The characteristics, structural requirements, and processing routes of thin-walled parts are theoretically analyzed in this paper. The technical challenges and solutions for processing thin-walled parts are elaborated, focusing on using a CNC lathe and machining center equipment to meet the structure and accuracy requirements of the parts through high-speed milling.

Thin-walled parts typically have a wall thickness to contour size ratio of no greater than 1:20, including thin-walled boxes, cylinders, and plates. Due to their relatively small size, lightweight, and other advantages, they are used extensively in aerospace, precision instrument, and other fields. Most thin-walled parts are processed using CNC technology, machining centers, and high-speed machining techniques. High-speed milling is particularly popular because it can meet the demanding processing accuracy needs of thin-walled parts while increasing productivity. The distortion of the thin-walled components during the high-speed cutting process is decreased by the machining process’s analysis and determination, and the workpiece shaping’s technical requirements are eventually met.

many causes of thin-walled parts deforming, as well as potential remedies

(1) The actual structure and material of the workpiece: In the automotive and aerospace industries, there are many rotary, plate and frame, and curved workpieces. The stiffness and strength of these various workpiece structures vary. Significant variations in machinability will result from differing materials and mechanical qualities.

(2) Fixture: The clamping force and fixture structure significantly impact the deformation of thin-walled items. If the clamping force on the workpiece is unequal, the form will vary, and the processing accuracy will suffer. Using circular jaws, point contact into surface contact, and increasing the contact area are preventive measures. Secondly, using open sleeves, point force into the open sleeves of the surface clamping so that the force is uniform; uniform deformation is a preventive measure. Thirdly, using soluble glue infusion, the injection of soluble glue into the workpiece after clamping, is a preventive measure.

(3) Process parameters: match a fair feed rate, speed, and depth of cut to the tool according to the workpiece drawing. High-speed cutting technology can be employed to lower the cutting force to lessen deformation during machining. When machining thin-walled parts, a smaller tool draft should be chosen to limit vibration to assure machining precision because as the cutting force increases with an increase in tool draft, the vibration of the workpiece also increases.

(4) Additional impacting factors: Heat is the main cause of workpiece deformation. The heat produced by the friction between the tool and the workpiece during the cutting process will also cause the workpiece to flex, lowering the machining accuracy if the cooling performance is subpar.

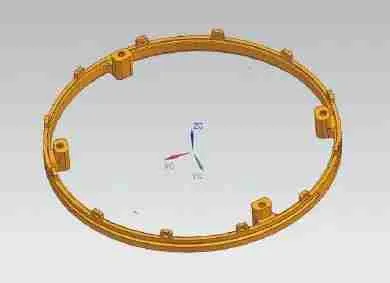

Workpiece structure

The workpiece in Figure 1 is built of the LY12CZ aluminum alloy and has a thickness of 7 mm and an outside diameter of 514 mm. Due to the long machining ring grooves on the outer circle and the uniformly spaced placement of 12 machining holes and 4 pivot lugs on the circumferential end face, the workpiece has weak stiffness and deformation during clamping, and machining is highly likely. The workpiece is more challenging to process due to the part’s high flatness requirements, high surface roughness requirements for the groove and external surface, and other factors like improper processing process route selection, uncontrollable processing accuracy, and unguaranteed workpiece quality.

Process Analysis

(1) Structural analysis: The workpiece is a ring-shaped part with an overall regular structure, symmetrical distribution of lugs, uniform distribution of grooves along the circle, no irregular surface, no complex structure, and a tidy and simple structure of the workpiece.

(2) Material analysis: The part’s material grade is LY12CZ, an aluminum alloy with a copper basis and a high magnesium content that performs well when annealed and quenched and has adequate cutting performance.

(3) Accuracy requirements: The focus of the workpiece must be flat and have a surface roughness of fewer than 0.05 millimeters (mm). The annular groove’s surface roughness must be 1.6 millimeters (mm), and the rest must be 3.2 millimeters (mm).

(4) Forming analysis: The workpiece is a ring-shaped rotary class item, which can be turned or milled to meet the structure and accuracy requirements of the formed parts. CNC lathes and machining centers are used most frequently for this task.

(5) Process challenges: The workpiece’s structure is straightforward, and accuracy is simple to manage. The difficulty of process forming is the control of deformation because of the thin wall of the workpieces and the large size of the outer circle (diameter up to 514mm), which make it very easy to produce deformation during the machining process. If reliable deformation control measures are not taken, it is easy to have unqualified products. Limiting the workpiece’s deformation and operating under the equipment’s and the tooling’s guarantees makes it possible to process quality finished goods.

Process Solutions

4.1 Choice 1

The following are the main procedures.

(1) CNC turning one: expand and clamp the inner hole of the part after the incoming material quality check, then lower the material.

(2) CNC Turning II: The end face will be exposed to light after aging treatment to ensure flatness and outer tolerance.

(3) Turning good end faces and outer circle positioning, the rough opening of the inner cavity, and the circumferential front of the lug, reserve margin, and guarantee the entire thickness.

(4) Machining center milling II: The outer circle is positioned, the ring groove and outside chamfer are milled into place, and finally, the threads of the supporting lugs are machined into place. This process is repeated for the inner cavity profile, thickness, and outer circle.

(5) Four-axis machining center milling: ring groove cleaning in place, inner circumferential hole centering, and outer circle centering.

(6) Deburring and sharp edge reversal during the clamp procedure.

4.2 Choice 2

The following are the main procedures.

(1) CNC turning one: expand and clamp the inner hole of the part after the incoming material quality check, then lower the material.

(2) CNC turning II: The end face is brightened following age treatment to guarantee flatness and outside tolerance.

(3) Machining center milling one: Creating a decent end face and outer circle positioning, turning a rough opening of the inner cavity, and the circumferential frontal opening of the support lug, all while leaving a margin and guaranteeing the overall thickness. Each piece is tagged with a CMM once the machining is finished to indicate the part’s deformation position and deformation quantity.

(4) Machining center milling II: To assure flatness after age treatment, the frontal milling reserve margin.

(5) Machining center milling three: milling good plane positioning, front milling internal cavity and process support ears, reserve margin, flip side open rough internal cavity and process support ears, reserve margin, after processing with three coordinate measuring machine focus on detecting the outer circle and flatness, mark the location of the part deformation, and if the deformation is greater than necessary, the whole batch processing this sequence.

(6) Machining center milling four: outer circle positioning, inner cavity process pivot, outer circle and surface to the remaining size, flip the front side of the inner cavity open rough and process pivot processing to the remaining size, focus on detecting the outer circle and flatness after processing with a three-coordinate measuring machine, mark the location of the part deformation, and if the deformation is greater than necessary, the entire batch process.

(7) Wire cutting: Flatting the interior cavity and removing two process bumps.

(8) Machining center milling five: external positioning, milling the internal cavity contour, process pivot, outer circle, and surface, reserve margin, use CMM to concentrate on testing the outer circle and flatness, mark the part’s deformation position, and confirm whether to intensify the heat treatment procedure in response to the deformation.

(9) Machining center milling six: external positioning, initial processing of the internal cavity profile of the part in place, modification of pressure plate, initial processing of outer circle and thickness in place, initial processing of circumferential semi-annular groove using T-shaped tool, initial processing of external chamfering, initial processing of frontal support ear, and initial part inspection.

(10) Four-axis machining center milling The circumferential inner hole and ring groove is cleaned and secured, and the outside circle is centered and adjusted.

(11) Pour a blunt, sharp edge into a clamp before deburring.

Comparison of process options

After the material has been discharged, the solution involves a single aging process in which the end face is exposed to light and precision is established. The end face is then used as a benchmark to process the inner cavity and outer circle, and the workpiece is twice machined to form it. While the method is straightforward and can guarantee the flatness of the end face and quick processing, it is difficult to control how the workpiece deforms, there is no process monitoring, it is simple for quality problems to manifest, and it cannot fulfill the demands for size and precision. Option 2’s first three steps are the same as Option 1’s. After the fifth step’s external and internal cavity roughing, the machining allowance is conserved, and the CMM measures the workpiece’s deformation. To ensure the qualifying forming rate, the workpiece is repeatedly machined by aging treatment, reserving a generous machining allowance, and the process inspection of external and flatness using CMM.

Option 2 has a scientific and reasonable process flow, takes deformation control measures, strictly controls the deformation of the workpiece during processing, and effectively solves the problem of defective products caused by workpiece deformation; however, Option 1 has a simple process flow, low processing cost, and high processing efficiency, making it easy to produce non-conforming products caused by workpiece deformation.

Option 2 for processing this thin-walled part is more in line with the technical requirements since it fundamentally addresses the deformation and quality issues of the workpiece and is superior to option 1.

Process inspection control

Inspecting the workpiece processing process is a crucial step in the machining process. Professional inspection tools and gauges must be used to complete the process inspection of the parts’ size and accuracy. Option 1 relies mostly on judgment based on subjective experience and does not use the appropriate detection methods to quantify the deformation of the workpiece; The focus of Option 2 is on the key deformation data indicators of the workpiece through the CMM, using objective scientific data to speak, accurately grasp and analyze the location and amount of deformation, to provide strong evidence for determining the next process operation, so that corresponding actions can be taken to eliminate the deformation caused by The deformation can be eliminated and qualified parts can be processed.

Control of deformation

Beginning with the components that influence the deformation of thin-walled parts, deformation control is mostly conducted from the following angles.

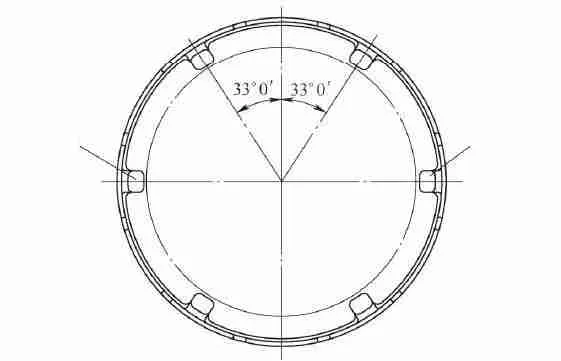

(1) Clamping method: Using soft jaws to expand the inner hole to prevent dimensional deviation due to workpiece deformation during turning. Additionally, leave the process tabs at the left and right sides of the workpiece’s inner cavity (see Figure 2); the shape of the tabs is consistent with the support lugs to make it easier to clamp the parts and lessen part deformation.

(2) Reducing the workpiece’s residual stress: Processing the LY12CZ aluminum alloy material results in internal stress release, which leads to material deformation. Due to the difficulty in controlling the deformation during the annealing process, the workpiece is subjected to an aging process that involves maintaining it at 200°C for 12 hours and air cooling to remove any remaining tensions.

(3) The use of suitable process parameters: For a high-speed cutting, attempt to use a modest axial depth of cut; alternatively, you can choose a bigger radial depth of cut, or even one that is more than the tool’s radius, to lessen the cutting force and prevent workpiece deformation when the cutting quantity increases and the radial depth of cut exceed the tool’s radius, the machining efficiency increases while the maximum cutting force stays constant. Thin-walled items’ geometric dimensions are unaffected by variations in cutting speed; thus, as long as the spindle speed permits it, you can select the highest cutting speed.

(4) Other factor control: In addition to the cutting process parameters, other comprehensive elements, including tool path, mechanical vibration, and cooling mode, also impact the deformation of thin-walled parts. As for cutting fluid, the daily inspection of the machining center should be strengthened to check whether the cooling circulation system is operating properly, whether the cutting fluid is being used properly, and whether the parameter settings are reasonable. The tool path should minimize the force on the lowest stiffness part of the workpiece. Reduce workpiece processing distortion, safeguard the tool, and increase tool service life.

Conclusion

Thin-walled components tend to become increasingly thin, and processing thin-walled parts are known to be problematic. Preventing thin-walled parts from deforming and affecting processing accuracy is the processing’s primary goal. The deformation of thin-walled components can be successfully reduced by creating a logical machining process route, enhancing the clamping fixture, and choosing scientific tool paths and process parameters, all of which ensure the workpiece’s machining accuracy and increase machining efficiency.

Elimold has its production facilities and excels at processing thin-walled parts. Contact us now to learn more about the technology involved in manufacturing thin-walled parts.