With the rapid development of the modern aviation manufacturing industry, CNC machining technology has become one of the key technologies for aircraft manufacturing. The progress of CNC machining technology has changed the aircraft design concept from the design of parts to the overall, complex direction. At the same time, the change in design concept also puts forward new challenges for CNC machining technology. How to complete the CNC machining of large parts with high quality, high efficiency, and low cost has become a problem that must be overcome.

Developed countries have a long history of aviation manufacturing, especially the design of large complex structural parts of aircraft. Manufacturing technology has been very mature. With the development of various civil and military aircraft types in recent years, the main aviation enterprises in the aviation CNC machining technology have accumulated a lot of technical experience and solved several key technical problems. Manufacturing large and complex aircraft structural parts represents this initial formation of the key technical advantages.

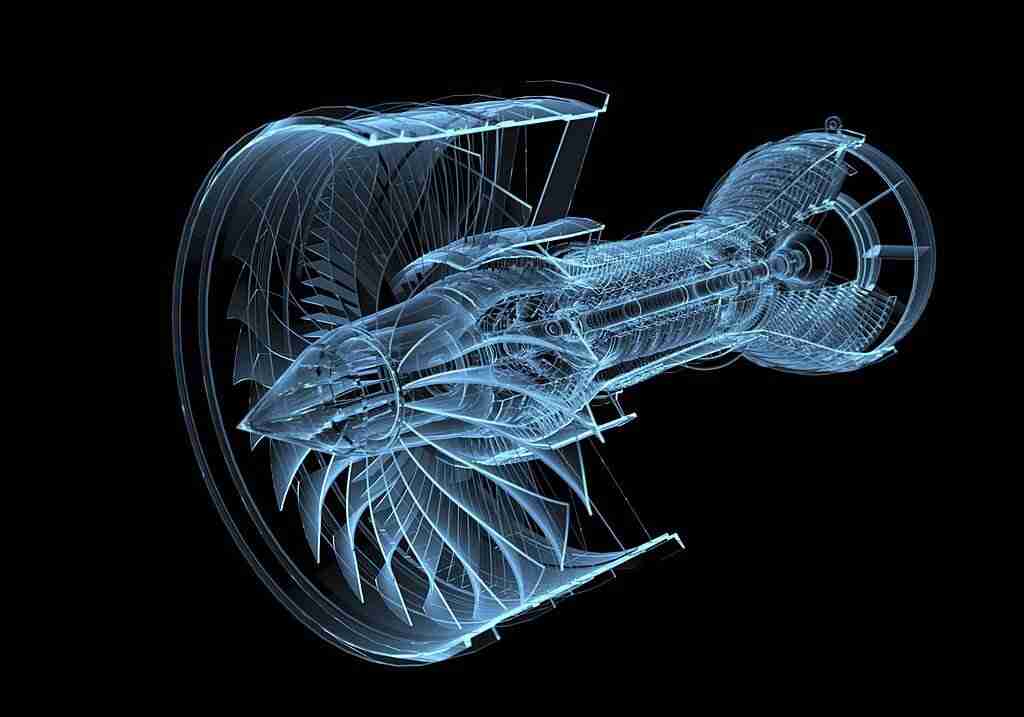

Status of CNC machining technology in aviation parts

Compared with other industry products, aviation products parts have some significant characteristics, thus determining the characteristics of aviation parts CNC machining technology and the direction of development. These characteristics are mainly reflected in the following areas:

(1) The product type is complex, with diverse characteristics in small batches. Due to the complex structure of modern aircraft, a wide variety of parts. At the same time, aircraft development is usually small-batch production, so you can not use large-scale assembly line production to improve efficiency and reduce costs. Aviation parts CNC machining must also adapt to this feature.

(2) The structure is complex and integral, and the process is difficult and complex to a machine. The progress of modern numerical control technology has prompted the design of aviation parts to be complex and integrated, simplifying the assembly and improving the structural performance, which also put forward higher requirements for CNC machining technology.

(3) thin-walled, large features are prominent, and deformation control is critical. To control the weight of the aircraft, a significant feature of the aircraft parts is the thin-walled design; on the other hand, the large-scale aircraft also makes the structure of the parts tend to be large, there are many super-large parts, so the processing deformation has become a prominent contradiction.

(4) The material removal amount is large, and the cutting efficiency problem is prominent. Aircraft parts material removal is generally above 90%, and cutting efficiency has a greater impact on production cycle time and cost.

(5) Stringent quality control standards. Due to the high safety requirements of aviation parts, the quality control of the product is very strict.

(6) Material variety in products. The development of materials, metallurgical technology, high-strength titanium alloys, composite materials, and other applications is gradually expanding the scope and amount. The adaptability of aviation CNC machining technology has put forward a wide range of requirements.

(7) Large structural parts with a high gross value and a high risk of quality failure.

After years of technical application research and exploration, the aviation industry has made great progress in the research and application of CNC machining technology for aviation parts, especially in developing large structural parts. Many problems need to be solved as follows:

(1) Mixed-line production with a low level of specialization and integration. In the current allocation of production resources, there is generally a low degree of specialization, unreasonable layout, and serious cross-production of various types of products, which greatly restricts the improvement of production efficiency.

(2) CNC machining preparation time, excessive auxiliary time, and low clamping efficiency. In the CNC machining program, adjustment, fixture preparation, tool preparation, parts testing, and other occupied time is more low processing efficiency. According to statistics, the proportion of effective cutting time of the machine tool is only 30%, greatly affecting the improvement of product processing efficiency.

(3) The efficiency of cutting processing is low, as is the proportion of high-speed cutting applications. There is a gap in CNC machining simulation, program optimization, process parameter library, manufacturing resource management, and other aspects of efficient processing needs; cutting parameters are unreasonable, low machine utilization, and other status quo severely limit the development of efficient CNC machining technology. In particular, the large aircraft parts, material removal, long processing cycle, and low processing efficiency have become the outstanding contradictions that restrict the development of production.

(4) A lack of information technology limits the efficient operation of product development. The CNC machine tool is a silo, and the various links of data information transfer and exchange of bottlenecks represent the overall constraints on the efficient operation of the enterprise. Production efficiency is affected.

(5) Large structural part deformation control remains an urgent need to solve the problem. Different types of aviation parts with different structures, sizes, and materials make it difficult to grasp the exact law of deformation, which is one of the largest variables in CNC machining.

(6) Expensive development and high development risk. When large aviation structural parts, new material components, and other general gross material values are high, any quality loss will bring a huge property loss to the enterprise.

CNC machining technology for aerospace components

The manufacturing and processing processes of aerospace parts have generally achieved high specialization, informatization, and automation without human intervention, simple and fast clamping and positioning processes, and high processing efficiency. These characteristics are mainly reflected in the following aspects: highly specialized production resource allocation and layout; universal application of high-speed unmanned intervention processing technology; universal application of high-powered and efficient cutting; spindle power utilization rate of more than 70%; universal realization of rapid clamping, pallet exchange, and other non-stop machining processes, reducing empty machine time; high degree of integrated information management of production resources; complete supporting facilities, including spindle probes, centralized tool magazine, safety protection, aluminum chip processing system, etc.; automatic tool measurement and chip reading and writing for tool parameters and tool life management.

Exploration of CNC machining technology for aviation parts

Formation of specialized lean production lines based on product feature grouping

In the large-scale development of aviation parts, many face a large passive situation, unable to form a highly competitive core technology advantage. The fundamental reason lies in the original relatively backward production resources configuration and layout, which has been unable to meet the current development needs.

Firstly, the concept of part family should be established, and the typical part family should be established by applying the grouping technique. Second, based on establishing the typical part family, the standardized process flow of the typical part family is classified and established.

Finally, a specialized and integrated production resource allocation and layout are formed based on the typically standardized parts family process flow. Finally, a lean production line for various typical aviation parts is formed. Especially for large structural parts, establishing typical specialized parts production units is important to improve their processing technology and reduce costs.

Formation of efficient and reliable clamping technology with the goal of quick clamping high-speed processing of CNC equipment, the correct design of fixtures, and shortening the fixture production preparation cycle to achieve rapid clamping and positioning of parts on CNC machine tools is very important. It can greatly improve the proportion of effective cutting time, ensuring the quality of processing to achieve the ultimate goal of improving the efficiency of CNC machining. In the traditional clamping process, the use of mechanical positioning, manual clamping, and disassembly usually take a lot of time and workforce. For high-speed processing of large workpieces, using semi-automatic or fully automated clamping technology is very economical. Hydraulic positioning and clamping are very effective.

The main advantage of hydraulic clamping is that it saves time when clamping and unclamping workpieces. Statistics show that hydraulic clamping saves about 90% of the time compared to mechanical clamping, reducing the production cycle time and costs. Another obvious advantage is that the clamping force remains constant during the positioning and clamping process, thus ensuring consistent machining quality in the same process.

Flexible clamping systems are also a new system to replace traditional clamping. Currently, advanced flexible clamping systems are self-adaptive. They can be adjusted automatically for product changes, thus adapting to the situation when the product changes significantly (e.g., the Airbus-MELT fully automated flexible clamping system and production line shown in Figure 3).

3 transition from conventional to high-speed cutting and gradually achieve unmanned high-speed machining

The high performance of modern aircraft requires its structure to have lightweight, thin-walled, and monolithic characteristics. Parts must achieve high precision and surface quality. The traditional low-speed machining methods have been difficult to meet the needs of modern aviation manufacturing. Many types of development applications prove that high-speed cutting technology has great superiority. Not only is processing efficiency greatly improved, but the quality of parts processing has also been improved.

4 Implement information management and optimal tool resource allocation.

With the increase in product tasks and equipment, the demand for tools used for machining is also increasing, and the variety is also increasing. However, the tool management mode mainly adopted the manual management mode for a long time. The tool management system is not sound, the tool warehouse is not standardized, and the centralized configuration in the tool is not perfect, which seriously affects the tool management level, increases the preparation time of CNC machining, and restricts the efficiency of CNC machining and the further improvement of machining capacity. With the rapid development of CNC machining and tool technology in the face of the challenges of efficient production and the pressure to continuously reduce manufacturing costs, the management of tools has become a hot spot of increasing concern to various manufacturing enterprises.

Establishing an automated and information-based tool management storage environment is an effective way to solve the current backward and inefficient status of tool application management. The complete life cycle management of tools can be carried out by implanting chips so that tool resources can be applied rationally.

5 Deepen simulation technology application research to promote the establishment of digital manufacturing systems

With the development of computer technology, CNC machining simulation technology has also been developed rapidly, especially in the development process of aviation, aerospace, national defense, and other large-scale complex systems. CNC machining simulation has significantly reduced losses, saved money, shortened the development cycle, improved product quality, and so on.

The CNC machining simulation environment built on VERICUT software performs virtual manufacturing of CNC programming, which is more realistic and intuitive than tool position file simulation and greatly improves the efficiency and quality of CNC programming. Simulation processing technology has now become an essential part of the development process of CNC machining. Especially for aircraft with large complex structural parts, their materials are expensive, and their complex structures require many high-speed cutting operations and related equipment. It is crucial to ensure the correctness and rationality of tool trajectory, cut parameters during machining, and eliminate accidental errors such as excessive margin cutting, collision interference, and overtravel. Therefore, it is necessary to establish an accurate and complete simulation machining environment.

6 key technological breakthroughs in typical large deformation control

Due to the various types of products, complex structures, and different processing conditions, the CNC machining deformation of the parts is the most difficult factor to determine in CNC machining, and machining deformation control is still one of the main problems plaguing CNC machining.

(1) The general CNC machining deformation control method.

- Stress release principle. A full release of internal stress is an effective means to reduce processing deformation. The state of finite element simulation proves that when the part material has a discontinuous state along a certain direction, then the internal stress along this direction will not be transferred, and the internal stress along this direction at this fracture interface is zero.

- The principle of stress balance is that internal stress cannot be eliminated but can only be minimized or made as much as possible in equilibrium. The balance of the internal stress so that the part is in a “dynamic” stable state to control the purpose of deformation.

- The compensation principle of balance. In the machining process, if significant deformation occurs, the deformation can be reduced by margin compensation. The measures to control the deformation based on this principle are the re-correction of the datum surface and datum hole and measures such as reserving an appropriate finishing allowance.

- This reduces the generation of stress. In addition to the inherent internal stress of the material, the machining process also generates stresses that cause machining deformation. Therefore, reducing the stresses generated in machining as much as possible is also one of the main measures to control deformation. For example, high-speed machining can greatly reduce the generation of machining surface stress, and improving the cooling effect can also greatly reduce the generation of machining surface stress.

(2) Finite element simulation-based CNC machining deformation simulation technology.

For the study of the part CNC machining deformation control, the aviation industry in actual production, mainly under the accumulation of technical experience and repeated testing as the basis for the design of the CNC machining process, there are great uncertainty factors and development risks.

Finite element simulation cutting analysis technology is one of the effective techniques for studying the deformation of CNC machining. Finite element simulation machining deformation simulation technology makes it possible to use numerical simulation technology to simulate the machining process before machining, analyze the machining process, determine the impact of various parameters on the deformation of the part, predict the deformation and rupture of complex parts during machining, and provide design and process technicians with the basis for design and process analysis.

7 Encourage cutting parameter optimization technology and the standardized application of cutting parameters.

Reasonable cutting parameters are the prerequisite for CNC machining to achieve high-speed and efficient machining and are also necessary to achieve high-speed unmanned intervention in the machining process. The basic cutting optimization technology includes three types: cutting optimization technology based on dynamics simulation; cutting parameter optimization based on superior milling technology; and optimization technology based on geometric simulation cutting, which have their application advantages and characteristics, respectively.

(1) cutting-edge optimization technology founded on dynamics simulation.

Cutting optimization based on dynamics simulation is a simulation cutting optimization technology based on the physical characteristics of the cutting machining system. The basic principle is to test and analyze the dynamic characteristics of the machine tool system to obtain the parameters of inherent frequency, damping ratio, and modal stiffness, and then use the cutting dynamics simulation system to carry out the chattering stability domain simulation and obtain the chattering stability domain simulation curve; finally, according to the chattering stability domain simulation curve, combine with the characteristics of the machined workpiece to select the reasonable cutting parameters.

(2) Optimization of cutting parameters based on Optimal Milling Technology (OPTIMILL).

Unwilling technology is an application system that uses adaptive control technology. The cutting process is controlled by calculating the optimal feed rate and the resulting optimal feed rate by monitoring the load and power on each machine spindle in real-time. This technique requires multiple cutting optimizations for each part, and the results are valid only for that part.

(3) Geometric simulation cutting-based optimization techniques

Geometry simulation-based cutting optimization is an optimization measure to automatically adjust the feed rate for real-time changes in cutting conditions and the amount of material to be cut during the cutting process, which can improve the machining efficiency and cutting process to a certain extent. The basic principle is that, based on the real-time material removal rate of the tool and the direction of tool advancement, the tool feed rate is reduced when cutting a large amount of material, and the feed rate is increased accordingly when cutting a small amount of material to maintain the relative balance of machine load and cutting stability.

These three optimization techniques each have characteristics and advantages in practical application, but they also have certain limitations, which can be combined to achieve better results. As a company that can process aerospace parts, Elimold is equipped with the production conditions for aerospace parts. If you want to know more about CNC machining of aerospace parts, contact us now.