at bringing closely toleranced designs to production. Gone are the days of living with a product that is not optimized for manufacturing. Let your manufacturing engineers work on improving the process and efficiencies and not on firefighting un-optimized designs. Once the product design is finalized, let 3D Engineering Solutions continue to support you by providing fixturing, gage design and FAI inspection services to support your manufacturing requirements.

Reverse Engineering

Our 3D engineering solutions have accumulated extensive experience in both contact and non-contact data acquisition methods, from on-site laser scanning to industrial CT scanning, enabling us to capture the "current state" of a product. Our engineers extract the geometry from the scan data and recreate the model in a CAD system. Your product improvements/modifications are also added to the new model. We then gather tolerance information from supporting components, your inputs, and other sources to create detailed drawings. From general mechanical components to your aerospace needs, we can meet your reverse engineering requirements. With an ISO17025 certified inspection background and experienced engineering technicians, we bring a wealth of knowledge and experience to your projects.

Product Teardown

Our product teardown analysis is a systematic approach to evaluating connection design and assembly cost drivers. We utilize Design for Assembly (DFA) and Design for Manufacturing (DFM) principles. Product teardown analysis focuses on total cost, involving the disassembly and analysis of the entire product to evaluate each component and connection design. Taking a manufacturing, service, and end-user perspective, product teardown analysis applies Design for Manufacturing (DFM) and Design for Application (DFA) principles to identify potential cost savings through consolidation or fastener replacement, improved assembly methods, and reduced scrap rates. Our product teardown analysis service includes a final report and a formal presentation at your company.

Why Choose Elimold Design Services?

We bridge the gap between innovative design and practical manufacturing.

Design Meets Manufacturing

Our cross-functional team understands creative design intent and real-world manufacturing needs, and bridges the gap between concept and production.

Speed Up Design Vallidation

We provide rapid DFM (Design for Manufacturability) reviews and real prototyping feedback so you can iterate quickly and prevent late-stage changes.

Smarter Cost Decisions

Our early-stage cost estimation and risk mapping let you make informed design decisions while reducing rework, delays, and waste later in the process.

What We Offer

Design and engineering support to help you turn ideas into manufacturable products. Design innovation can be the difference between a product that gets to market and one that defines the market.

Industrial Design (ID)

- Concept Sketches: Capture creative ideas and show the evolution of product appearance during the design process.

- Product Renderings: Display the product from multiple views—front, side, top, and perspective—for a clear visual understanding.

- Design Specifications: Detail dimensions, color codes, materials, and surface finishes to ensure accurate production.

Mechanical Structure Design

- Structure Drawings: Provide detailed 2D and 3D representations of a product’s internal framework and external layout, including dimensions, shapes, positions, and connection methods of each component.

- Engineering Drawings: Focus on manufacturing and processing details, with precise annotations of process parameters, material specifications, and heat treatment requirements to support accurate production.

CMF Design

- Color, Material, and Finish Selection: Choose the right colors, materials, and surface treatments to achieve the desired look, feel, and durability of the product.

- Design Support: Address challenges when designers are unfamiliar with specific materials or special manufacturing processes, ensuring practical and reliable solutions

Cost Estimation & Design-to-Cost

Use experience-based and top-down models to estimate manufacturing costs early.

Provide actionable cost-reduction strategies (e.g. simplified design, material substitution, assembly optimization).

Benefits of Working with Elimold's Team

Design Leadership

Our talented team collaborates with you to design products right the first time – addressing your challenges with innovative solutions that give you an edge in your market.

We help you bring new products to market quickly and cost-effectively while improving the competitiveness of your existing inventory. Our partnerships across the design ecosystem enable us to provide greater flexibility, scale and support.

Get to Market Faster

Our engineering expertise spans product development, test, assembly, quality and reliability – improving speed-to-market, quality and total product cost.

- Product Development: Early partnership with Elimold drives enhanced quality, faster speed-to-deployment and the lowest total cost of ownership throughout the product lifecycle. We work as an extension of your team – bringing unique insight that simplifies the manufacturing process.

- Proven Product Accelerators: We invest in developing proven reference designs and proprietary product platforms that accelerate the product development process – getting you to market faster.

Engineering Excellence

At Elimold, our engineering and design team leverages a long heritage of technical leadership that can support your products through their entire lifecycle. We are leaders in:

- Test Development: We build custom test solutions rooted in manufacturing expertise. Our collaborative approach analyzes variables, weighs risks and balances the cost – for optimal test solutions.

- Assembly Technology: Our global expertise and technical understanding optimizes processes across the entire product development lifecycle – from component package selection, to qualification, test vehicle design and assembly.

- Quality & Reliability: Our engineering team helps you innovate quickly and competitively while maintaining the quality and reliability your brand stands for.

Get Expert Advice on Your Product Design

Streamline your supply chain and meet tight production schedules with Elimold’s expert engineering and design services. Our team, with over 20 years of experience, provides tailored solutions to ensure smooth operations.