Why do engineers prefer CNC machining for custom parts?

- Why do engineers prefer CNC machining for custom parts?

- Technology Overview

- Market Demand Analysis

- CNC Technology and Service Types

- Technical Advantages

- Range of Machining Materials (Comparison)

- CNC Machining Standards and Tolerances

- Risk Trade-offs and Mitigation

- Application Areas

- Why Engineers Choose CNC Machining for Custom Projects

- How to Choose the Right CNC Machining Supplier?

- Choose Elimold for one-stop service

- Conclusion

- FAQ

From a CNC machining analyst’s perspective, engineers choose CNC machining for custom parts because it offers unparalleled precision, consistent quality, broad material compatibility, and predictable engineering results. In real-world project workflows, CNC machining can shorten design iteration times, simplify tolerance control, and support functional prototyping and on-demand small-batch production. The following sections provide a structured analysis covering technology, market demand, service types, technological advantages, and application areas—supplemented with data tables and expert summaries.

Technology Overview

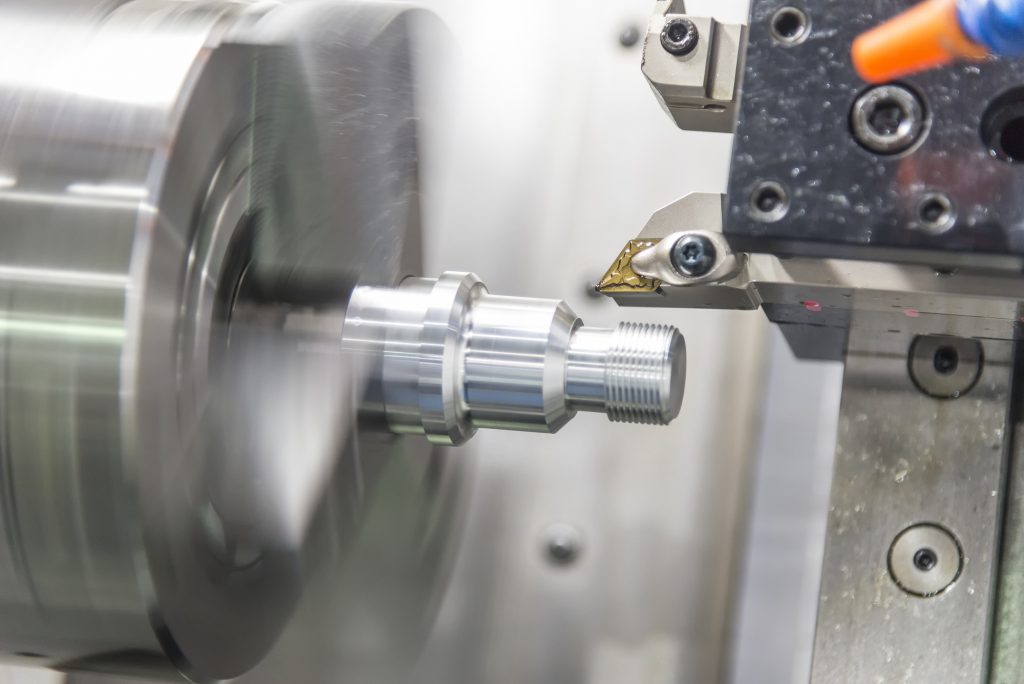

CNC machining uses digital toolpaths to perform highly repeatable shaping of metal and plastic materials. With the rise of five-axis machining systems, automation, CAM optimization, probe measurement, and digital quality control, CNC has become the most reliable machining process for custom parts that meet stringent engineering requirements. For engineers responsible for R&D iterations, durability testing, or multi-material assembly, CNC remains the most controllable and predictable choice in the manufacturing process.

Market Demand Analysis

Engineers increasingly rely on CNC because it supports rapid engineering iterations and real-material testing without the cost of molds or tooling. CNC machining also aligns well with industries requiring documented quality control, which is crucial in aerospace, medical devices, and custom industrial machinery.

| Market Demand Factor | CNC Capability Level | Engineering Benefits |

| Rapid prototyping | Excellent | Shorter development cycles and faster validation |

| Functional testing components | Excellent | Real material properties and load-bearing performance |

| Low–mid volume custom parts | Excellent | No tooling investment; high dimensional consistency |

| Design flexibility | High | Complex geometry freedom; fewer DFMA constraints |

| Certification/traceability | High | Inspection reports, digital programming records |

CNC Technology and Service Types

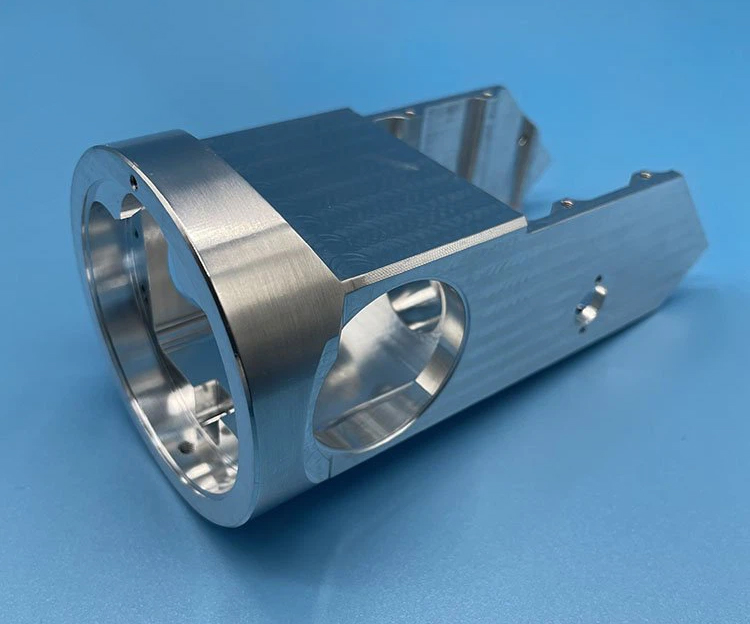

A diverse range of machining services enables engineers to manufacture parts of virtually any geometry, from simple brackets to highly complex aerospace components. The combination of turning, five-axis milling, and EDM enables complete part manufacturing with fewer connection points, lower tolerance stack-ups, and higher performance reliability.

| Service Category | Machine Types | Typical Engineering Use |

| 3-axis milling | Vertical/horizontal mills | Prismatic parts, brackets, housings |

| 4/5-axis milling | 4/5-axis centers | Complex surfaces, undercuts, mold inserts, impellers |

| CNC turning | Lathes, mill-turn | Shafts, bushings, threaded parts |

| Swiss machining | Sliding-head lathes | Small, high-precision components |

| EDM (wire/sinker) | EDM systems | Hard materials, sharp corners, deep cavities |

| Secondary operations | Grinding, polishing, anodizing, heat treating | Surface improvement and functional finishing |

Technical Advantages

From an engineering perspective, the advantage of CNC machining lies in its ability to deliver predictable results with minimal risk. Tolerances, surface finishes, and materials are all tightly controlled, ensuring parts meet performance requirements with minimal redesign or rework. This predictability is critical for engineers managing complex assemblies and high-performance applications.

| Advantage Type | CNC Output | Engineering Impact |

| Dimensional precision | ±0.005–0.05 mm | Stable fit/function across assemblies |

| Material variety | Metals, plastics, composites | Design freedom and functional testing accuracy |

| Repeatability | High | Reliable multi-part or multi-batch consistency |

| Lead time | Short | Faster prototypes and on-demand production |

| Surface finish | Ra 0.1–3.2 µm | Improved sealing, aesthetics, and friction control |

| Scalability | Prototype→production | Smooth transition without redesign |

Range of Machining Materials (Comparison)

CNC machining covers virtually all engineered materials. The key lies in selecting the appropriate cutting tools, coolant strategies, and machine tool rigidity to address the specific challenges of each material (e.g., titanium requires low chip loads and high rigidity; composite materials require dust removal systems and wear-resistant cutting tools).

| Material Category | Typical CNC Considerations | Examples |

| Ferrous metals | Tool wear, cooling, feeds, hardness | Steel, stainless, tool steels |

| Non-ferrous metals | Chip control, spindle speed | Aluminum, brass, copper |

| Exotic alloys | Tooling grades, slower feeds | Titanium, Inconel, Hastelloy |

| Plastics | Melting/zoning, chip evacuation | ABS, PEEK, Delrin (acetal) |

| Composites | Abrasive wear, dust control | Carbon fiber, G10 |

| Ceramics & glass | Specialized tooling / EDM | Silicon carbide (limited) |

CNC Machining Standards and Tolerances

Linearity and angular measurements of CNC workpieces follow ISO 2768-1, while surface roughness follows ISO 2768-2. Manufacturers must ensure compliance with the required tolerances to obtain reliable and accurate machining results. The following is a general CNC machining tolerance table, showing the range of dimensional deviations during machining. This table helps engineers and machinists clearly understand the acceptable ranges for parameters such as surface finish, geometry, and dimensions.

| Linear Dimension Range (mm) | F (Fine) | M (Medium) | C (Coarse) | V (Very Coarse) |

| 0.5 up to 3 | +/- 0.05 | +/- 0.1 | +/- 0.2 | – |

| Over 3 up to 6 | +/- 0.05 | +/- 0.1 | +/- 0.3 | +/- 0.5 |

| Over 6 up to 30 | +/- 0.1 | +/- 0.2 | +/- 0.5 | + 1.0 |

| Over 30 up to 120 | +/- 0.15 | +/- 0.3 | + 0.8 | + 1.5 |

| Over 120 up to 400 | + 0.2 | + 0.5 | + 1.2 | + 2.5 |

| Over 400 up to 1000 | – | + 0.8 | + 2.0 | + 4.0 |

| Over 1000 up to 2000 | + 0.5 | + 1.2 | + 3.0 | + 6.0 |

| Over 2000 up to 4000 | – | + 2.0 | + 4.0 | + 8.0 |

Risk Trade-offs and Mitigation

Most CNC machining risks can be controlled through early engineering design: reasonable tolerances, thorough material selection, and early communication regarding fixtures and inspection.

| Risk | Impact | Mitigation |

| Over-tight tolerances | Cost and scrap | Only specify where necessary |

| Improper material selection | Poor performance | Engineer material selection + supplier input |

| Inadequate fixturing | Distortion, runout | Design for proper clamping and support |

| Long lead on exotic tooling | Delays | Early procurement; use alternatives if possible |

| Thermal distortion | Dimensional drift | Use thermal-stable machines/processes, stress-relief |

Application Areas

CNC machining is a vital manufacturing foundation in many performance-oriented industries. Engineers value CNC machining because it ensures structural integrity, extends service life, and meets certified material standards—all critical for custom components. Suitable for regulated or high-load environments.

| Industry | Typical CNC Parts | Why CNC Is Preferred |

| Aerospace | Brackets, turbine components | High strength alloys, tight tolerances |

| Automotive | Powertrain components, prototypes | Speed and material durability for testing |

| Medical | Surgical tools, implants | Biocompatible materials and clean surface finishes |

| Electronics | Enclosures, heat sinks | Precision thin-wall features and thermal performance |

| Energy & Power | Valve bodies, insulating fixtures | High reliability and corrosion resistance |

| Industrial Machinery | Shafts, housings | Strength, dimensional stability |

Why Engineers Choose CNC Machining for Custom Projects

Engineers favor CNC machining because it perfectly combines speed, precision, and material authenticity in a way that molding or additive manufacturing processes cannot fully replicate. CNC machining supports practical testing, precise fit, and small-batch production without the delays caused by molds or tooling. For design engineers, mechanical engineers, and R&D teams, CNC machining reduces risk, accelerates validation, and ensures parts function correctly in mission-critical components.

One key reason engineers prefer CNC machining is its efficient production method. The cycle from design to the first actual prototype is quite short. CNC prototypes require no molds, thus reducing the production cycle to 1-3 days, allowing engineers to validate the design to fully meet intended functions in the shortest possible time. Furthermore, CNC prototypes can be made before the final design is finalized, allowing for flexible improvements if the design fails to meet expectations. This significantly shortens the project development cycle and avoids the risk of investing in molds before design optimization.

How to Choose the Right CNC Machining Supplier?

Choose a custom CNC parts manufacturer with extensive experience and technical expertise. Precision parts machining requires advanced skills and knowledge. Only manufacturers with relevant expertise can provide high-quality products. Assess their machining experience and capabilities through their website or by directly consulting their sales representatives.

When screening and judging a supplier’s capabilities, determine if they possess advanced equipment. State-of-the-art equipment and processes are crucial for precision machining. Complete equipment configurations ensure product accuracy and stability, while efficient production capacity guarantees timely delivery.

Furthermore, prioritize manufacturers that implement quality management systems and standards. Strict quality control is essential for compliance in precision machining. Choose manufacturers with ISO or similar certifications, as strong quality assurance saves time in the long run. Although this is a technology-intensive industry, pricing remains an important consideration. Obtain quotes from multiple manufacturers, comparing not only costs but also included services and after-sales support.

Choose Elimold for one-stop service

Obtaining high-quality CNC machining services remains a fundamental goal for rapid production success. At Elimold, as a professional CNC machining factory, we offer a full range of machining services to meet your needs from initial roughing to final finishing. With over 15 years of manufacturing experience, we handle CNC parts with tolerances up to 0.005 mm, offering a 4-hour rapid quote and 72-hour delivery. We produce over 800,000 parts in varying quantities. Our goal is to provide the highest quality and most efficient metal parts machining services for both prototyping and mass production clients. From raw material control to product inspection, we consistently pursue excellence in quality to deliver impeccable results. The Elimold team recognizes the importance of every detail in production, ensuring that our products not only meet your expectations but exceed them in terms of quality and visual appeal. When seeking a reliable and professional CNC machining service provider, consider Elimold as a trusted partner for achieving efficiency and excellence in your machining process.

Conclusion

CNC machining remains the cornerstone of custom parts due to its precision, flexibility, predictable lead times, and extensive material support. Engineers favor CNC machining because it minimizes compromises in design and manufacturing, accelerates development cycles, and delivers reliable and repeatable parts across numerous industries, especially those where performance, certification, and assembly accuracy are not compromises.

FAQ

Which materials are best suited for CNC machining?

Metals such as aluminum, steel, stainless steel, titanium, and copper alloys, as well as plastics such as POM, PEEK, PTFE, PC, and ABS, can generally be efficiently CNC machined.

How to choose between three-axis and five-axis machining?

For simple planar geometries, choose three-axis machining; for complex surfaces, deep cavities, or machining requiring fewer setups and higher tolerance accuracy, choose a five-axis machining center.

How to reduce CNC machining costs for a project?

Simplify the geometry, avoid ultra-thin walls, use standard tolerances whenever possible, and choose materials that are easy to machine (e.g., use aluminum instead of stainless steel if functionality allows).

How large should I specify tolerances?

Use the most lenient tolerances possible to meet functional requirements; typical tolerances for most parts are

±

0.05 mm, use tighter tolerances only when functionality demands them.

Is CNC machining better than 3D printing for functional prototypes?

Yes, CNC machining is superior when mechanical strength, temperature resistance, surface finish, or precise dimensional accuracy are required.

Can CNC machining support mass production?

For small to medium batch production, yes. For very large batches (over 10,000 pieces), molding or casting may be more cost-effective, but CNC machining can still provide higher precision.