What is the metal injection molding process?

- What is the metal injection molding process?

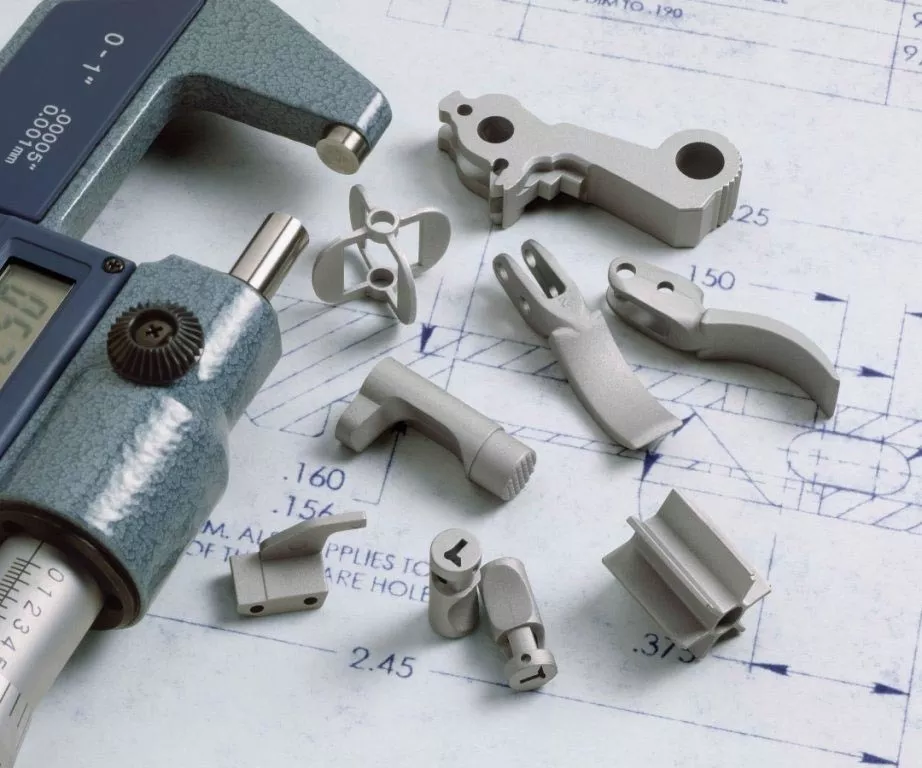

Metal injection molding is one of the main methods of manufacturing parts from powdered metal. It is suitable for simplifying the production of large products or products with complex shapes. It is usually used to manufacture small parts weighing less than 100 grams.

If you have followed information related to powder metallurgy, you may have noticed that metal injection molded (MIM) parts are consistently well-received in the business. You may also have heard statements from potential suppliers about the superiority of MIM parts over traditional powder metallurgy (PM). At the same time, the metal injection molding (MIM) process is a good option. However, the part manufacturer’s choice should be kept from jumping to conclusions that could lead to outright project failure due to production issues.

There are multiple options for how parts are manufactured. From small, complex pieces to large, simple assemblies, choosing the correct part manufacturer can come down to various factors such as raw materials, product design, and cost. Therefore, it is essential to understand the advantages and disadvantages of each process, the process flow, etc., before selecting the proper manufacturer for your project.

Metal Injection Molding Process Overview

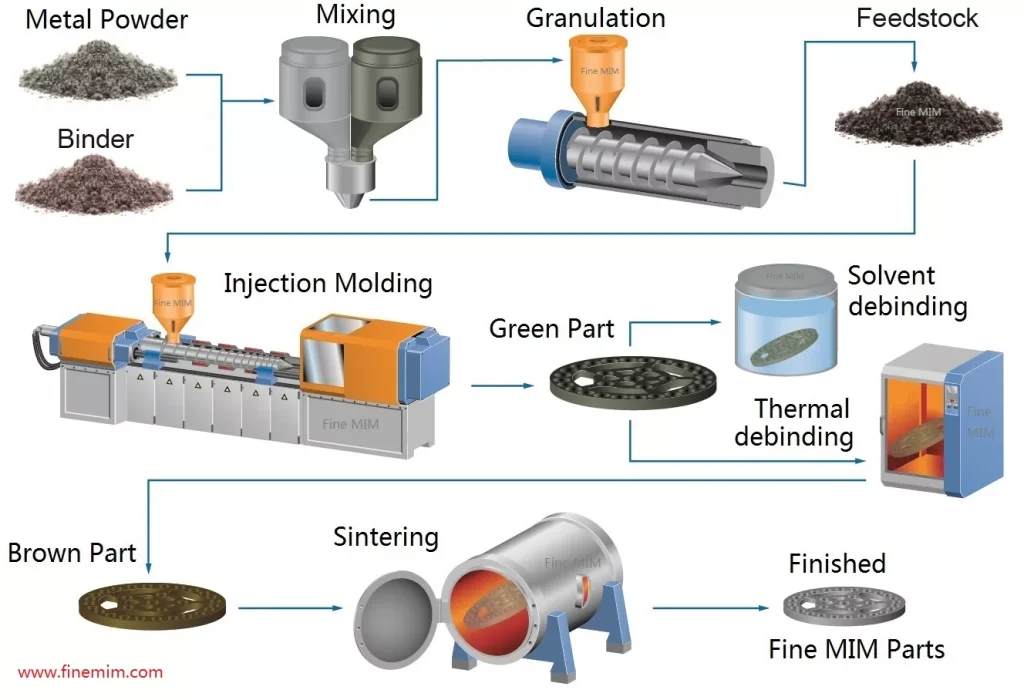

Metal Injection Molding (MIM) is a manufacturing process that allows for the one-step production of complex metal parts. The parts produced have high strength, durability, and wear resistance properties. This process is ideal for use when parts have a thin-walled design. Many customers also choose the MIM process for cost reasons. The process is inexpensive to perform. The entire execution process consists of four main steps.

First, the raw material is prepared, commonly called the raw material for metal injection molding. The feedstock is formed by thoroughly mixing the powdered metal material with a polymer binder (not limited to waxes or thermoplastic polymers). Second, the feedstock is injected into the mold through an injection molding machine, and when completed, the mold is uncooled and removed from the mold through a demolding process. In the third step, the binder material used only to bring the powdered metal into the mold is removed. Depending on the binder used, the thermal catalyst, solvent catalyst or water catalyst, etc., is removed. The solidified raw product is then sent to be cleaned and degreased to make a plain blank. Fourth, the part is sintered and hardened. This is usually done in an intermittent furnace or continuous belt furnace. The purpose of sintering is to consolidate and mechanically bind the individual particles of powdered metal, which is required to bring the part to the designed alloy system to achieve mechanical and chemical properties.

The entire part production process requires low cost and provides batch parts with good repeatable quality. The manufacturer will also have good process control management in the region’s production, reducing waste and thus lowering the overall manufacturing cost of the turn. Another advantage of this process is that the finished part usually does not require machining or finishing once completed. This relatively simple process makes metal injection molding cost-effective for producing small pieces.

Why the MIM process has become so popular in the marketplace

Metal Injection Molding (MIM) is the quintessential crossover between two completely different processes (plastic injection molding and powder metallurgy) into one. It enables designers to break free from traditional constraints and obtain low-cost, exotic stainless steel, nickel, iron, copper, titanium, and other metal parts in plastic molding. Thus, they have greater design freedom than many different production processes.

The raw materials used in the process can consist of any number of metals, and as the product is molded, the binder material is removed, and the metal particles are subjected to a refining process to maximize the strength and durability of the material. This process typically reduces the size of the item by approximately 15%. Only 100 grams or less can be placed in the mold per “shot” when the product is formed, but multiple cavities can be set per shot. This means that many small items can be made at the same time, reducing production costs per item.

From 1986 to 2023, the MIM market grew from $10 million to about $5 billion-a considerable leap. One of the reasons the process is so popular is its efficiency and cost-effectiveness. In addition, the process has significant advantages in producing complex, precise, and miniaturized metal products. In recent years, with the rapid development of global consumer electronics, automotive, medical equipment, hardware, machinery, and other industries, the market demand for comprehensive performance of metal parts has gradually increased. The metal parts manufactured by traditional processes gradually failed to meet the consumer demand of modern industries, which gave rise to metal injection molding technology. Its industry has also ushered in a good development opportunity.

Advantages and disadvantages of the metal injection molding process

Metal injection molding is a new technology for the near-net forming of metal parts, which has unique advantages in preparing high-precision near-net developed products with complex geometry, uniform structure, and high performance. In addition, metal injection molding is capable of fully automated and continuous operation for efficient production. With its tremendous advantages and features, the automotive industry is now using metal injection molding technology for many complex metal parts.

This technology allows manufacturers to combine several stages and operations into a single process, significantly reducing production costs and lead times. At the same time, powder injection molded parts are manufactured to their exact net weight, thereby reducing material waste and associated costs.

The powder products are clean, spherical, gas-atomized metal powders cleverly designed to provide high bulk density, consistency, and immaculate raw materials. This excellent level of quality provides customers with many advantages, including greater design complexity, improved mechanical properties, better surface finish, and the ability to produce flexible volumes.

MIM technology advantages:

- · Adds complexity, thinner, more arduous, denser, and more flexible designs.

- · Has better mechanical properties and strength than CNC machining and casting.

- · It is more efficient than CNC machining, the process produces less waste, and much can be recycled or reused.

- · Has a better surface finish than casting and conventional forging.

- · It is widely used for different metals and advanced materials.

Disadvantages of MIM technology:

- · High running costs for large-size products

- · requires skilled supervision

Typical Metal Injection Molding Applications

Metal injection molding is an excellent manufacturing process because it allows manufacturers to make complex, intricate, small parts with tight tolerances and thin walls. Some MIM application areas include

Computers and their ancillary equipment: such as printer parts, magnetic cores, firing pins, drive components, etc.

Tools: such as drills, bits, nozzles, gun drills, spiral mills, punches, sockets, wrenches, power tools, hand tools, etc.

Household appliances: such as cases, watch chains, electric toothbrushes, scissors, fans, golf heads, jewelry links, ballpoint pen clips, cutter heads, and other parts.

Medical machinery parts: such as orthodontic frames, scissors, tweezers, etc.

Military parts: missile tail, gun parts, warhead, medical cover, fuze parts.

Electrical parts: electronic packages, micro motors, electronic parts, sensor parts.

Mechanical parts: such as cotton opening machines, textile machines, curling machines, office machinery, etc.

Automotive and marine parts: such as clutch inner ring, fork bushing, splitter bushing, valve guide, synchronous wheel hub, airbag parts, etc.

Selecting the proper metal-forming manufacturer

Metal injection molding is suitable for producing small, complex metal parts that conventional processes cannot make. This is fine if the position has simple, thin, or fine design details. As you know from the metal casting process, the metal does not melt during the MIM process, which extends tool life. The metal injection molding process is efficient, easily repeatable, and cost-effective. In just one step, complex parts can be mass-produced and perfectly formed. Best of all, after your first production run, setting up future runs is quick and easy.

If you are looking for a partner that offers high-quality metal injection molding services, we would be happy to provide you with a quote for your project. Please email us today for a quote for your metal injection molding project.

Summary

Powder metal injection molding is a popular and cost-effective manufacturing process for small, complex, high-density parts. However, it is still limited to being profitable only when high volume production of small detailed parts is required. The manufacturing costs of metal injection molding are much higher than traditional powder metallurgy, so you must carefully examine your specific performance needs. Parts obtained through MIM can be more complex and require less machining. You know how important it is to control your budget – which is probably why you first approached powdered metal. It often means giving up the most extraordinary, sexiest processes for something more economical and reliable. But is the complexity and the benefit of avoiding machining worth the cost? Remember that many traditional PM projects can also produce net shape parts.