CNC machining and 3D printing are two leading manufacturing techniques for rapid prototyping and low-volume production, but they use completely different production techniques. Both manufacturing methods have advantages and disadvantages, and there is no perfect, one-size-fits-all technology. While both methods are very competent and useful, the most suitable ones depend on materials, geometric complexity, fabrication volume, and budget. To find out what works best for your particular job, we recommend contacting your local or international service and asking for their advice.

CNC VS 3D PRINTING

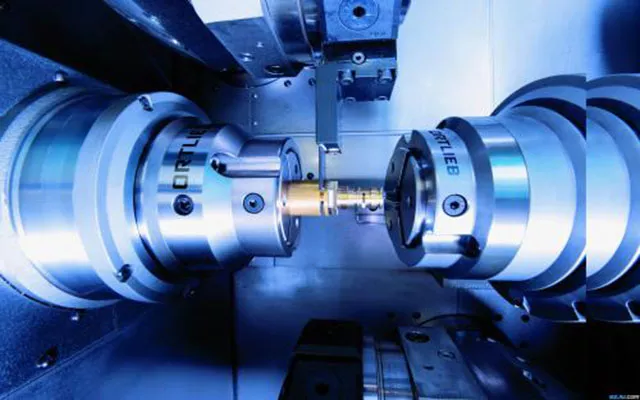

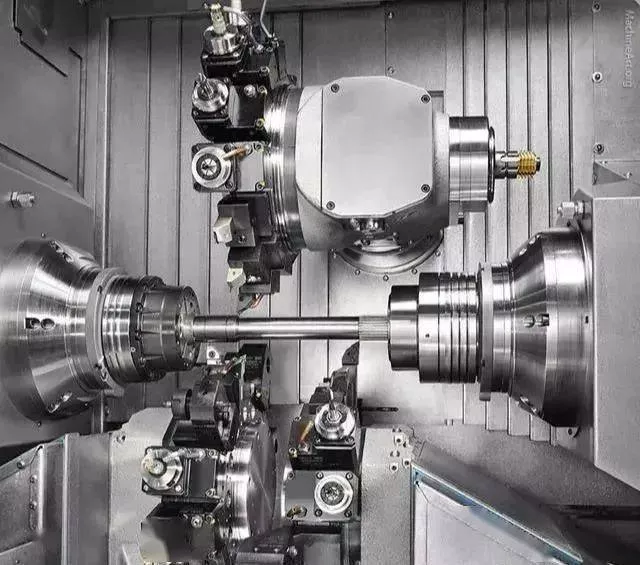

CNC machining starts with a piece of material called a blank, which is then cut to create a finished part. To do this, use knives and rotary tools to shape the piece. Some advantages of CNC machining include high dimensional accuracy and many compatible materials, including wood, metal, and plastic. . In fact, subtractive manufacturing is more popular and functional than other manufacturing processes. When a fully functional prototype, part, or detail is often required, CNC technology is the first method used. Most are used for industrial evaluation and testing. In military terms, subtractive manufacturing is the vanguard, while additive manufacturing is the reserve army that comes along when needed.

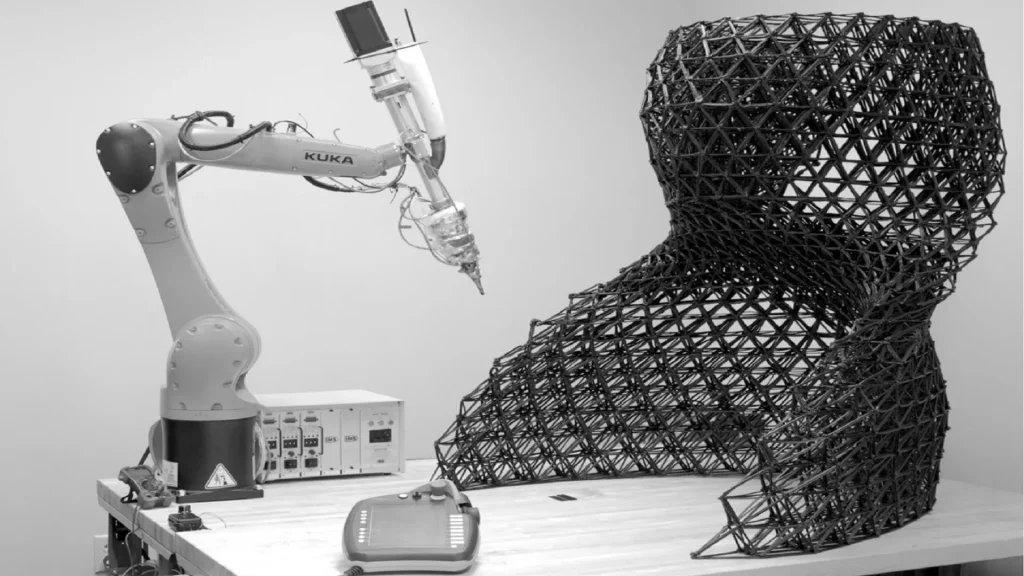

3D printing is a rapidly evolving technology that offers many advantages over traditional manufacturing methods. 3D printing or additive manufacturing involves creating parts layer by layer using materials such as plastic filaments (FDM), resins (SLA/DLP), and plastic or metal powders (SLS/DMLS/SLM). Using energy sources such as lasers or heated extruders, layers of these materials are cured to form finished parts. The advantages of 3D printing include its freedom of shape, application in many fields, accuracy, speed, and ability to reduce part cost and weight. However, it also has problems, including that 3D printing cannot be used effectively for mass production and is limited in speed and accessibility. With the news of the first successful 3D printed gun manufacturing, 3D printing has become a hot topic and has squeezed into the forefront of our attention. One of the biggest reasons for the hype around 3D printing is that it’s so foreign to us—most people know very little about the purpose, utility, process, and capabilities of 3D printing. This curiosity is exacerbated by the fact that 3D printing is already quite complex and rigorous, making it difficult for 3D printing shops to market this new process to consumers.

Will 3D printing replace CNC?

CNC machining has become the most common prototyping method. But what will the future be like? Can 3D printing replace CNC? Now, 3D printing has taken on some of the tasks that were once CNC-made, but only a small part. In addition, CNC technology processing tends to be cheaper than 3D printing. It can also be said that the current CNC machining is at the peak of its development. Some industrial CNC machining is like a small factory combining small-scale with large capabilities. They can accomplish a surprising number of tasks. However, they also have disadvantages. Using a 3D printer, you can manufacture a finished product from a first draft in a few days. In some cases, subtractive and additive manufacturing can overlap, but each has advantages and disadvantages. I think these two technologies will be complementary technologies for a long time.

What is the difference between 3D printing and CNC machining applications?

Material

Materials Commonly used thermoplastics in 3D printing include ABS, PLA, nylon, ULTEM, and photopolymers such as waxes and calcinable or biocompatible resins. Some niche 3D printers can also print parts in the sand, ceramics, and living materials. The most commonly used metals in 3D printing include aluminum, stainless steel, titanium, and Inconel. It’s also worth noting that to 3D print metal, expensive ($100,000+) industrial machines are required. Some materials, such as superalloys or TPU (flexible materials), cannot be manufactured with CNC, so 3D printing or rapid tooling techniques must be used.

3D printing and CNC machining are compatible with many materials, including plastics and metals. However, 3D printing, in general, is more focused on plastics, although this is changing rapidly; the most commonly used plastics in CNC include ABS, Nylon (PA66), Polycarbonate (PC), Acrylic (PMMA), Polypropylene (PP), POM and PEEK. A commonly used metal in CNC machining is aluminum, which prototyping companies use to create high-quality prototypes in various industries. Aluminum is recyclable, has good conservation qualities, and can create efficient machining prototypes. Other common metals include stainless steel, magnesium alloys, zinc alloys, titanium, and brass.

Accuracy, size constraints, and geometric complexity

While there are many 3D printing technologies, we chose to compare CNC machining to SLS, industrial (non-desktop) FDM, and DMLS metal 3D printing. In terms of tolerances, CNC machining is superior to all 3D printing processes, even DMLS. However, for minimum layer thicknesses, the advantages are not as profound and not as precise as DMLS.

However, powder bed fusion 3D printing processes such as SLS and DMLS have limited build volumes. Even bulkier technologies such as FDM cannot compete with CNC in maximum part size.

3D printing is known for its advantages in creating parts with high geometric complexity. Although some technologies require support, 3D printing can create parts with geometries that traditional manufacturing methods cannot replicate.

Rapid Prototyping and Mass Production

3D printing is a relatively new concept and has not yet reached its full potential, so the capabilities of 3D printing are still being explored; however, it is clear that although 3D printers and CNC machining appear to do similar things, they will have different For commercial purposes, ultimately there will be different markets. CNC machining is an important industrial technology for large-scale and scalable mass production. It can efficiently manufacture large, intensive products for high-tech machinery. On the other hand, 3D printing is more suitable for home, creative, and medical use for rapid prototyping. With scalability that can’t produce large quantities of products simultaneously, 3D printers are using themselves for individually produced items, which is ideal for the custom consumer industry. They give consumers less of what they need and more of what they want. They can make small industrial parts but are not mass-produced, which means it’s more suitable for personal home creativity and household needs, such as unique gifts, custom iPhone cases, artwork, and more.

Small and large products

3D printing at this stage cannot make a product larger than a mini fridge, and even that product would take days to complete with a 3D printer. The layering process does not mean creating large products, which is a huge advantage for CNC machining. 3D printing has mainly succeeded in layering smaller and simpler designs. CNC machining is a powerful industrial technique capable of producing the largest parts, such as those required for aerospace, marine, construction, and automotive.

What’s the best way to make parts?

Is it urgent?

If rapid parts prototyping is urgent, 3D printing can be a good option. 3D printing can often give you the part the next day, and with 3D printing, part size does affect time; larger parts take longer to print. If a part fits in the palm of your hand, you can usually have it the same day. For smaller parts, 3D printing is often faster than a machine.

CNC machining can often remove material faster than 3D printing deposited material. Size generally does not affect time constraints as much as machining; the amount of material removal required is more critical. But the process for CNC machining services typically takes at least a few days between part review, creating drawings, sending a quote, and purchasing review. This, combined with store shipping and delivery times, can sometimes lead to a lengthy process.

Is it mass production?

When you break down the cost of machining parts in small batches, most of the cost comes from the time it takes to program and set up; the actual time to cut metal is usually quite short. Increased throughput is often achieved by making larger setups to cut more parts unattended. As part complexity and the number of features increase, so do the programming time and the number of required settings. However, the cost of additional units has fallen fairly quickly. Depending on the geometry, CNC unit costs can scale well to orders of hundreds or thousands of units per month because programming and settings can be reused.

Using 3D printing, programming (slicing) can be done in minutes, and complexity has little impact on programming time. While the first unit cost and effort are low, the unit cost is not much affected by volume. Expanding production is usually achieved by bringing more machines online.

The 3D printing process can save manufacturers time and money while still producing the quality needed for industrial-grade production.

Manufacturers making the switch can utilize 3D printing software to prototype and produce parts daily at a fraction of the cost of traditional CNC machining. However, there are several key areas where CNC may still be the right choice for part production. 3D printing won’t solve all your production problems overnight. Economic constraints limit the number of cost-effective parts that can be 3D printed into small batches, and material and process constraints may limit application space. On the other hand, CNC machining sees favorable economies of scale once the volumes are slightly higher (usually in the hundreds of units per month).

Elimold, We are here to help you with your manufacturing challenges. We can provide guidance and production services if you need help designing your product.