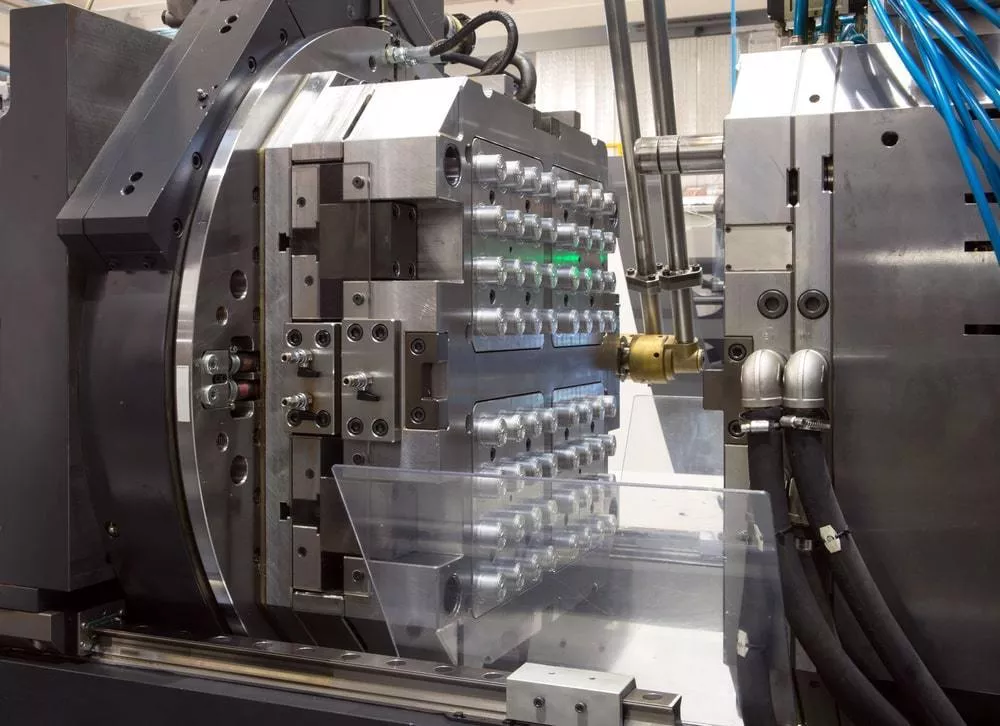

Opting for injection molding is the most beneficial method when you need many identical plastic parts. However, it requires a high degree of expertise to master, so it is easy to make costly mistakes when it comes to injection molding. Especially in the early stages of a product’s inception, a seemingly minor error can lead to major problems and compromise the integrity of the product.

Quality problems with injection molded products are typically minor surface defects, substandard product performance, and more serious problems. They are generally generated by the three core elements of injection molding: molding process, material use, and mold design.

The purpose of this article is to discuss the disadvantages of injection molding.

Disadvantages of Injection Molding

The injection molding process has many advantages, but even with perfect technology, there are disadvantages. In this article, we focus on the bad aspects of injection molding. The bad points include:

1, high start-up costs.

The first need is to design and manufacture the corresponding mold for each injection molding project. Even if the simple design for rapid prototyping or mass production of molds needs to spend the cost of basic between 2000-10000 U.S. dollars. In addition, if you do not have your engineers to design and provide drawings for the new product, the design cost is also a significant expense. This is the reason for the high initial start-up cost of an injection molded parts project.

2. Long initial lead times.

An injection molding project requires molds that take 5-7 weeks to manufacture and 2-4 weeks to produce parts for shipment. Even for a typical injection mold, there is very high complexity in the design and manufacturing required. As a result, molds are designed and tested over a long period before the final mold is put into production, and any design changes add to the project time. Also, the testing time will be longer if the material is not selected correctly.

3. Design changes are costly.

Injection molding projects require you to design and build new molds from scratch, which means more time and money will need to be invested. A mature injection mold requires a lot of time for mold design engineers to design and improve. As a result, each time the mold is improved, you may need to pay a fee to the mold design engineer. Now the good news is that if you only need a rapid prototype to test the performance of your product, you can use 3D printing technology to print the mold and thus validate it (there are still considerable limitations to 3D printing technology, and not all industries are applicable).

Conclusion

Manufacturing with injection molding usually requires a significant amount of capital, which is mainly spent on upfront mold design and manufacturing. The other is testing materials, designs, and mold improvements. This is why designing the mold correctly the first time is especially important. Because every improvement will cost a lot of money and time, now that you understand the drawbacks of injection molding, you can consider choosing an injection molding service provider who is experienced and can provide services from mold design to mass production. Such a service provider can greatly reduce your workload and shorten your project cycle time, and Elimold is your first choice. Contact us now.