- The importance of rapid prototyping in the development of new medical devices

- Design and Development Oversight and Risk Management

- Choose a good medical device manufacturer

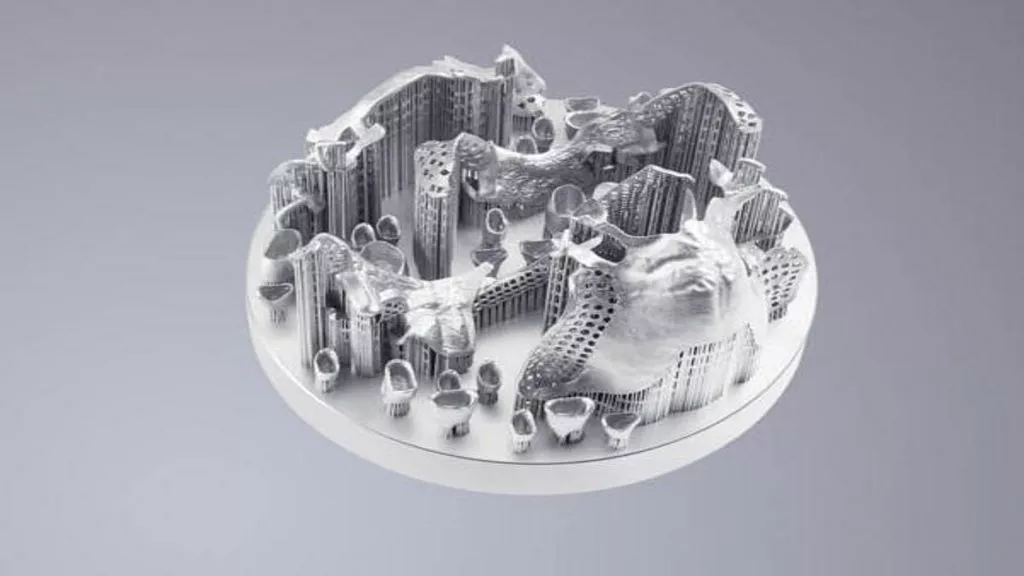

In today’s technologically advanced world, medical device innovators have a great opportunity to turn their concepts into prototypes that will profoundly impact the future of healthcare. Rapid prototyping of medical devices is an exciting and critical part of product development for creators. As preliminary design images emerge, concepts move from conceptualization to physical entities.

After all, bringing a clinically significant product to market is both hugely rewarding and satisfying. But as Thomas Edison of Illuminating the World says that it can be a complex and arduous path from identifying market needs to build the device.

An optimized prototyping process can improve medical manufacturing in almost any field. Manufacturers can save money, ensure compliance, produce better-selling products and, most importantly, save lives. Manufacturing cannot afford to ignore these benefits.

Rapid prototyping is a useful resource in any field. They are critical in medical manufacturing as responsibilities, costs, and standards increase in the healthcare industry.

Modern technology has made the healthcare industry better. New devices can improve patient care and save lives, providing opportunities and greater responsibility for manufacturers. Manufacturing may be lucrative, but it must also meet higher standards.

Given this dynamic situation, additive manufacturing is a necessity. While prototyping is a standard practice in all manufacturing areas, it has a unique importance in the medical field. It can increase profits, reduce risk, and even save lives.

The importance of rapid prototyping in the development of new medical devices

Many revolutionary ideas could lead to a new generation of treatments for certain diseases and disorders that unfortunately never come to fruition – all because the inventors don’t know where to start developing a working prototype. Similarly, the excitement of bringing a new medical device to market often leads to the temptation to bypass the key procedural elements that must be in place before and after rapid prototyping. This usually happens when there are financial constraints.

However, building a rough proof-of-concept prototype is an effective means of reducing expenses. Individuals or companies can assess and evaluate their concepts during medical device engineering and make strategic decisions to improve their designs and capabilities. Samples also allow manufacturers to analyze the efficacy of their designs, which is an important part of the mass production and distribution process.

Because medical devices directly impact the health and well-being of patients, the design and development of medical devices always entail a degree of risk. The design and development of a medical device are more than just coming up with an idea, building it, and making it available to the public. It is a complex process that requires careful consideration of laws, regulations, application requirements, and user needs to produce a safe and effective product that will be successful in the marketplace.

Design and Development Oversight and Risk Management

When designing medical devices to improve lives, it is important to ensure that the risk to the end user is as low as possible. Regulatory agencies such as the U.S. Food and Drug Administration (FDA), the European Medicines Agency (EMA), and other international counterparts have developed extensive regulatory documents and risk management procedures to ensure safety measures and production. The International Organization for Standardization (ISO) is a non-governmental, global organization that develops standards to ensure the quality, safety, and efficiency of products, services, and systems. Some of the most common ISO standards for medical device risk management include the following:

ISO 13485 specifies the requirements for a quality management system (QMS) that medical device developers and manufacturers can use. The standard guides for medical device companies to help ensure the highest levels of safety and quality for these products.

ISO 14971:2007 is specifically designed to identify the risks associated with medical devices and how to estimate, assess and control those risks.

IEC 60601-1-2 ensures the basic safety and essential performance of electromechanical medical devices in the presence of electromagnetic energy.

These are the primary standards, but many others must be considered when designing medical devices. Several techniques are used for risk management, including hazard and operability studies (HAZOP) and failure modes and effects analysis (FMEA).

HAZOP is a study designed to examine and analyze existing processes or operations to identify any potential problems or risks associated with the design of a medical device.

FMEA is a structured method for reviewing all device components, searching for and examining parts of the system that could fail, and analyzing the associated risks.

Choose a good medical device manufacturer

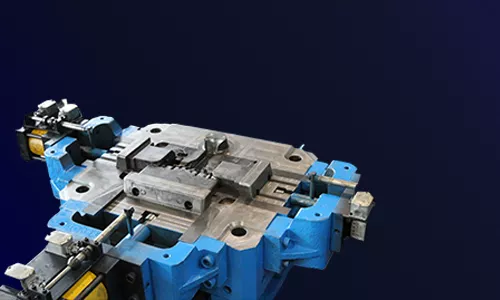

Our rapid prototyping and sewing creation process are simple: we meet with you, review the product implementation documentation, and recommend materials, creation patterns, and prototype solutions. We will immediately adjust patterns and update sewing solutions as needed. For all sewn products, we can provide the perfect solution for your project from a simple sketch or DXF file. We can efficiently determine the appropriate materials and test criteria from the product realization documentation for the project.

We use the most appropriate manufacturing technologies and advanced manufacturing methods throughout the entire process of medical device product development and engineering. We also streamline production by working with our supply chain partners early in the process to leverage their expertise.

At TPI Custom Solutions, we are always committed to working closely with our customers to provide the best possible solution. Our expertise in medical device product development and sewing allows us to develop the most challenging custom concepts. Our medical equipment program includes respirator kits for carrying portable ventilators, CPAP helmets, and military medical kits with stretchers.

Contact us today to help you with specific medical device product development requirements.