Thanks to the reliability and versatility of CNC milling, countless products, from smartphones to supersonic jets, are possible today. It is ideal for rapid prototyping and batch manufacturing of plastics and metals.

Digital technology and CNC milling can solve many problems that are difficult to solve with existing methods. This technology handles workflow more efficiently. For example, cutting metal for automotive parts or even aerospace parts is much riskier without CNC milling machines. With the support of computer programs, one can create high-definition product designs that can be easily converted to Cartesian coordinates. This process even helps to reduce the cost of prototyping!

What is CNC Milling?

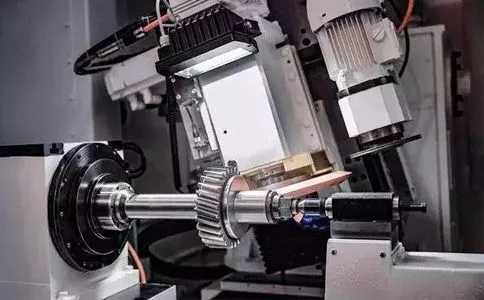

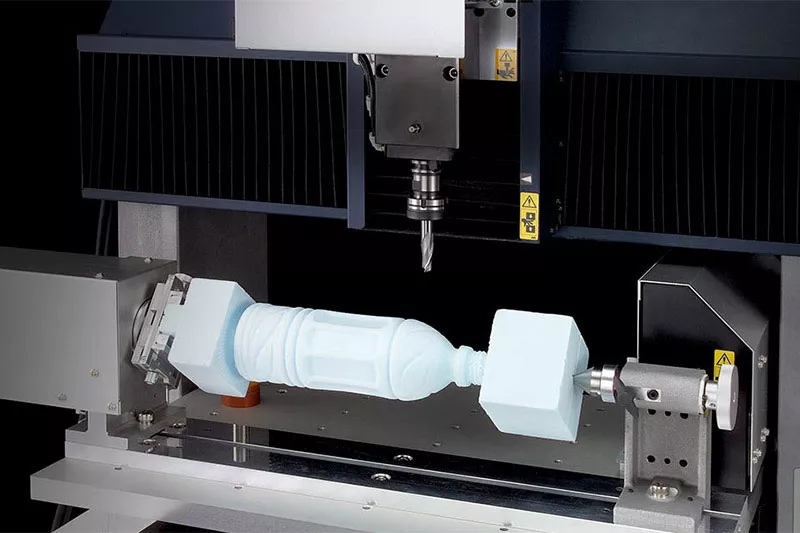

CNC milling is a manufacturing process that uses a cutting tool mounted on a rotating spindle to selectively remove material from the original substrate. The workpiece is firmly mounted on a table that can be moved or rotated in different planes so that the tool can work at multiple angles. A complex CNC milling machine can have five or more independent axes of motion to create more complex shapes or to avoid moving the workpiece to a separate machine.

Understanding the CNC Milling Process

CNC (numerical control) milling is responsible for revolutionizing machine shops, allowing them to mass produce detailed parts faster and more accurately than traditional methods. Once a CNC machine is programmed and set up, operators can produce more parts faster and with good repeatability between parts, making the process ideal for mass manufacturing.

CNC milling machines incorporate computer-controlled precision to rotate and position multi-point tools. As the raw material moves through pre-programmed machining operations, the tool moves along three spindles, X, Y, and Z, to precisely cut the material. The five-axis CNC milling machine will move along three linear axes and two rotary axes for complex geometries.

Elimold is an expert in CNC milling and other CNC machining services. We can help you choose the right material and method for your production operation. This blog post will focus on CNC milling capabilities and common materials used in the process.

What are the advantages of CNC milling computer numerical control?

CNC milling machines rely on computerized digital control for all these movements, a computer program derived from a 3D digital file of the desired finished part.

Early automated machines relied on piercing cards to systematically control their basic movements. This technique was feasible, but it was a slow and complex system, and once the perforated cards were made, they could not be modified. These were later replaced by digital instructions on tape, disk drives, and now in g-code.

This control system is not only fast and accurate. Unlike earlier systems, it can be easily modified line by line in real-time as needed to fine-tune the machining program for optimal CNC milling results.

How can CNC milling help you get quality parts?

Circular or radially symmetrical parts are best machined on a CNC turning center for maximum efficiency and accuracy. But most of the parts we use are not round or symmetrical, so they must be machined on a milling machine.

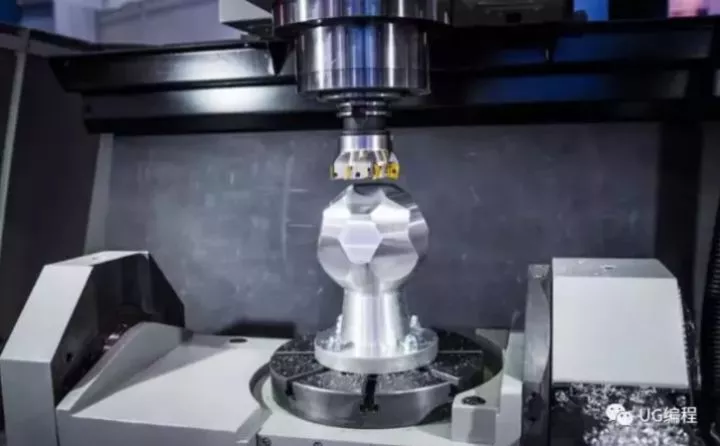

Multi-axis milling machines are unmatched in creating squares, bevels, angles, recesses, and complex curves – any cutting process can be done on a milling machine, including making circles. They are also extremely accurate, typically holding 0.01 mm or 10 mm tolerances. We offer a wide range of stock materials for any application and provide the best incoming inspection and testing services.

When you send CAD files to your Elimold email address for a free quote, you can get high-quality parts and prototypes quickly and rest assured of our custom fabrication services.

CNC Milling Model

CNC milling is a form of subtractive manufacturing, which means the material is removed from the part to produce the final design shape. The process begins with a computer-aided design (CAD) drawing or 3D model of the final assembly. This dimensional data is then exported into a language that can be understood by computer-aided manufacturing (CAM) software. CNC milling machines read the generated CAM instructions and perform precise machine movements along various paths and axes.

The following are the most common CNC milling methods:

Flat milling. Also known as surface milling, this process uses cutting tools to remove material along the surface of the workpiece. In face milling, the axis of rotation is parallel to the workpiece.

End milling. End milling uses a rotary axis perpendicular to the surface of the material. The cutting or grinding tool is placed face down on the workpiece surface to remove material.

Angular milling. In this milling method, the tool’s axis of rotation is positioned at an angle to the workpiece surface to produce a designed slope, such as an angle or dovetail joint.

They are forming milling. Milling allows for non-planar cuts such as contours, curves, and radii. Each type of curve requires specific cutting tools to create precise shape cuts.

What industries is CNC milling typically used in?

With the development of CNC machines, more and more industries need to use CNC milling to machine product parts. Here are some of the industries that require CNC milling:

One, the manufacturing industry

Manufacturing is the first industry to apply CNC technology, with the responsibility of providing advanced equipment for various industries of the national economy. In the automotive industry, the production of engines, transmissions, crankshafts, and other components, as well as welding, assembly, painting robot, flatbed laser welding machine, and laser cutting machines, as well as aviation, shipbuilding, power generation industry propellers, engines, generators, turbine blades processing, will be applied to CNC milling processing of related parts.

Second is the information industry.

In the information industry, from computers to networks, mobile communications, telemetry, remote control equipment based on ultra-precision technology, and nanotechnology manufacturing equipment, such as lead bonding machines for chip manufacturing, wafer bonding machines, lithography machines, etc.., these all need CNC technology to control.

Three. Medical equipment industry

In the medical industry, many modern medical diagnostic equipment components are used CNC technology, such as CT diagnostic equipment, surgical tools, and vision-based guidance robot. All need to use CNC technology to produce related products.

Four. Military equipment

Modern military equipment has many servo-motor control technology, such as automatic artillery targeting control, radar tracking control, automatic missile tracking control, etc. Equipment metal shells will also apply CNC technology processing.

other industries

Light industry, the use of multi-axis servo control of printing machinery, textile machinery, packaging machinery, and woodworking machinery; in the building materials industry, CNC water jet cutting machine for stone processing; CNC glass engraving machine for glass processing; CNC sewing machine for Simmons processing and CNC embroidery machine for garment processing will also apply CNC technology.

Choose a CNC milling service.

CNC milling can be used in any industry that requires precision parts, including complex industries such as aerospace and military. Regardless of part geometry or material, Elimold has the right CNC milling process to meet your needs. Please get in touch with us or request a quote to learn more about our capabilities.