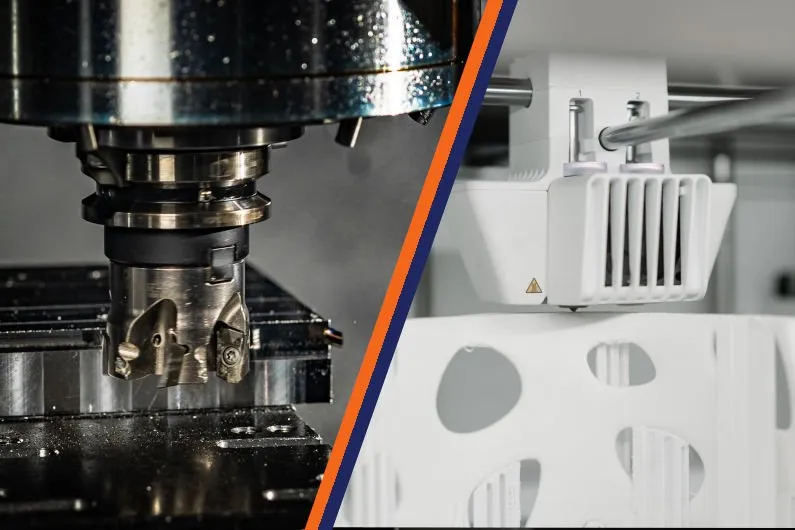

CNC machining is suitable for high-volume production. It can create many products in a much shorter period, whereas 3D printing takes hours to create a single product. This is just one of the advantages of CNC. Let us take a look at some of the others.

Prototyping made easier

CNC machines are better suited for prototypes that can withstand structural testing because they carve designs out of materials. They can also build prototypes using the same materials used to make the final product.

Structural tests and changes will be more accurate because they use the same materials. This speeds up the production process because the changes will be in the design, not the material. 3D printers cannot build prototypes with structural strength and cannot be physically tested.

Prototype integrity is improved.

CNC machines do not heat the material and modify it. The material is stronger and has better structural integrity than 3D printers, which must heat the material to create the desired product. 3D printers may also have to add foreign materials to the mixture to make prototypes, which CNC machines do not.

Surface finish advantages

CNC machines provide a better surface finish than 3D printing because the material is not deformed during the process. The rigid material and cutting action keep the product together, and there is less chance of error or distortion. 3D printing has a poorer surface finish. Because the material is layered and heated plastic, the material can bend, warp, or distort.

Increased Tolerance

CNC machines work more precisely, so parts have better tolerances than 3D printers. Prototypes with shafts or connections to other parts will have higher quality and are more likely to fit with other parts because of the tolerance levels.

Price and quantity do not determine the price.

The cost of 3D printing depends on the amount of material required. The quantity of the final product does not determine the price of the CNC machine. 3D printing will not be cost-effective for larger orders, which happens with the CNC machine boom.

Quality benefits CNC

Larger layers from a 3D printer are faster but not as high quality as smaller layers. If you need a prototype, you can get it quickly but with slightly less quality or wait longer for the best quality the printer can provide. CNC machines allow you to choose the resolution for your project. They can deliver different qualities quickly, making them ideal for quick builds and instant test results.

Reduce costs

If you have a choice of which manufacturing method to use for your product, CNC machining is often cheaper than 3D printing.

Contact Elimold for your CNC machining needs.

CNC machining can create the parts your business needs. Our expert machinists at Elimold will provide excellent work to help you achieve your goals. We aim to help you get the right part for your project.

Elimold offers custom machine building, precision parts machine, and reverse component engineering services to get the required product on time. We provide superior CNC machining solutions to manufacturers across multiple industries. Our expertise and dedication to our work will help you and your business stay at the forefront of your industry. We have the solutions you need. Contact us today.