Many businesses will need prototypes for several opportunities and reasons, among different factors. Therefore, when obtaining rapid prototyping services, it is important to consider meeting the needs of global customers. The customer concept relies on services such as 3D printing pressure, die casting rapid injection, rapid tooling, and another sheet manufacturing system. So many companies do it all right. In most cases, you will need to see the modelling and drawings of the desired product. Such services provide you with all types of experiences with your customers. However, there are many factors that you must also consider when hiring a business to perform important services for you.

It manages customer processing.

When considering a rapid prototyping company, you must know how to handle clients. It deals with clients in a very simple way, so it works. Ensure all products are manufactured to specification and ensure customer-requested clarifications should be made on prototypes.

Consider professionalism

Apart from enjoying different services, it would help to consider everything professionally. For example, the office has a lasting benefit if you choose a good company with a solid team of prototyping engineers. You have real-world experience handling all client needs, including advising clients on the best crafting materials and even getting the project done right; you can easily see how professional and flawless the team working on your project is. Make sure you have to check the replies. Often, you need to consider the entire process when working on your work.

including technological advancements

You need to deploy a rapid prototyping firm to get the desired results. They can provide you with the latest services based on machines and technology. Always remember that machines and prototyping techniques can easily determine results that can be easily enjoyed. Therefore, you must also determine your company’s manufacturing capabilities, especially for larger products, to ensure the accuracy of the materials and machines used by your service provider. So you have to manage all the tough products at the end that should meet all your needs. Once you can meet all your needs, it will make your life normal.

Turnover System Quality

This is the biggest advantage of rapid prototyping as it drastically reduces the overall time. So whenever you want the desired results and other specifications, you must choose the perfect company. They can deliver all your models within the stipulated time to ensure all your items are down or not down. In addition to getting more information about your model, you can choose the right company to provide high-quality results. On the other hand, you need to consider the qualifications and skills of the workers to provide you with real services. For extra confidence, you need to increase the efficiency of your business.

How to choose between rapid prototyping processes

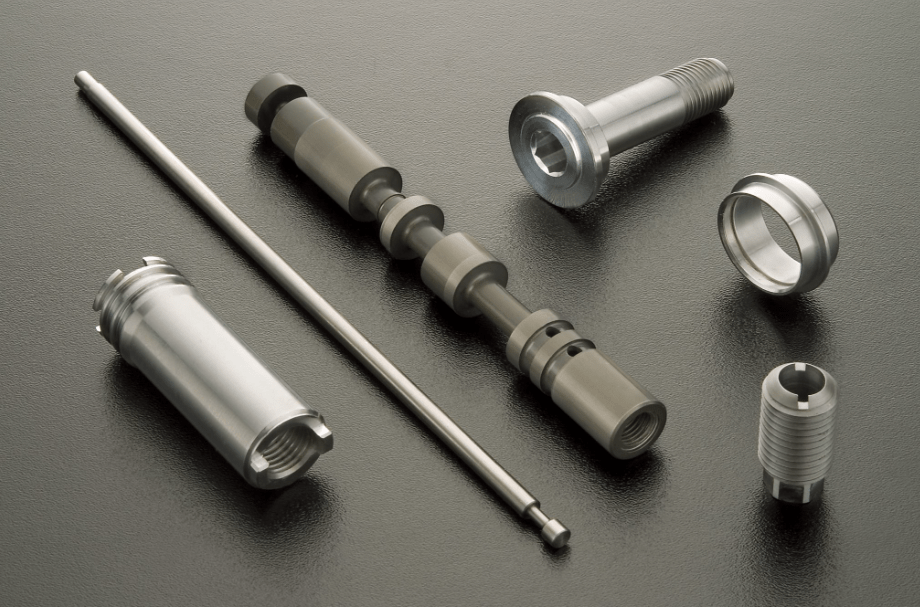

CNC Machining Services

CNC machining is a subtractive manufacturing process that involves the use of a computer-driven milling machine. This technology makes parts and removes layers from metal, plastic or wood blocks. It is one of the most common prototyping techniques.

Prototype makers use CNC machining services because it is fast and economical for customers who need a small number of prototypes. You can use this technique to create detail-oriented parts as a rapid prototyping process. In addition, CNC machines can cut various materials, making it easier to design precision parts with speed and excellent surface finish.

application

Custom Small Batch CNC Machining, CNC machining is best for small batch production. During prototyping and production, customers need to get parts to market faster. Manufacturers can use this process to manufacture parts more flexibly and efficiently at a lower cost.

materials used

CNC Plastics For visual clarity, you must choose the right rapid prototyping service. CNC plastic processes manufacture clear custom parts to meet their functional needs. You can achieve optical functions, see inside the product, and improve aesthetics with clear plastic parts. For example, automotive lighting lenses, light guides, and displays are all created using this process.

• CNC Metal ,CNC aluminium parts are the first choice for most prototype builders. This material offers robust durability and resistance, making it ideal for complex manufacturing projects.

Part Finishing

Prototypes must go through a critical finishing process for the accuracy of the final product. Such as sanding, sandblasting, polishing, painting or printing, all of which help bring the final product to life.

3D printing service

3D printing is the first choice for engineers looking for rapid prototyping solutions. Designers can print custom parts quickly and cost-effectively using various metals and plastics.

As an additive manufacturing process, it combines multiple layers of materials to create prototypes. Designers can then use these parts to detect and fix problems before going into mass production.

The most commonly used 3D printing services are SLA 3D printing (stereolithography) and SLS 3D printing (selective laser sintering). These technologies offer different mechanical properties and smooth surface finishes. Let’s look at them in detail.

SLA (stereolithography)

SLA 3D printing (stereolithography) is a unique process using a computer-controlled laser beam. It uses an ultraviolet laser aimed at the surface of a liquid thermoset resin to draw thousands of thin layers to create the final part. It can be used in various materials and is ideal for high-quality finishes.

• SLS (Selective Laser Sintering)

On the other hand, SLS 3D printing (Stereo Laser Sintering) uses a high-power optical laser to fuse small powder particles layer by layer to produce complex and durable geometric parts. This process is great for creating nylon-filled parts for functional prototypes.

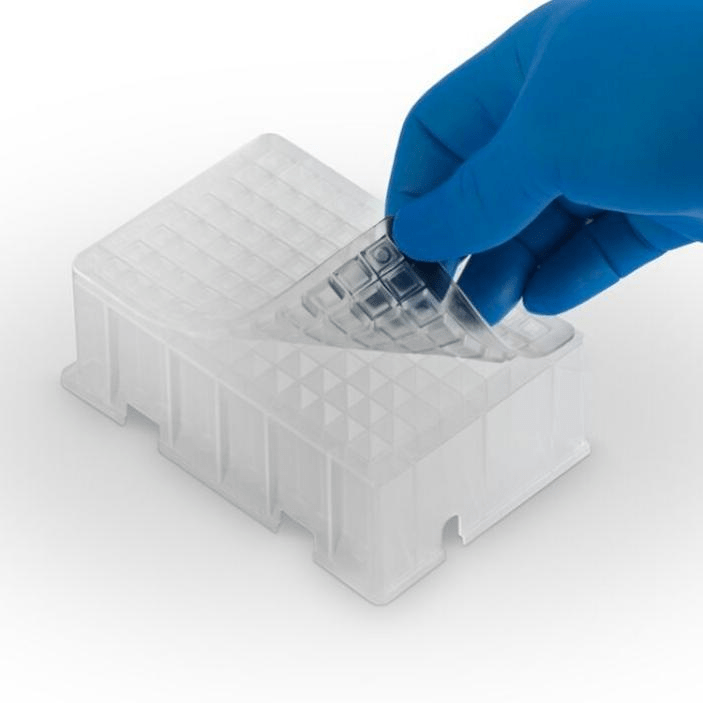

Quick Die

Quick tools are also known as prototyping tools. The technology includes processes such as vacuum casting and rapid injection moulding. Designers use this method to make moulds for parts.

Using the Quick Tool, you can mould your prototype from various rubber, metal or plastic materials. Rapid machining is the best option if you need more than 100 batches of prototypes. Additionally, you can design low-volume orders for marketing, product evaluation, and process design.

Rapid die involves the following process.

Vacuum casting Also known as polyurethane casting, vacuum casting is a process in which prototyping mainly uses silicone moulds to make polyurethane castings to produce functional plastic parts. This technique is more economical and can be used as an alternative to low-volume injection moulding plastic parts.

• Rapid injection moulding This production method is suitable for plastic moulding. Because of its effectiveness in developing moulds for commercial purposes, it is ideal for making hundreds of trial runs for testing rapid prototyping parts. The reliance on this program stems from the short production time from start to finish.

Top 5 Rapid Prototyping Companies in the Market

Carbon 3D

Carbon’s Digital Light Synthesis (DLS) technology, powered by its proprietary CLIP process, utilizes digital light projection, oxygen permeable optics and programmable liquid resins to rapidly produce parts with outstanding mechanical properties, resolution and surface finish. Their 3D printers are widely used for prototyping and end-use applications, perhaps most notably the 3D-printed soles of Adidas Futurecraft sneakers.

Xometry

Xometry claims to be the largest on-demand manufacturing market. With a vast network of 3,000 manufacturers, Xometry uses an instant quote engine that enables startups and Fortune 500 companies to easily price production jobs. Earlier this month, they acquired Shift, an on-demand marketplace in Europe, to build a global network.

Elimold

Elimold is a stealth-mode startup dedicated to providing companies with advanced additive manufacturing solutions, including 3d printing, rapid prototyping, CNC machining and injection moulding. That is a shop floor system for high-volume manufacturing and low-volume prototyping. Shop systems designed for machine shops producing mid-volume, mass-produced end-use parts. Why Elimold? Their customer service ensures on-time delivery and quick response to inquiries. In addition, they ensure quality manufacturing of their products and sell them at cost-effective prices that benefit their customers.

3ERP

It has ISO9001 certification and is based on the 3E pillars; excellence, efficiency, economy and general services for rapid prototyping and low-volume manufacturing.

Behind the scenes, professional teams use high-precision 3-axis, 4-axis and 5-axis machines, material testers and CMMs to obtain quality and reliable products.

Industries they serve include, but are not limited to, medical device prototyping, robotics and automation, aerospace prototyping, and industrial.

Star Rapid

Star rapid has been operating for over 14 years. During this time, they have reached around 800 companies and serve as many as 48 countries. Additionally, they pride themselves on producing over 4 million parts for their customers.

Companies they have captured include nedap, Gate, Visionflex, Quirky, Mistywest, Biorep Technologies, Starfish Medical, Swivel, and more.

Other industries include; medicine, consumer goods, electronics, agriculture, etc.