A plastic mold is a tool in the plastic processing industry used with a plastic molding machine to give plastic products a complete shape and precise size. Because of the variety of plastic and processing methods, plastic molding machines and plastic products, and the structure of the simple and complicated plastic mold types and structures are also various.

A combination plastic mold for compression molding, extrusion, injection molding, blow molding, and low foam molding, which mainly includes a concave mold with variable cavities composed of concave mold combination substrate, concave mold assembly, and concave mold combination card plate, and a convex mold with a variable core composed of convex mold combination substrate, convex mold assembly, convex mold combination card plate, cavity cut-off assembly, and side cut-off combination plate. Coordinated change of mold convex and concave dies and auxiliary molding system. It can process a series of plastic parts of different shapes and sizes. It is a tool for the plastic processing industry and plastic molding machines to give plastic products a complete configuration and precise size. Because of the variety of plastic and processing methods, plastic molding machines and plastic products and the structure of the simple and complicated plastic mold types and structures are also varied.

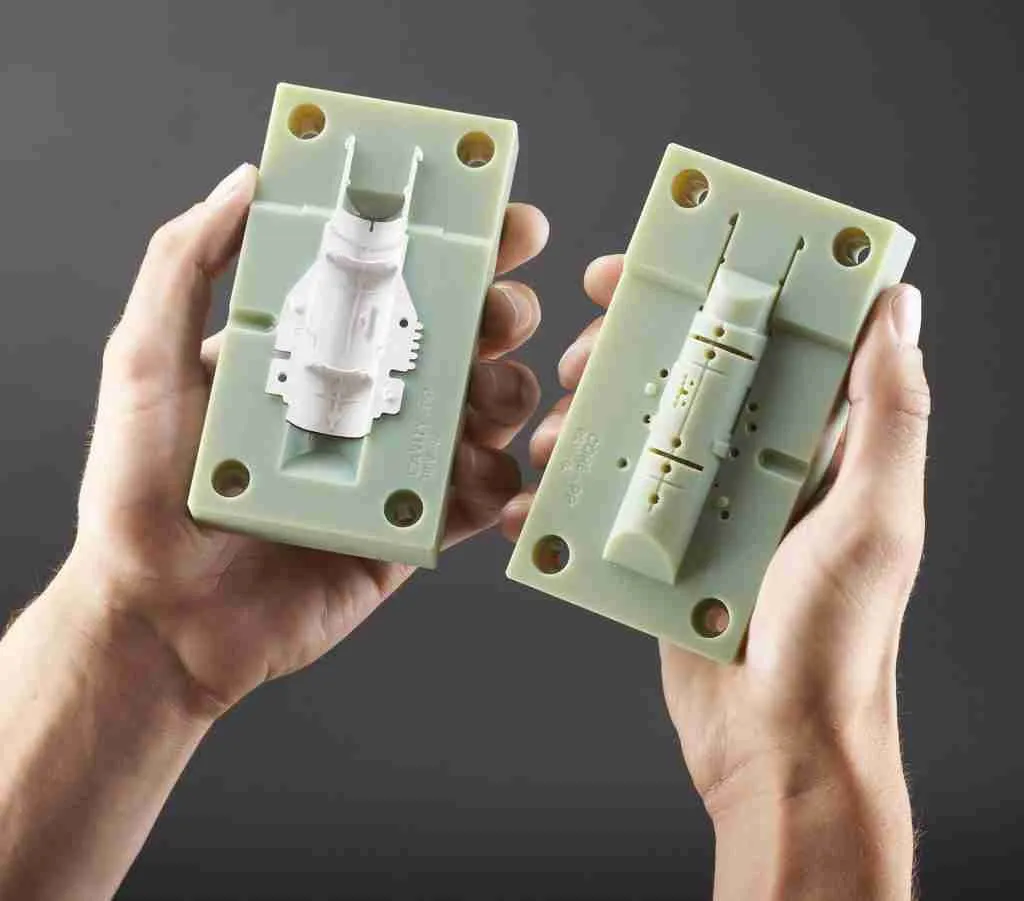

A plastic mold is a tool for producing plastic products. It is composed of several groups of parts, and this combination has molding cavities inside. The mold is clamped on the injection molding machine during injection molding, and the molten plastic is injected into the molding cavity and cooled and shaped. The upper and lower molds are separated, and the product is ejected from the cavity and leaves the mold through the ejector system. Finally, the mold is closed again for the next injection; the process is cyclic.

Generally, the plastic mold consists of two parts: the movable mold and the fixed mold, the movable mold is installed on the moving template of the injection molding machine, and the fixed mold is installed on the fixed template of the injection molding machine. During injection molding, the mold and the fixed mold are closed to form the pouring system and cavity, and when the mold is opened, the mold and the fixed mold are separated to take out the plastic products.

Although the mold structure may vary depending on the variety and properties of plastics, the shape and structure of plastic products, and the type of injection machine, the basic structure is the same. The mold comprises a pouring system, a temperature regulating system, molding parts, and structural parts. Among them, the pouring system and molding parts are the parts in direct contact with plastic and change with plastic and products. These are the most complicated and changeable in the mold and require the highest processing finish and precision.

The pouring system is the part of the flow channel before the plastic enters the cavity from the injection nozzle, including the main flow channel, cold cavity, manifold and gate, Etc. Molding parts are the various parts that make up the product’s shape, including moving mold, fixed mold and cavity, core, molding rod and exhaust port, Etc.

Today we want to talk about how to test the plastic mold molding parts, parting surface, exhaust slot qualification, molding, and parting type can be said to be the most important part of the plastic mold, mold after completion; these parts of the test are also to be very strict, we can test from these points to carry out.

1. the surface of the front and rear mold should not have unevenness, pits, rust, and other defects that affect the appearance.

2. the inserts and mold frame with rounded corners should be less than 1 mm clearance. 3.

3. the fractal surface is kept clean, neat, and tidy; no hand-held grinding wheel to avoid hollowness and no depression in the sealing part.

4. the depth of the venting groove should be less than the value of the overflow edge of the plastic.

5. The insert should have smooth placement and reliable positioning.

6. Inserts, cores, Etc. should be reliably positioned and fixed; round pieces have a stop turn and no copper or iron pads under the insert.

7. the top bar end face and core are consistent.

8. before and after the mold-forming part without inverted buckle, chamfering, and other defects.

9. The ejection of the bar should be smooth.

10. multi-cavity mold products, left and right pieces symmetrical, should be indicated L or R, customer requirements for the location and size should be in line with customer requirements, generally in the place does not affect the appearance and assembly plus, the number of 1/8.

11. mold frame locking surface research and matching should be in place, more than 75% of the area encountered.

12. the top bar should be arranged closer to the side wall and next to the tendons and tabs, and use a larger top bar.

13. The same piece should indicate the number 1, 2, 3, Etc…

14. each touch through the surface, insert through the surface, and parting surface should be in place.

15. The sealing part of the parting surface should conform to the design standard. Below medium-sized mold 10 ~ 20 mm, large mold 30 ~ 50 mm, the rest of the machine processing to avoid empty.

16. the skin pattern and sandblasting should evenly meet customer requirements.

17. the appearance of products with requirements and products on the screw should be anti-shrinkage measures.

18. the depth of the screw column of more than 20 mm should be selected to use the top tube.

19. The product’s wall thickness should be uniform, and the deviation should be controlled below ±0.15 mm.

20. the width of the bar should be in the appearance of the wall thickness of sixty percent or less

21. the slanting top and the core on the slider should be a reliable way to fix it.

22. the front mold inserted into the back mold or the back mold inserted into the front mold should be locked around and machined to avoid hollowness.